Patents

Literature

50results about How to "Improve sanding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acrylic acid-epoxy ester hybrid resin and coatings thereof

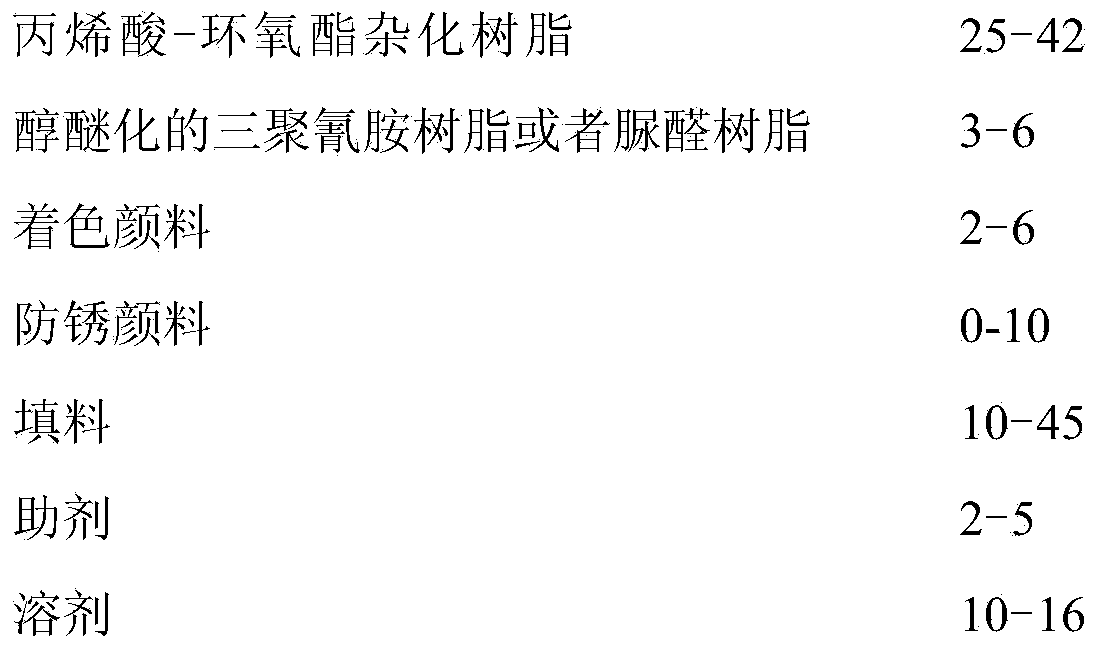

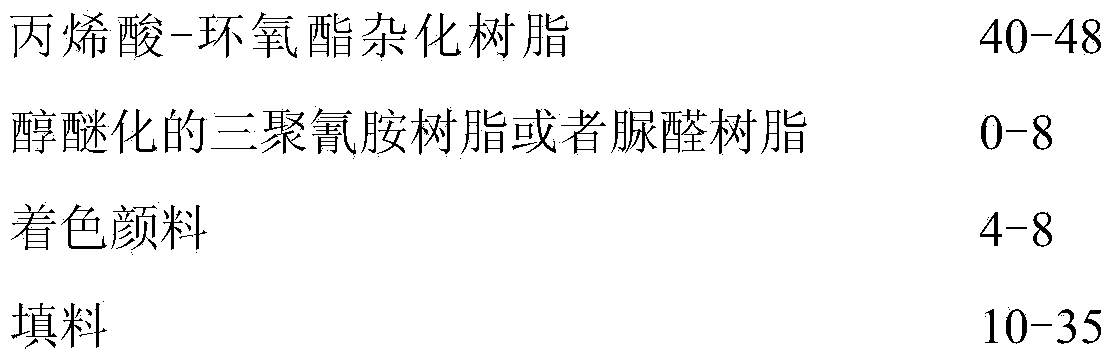

The invention provides an acrylic acid-epoxy ester hybrid resin. The acrylic acid-epoxy ester hybrid resin is prepared by reacting an epoxy resin and aliphatic acid under the action of a catalyst so as to prepare epoxy ester and then adding acrylic monomers and an initiator under certain conditions. A self-drying type antirust coating can be prepared with the acrylic acid-epoxy ester hybrid resin provided by the invention as a main film forming substance; a dried anticorrosive coating can also be prepared, especially coatings for curtain spraying sliver-coated mirrors, color films and aluminum mirrors; the coatings can meet coating process requirements of a wide-curtain spraying and coating production line with a maximum length of 3 m and are completely dried when baked at a temperature of 130 to 150 DEG C for 5 to 3 min, a film obtained after complete drying has excellent anticorrosion performance, can resist CASS, dampness, dryness and water with a temperature of 60 DEG C for more than 240 h, satisfy requirements of edging and texturing process of a downstream client and do not suffer from edge blackening and corrosion of clad layers.

Owner:常州市弘可利办公用品有限公司 +1

Comb type polymeric dispersant and preparation method and application thereof

InactiveCN106492706AImprove the lubrication effectReduce the chance of collisionBiocideTransportation and packagingPropanoic acidCarboxylic acid

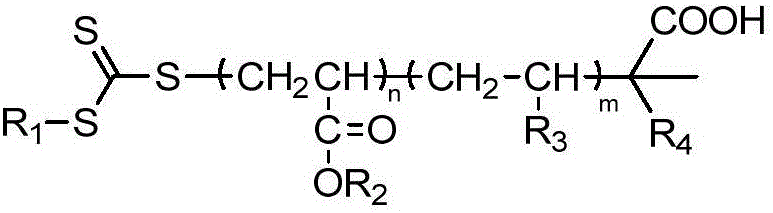

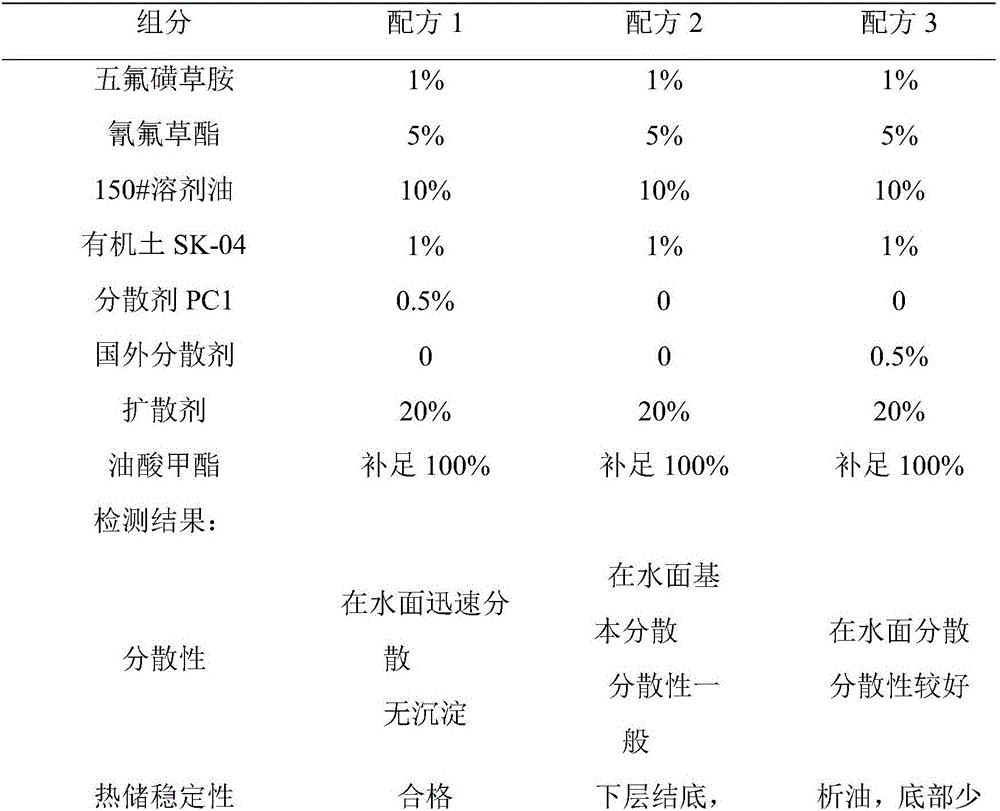

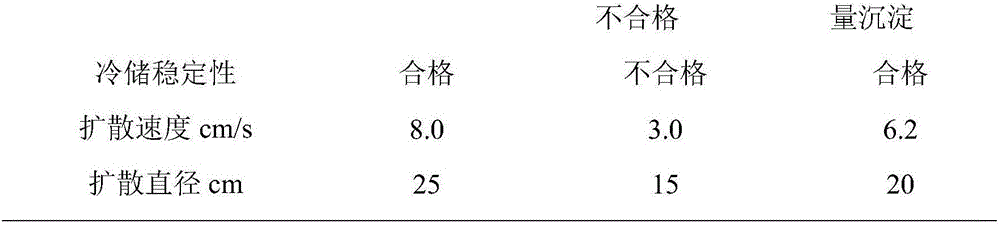

The invention discloses a comb type polymeric dispersant and a preparation method and application thereof. The structural formula of the polymeric dispersant is defined in the specification. The preparation method comprises the steps that the RAFT living polymerization technology is adopted, dodecane sulfenyl sulfo-carbonyl sulfenyl propionic acid serves as a chain transfer agent, azodiisobutyronitrile serves as an initiator, and the comb type polymeric dispersant is obtained through graft copolymerization between unsaturated monomers. According to the application, the dispersant is applied to a spreading oil system, methyl oleate and other environment-friendly solvents are adopted as an organic carrier, an oil-dispersible system is obtained through a wet sanding process, a dispersing agent is added, and spreading oil of different conventional processes is obtained. According to the structure of the comb type polymeric dispersant, polyoxyethylene ether, benzene rings, carboxylic acid groups and other group repetitive units are contained, multipoint adsorption is achieved in the wet sanding process, the dispersant has good compatibility with an oil phase, the lubricating function among particles is improved, the collision probability among the particles is reduced through a macromolecular main chain steric hindrance, and sanding efficiency is improved.

