Load type acidic ionic liquid catalyst and preparation method and application thereof and preparation method of ethyl acetate and methyl oleate

A technology of acidic ionic liquid and catalyst, applied in the field of supported acidic ionic liquid catalyst and its preparation, can solve the problems of unfavorable esterification reaction of oleic acid and alcohol, small pore size unfavorable esterification reaction of carboxylic acid and alcohol, etc., and achieve easy operation , fewer side reactions, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037] According to one embodiment of the present invention, the supported acidic ionic liquid catalyst of the present invention is prepared by the method of following steps:

[0038] (1) Stir the template agent, ethanol, acetic acid and sodium acetate buffer solution with a pH value of 3-5 at a temperature of 15-35°C until the template agent dissolves;

[0039] (2) Add 2,2,4-trimethylpentane to the solution obtained in step (1) and stir at 15-35°C for 6-10h;

[0040] (3) adding tetramethoxysilane to the solution obtained in step (2) and stirring at a temperature of 15-35°C for 10-30h;

[0041] (4) The product obtained in step (3) is crystallized under crystallization conditions, including a crystallization temperature of 45-80°C and a crystallization time of 15-40h;

[0042] (5) Heating the crystallized product obtained in step (4) to remove the template agent to obtain a hollow spherical mesoporous silica carrier, the heating temperature is 400-600°C, and the heating time i...

Embodiment 1

[0057] (1) Preparation of hollow spherical mesoporous silica support

[0058] Add 1.0 gram of polyoxyethylene-polyoxypropylene-polyoxyethylene triblock copolymer (Aldrich Company, P123) and 1.69 gram of ethanol into the buffer solution of acetic acid and sodium acetate of pH=4.4 of 28ml, at 15 ℃ Stir until the polyoxyethylene-polyoxypropylene-polyoxyethylene is completely dissolved, then add 6 grams of 2,2,4-trimethylpentane to the above solution, stir at 15°C for 8 hours, then add 2.13 grams of tetramethylpentane Add methoxysilane to the above solution, stir at 15°C for 20 hours, transfer the solution to a polytetrafluoroethylene-lined reaction kettle, and crystallize in an oven at 60°C for 24 hours, then filter, wash with distilled water, and dry A hollow spherical mesoporous silica raw powder is obtained.

