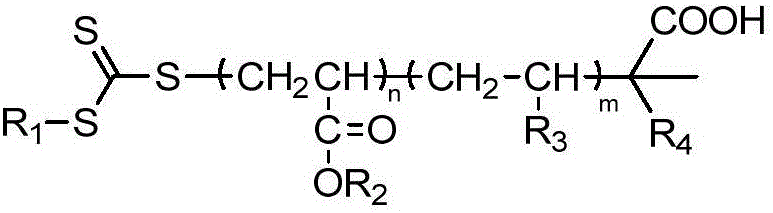

Comb type polymeric dispersant and preparation method and application thereof

A polymer dispersant and comb-shaped polymer technology, which is applied in the application field of pesticide film spreading oil agent, achieves the effects of wide application prospects, reduced usage, and reduced steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

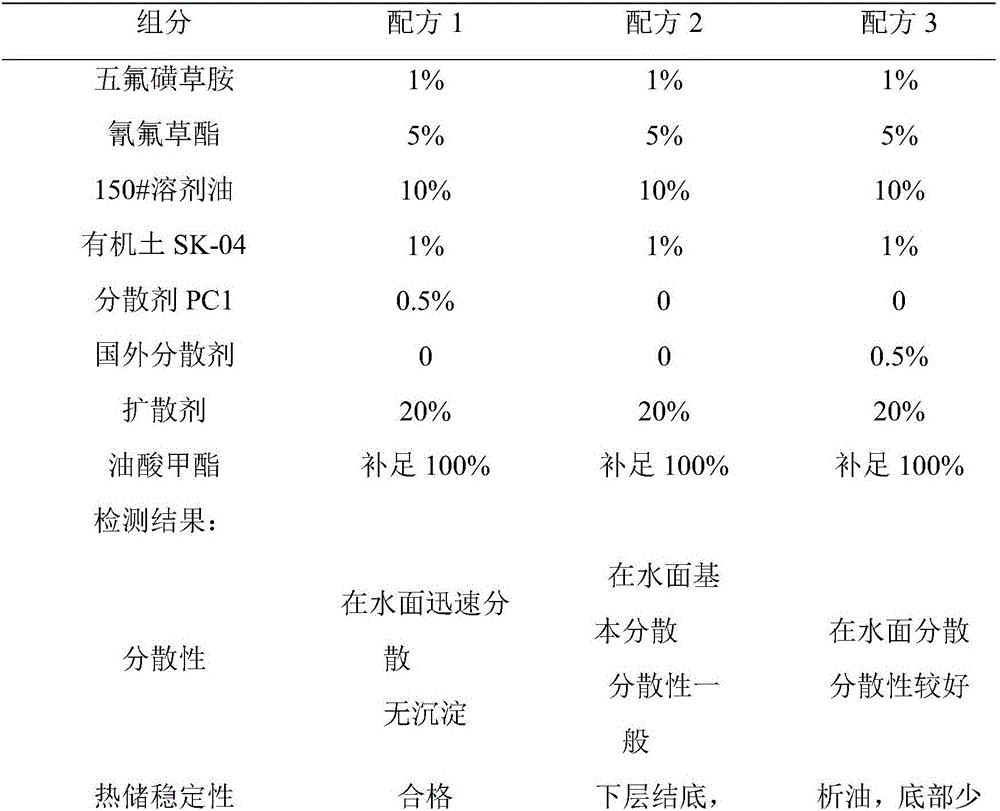

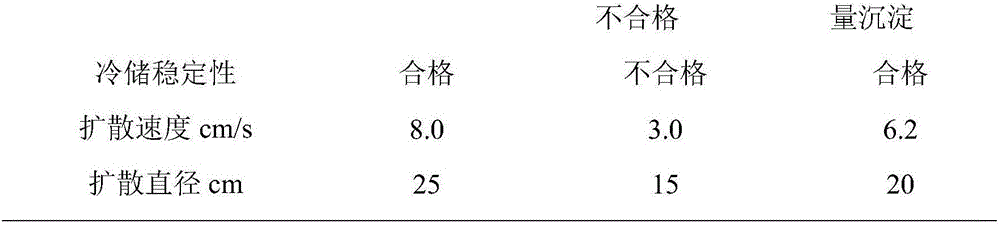

Examples

Embodiment 1

[0021] Monomer molar ratio: allyl polyoxyethylene ether XPEG400 / styrene St / isooctyl acrylate EHA=1:2:1

[0022] The amount of RAFT reagent (dodecylthiocarbonylthiopropionic acid) accounts for 0.5% of the total effective substance molar ratio

[0023] Initiator consumption is 0.1% of the total effective substance molar ratio

[0024] Solvent: Isopropanol

[0025] Add XPEG1000, RAFT reagent and isopropanol into a four-neck flask equipped with a stirrer, constant pressure dropping tank, thermometer and condenser, stir and heat to dissolve the materials, when the temperature reaches 70°C, add styrene and acrylic acid dropwise The mixed solution of isooctyl ester and the isopropanol solution of the initiator azobisisobutyronitrile (AIBN) are added dropwise in 0.5-1h, and kept warm for 4h. After the reaction was completed, the solvent was replaced with methyl oleate, and the pH was neutralized to 4-6 with ethanolamine. The product is denoted as PC1 with a molecular weight of 2500...

Embodiment 2

[0027] Monomer molar ratio: isopentenol polyoxyethylene ether TPEG2400 / styrene / lauryl methacrylate=0.5:2:1

[0028] The amount of RAFT reagent (dodecylthiocarbonylthiopropionic acid) accounts for 0.5% of the total effective substance molar ratio

[0029] Initiator consumption is 0.1% of the total effective substance molar ratio

[0031] Technology is with embodiment 1. The product is denoted as PC2 with a molecular weight of 31000 and a molecular weight distribution of 1.36.

Embodiment 3

[0033] Monomer molar ratio: maleic anhydride fatty alcohol polyether monoester (maleic anhydride and AEO-5 are esterified by 1:1 mole) / styrene / butyl acrylate=0.5:1:1

[0034] The amount of RAFT reagent (dodecylthiocarbonylthiopropionic acid) accounts for 0.5% of the total effective substance molar ratio

[0035] The amount of initiator BPO is 0.1% of the molar ratio of the total effective substance

[0037] Technology is with embodiment 1. The product is denoted as PC3, the molecular weight is 28000, and the molecular weight distribution is 1.19.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com