Owner:NANJING UNIV OF TECH +1

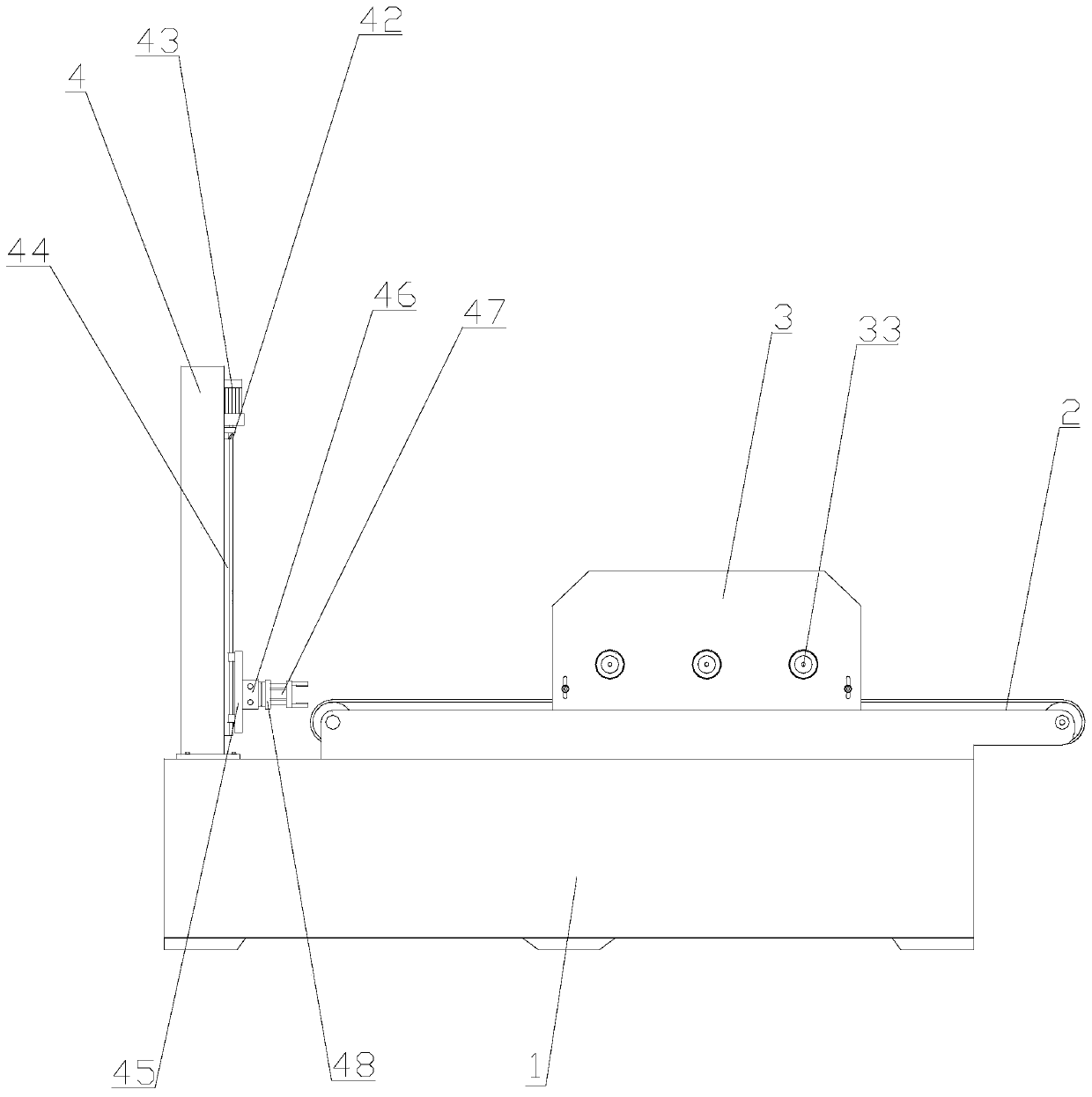

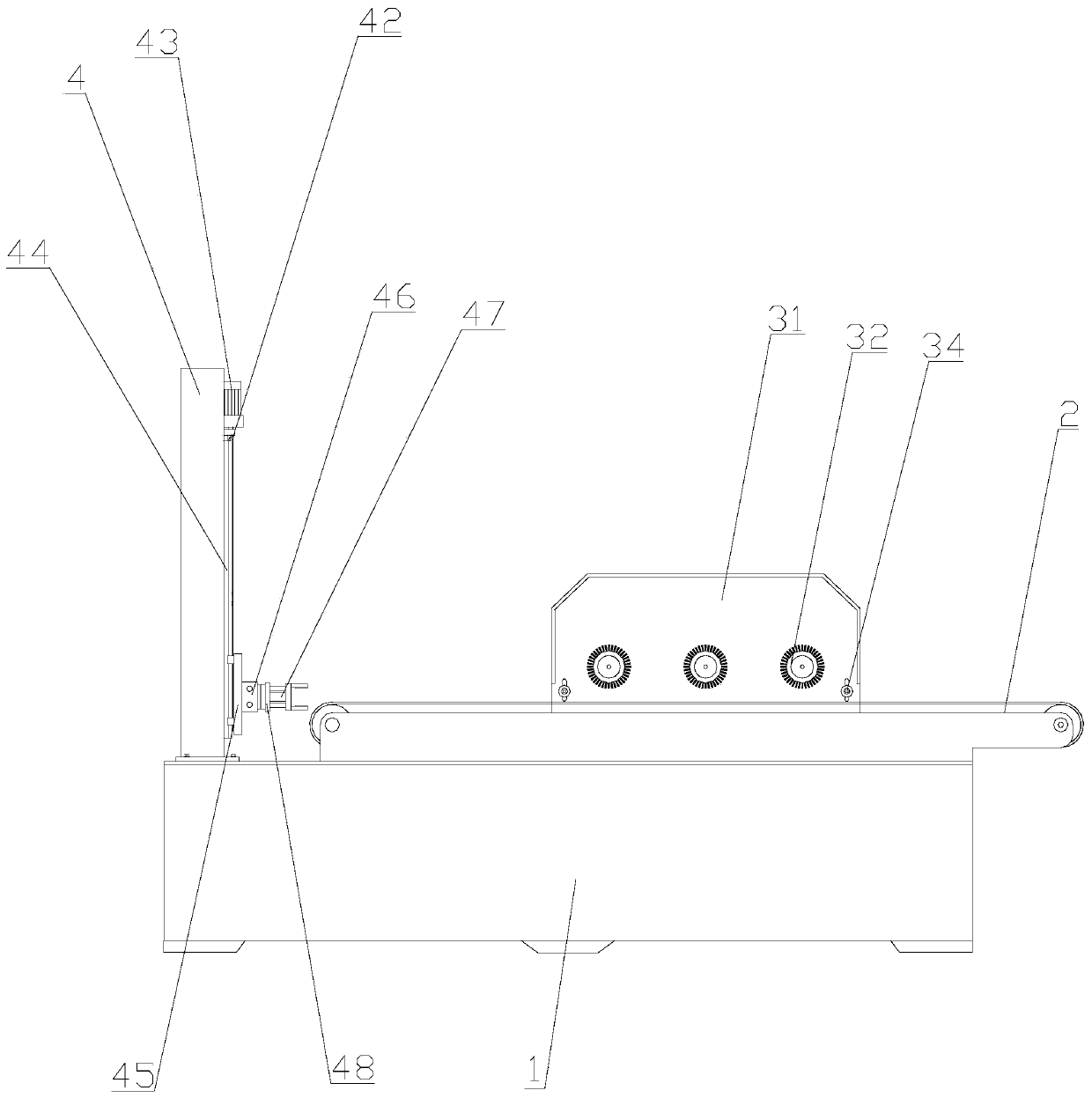

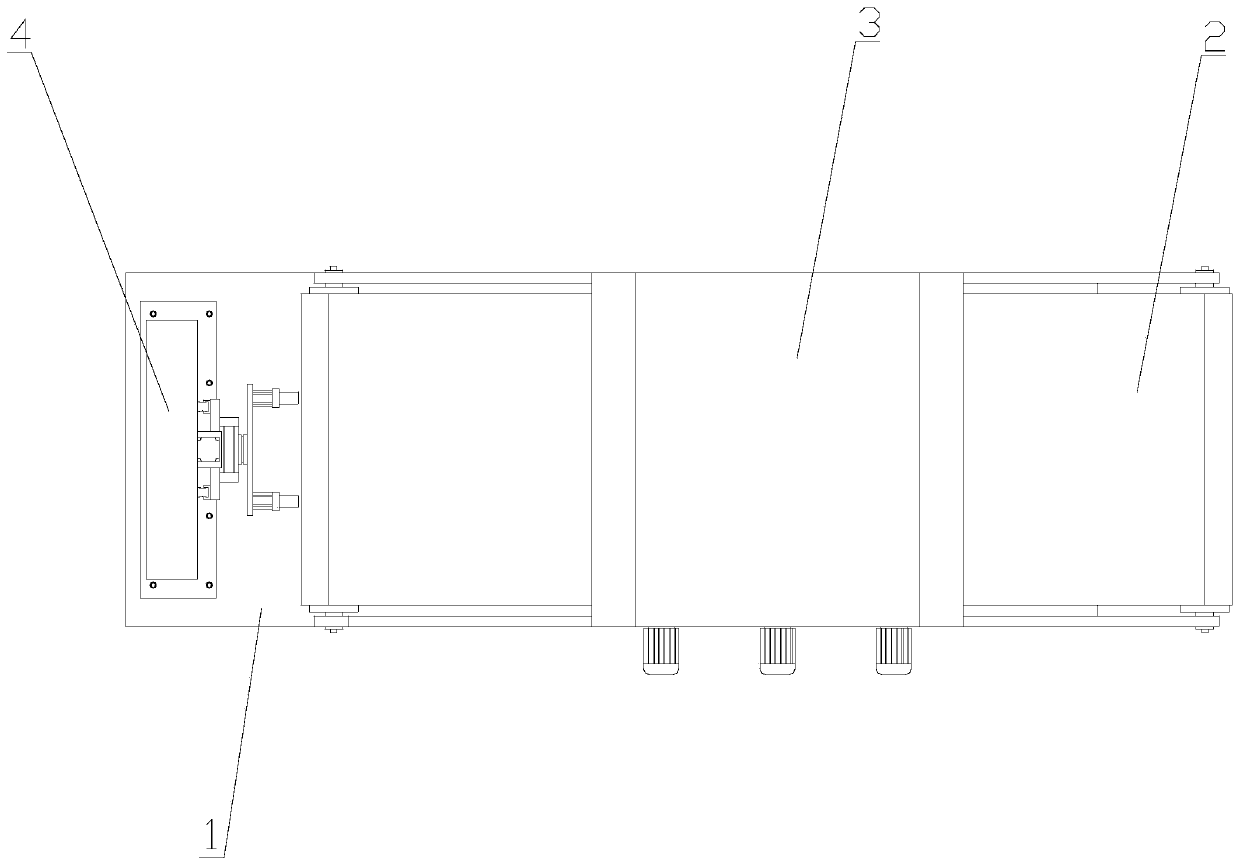

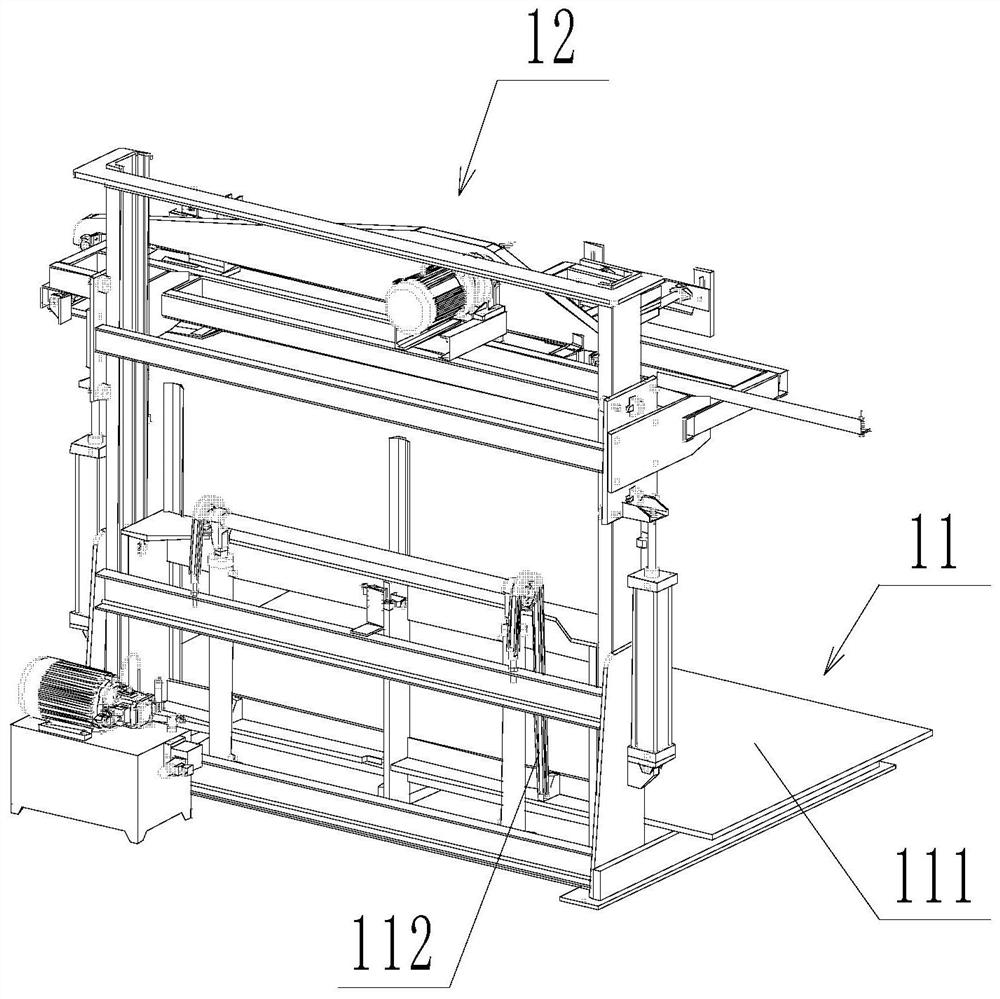

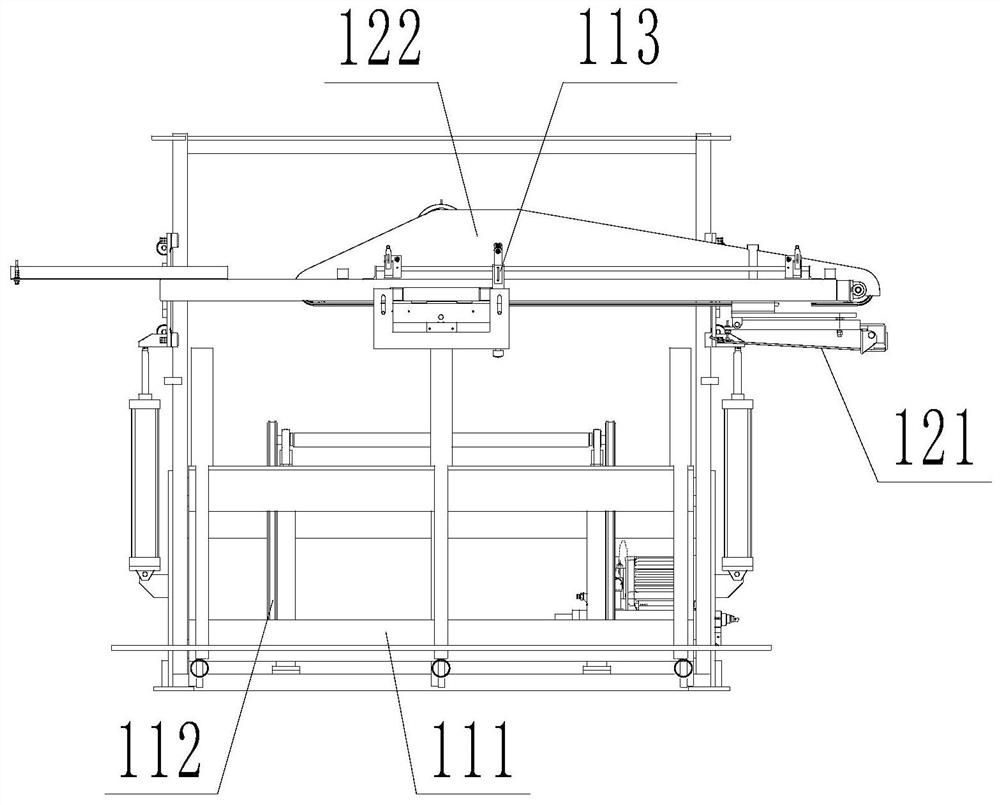

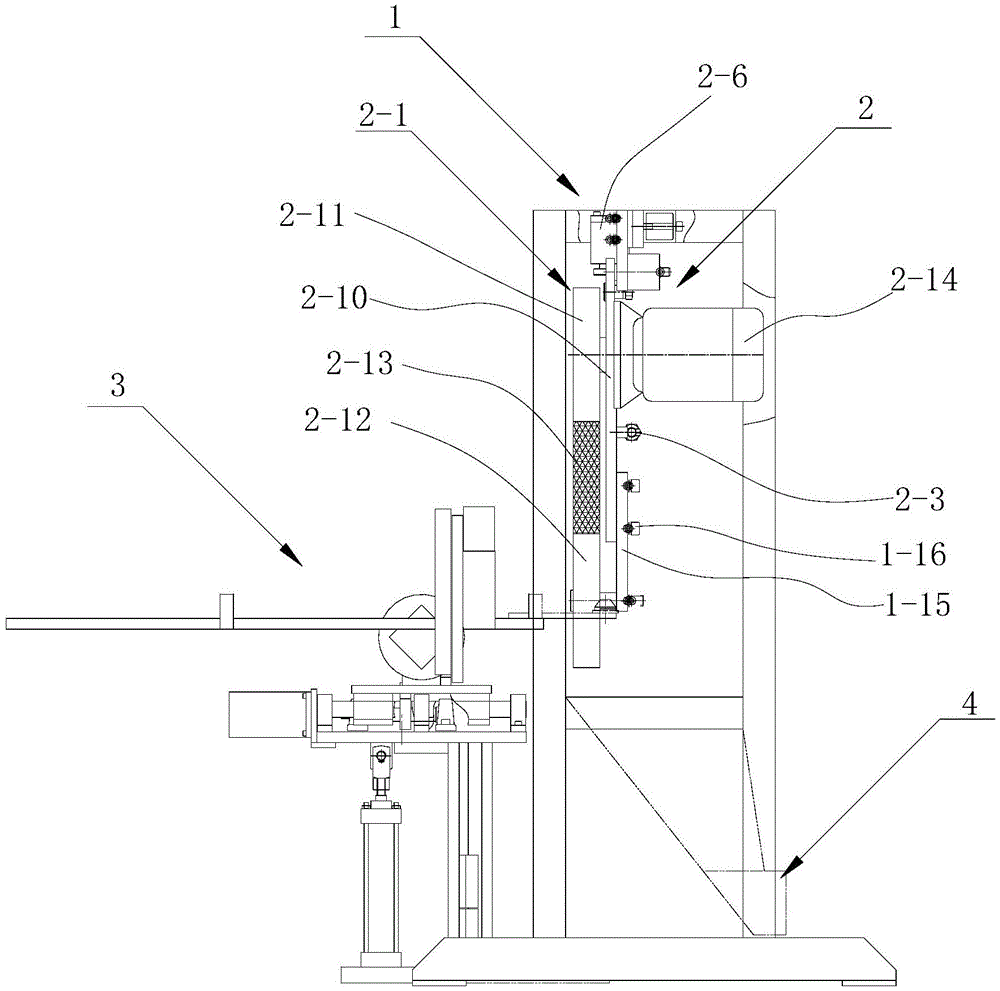

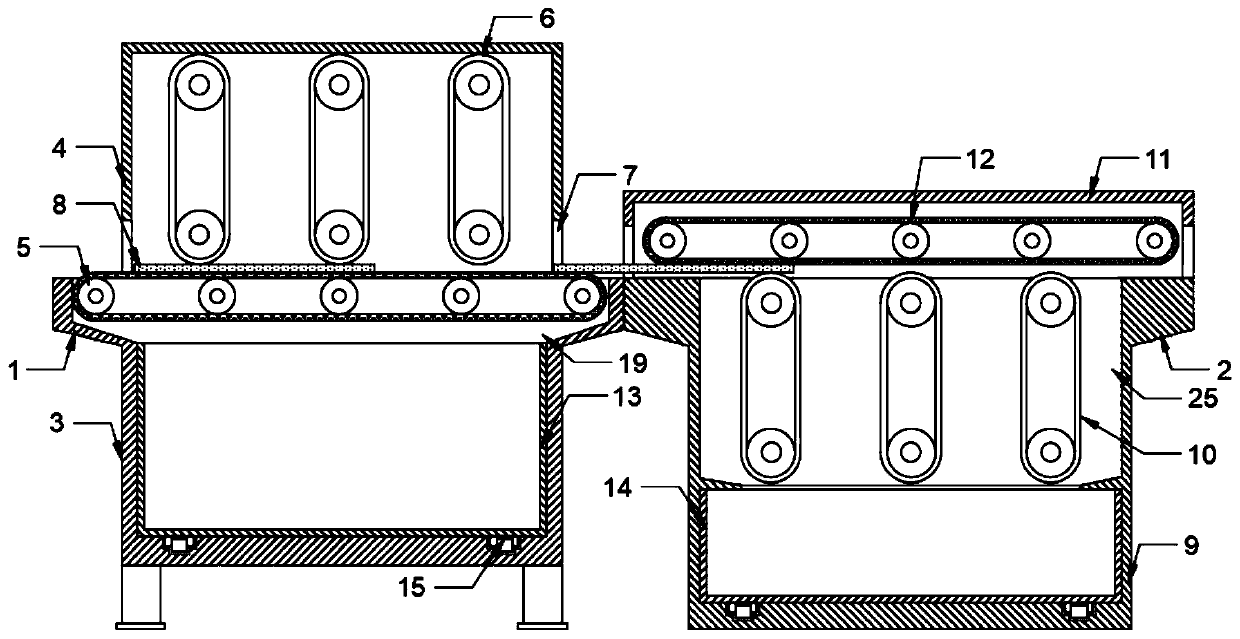

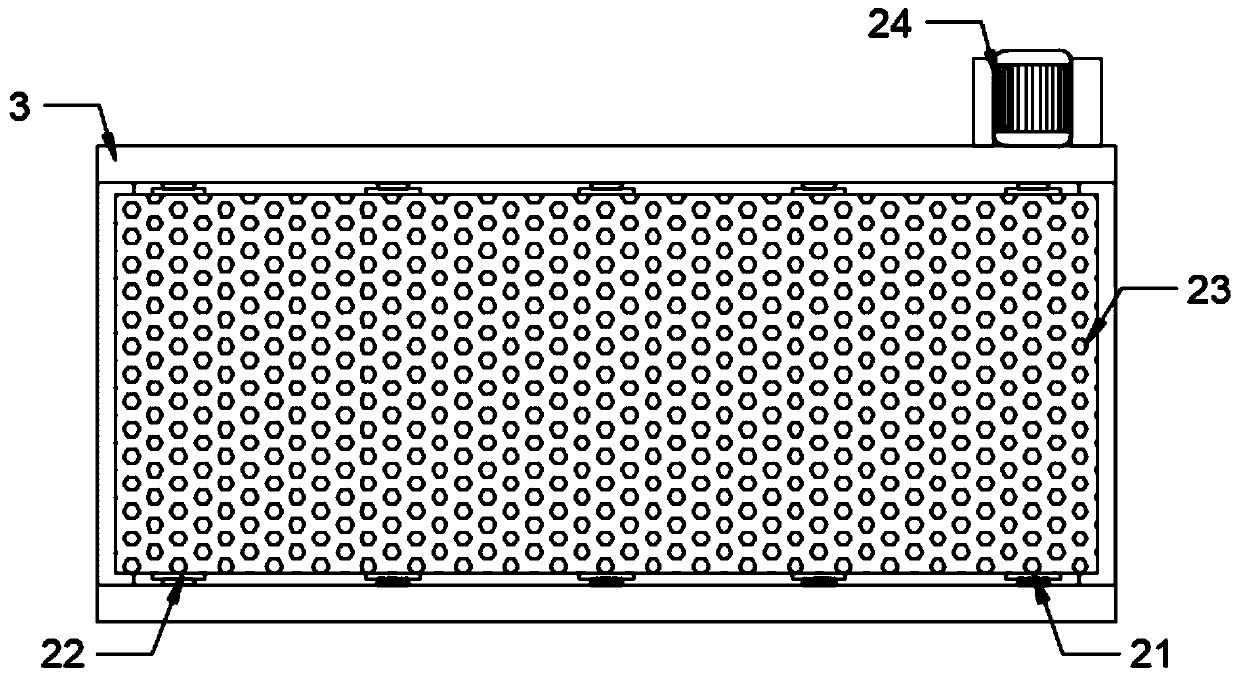

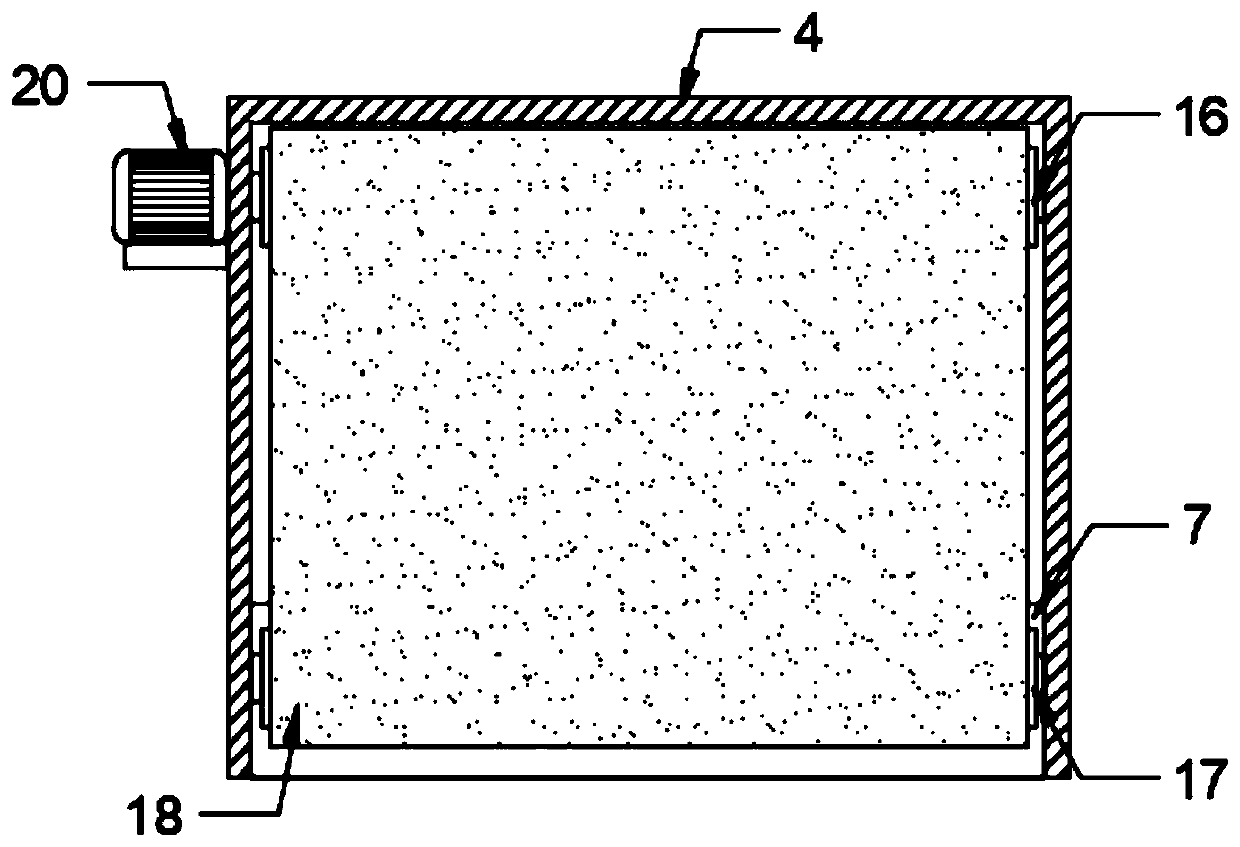

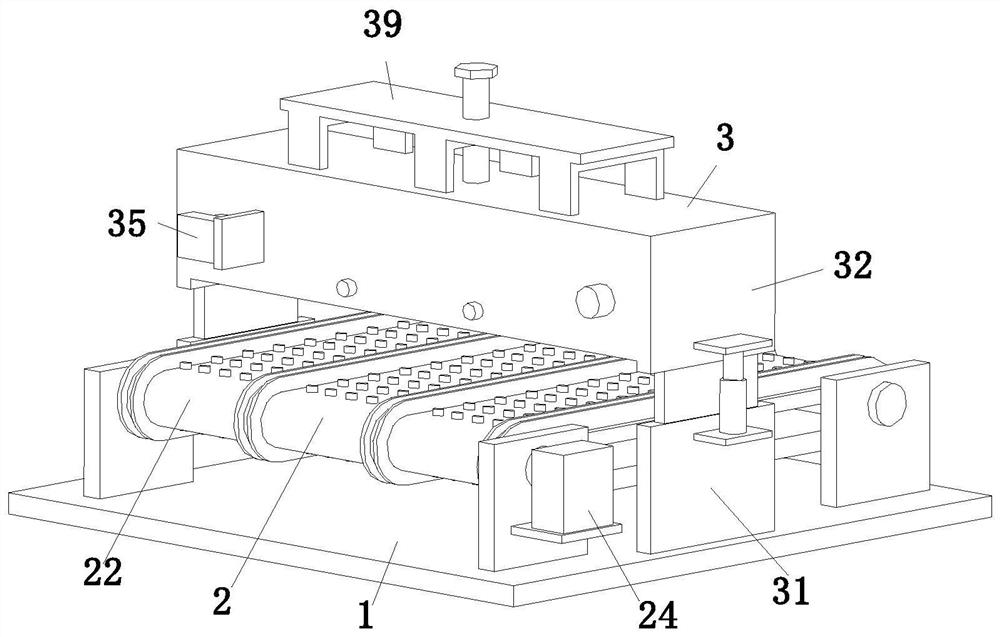

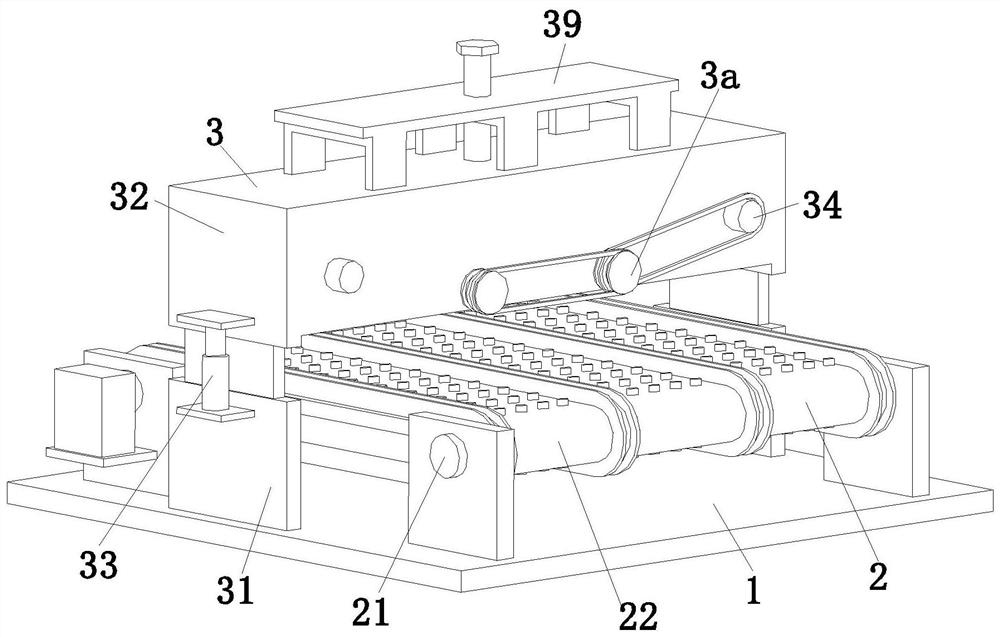

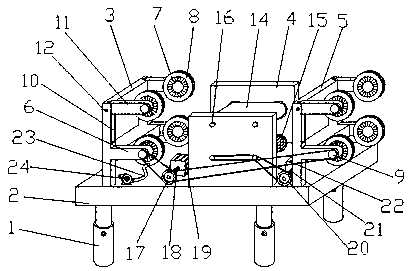

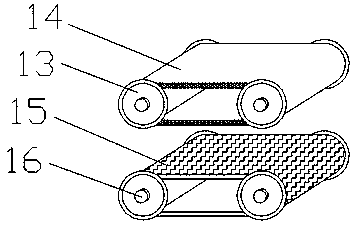

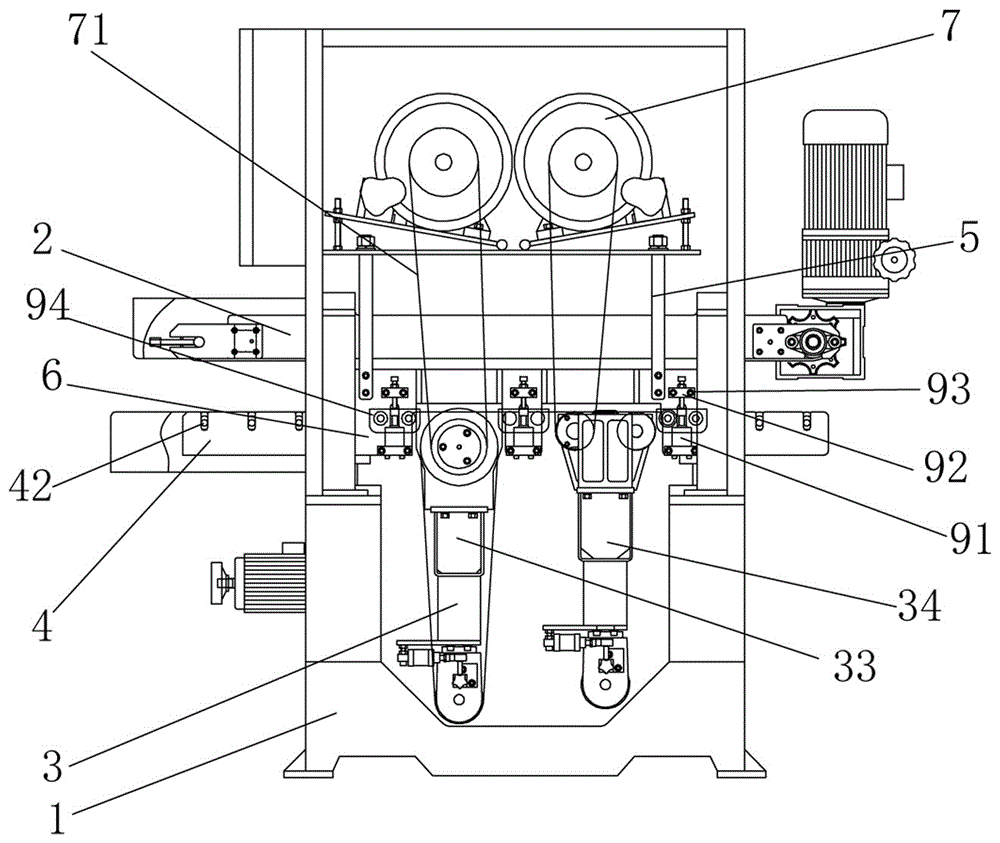

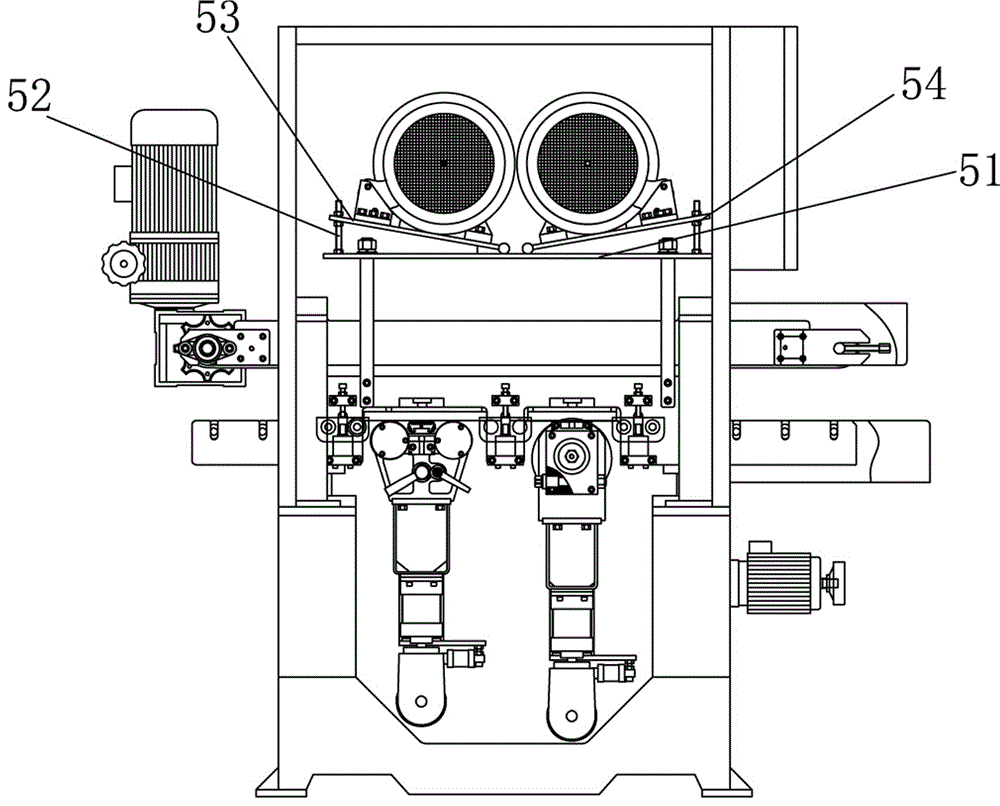

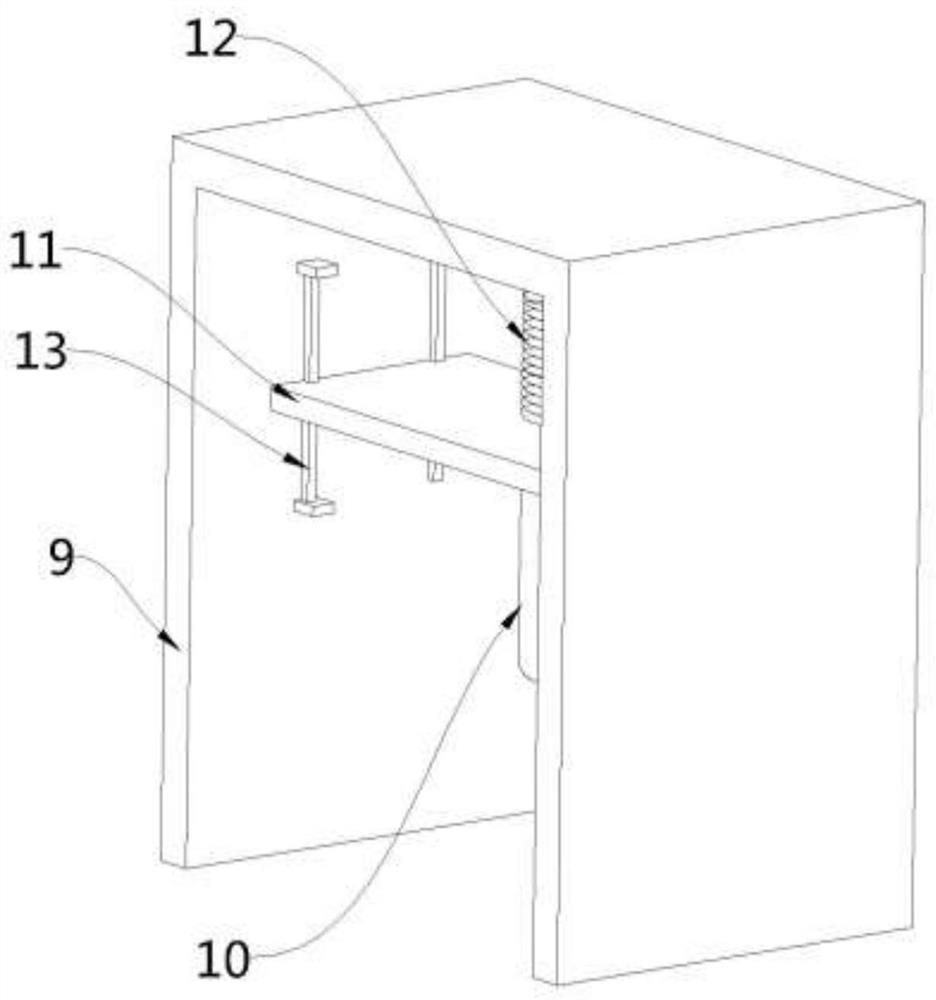

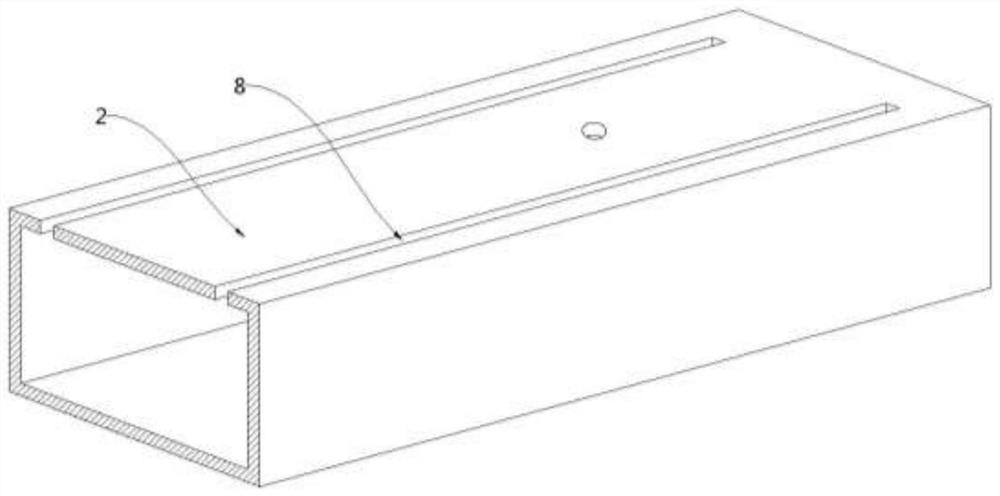

Automatic turnover double-sided sanding machine used for furniture production

InactiveCN110977642AImprove sanding efficiencyImprove sanding qualityGrinding feedersPlane surface grinding machinesSanderConveyor belt

The invention discloses an automatic turnover double-sided sanding machine used for furniture production. The automatic turnover double-sided sanding machine comprises a machine frame, a conveyor belt, a sanding mechanism and an automatic turnover mechanism. The conveyor belt is arranged at the upper end of the machine frame in the transverse direction and is arranged in the long side direction ofthe machine frame. The sanding mechanism capable of cooperating with the conveyor belt is arranged at the upper end of the conveyor belt. The automatic turnover mechanism capable of cooperating withthe conveyor belt is arranged at the position, close to the conveyor belt, of the upper end of the machine frame. According to the automatic turnover double-sided sanding machine, by arranging the sanding mechanism at the upper end of the machine frame and making the sanding mechanism cooperate with the conveyor belt, sanding can be conducted on the upper end face of a furniture plate; by arranging the automatic turnover mechanism, the furniture plate can be automatically turned over to be subjected to double-sided sanding, the plate sanding efficiency is improved, the sanding quality is improved, and the manual labor intensity is lowered.