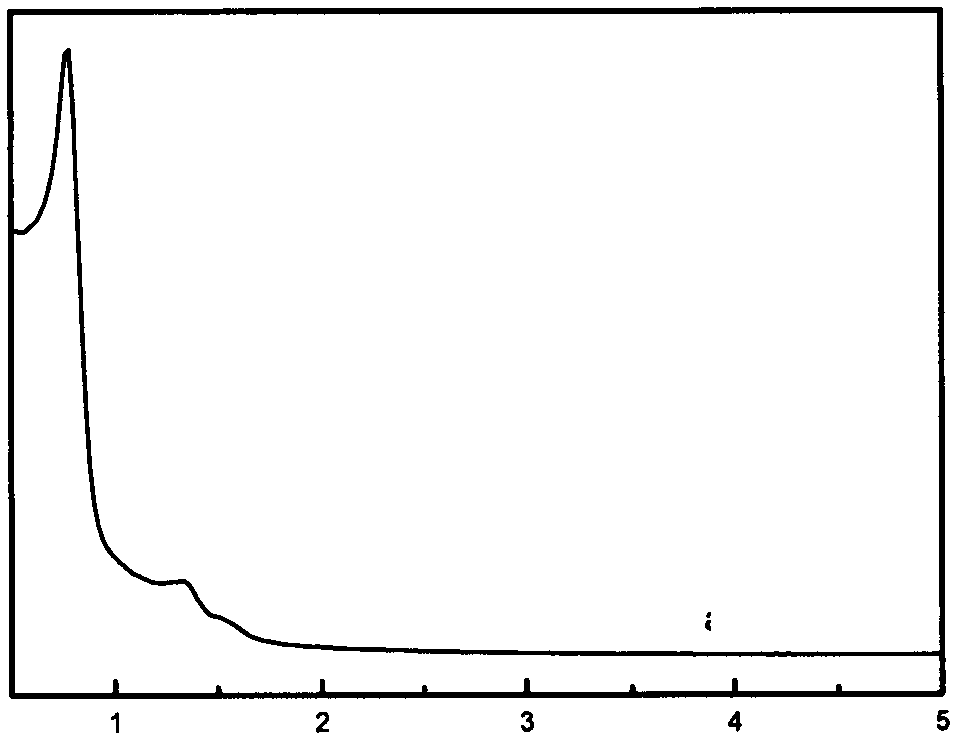

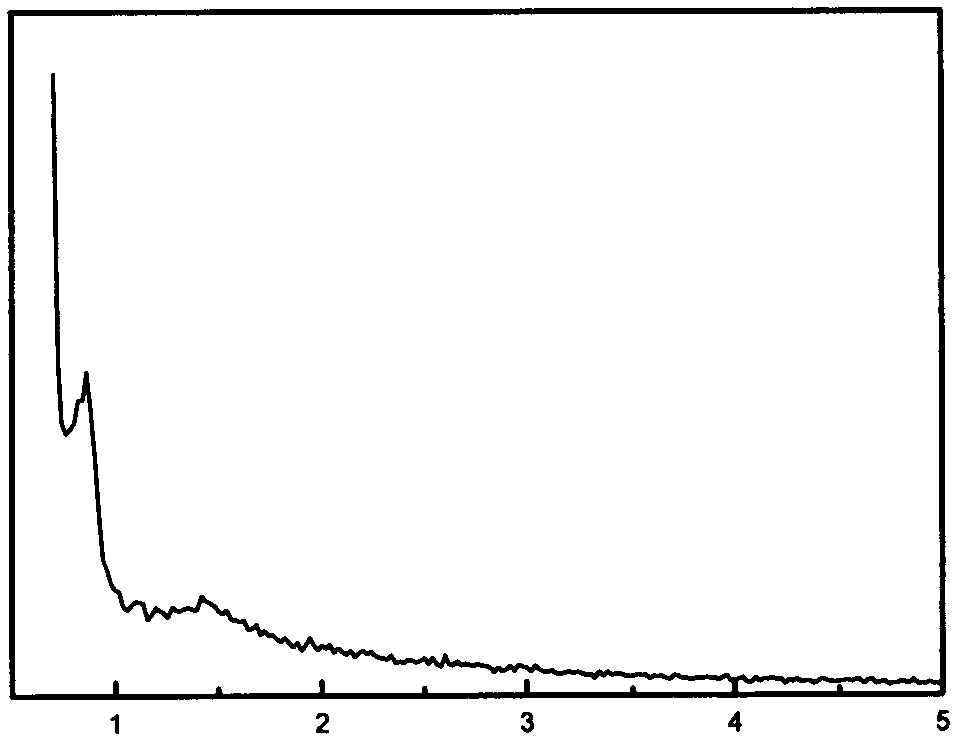

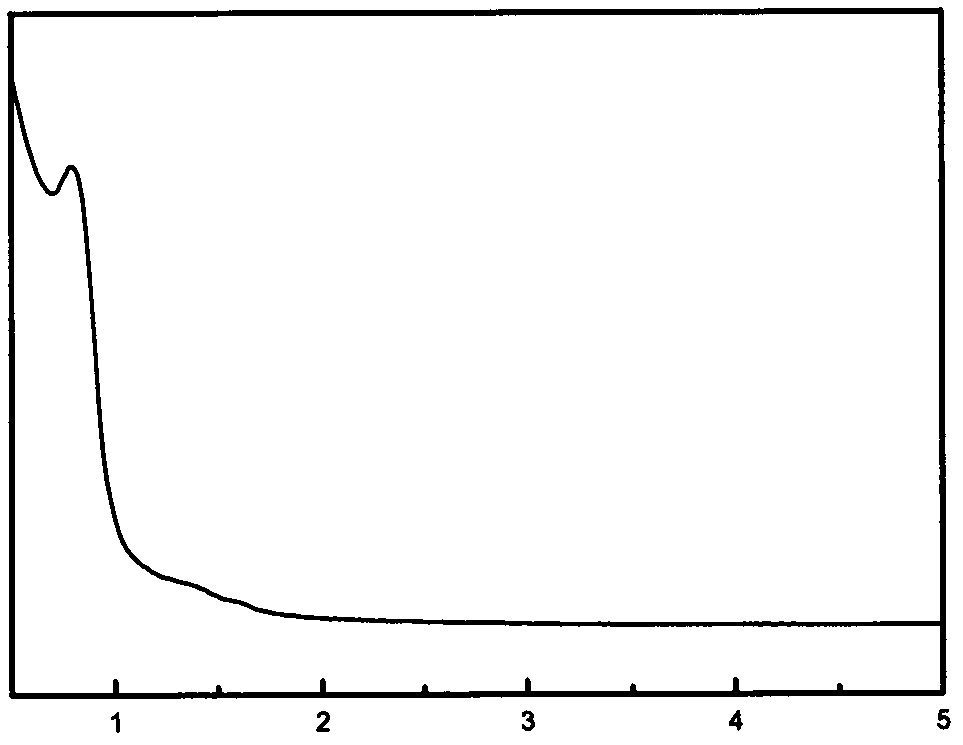

[0059] The hollow spherical mesoporous silica raw powder was calcined in a muffle furnace at 550° C. for 24 hours to obtain hollow spherical mesoporous silica (named MS...

Embodiment 2

[0070] Prepare the supported acidic ionic liquid catalyst according to the method of Example 1, the difference is that the acidic ionic liquid is 5 grams of 1-(4-sulfonic acid) butyl-3-methylimidazolium methanesulfonate, to obtain a supported The acidic ionic liquid catalyst (named MS-ILb-1) has a mass of 1.61 grams after drying. According to calculation, based on the total weight of the catalyst, the content of the 1-(4-sulfonate) butyl-3-methylimidazolium methanesulfonate is 38% by weight, and the hollow spherical medium The content of the porous silica support was 62% by weight.

[0071] The supported acidic ionic liquid catalyst was characterized by XRD, nitrogen adsorption-desorption experiment, and scanning electron microscope, and the results were: X-ray diffraction pattern, nitrogen adsorption-desorption isotherm and scanning electron microscope of catalyst MS-ILb-1 The photos are all similar to the catalyst MS-ILa-1, and the structural parameters are as shown in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com