Owner:嘉兴智华家居有限公司

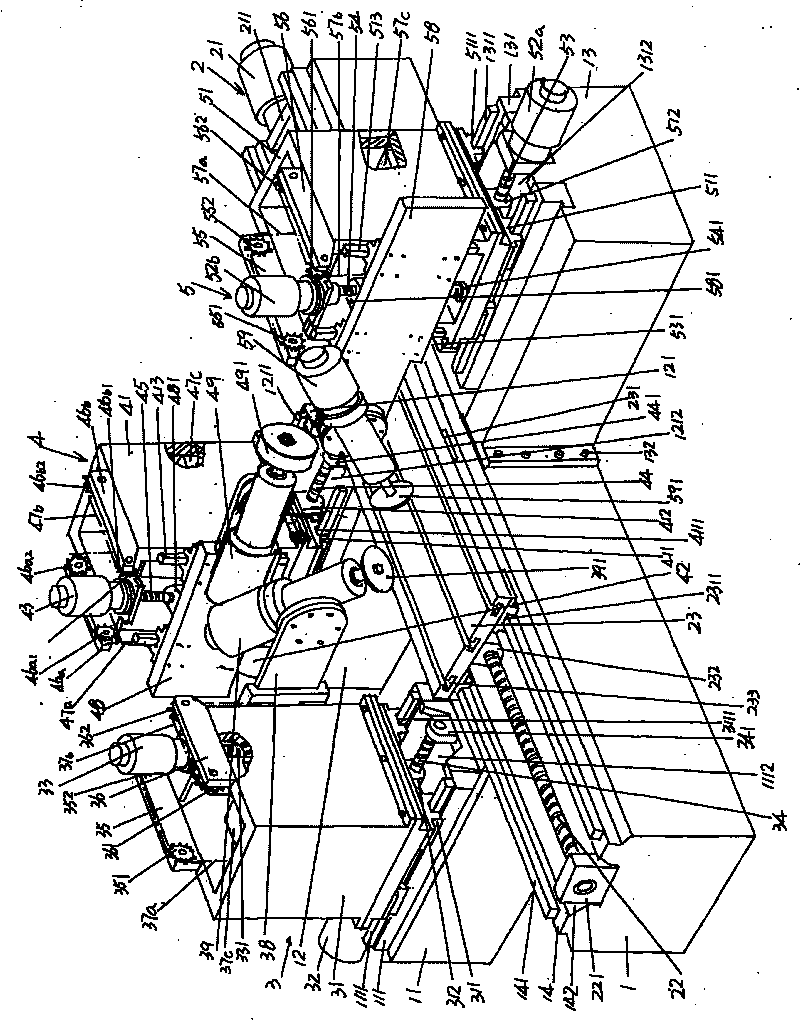

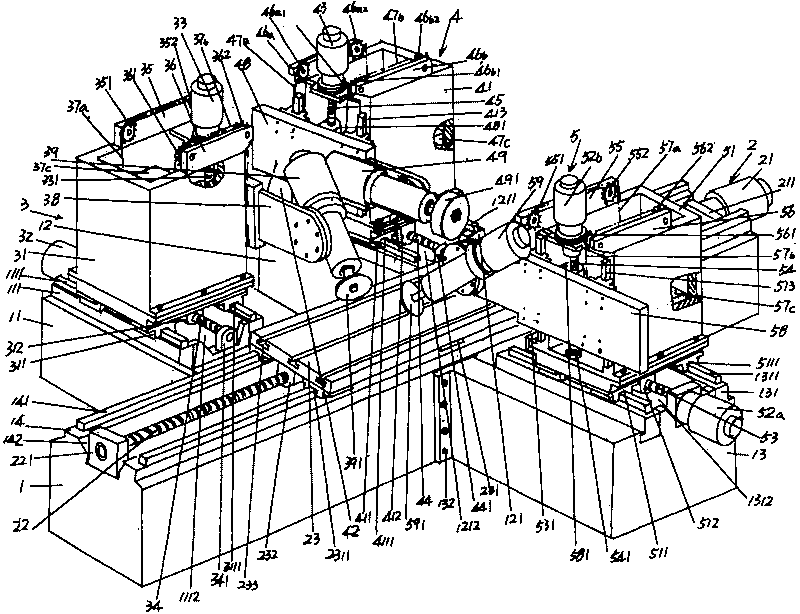

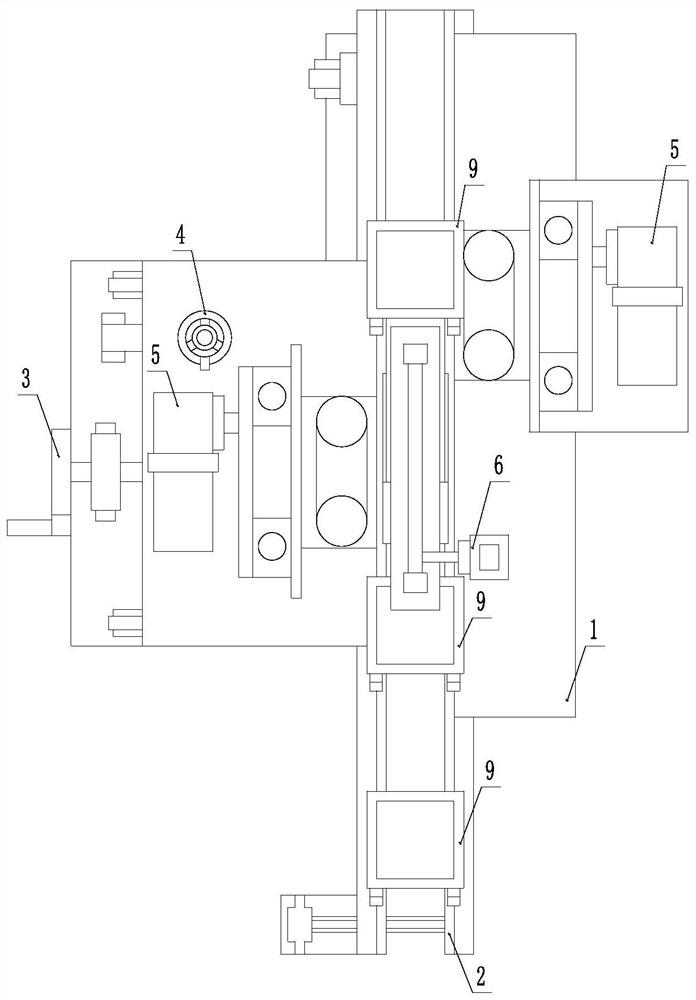

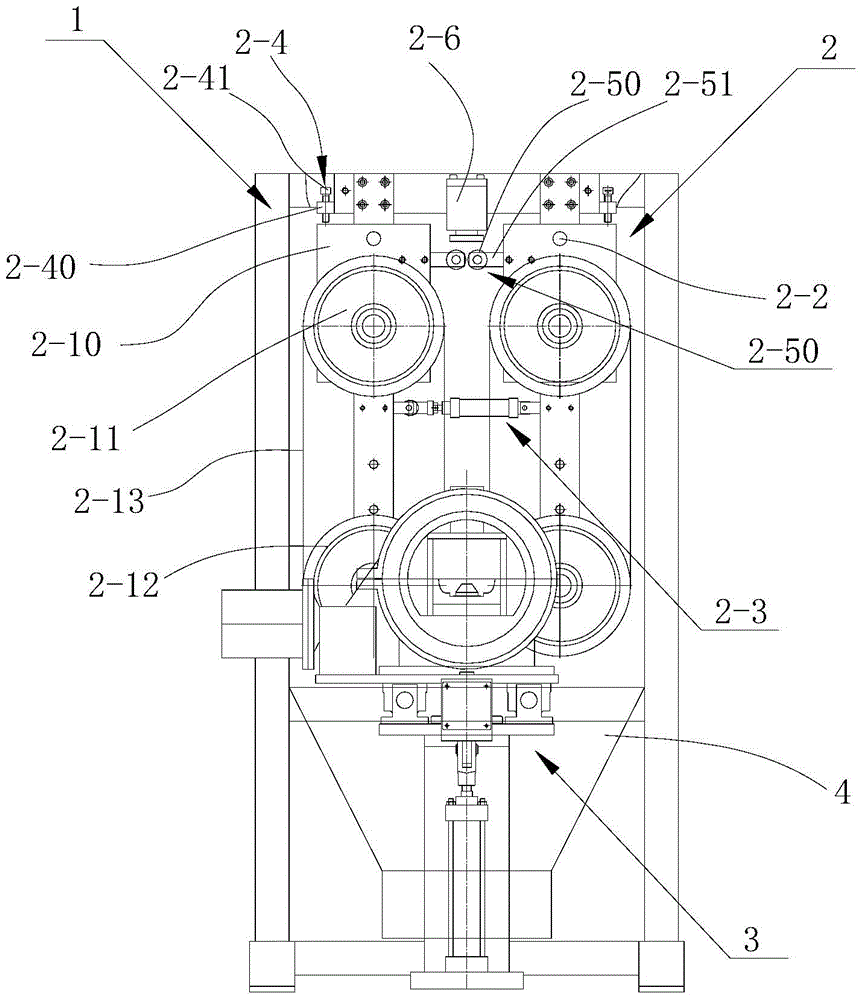

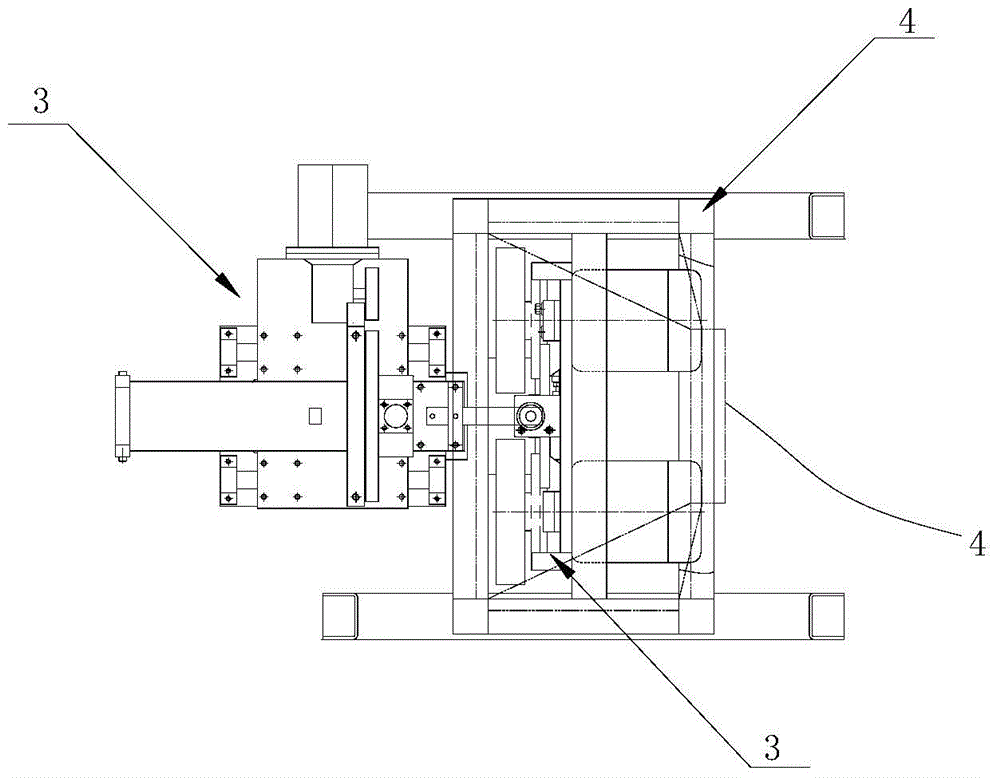

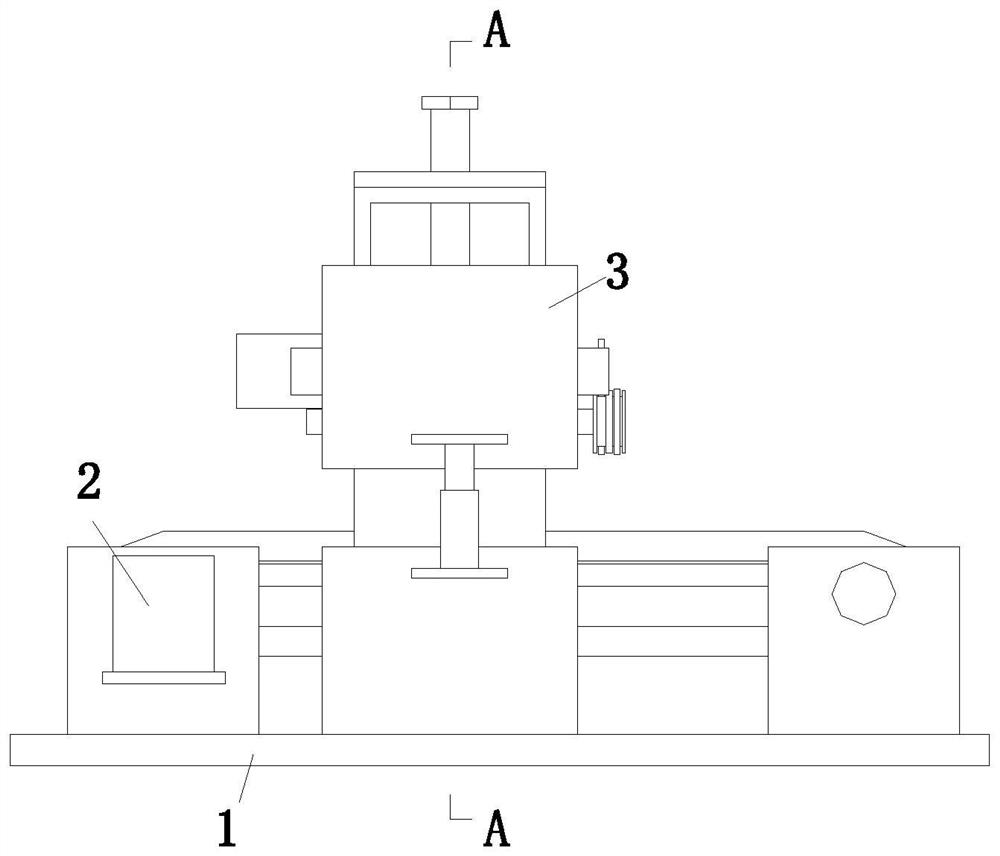

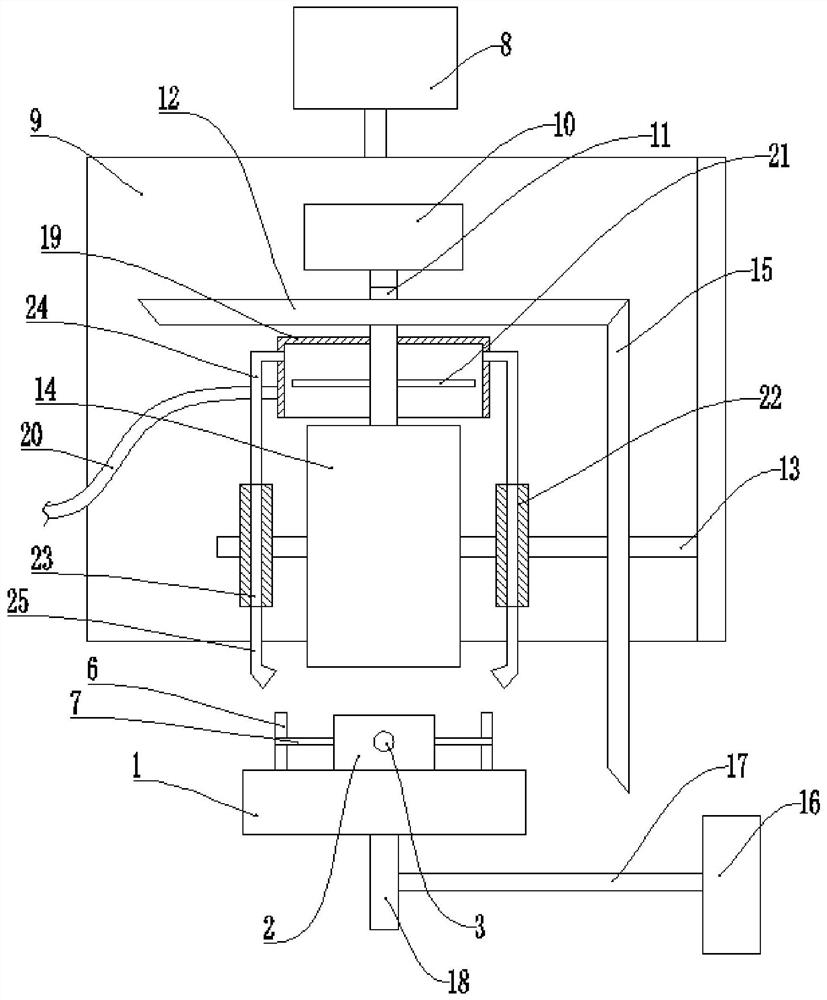

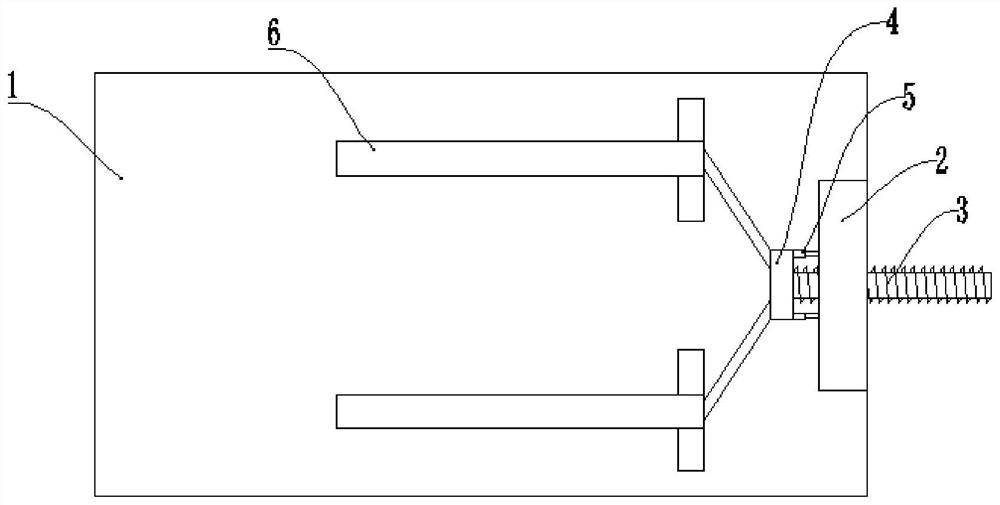

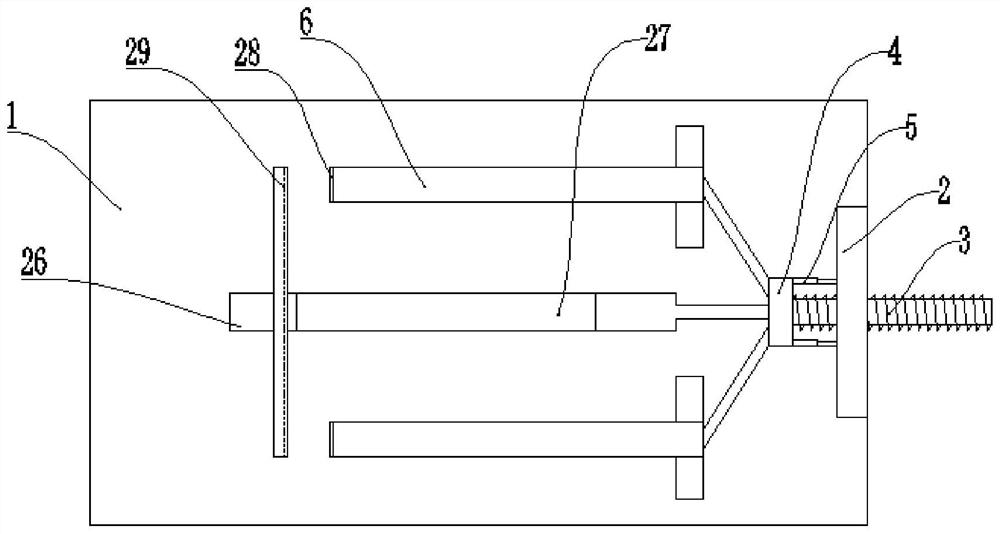

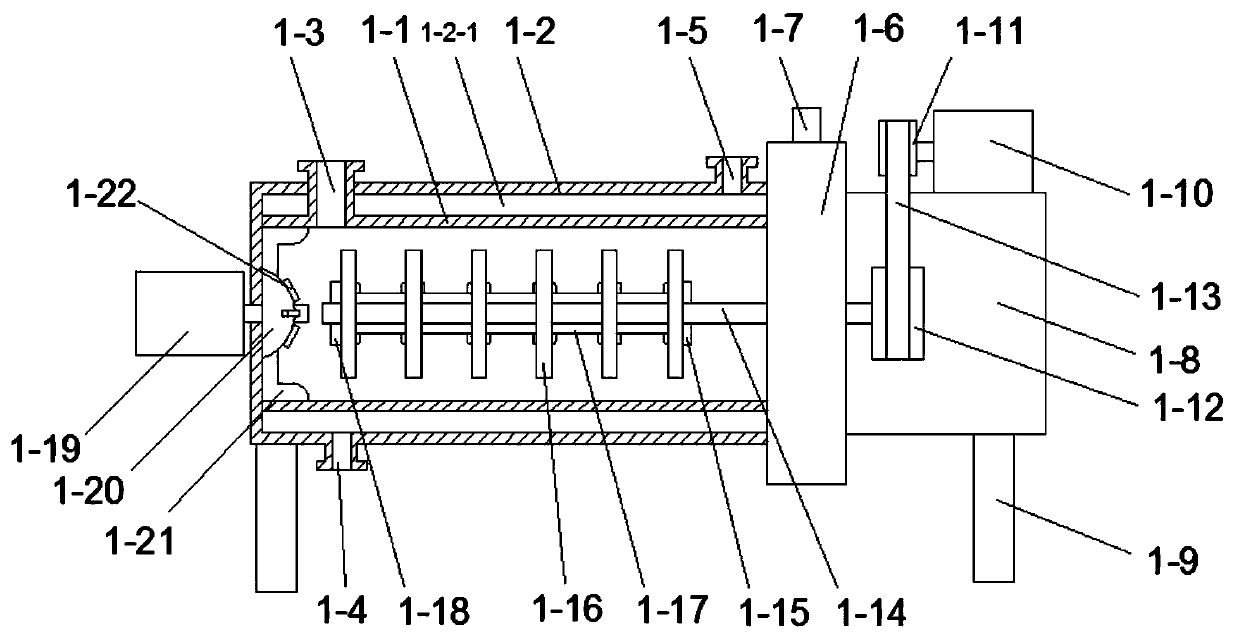

Multi-station grinding machine for processing needle bed inserts of computer flat knitting machine

InactiveCN101700641AQuality assuranceImprove sanding efficiencyGrinding machinesReciprocating motionEngineering

The invention relates to a multi-station grinding machine for processing needle bed inserts of a computer flat knitting machine, belonging to the technical field of grinding machines. The multi-station grinding machine comprises a grinding machine body, a workpiece table reciprocating motion device, a first sanding device, a second sanding device and a third sanding device, wherein one side of the grinding machine body in a length direction is matched with a first machine seat and a second machine seat which are mutually parallel, the other side is matched with a third machine seat, a first guide rail seat is respectively formed at two sides corresponding to an upper surface of the grinding machine body in the length direction, each first guide rail seat is fixedly provided with a first guide rail, and a first screw cavity is formed between a pair of first guide rail seats; the workpiece table reciprocating motion device is matched with each first guide rail in a sliding way; and the first sanding device is matched on the first machine seat in a sliding way, the second sanding device is matched on the second machine seat in a sliding way, and the third sanding device is matched on the third machine seat in a sliding way. The technical scheme not only can improve the sanding efficiency but also can ensure the workpiece quality.

Owner:PACIFIC TEXTILE MACHINERY CHANGSHU CO LTD

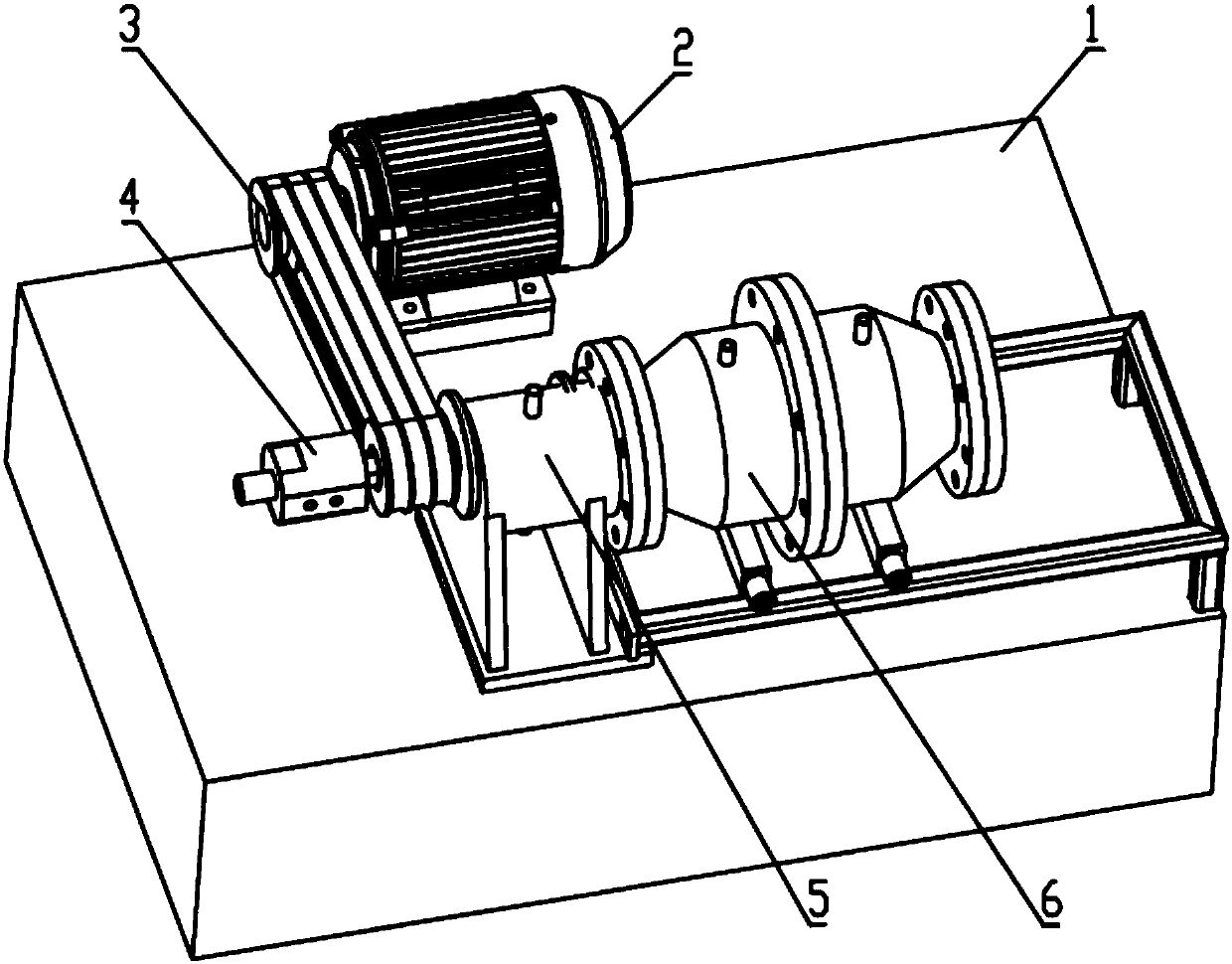

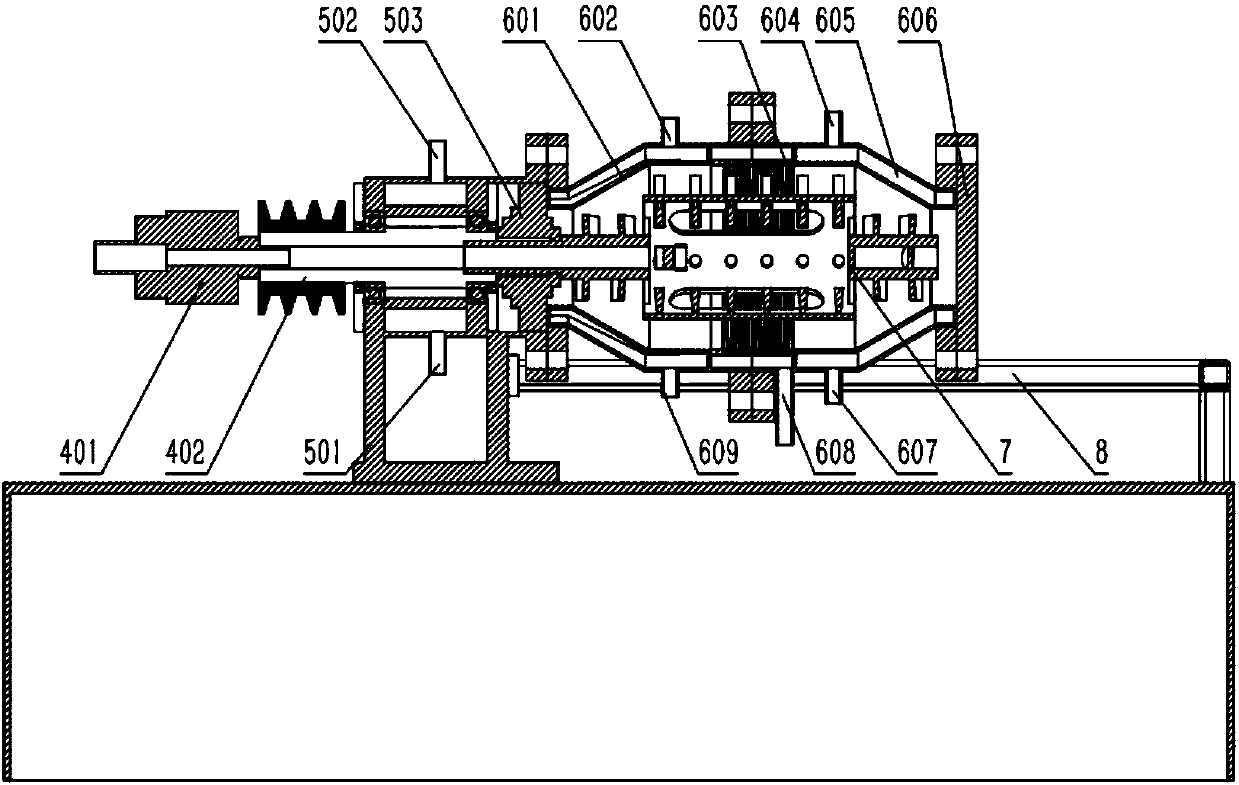

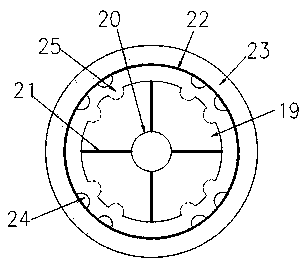

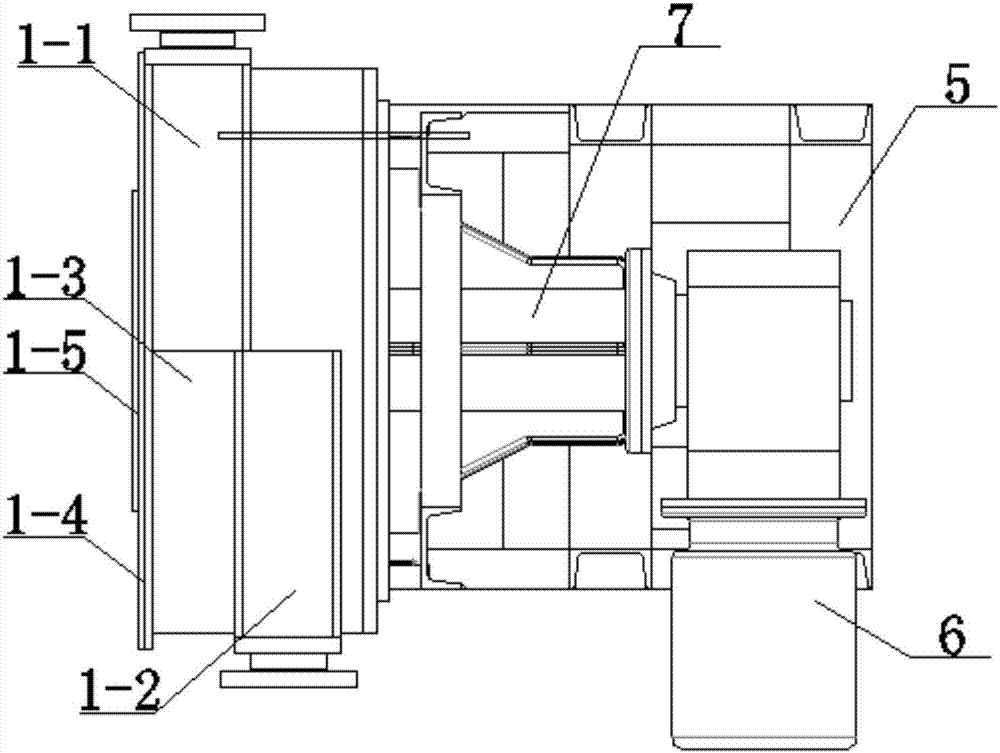

Rod pin type bifrustum-shaped sand mill device

ActiveCN107626395ACompact structureReasonable structureGrain treatmentsSurface mountingElectric machinery

The invention relates to a rod pin type bifrustum-shaped sand mill device. The rod pin type bifrustum-shaped sand mill device comprises a rack, wherein a motor is arranged on the upper surface of therack; the output end of the motor is connected with a spindle component through a driving component; one end of the spindle component is supported by a bearing base component; a sand mill barrel bodycomponent is arranged at the outer end of the bearing base component through a sealing device; a stirrer connected with the spindle component is arranged inside the sand mill barrel body; rollers arearranged on two sides of the sand mill barrel body component; a guide rail bracket for the rollers to run is arranged on the upper surface of the rack. The rod pin type bifrustum-shaped sand mill device disclosed by the invention has the advantages of compact and reasonable structure and convenience in operation; a barrel body with a conical structure is adopted, and the inner part of the barrel body is matched with the pin rod type stirrer for grinding materials, so that good milling effect and high working efficiency are realized.

Owner:WUXI HOPE LIGHT IND EQUIP TECH

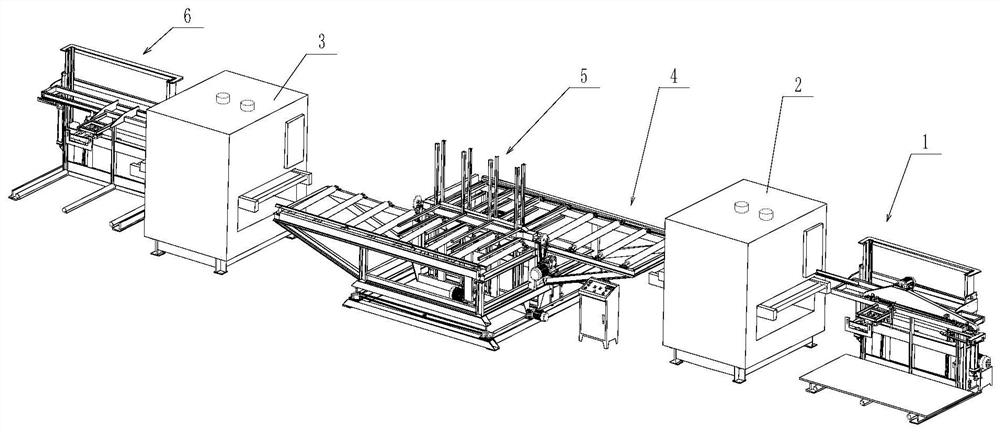

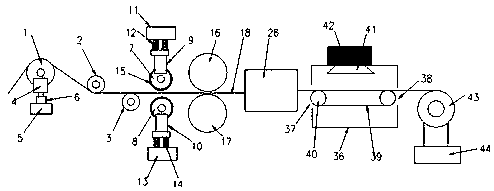

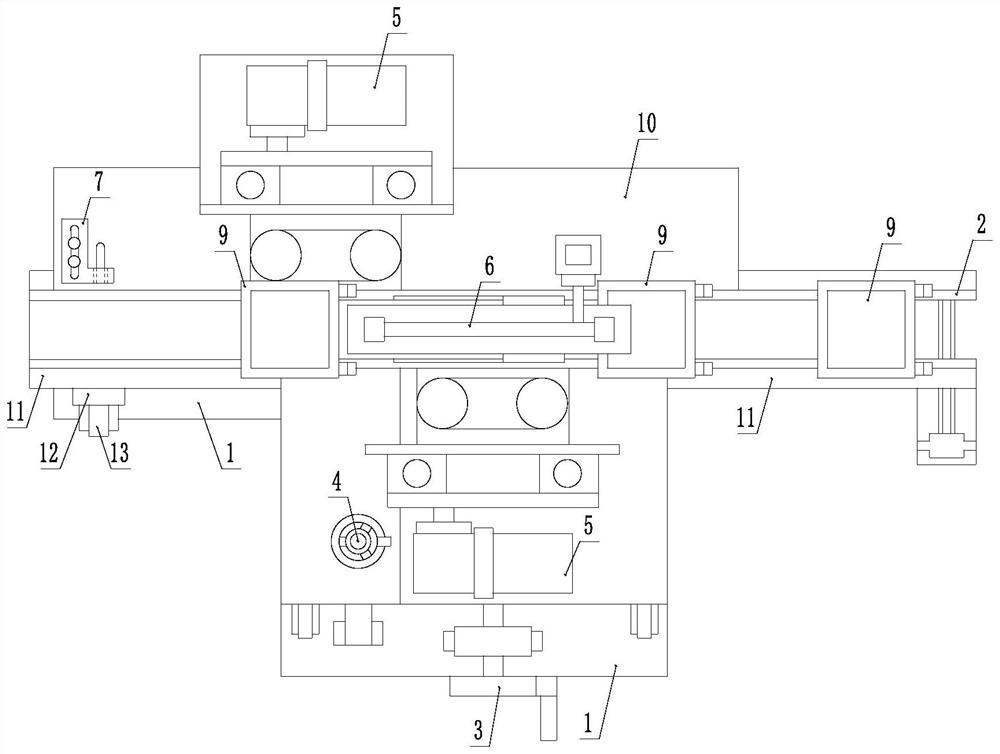

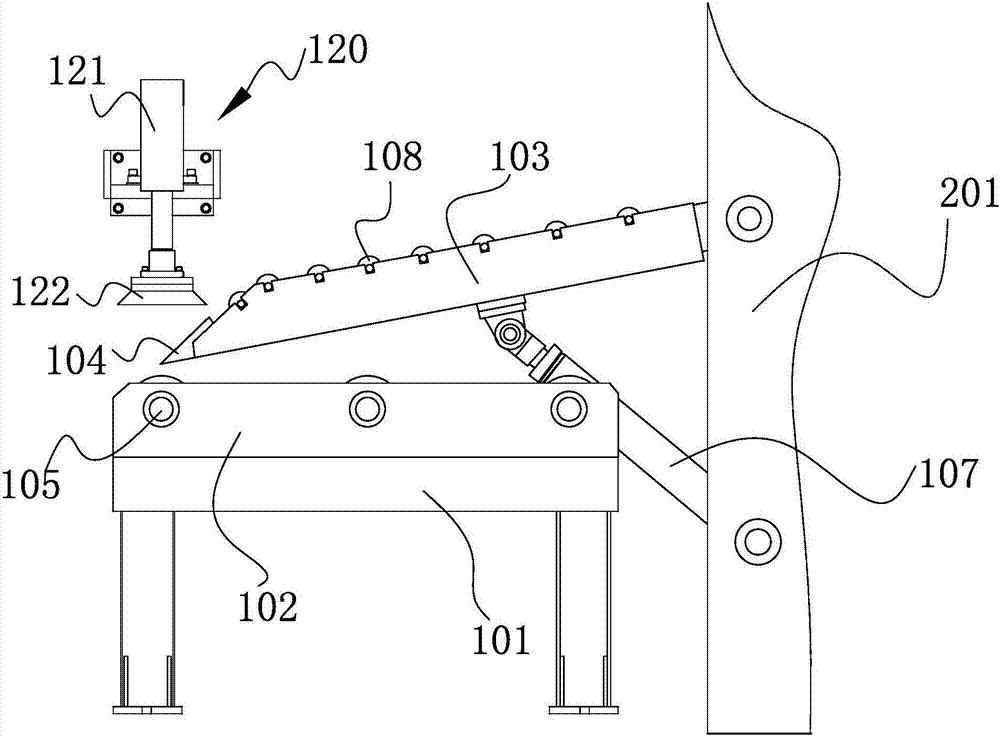

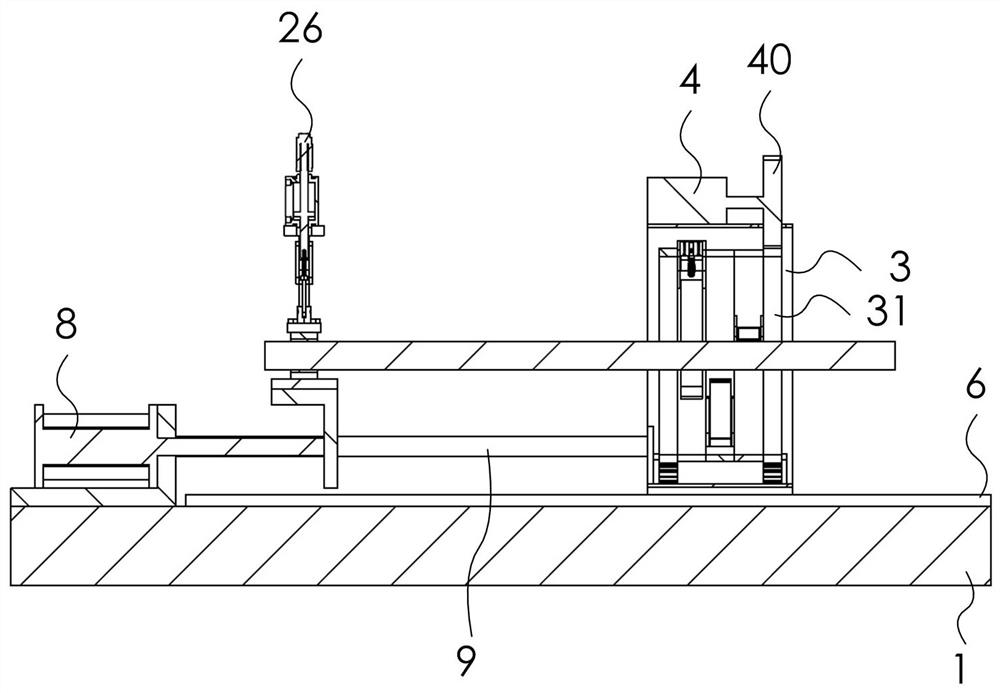

Automatic wood sanding production line

PendingCN112720124AHigh degree of automationImprove sanding efficiencyAutomatic grinding controlGrinding feedersSanderPulp and paper industry

The invention relates to the technical field of wood processing, in particular to an automatic wood sanding production line. The automatic wood sanding production line comprises a feeding device, a front surface sanding machine, an overturning device, a back surface sanding machine, a discharging device and a conveying device. Wood is automatically conveyed to the front sanding machine through the feeding device, the front surface sanding machine conducts coarse sanding and fine sanding treatment on the front surface of the wood, so that front surface sanding treatment of the wood is completed; wood output by the front surface sanding machine is conveyed to the turnover device through the conveying device, the wood is turned over through the turnover device, the reverse surface of the wood faces upwards, the wood is conveyed into the reverse surface sanding machine through the conveying device to be subjected to reverse surface sanding, and after sanding is completed, the wood output by the reverse surface sanding machine is received through the discharging device to be subjected to discharging treatment. According to the sanding production line, the front and reverse surface sanding treatment on the wood can be conducted, so that the sanding production line is high in degree of automation and improves the sanding efficiency greatly.

Owner:江西兴创木业有限责任公司

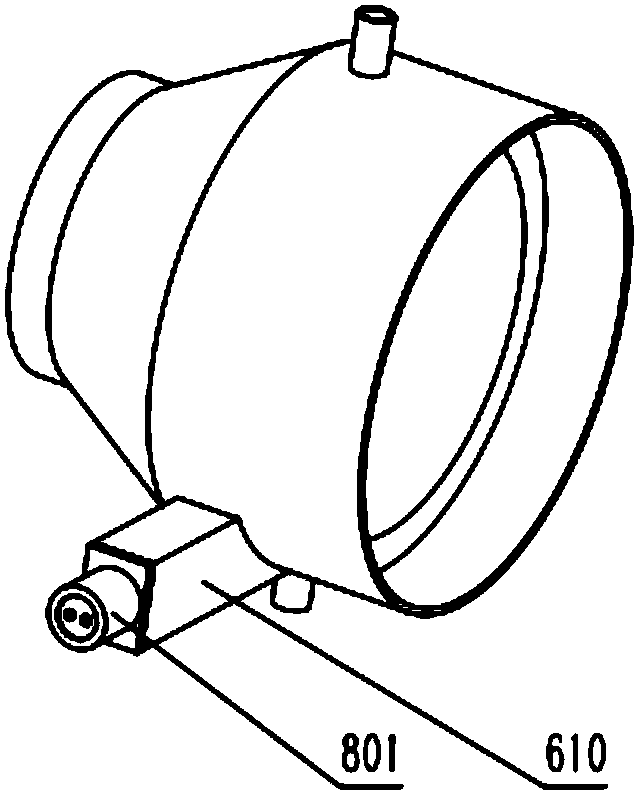

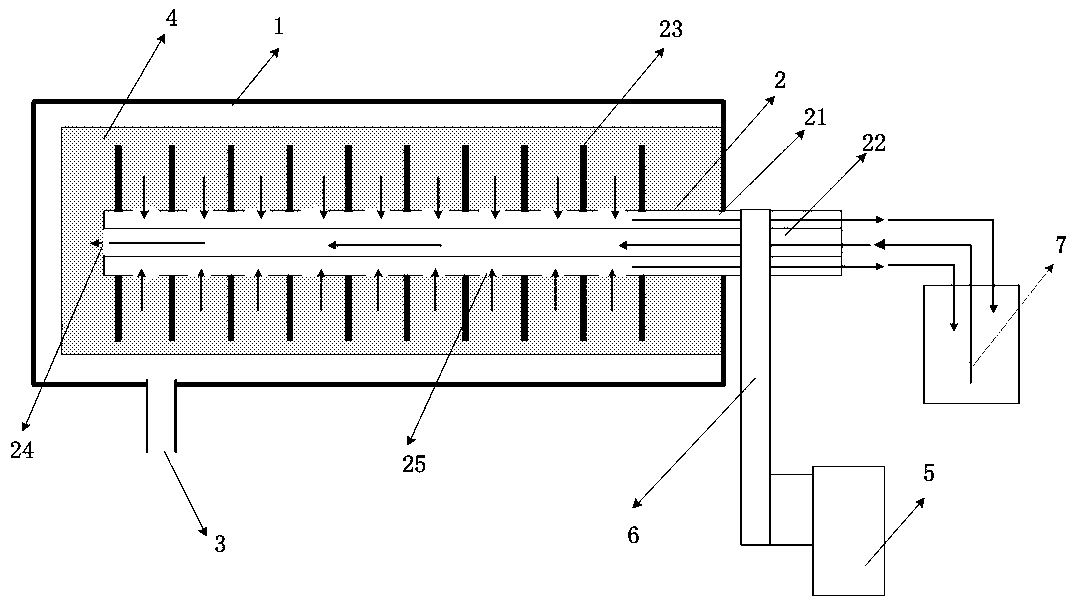

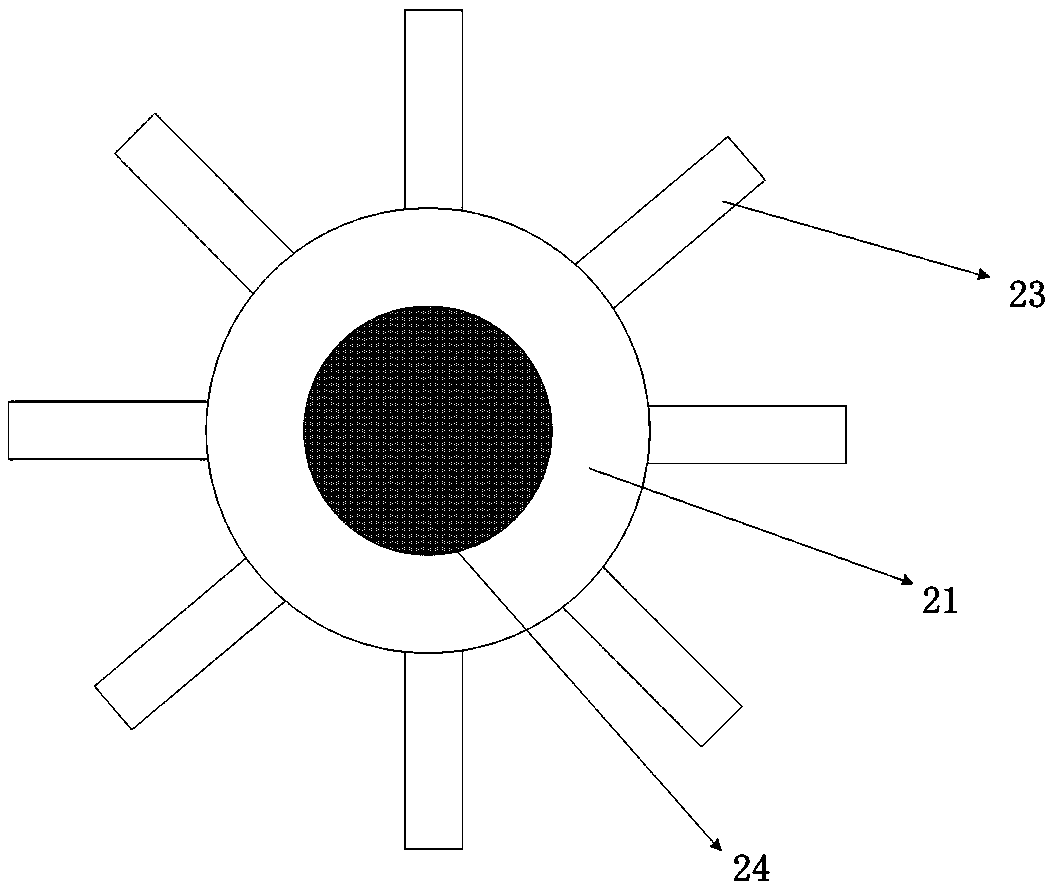

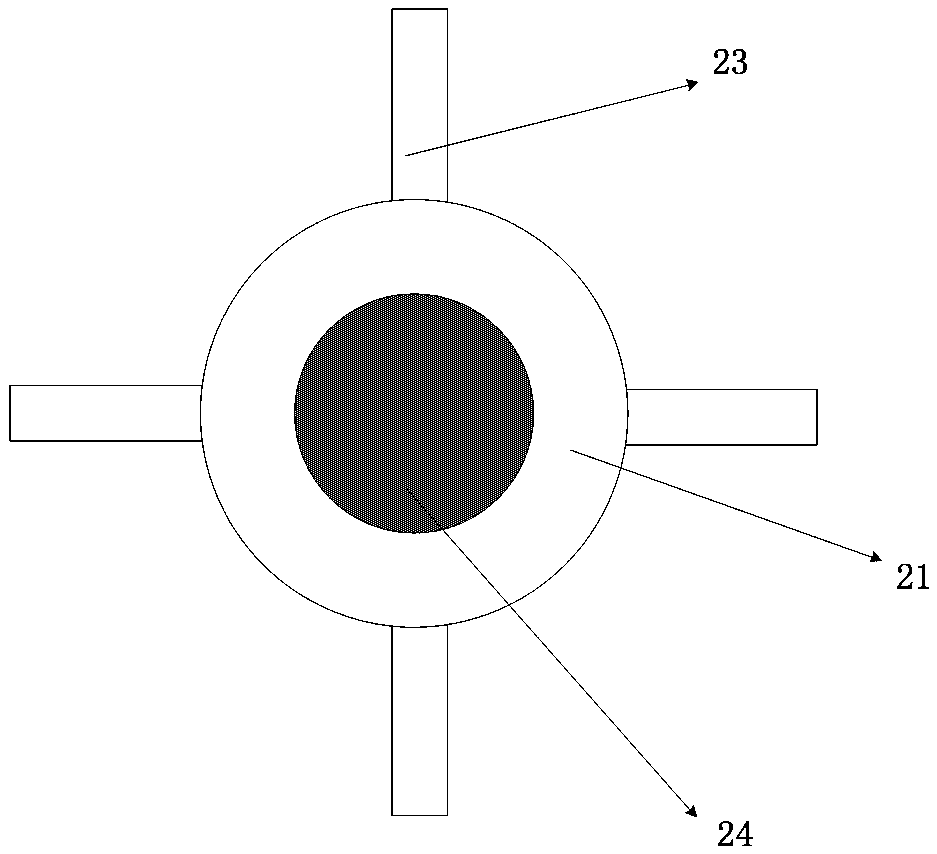

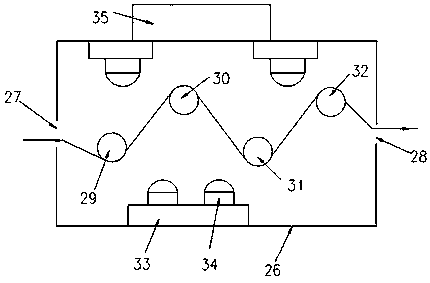

Graded-discharge sand mill

PendingCN108479963ANarrow particle size distributionImprove sanding efficiencyGrain treatmentsSanderMetallurgy

The invention discloses a graded-discharge sand mill. The graded-discharge sand mill comprises a sand mill main body, wherein a fine material discharge port is formed in the lower part of the sand mill main body; a separator is arranged in the sand mill main body; a rotor enters from one end of the sand mill main body, and is fixedly installed in a cavity body of the sand mill main body; the rotoris of a hollow interlayer structure, and composed of an outer rotor interlayer, an inner rotor interlayer and a rod pin installed on the outer surface of the rotor; a coarse material discharge port is formed in the outer rotor interlayer; a charge port is formed in the bottom of the inner rotor interlayer; and the rotor communicates with a material circulation system. According to the graded-discharge sand mill disclosed by the invention, through the design of a graded outlet, graded discharge is performed on the materials, the fine materials which reach a grinding particle size are discharged in one process through the separator, and coarse materials which do not reach the grinding particle size are secondarily grinded; and due to the graded grinding manner, the sand grinding efficiencyis greatly increased, the grinded materials are narrower in particle size distribution, and the grinding effect with higher efficiency and the narrower particle size distribution is realized.

Owner:TIANJIN B&M SCI & TECH

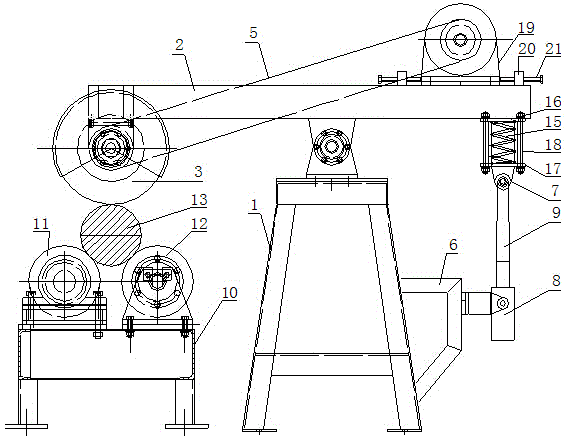

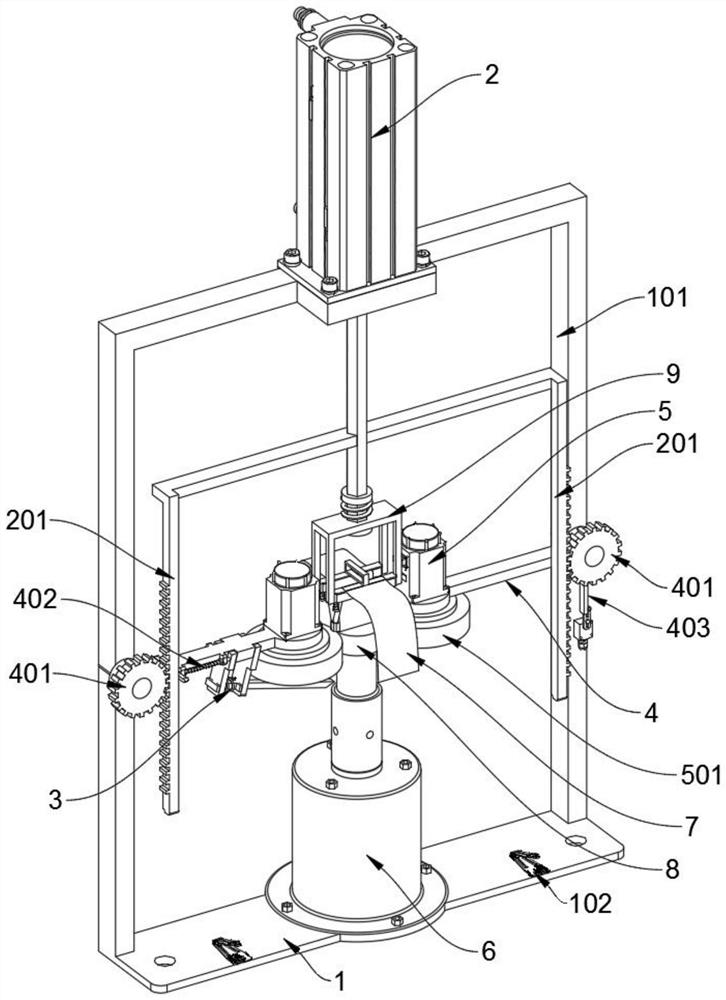

Structural steel surface sanding device

ActiveCN104440487AConducive to manipulationImprove sanding efficiencyGrinding machine componentsRevolution surface grinding machinesElectric machineryLeather belt

The invention discloses a structural steel surface sanding device. The device comprises a machine frame, a grinding machine arranged on the machine frame, and a containing device arranged on one side of the machine frame, wherein the grinding machine comprises a cantilever arranged at the upper end of the machine frame in a rotary mode, a grinding wheel disc and a grinding wheel motor, the grinding wheel disc and the grinding wheel motor are located at the two ends of the cantilever respectively, the grinding wheel disc is located above the containing device, and the output end of the grinding wheel motor is connected with the grinding wheel disc through a belt and is used for driving the grinding wheel disc to rotate. The device is characterized in that a cylinder installation base is further arranged on the side, away from the containing device, of the lower portion of the machine frame, a cylinder is hinged to the cylinder installation base, and a telescopic arm of the cylinder is arranged upwards and is connected with the end, provided with the grinding wheel motor, of the cantilever. The device has the advantages that the structure is simple, operation and control are easy, sanding efficiency is high, the surface of round steel is not damaged easily, grinding wheel protecting effect is good, and safety performance is higher.

Owner:宝武特冶航研科技有限公司

Cloth sueding machine and use method

InactiveCN110284288AEasy to handleQuality improvementSucessive textile treatmentsTextile treatment containersPulp and paper industryTelescopic cylinder

The invention discloses a cloth sueding machine and a use method thereof. The machine comprises a tension roller, an upper conveying roller, a lower conveying roller, a cloth-pressing roller assembly, a sueding assembly and a cleaning and drying assembly; the tension roller is installed on a tension roller fixing column, a telescopic cylinder is installed between the tension roller fixing column and the mounting plate, the upper conveying roller is arranged on one side of the tension roller, the lower conveying roller is arranged on one side of the upper conveying roller, and the cloth-pressing roller assembly is arranged on one side of the lower conveying roller, the sueding assembly is arranged on the right side of the cloth-pressing roller assembly, the cleaning and drying assembly is arranged on the right side of the sueding assembly, a cloth is tensioned through the tension roller, then conveyed into the cloth-pressing roller assembly through the conveying rollers for the pressing process, and then conveyed into the sueding assembly for the sueding process, and finally cleaning, drying and collecting are conducted. Accordingly, the structure principle is simple, the cloth can be processed rapidly, the cloth quality is improved, and subsequent processing is facilitated.

Owner:陶媛媛

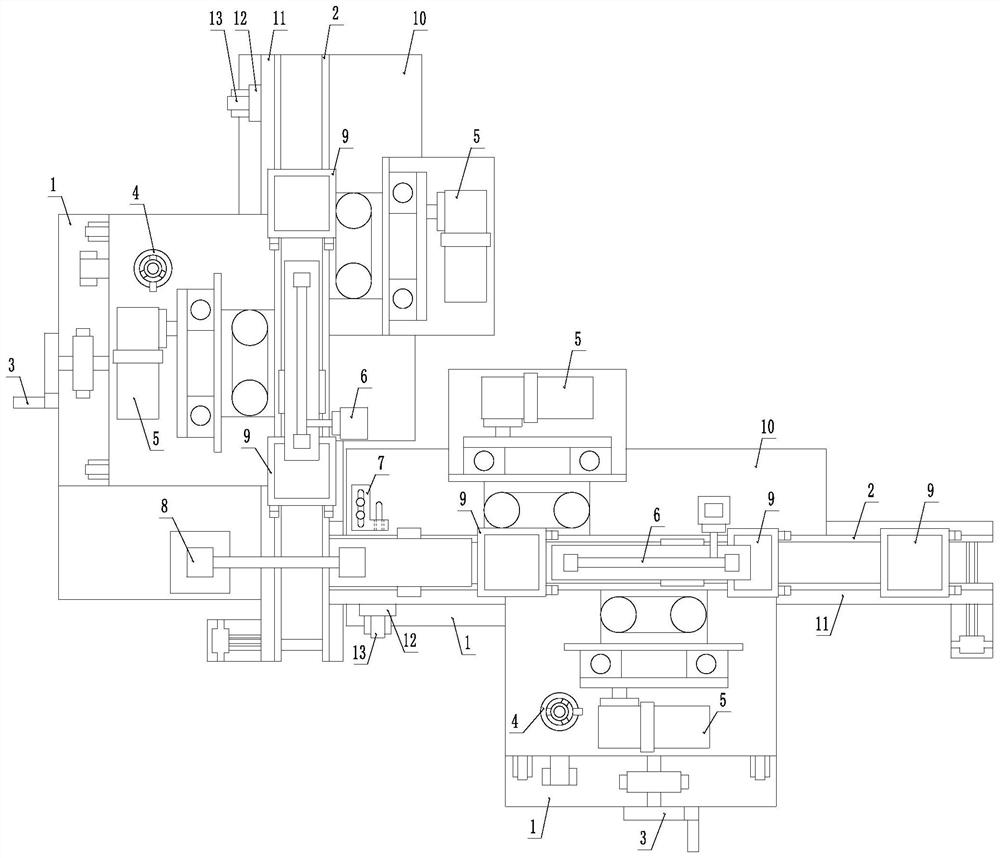

Four-side sanding system

PendingCN113510578AShorten the timeImprove sanding efficiencyGrinding carriagesBelt grinding machinesSanderStructural engineering

The invention discloses a four-side sanding system. The four-side sanding system involves a transversely-arranged sanding device and a vertically-arranged sanding device, wherein the tail of the transversely-arranged sanding device is perpendicularly connected with the vertically-arranged sanding device, a sensing assembly is arranged on one side of the tail of the transversely-arranged sanding device, and a pushing mechanism is arranged between the transversely-arranged sanding device and the vertically-arranged sanding device; the sanding devices comprise bottom frames, fixed working racks and lifting sanding mechanisms are fixed to one sides of the bottom frames, and driving mechanisms and control mechanisms are arranged in the fixed working racks; the other sides of the bottom frames are slidably connected with movable working racks, distance adjusting mechanisms and locking mechanisms, and the lifting sanding mechanisms are fixed to the distance adjusting mechanisms; and conveying mechanisms are arranged between the fixed working racks and the movable working racks, and downward pressing mechanisms are arranged on the upper portions of the conveying mechanisms. According to the four-side sanding system, four-side sanding of a wooden drawer box is achieved through the two sanding devices which are perpendicular to each other, the sanding efficiency is high, the quality is good, and the four-side sanding system can be suitable for sanding wooden drawer boxes with different widths.

Owner:浙江世新精密机械有限公司

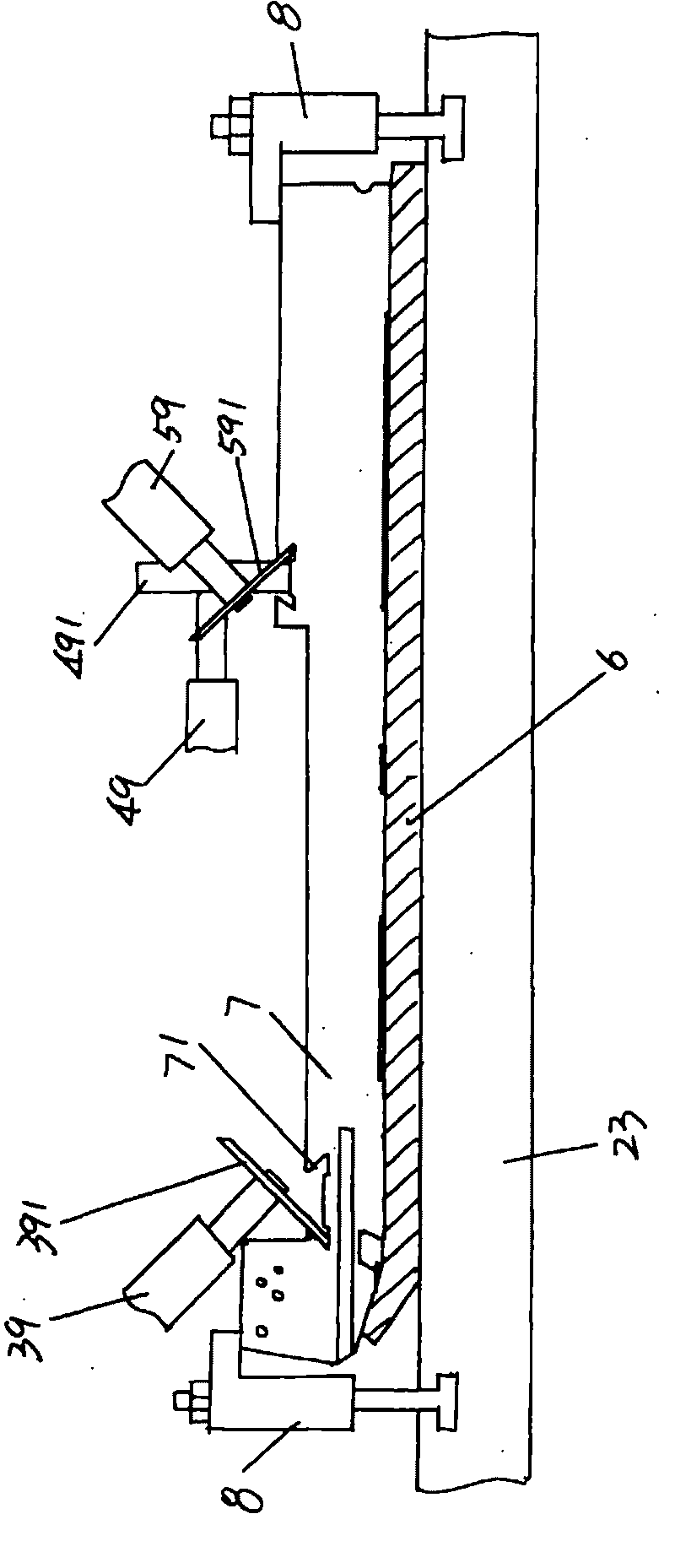

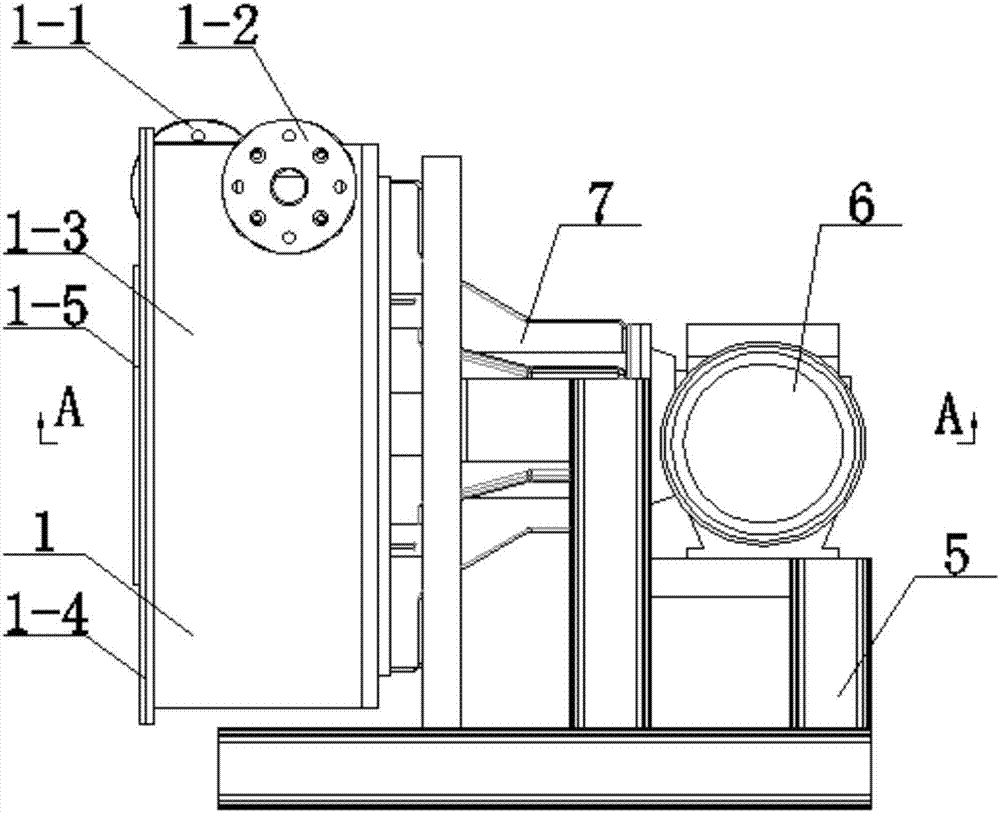

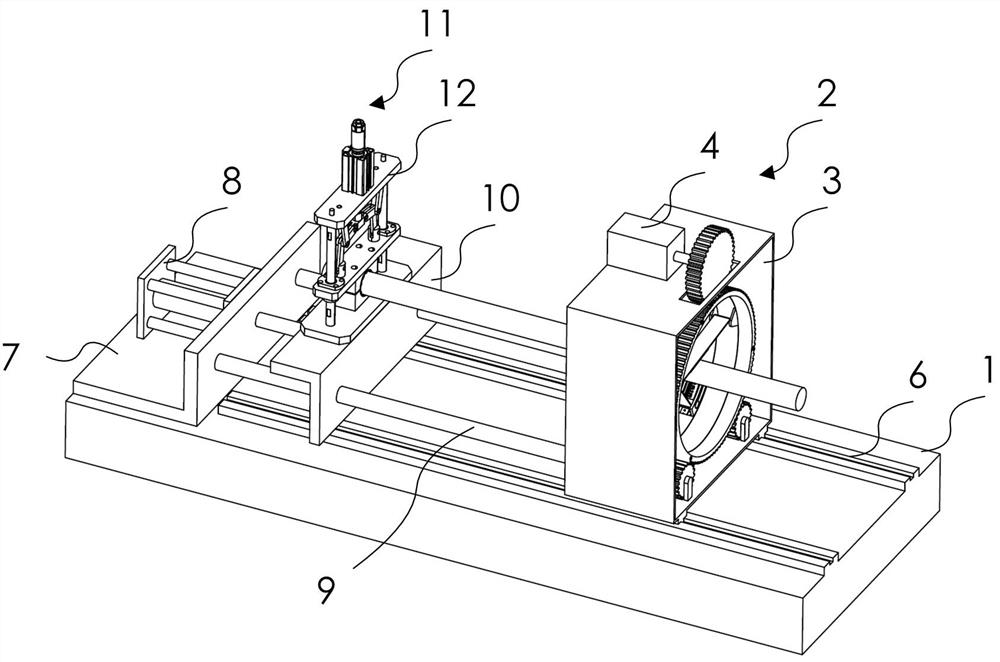

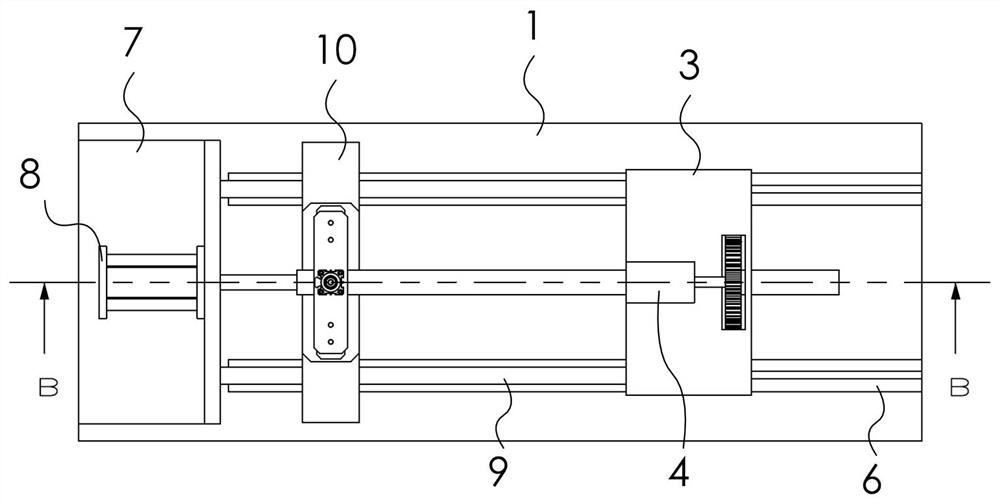

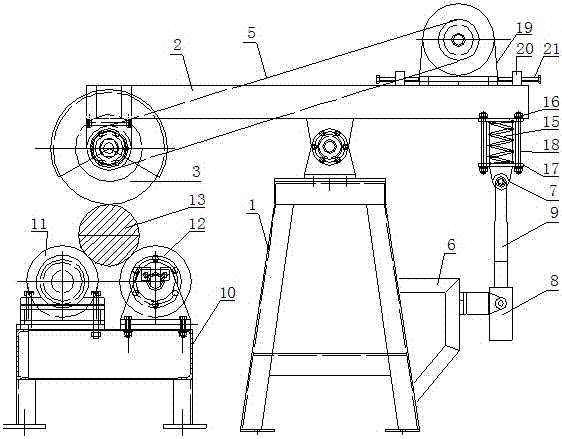

Pipe and column part butt weld polishing machine

InactiveCN104308698AImprove sanding qualityImprove sanding effectBelt grinding machinesWeld seamEngineering

The invention relates to a pipe and column part butt weld polishing machine. The machine comprises a frame, a polishing mechanism and a part clamping, rotating and moving mechanism; the suspended self-aligning polishing mechanism is arranged on the frame in a suspension manner and comprises two suspension bracket assemblies with the same structure; the upper end part of each suspension bracket assembly is arranged on the frame in a hinging manner; each suspension bracket assembly comprises a suspension plate, a driving abrasive belt wheel, a driven abrasive belt wheel, an abrasive belt and a driving motor; each driven abrasive belt wheel is arranged on a tensioning plate; each tensioning plate is detachably and fixedly arranged at the lower end of the corresponding suspension plate; a telescopic clamping component and a lower rotary limiting mechanism are arranged between the two suspension bracket assemblies; two ends of the telescopic clamping component are respectively hinged to suspension plates; upper rotary limiting mechanisms for limiting the maximum opening angles of the two driven abrasive belt wheels are arranged above the two suspension bracket assemblies. The pipe and column part butt weld polishing machine has the advantages of simple structure, small size, convenience in installation and use, high grinding accuracy, long service life, low maintenance cost and the like.

Owner:王建利

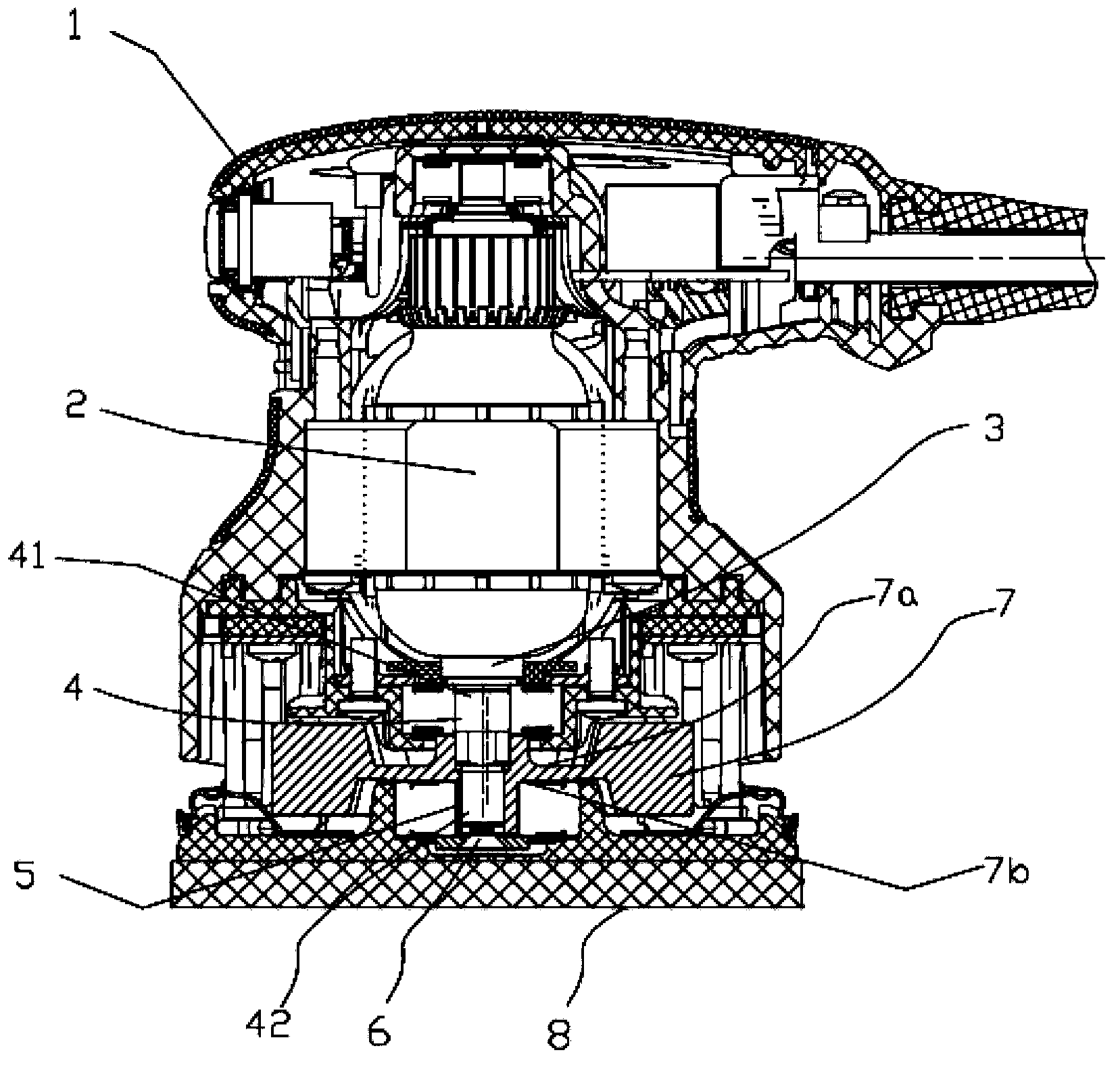

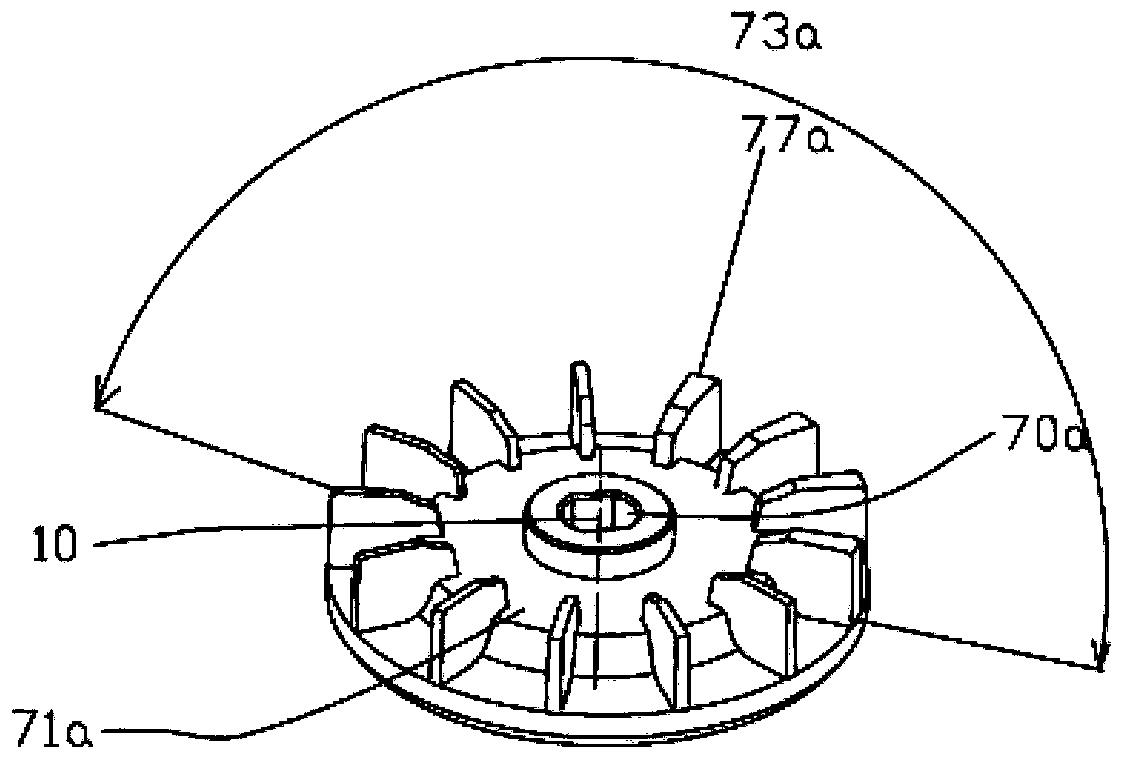

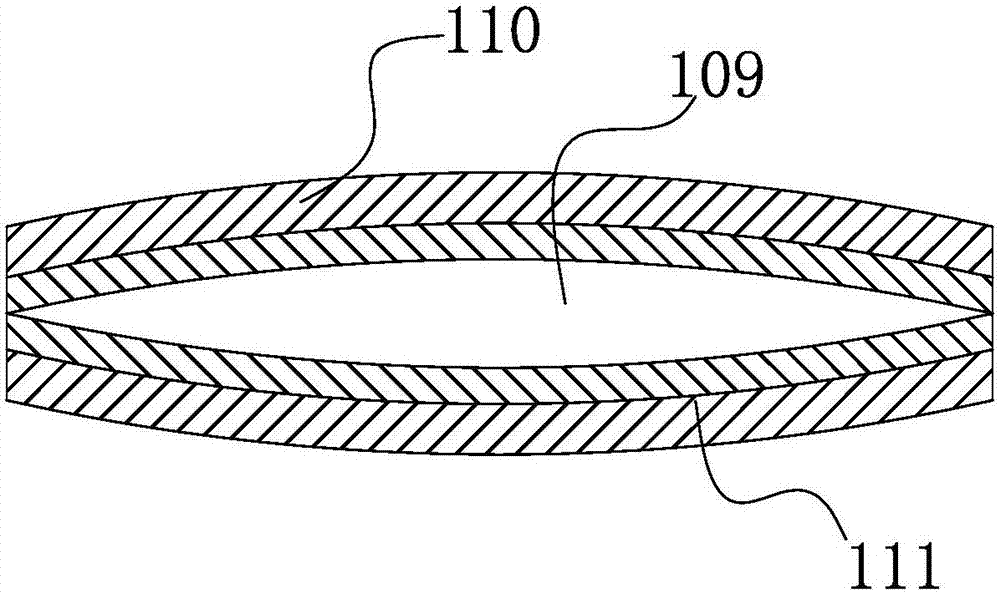

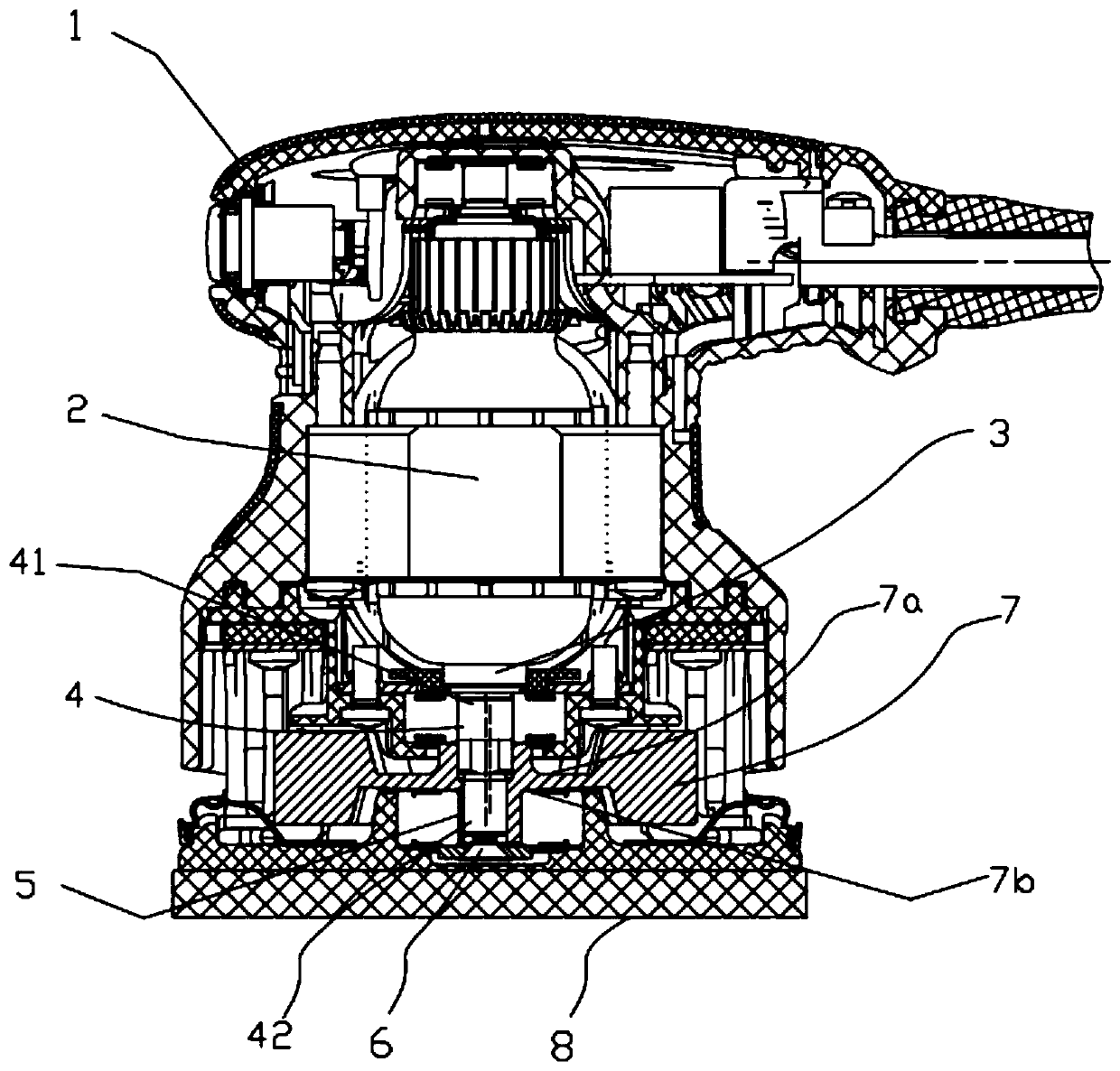

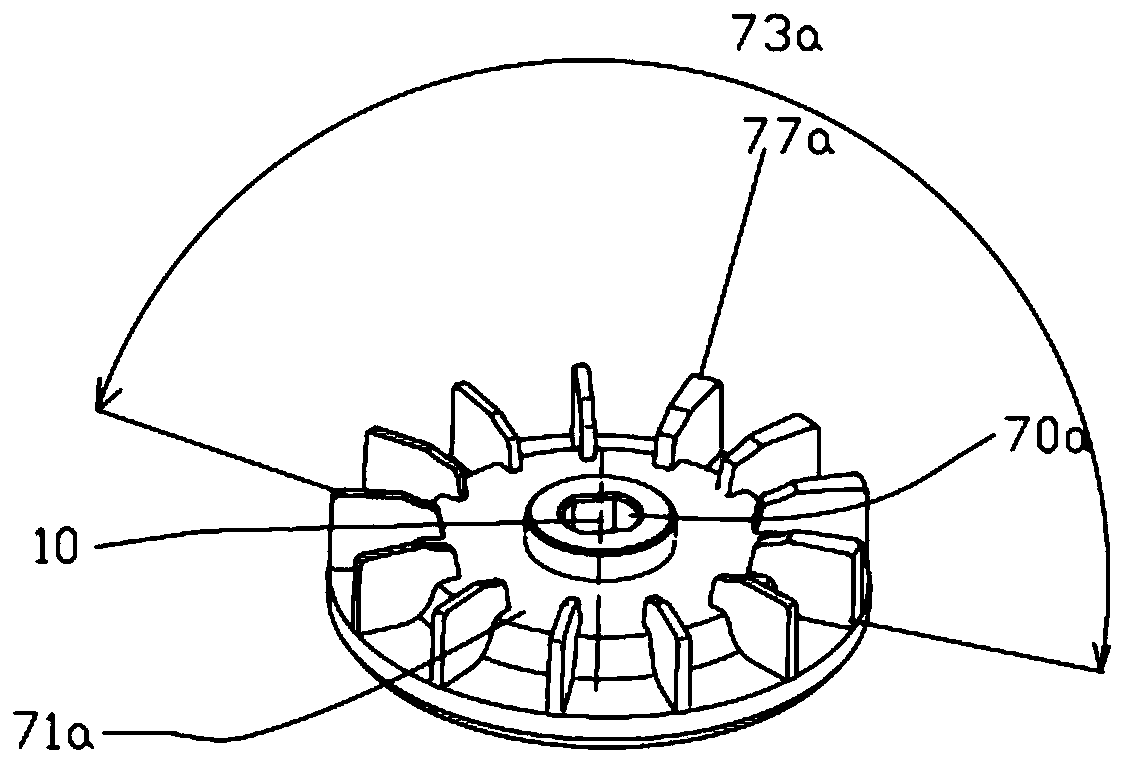

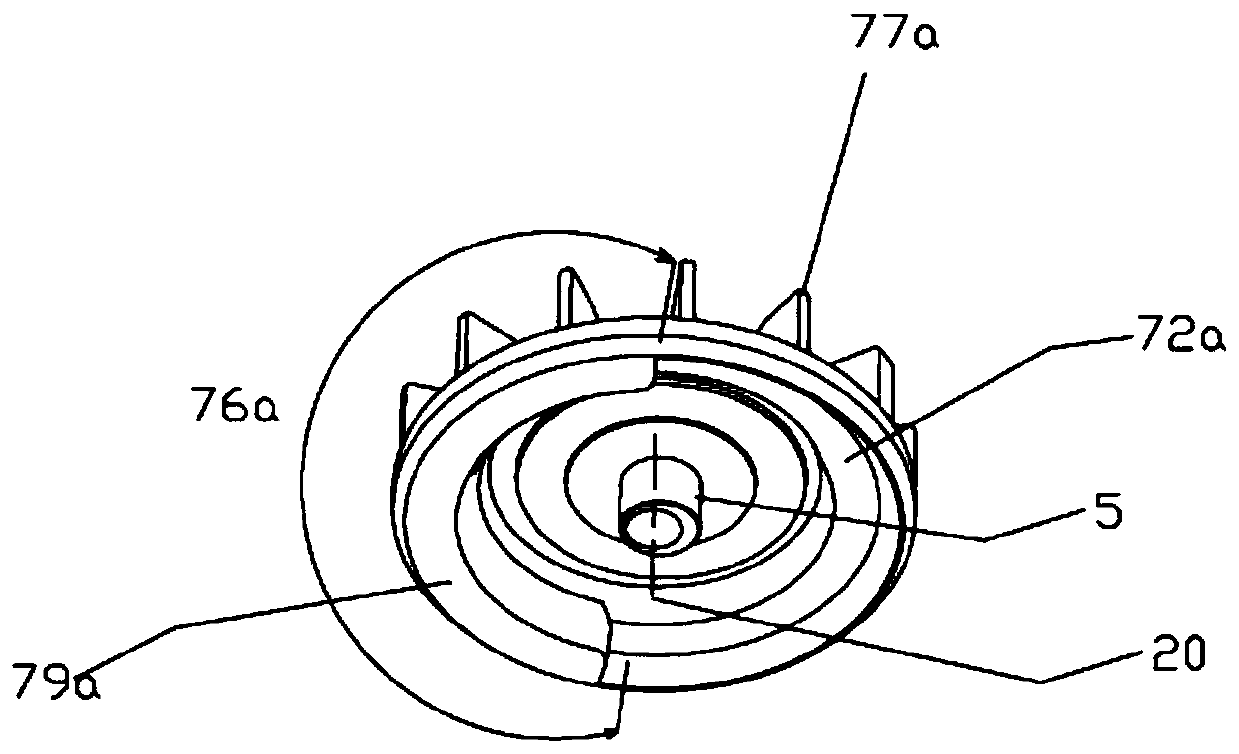

Handheld sanding machine

InactiveCN104275630AReduce load vibrationReduce or eliminate spinning torquePlane surface grinding machinesGrinding/polishing safety devicesDrive shaftFan blade

A handheld sanding machine comprises a machine body, a motor, a driving shaft, an eccentric shaft, a fastening piece, a fan and a bottom plate; the motor is accommodated in a machine shell and is connected through the first end of the driving shaft; the driving shaft can rotate around a first axis; a first surface and a second surface opposite to the first surface are arranged on the body of the fan; the second end of the driving shaft is combined with a mounting hole in the first surface of the fan; the eccentric shaft can rotate around a second axis; the first axis is parallel to the second axis; a first fan blade area provided with ordinary fan blade parts is arranged on the first surface of the fan, wherein the eccentric shaft is arranged on the second surface of the fan; a counterweight area is arranged on at least one of the first surface and the second surface of the fan. The handheld sanding machine can alleviate or eliminate whirling moment borne vibration and loading vibration when a flat-plate sanding machine operates on a working face, the manoeuverability of the flat-plate sanding machine is greatly improved, and the comfort degree when the flat-plate sanding machine is used by an operator and the sanding efficiency are improved.

Owner:NANJING CHERVON IND

Nano silica sand grinding preparation method taking polyvinylpyrrolidone as dispersing agent

PendingCN111392731ALow costImprove sanding efficiencyMaterial nanotechnologyCell electrodesPyrrolidinonesSlurry

The invention discloses a nano silicon sanding preparation method taking polyvinylpyrrolidone as a dispersing agent, which relates to the technical field of production of silicon-carbon negative electrode materials of lithium ion batteries, which comprises the following steps of: dispersing coarse silicon powder into a solvent and a dispersing agent, and sanding in a sand mill with a grinding medium to obtain slurry containing nano silicon; wherein the dispersing agent at least comprises polyvinylpyrrolidone. The nano silicon is prepared by adopting a liquid phase sanding method; through grinding, the silicon particles collide and the grinding medium are subjected to high-speed impact for crushing into nanoscale particles; the dispersing agent polyvinylpyrrolidone plays an extremely important role in crushing of the silicon particles, and the polyvinylpyrrolidone can remarkably reduce aggregation of the silicon particles and viscosity of the slurry, so that sanding efficiency, uniformity of the particles and dispersity of the silicon particles in the solvent are improved. According to the present invention, the coarse silicon powder with the particle diameter of 0.24-60[mu]m can besubjected to the nanocrystallization treatment, and the coarse silicon powder can be monocrystalline silicon or polycrystalline silicon.

Owner:江苏新效新材料科技有限公司

Method for reducing viscosity of titanium dioxide slurry

The invention relates to a method for reducing viscosity of titanium dioxide slurry, and belongs to the technical field of production of titanium dioxide. The technical problem to be solved by the invention is to provide the method for reducing the viscosity of the titanium dioxide slurry. The method grinds a raw product of titanium dioxide to reach a fineness of not more than 40 meshes, and performs the pulping dispersion. The method can screen and classify grinded materials through controlling related process parameters of rolling, pressing and milling, changes the fineness of pulping materials to increase the concentration of the titanium dioxide slurry and to reduce the viscosity thereof, improves the quality of the titanium dioxide slurry, improves the grinding efficiency, and improves the abrasive material quality and the final product quality. The method is simple in operation, high in implementability, capable of not changing traditional medium powder equipment, suitable for popularization and broad in application prospect.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Double-layer composite plate finishing unit

The invention discloses a double-layer composite plate finishing unit and relates to finishing unit equipment. The double-layer composite plate finishing unit comprises a double-layer composite plate shoveling-separating device, a double-layer composite plate bidirectional tortoise back straightening machine, a double-layer composite plate slag removal machine, a double-layer composite plate leveler, a double-layer composite plate finishing machine and a double-layer composite plate sand mill which are connected sequentially. Therefore, the double-layer composite plate finishing unit adopts a layering, tortoise back treatment, slag removal, leveling, finishing and sand milling combined process for achieving finishing of a double-layer composite plate and removing oxide on the composite surface. Through the double-layer composite plate finishing unit, finishing treatment can be conducted on upper double metal composite plates and lower double metal composite plates simultaneously, production efficiency is high, and production cost is reduced.

Owner:山东易川新材料科技股份有限公司

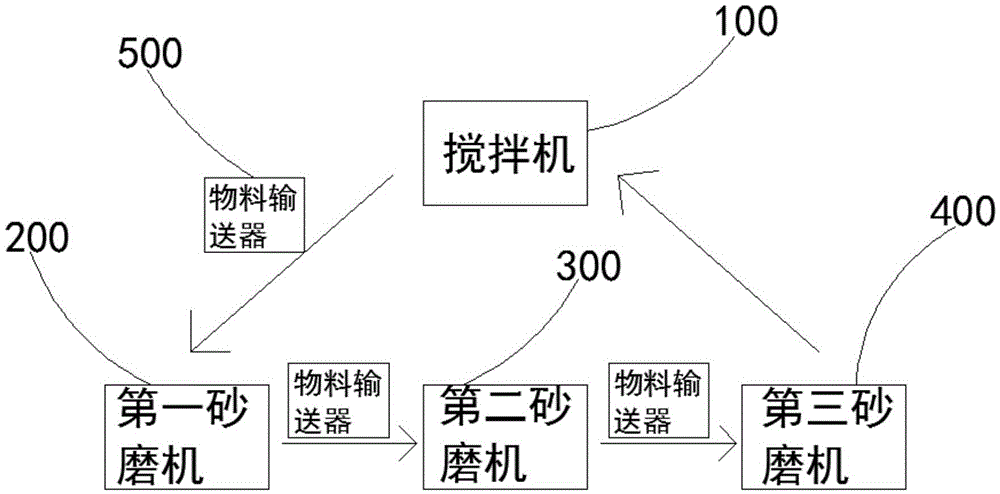

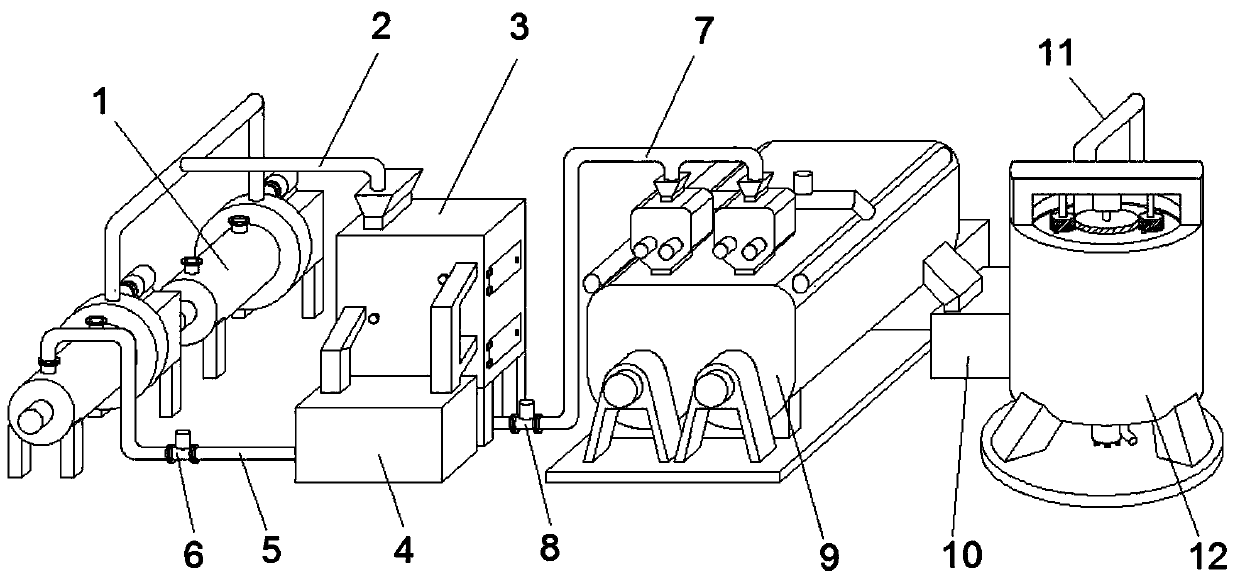

Sanding device and method using zirconium balls in different sizes

The invention provides a sanding device and method using zirconium balls in different sizes, and belongs to the field of sanding equipment. The sanding device comprises a stirrer, a first sanding machine, a second sanding machine and a third sanding machine which are sequentially communicated; a material conveyor is arranged between the stirrer and the first sanding machine, a material conveyor is arranged between the first sanding machine and the second sanding machine, and a material conveyor is arranged between the second sanding machine and the third sanding machine; and a plurality of big zirconium balls are arranged in the first sanding machine, a plurality of medium zirconium balls are arranged in the second sanding machine, and small zirconium balls are arranged in the third sanding machine. The sanding method includes the following steps that firstly, materials are injected into a stirring barrel to be evenly stirred; then the evenly-stirred materials are conveyed to the first sanding machine through the corresponding material conveyor for sanding; then the materials sanded through the first sanding machine are conveyed to the second sanding machine through the corresponding material conveyor for sanding; and finally the materials sanded through the second sanding machine are conveyed to the third sanding machine through the corresponding material conveyor for sanding.

Owner:HUNAN SHENGHUA TECH

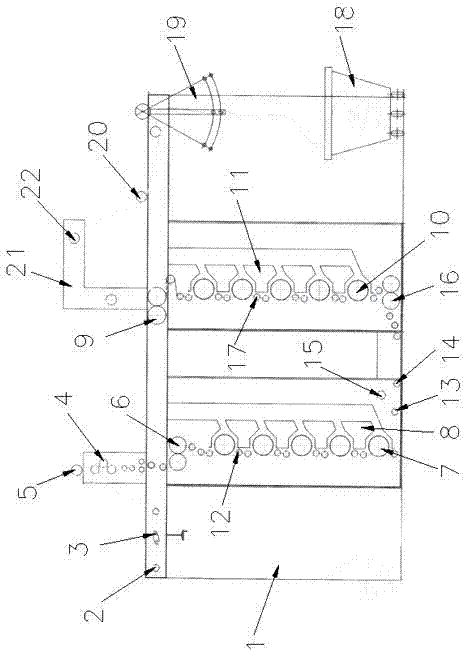

High-precision automatic double-sided sanding machine for bamboo wood processing

PendingCN111482874ASimple and efficient operationImprove sanding efficiencyBelt grinding machinesGrinding feedersWood wasteManufacturing engineering

The invention discloses a high-precision automatic double-sided sanding machine for bamboo wood processing. The high-precision automatic double-sided sanding machine comprises a top surface sanding device and a bottom surface sanding device; the side of the top surface sanding device is connected with the bottom surface sanding device; the top surface sanding device includes a first support table,a fixed box, a first conveying mechanism and top surface sanding mechanisms; the top of the first support table is configured with a mounting groove, and the first conveying mechanism is mounted inside the mounting groove; the top of the first conveying mechanism is provided with a bamboo wood body; the top of the first support table is fixedly connected with the fixed box; and three top surfacesanding mechanisms are equidistantly mounted in the fixed box. The whole process of the double-sided sanding machine provided by the invention is simple and convenient to operate, time-saving and labor-saving, double-sided continuous sanding is achieved, the sanding efficiency of the bamboo wood is greatly improved, collection of bamboo wood waste after sanding can be achieved through a first waste collecting groove and a second waste collecting groove, waste scraps are prevented from being dispersed in air to harm human health, and meanwhile, recycling and reuse of the waste can also be realized.

Owner:龙泉市餐餐乐竹木制品有限公司

Handheld sanding machine

InactiveCN109773635AReduce load vibrationReduce or eliminate spinning torqueGrinding machine componentsPortable grinding machinesSanderDrive shaft

The invention discloses a handheld sanding machine. The handheld sanding machine comprises a machine body, a motor, a driving shaft, an eccentric shaft, a fastening piece, a fan and a bottom plate; the motor is accommodated in a machine case and is connected with the machine case through a first end of the driving shaft; the driving shaft can rotate around a first axis; a first surface and a second surface which is opposite to the first surface are arranged on the body of the fan; a second end of the driving shaft is combined with a mounting hole in the first surface of the fan; the eccentricshaft can rotate around a second axis; the first axis is parallel to the second axis; a first blade area with a common blade component is formed on the first surface of the fan, wherein the eccentricshaft is arranged on the second surface of the fan; and a counterweight area is formed on at least one of the first surface and the second surface of the fan. According to the handheld sanding machine, the swirling moment load vibration and the load vibration of a sheet sander when operating on a working surface can be reduced or eliminated; the operability of the sheet sander is greatly improved; and the comfort and the sanding efficiency when the sheet sander is used by an operator are improved.

Owner:NANJING CHERVON IND

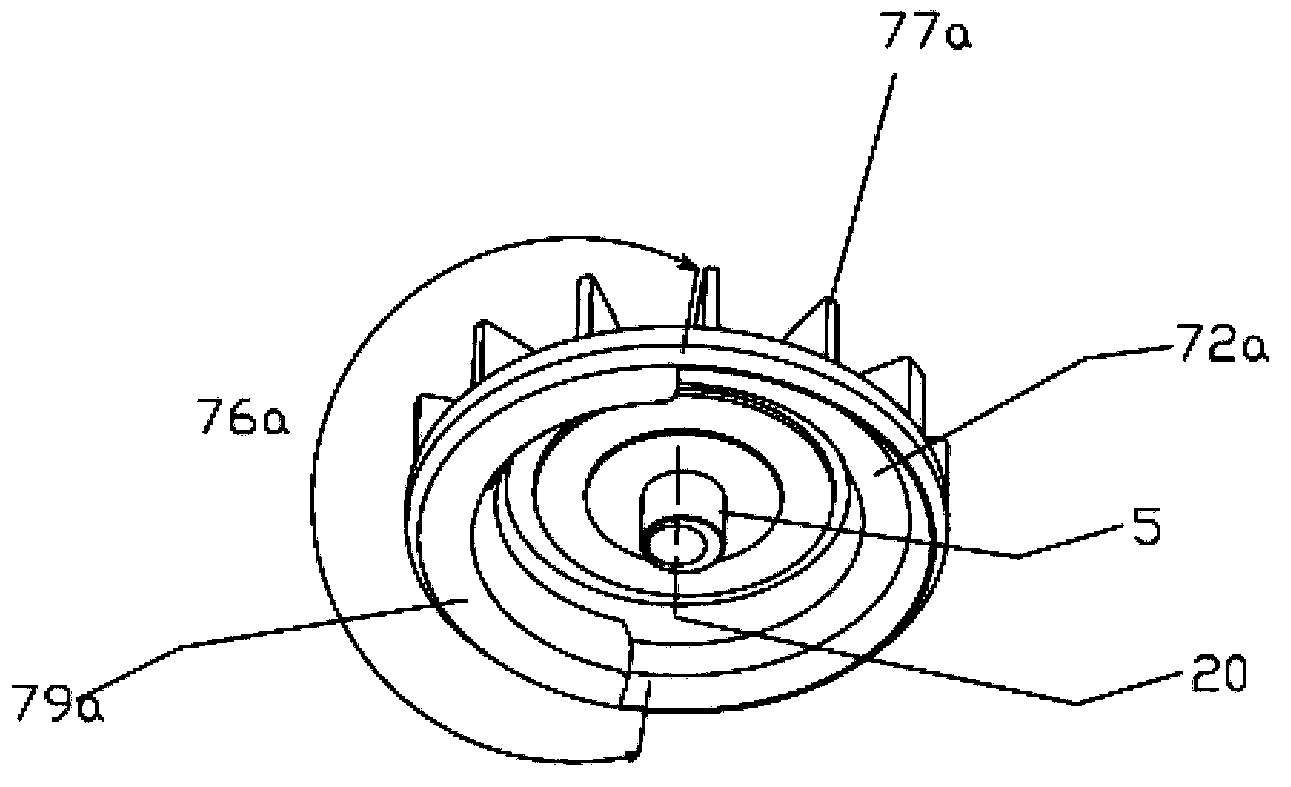

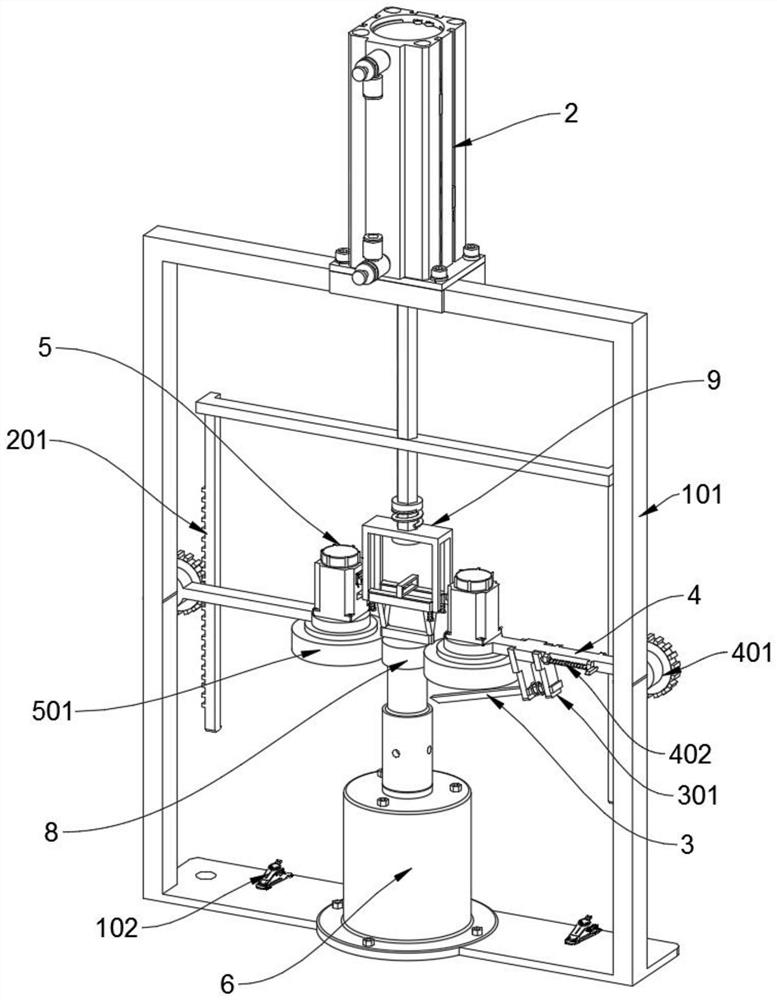

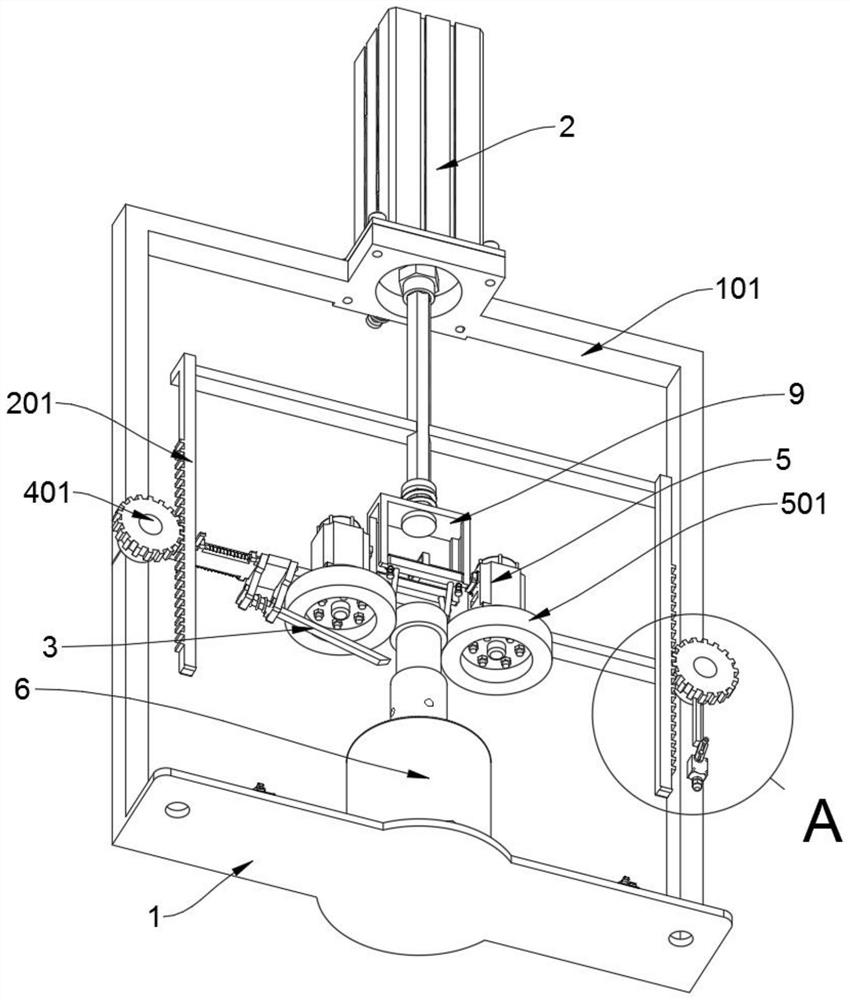

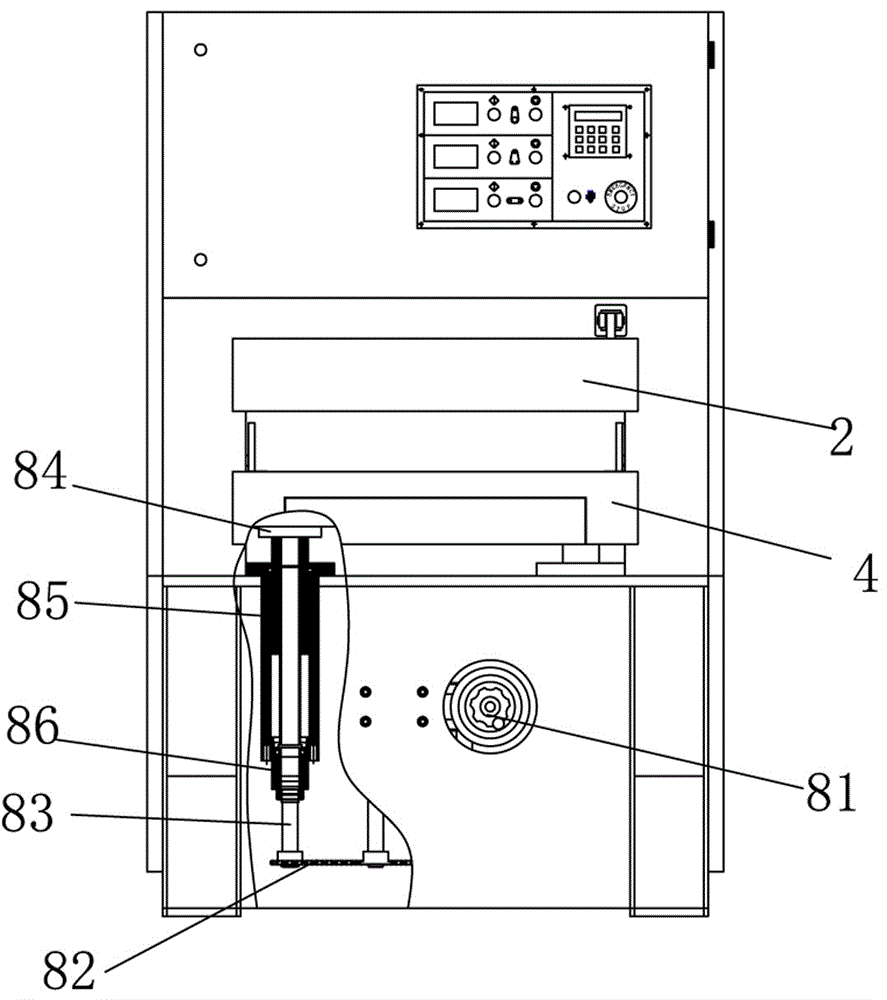

Sun pattern sanding equipment for processing of mechanical bottle cap

InactiveCN111958460AConvenient drag and drop switchingThe grinding process is simplePolishing machinesGrinding drivesHydraulic cylinderCircular disc

The invention discloses sun pattern sanding equipment for processing of a mechanical bottle cap, relates to the technical field of sanding equipment, and solves the problems in the prior art that after polishing is completed, most bottle caps need to be manually disassembled and dropped, the operation is tedious, and the labor intensity of workers is large. The sun pattern sanding equipment for the processing of the mechanical bottle cap comprises a base; the base comprises a support frame and pedal switches; the base is of a rectangular central disc structure as a whole, and a second motor islocked and supported on the central disc of the base; the top end of a rotating shaft of the second motor presses a buckle cover to place a metal bottle cap; the support frame is welded to the top end of the base, and two pedal switches are welded symmetrically on the top end of the base; and the two pedal switches are used for controlling the lifting of a hydraulic cylinder. According to the sunpattern sanding equipment for the processing of the mechanical bottle cap provided by the invention, the abrasive cloth is wound on three positioning strips and is pressed and fixed by a pressing piece, and the pressing piece is installed by spring pushing and can be quickly lifted and loosened, and it is convenient to drag and switch the worn sandpaper section.

Owner:房金祥

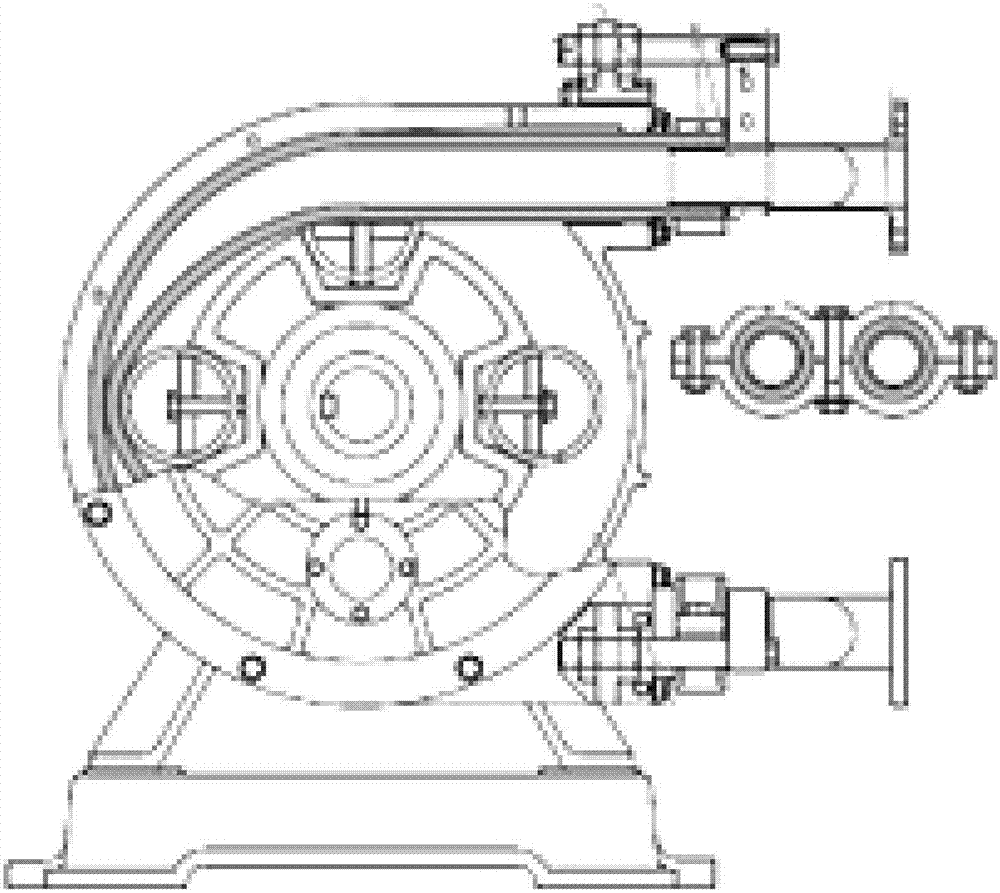

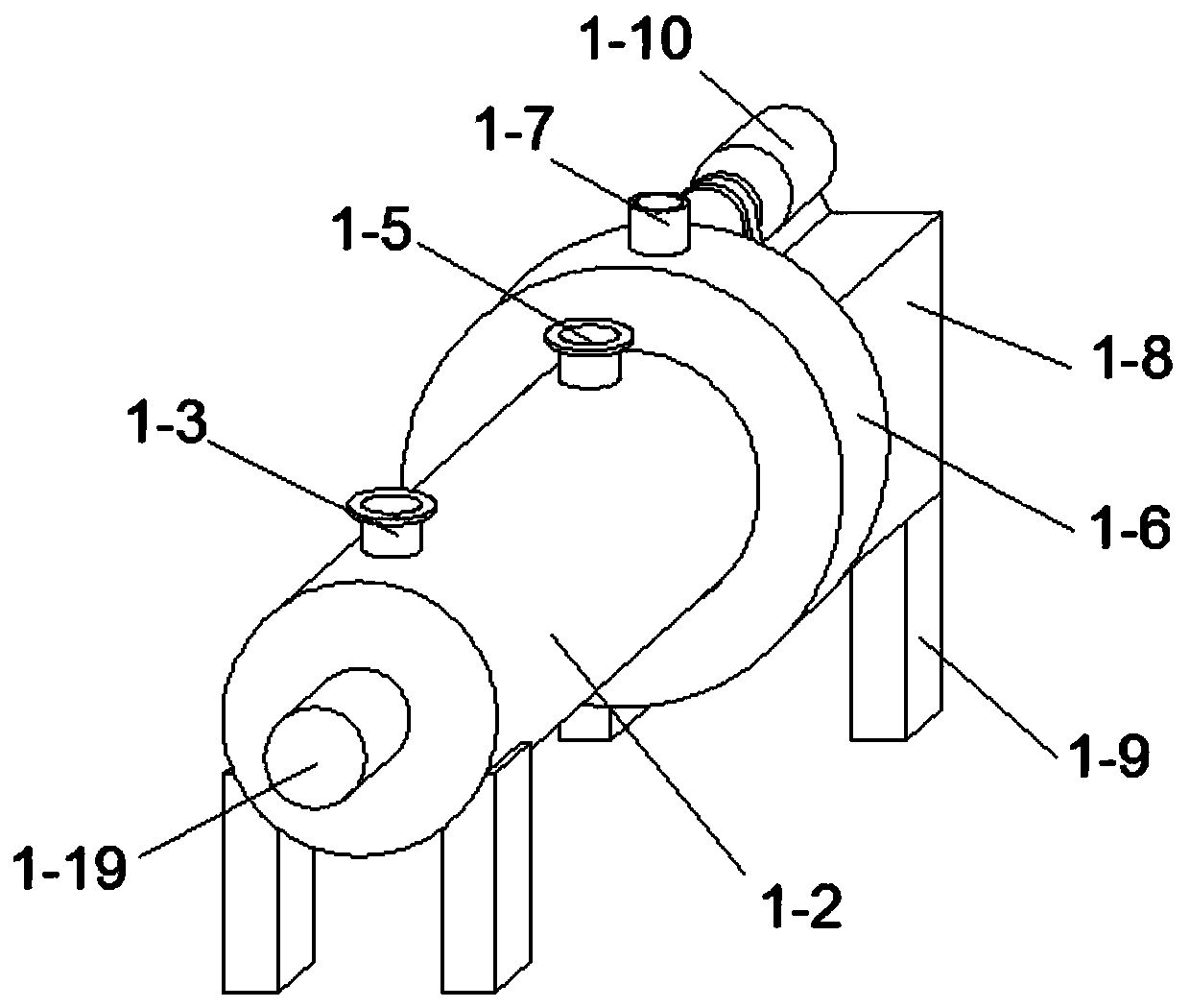

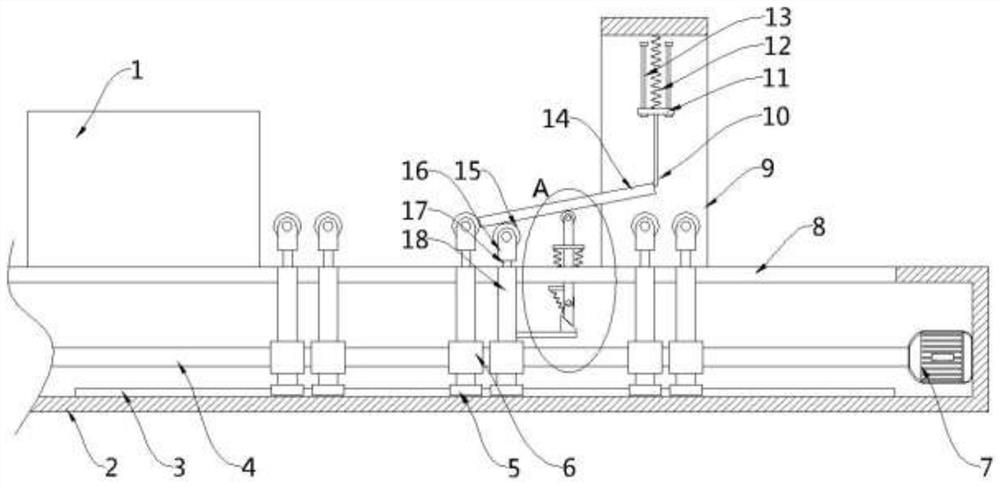

Sand mill circulating pump for production of high-performance metal soft magnetic ferrite

InactiveCN107061242ANo extrusion dead angleAccurateFlexible member pumpsPositive-displacement liquid enginesSanderLow load

The invention discloses a sand mill circulating pump for producing metal soft ferrite with high performance, belonging to the technical field of soft ferrite production. It includes the pump casing, the feed inlet and outlet set on the pump casing, the crankshaft, the extrusion roller, the hose, the geared motor and the bearing seat fixedly installed on the base, and the feed inlet and outlet are 180° Horizontal staggered arrangement, one end of the hose is connected to the material inlet, and the other end is connected to the material outlet. The central axis of the hose is located on the spiral surface. The crankshaft is passed through the bearing seat and connected to the geared motor. The extrusion roller is fixed on the crankshaft. The crankshaft drives the squeeze rollers to squeeze the hose. The invention adopts 180°horizontal staggered arrangement of the feed inlet and the discharge outlet, which solves the problem that the slurry flow rate is not high, and its state changes greatly when carrying out high and low conveying loads. Extrusion dead angle will be produced, so that the accuracy can be easily and precisely controlled.

Owner:马鞍山新康达磁业股份有限公司

Corrosion-resistant and mothproof wood board production and processing machine and processing technology

InactiveCN113182991AReduce gapReduce unprocessedBelt grinding machinesAbrasive surface conditioning devicesMachining processMechanical engineering

The invention relates to a corrosion-resistant and mothproof wood board production and processing machine and a processing technology. The machine comprises a placing plate, a conveying device and a sanding device, the conveying device is installed at the upper end of the placing plate, the sanding device is arranged above the conveying device, and the sanding device is installed at the upper end of the placing plate. The machine and method can solve the problems that when existing equipment carries out sanding machining on wood boards, the surfaces of the wood boards cannot be tightly attached, gaps are prone to appear between the equipment and the wood boards during sanding, the phenomenon that the surfaces of the wood boards are not machined after sanding is prone to be caused, and thus the sanding success rate is reduced, and meanwhile, in the sanding process, chips on the equipment cannot be knocked off, the chips on the equipment tend to influence sanding in a later stage, and thus the sanding effect of the wood boards is reduced, the wood boards needs to be subjected to secondary sanding, and the sanding cost is increased.

Owner:翁群林

Adjustable clamping plate platform for wood sanding and sanding process

InactiveCN110919503ASmooth connectionConsistent forceGrinding carriagesBelt grinding machinesAir pumpFoam rubber

The invention discloses an adjustable clamping plate platform for wood sanding, which comprises telescopic supporting legs and a smooth table top, wherein a plate feeding supporting frame, a grindingbelt supporting frame and an outgoing plate discharging supporting frame are arranged on the smooth table top, an incoming plate feeding supporting frame is provided with a fixed flat rod and a sliding flat rod, and each of the fixed flat rod and the sliding flat rod is provided with a wheel hub, a vacuum tire and a first driven belt wheel by means of a wheel shaft; belt rollers are erected between two vertical plates of the grinding belt supporting frame, foaming rubber belts are wound around the upper belt rollers, grinding belts are wound around the lower belt rollers, and the belt rollersare connected with a second driven belt wheel; the first driven belt pulley is connected with a first driving belt pulley, and the second driven belt pulley is connected with a second driving belt pulley; and the vacuum tire is communicated with an air pump by means of an air pipe. The adjustable clamping plate platform adopts the vacuum tire for extrusion as a plate conveying and clamping mechanism, adopts reverse extrusion grinding of the grinding belts and the foaming rubber belts, and achieves the processes of two-way extrusion material conveying and two-way extrusion reverse grinding; andadjustable clamping plate platform has small extrusion force, large friction force and high grinding efficiency.

Owner:利辛县爱侣家俱加工有限公司

Vertical double-sided sanding machine

PendingCN107338609AAchieve double-sided sandingPrevent getting involvedMechanical cleaningPressure cleaningMechanical engineeringIndustrial engineering

The invention discloses a vertical double-sided sanding machine. The sanding machine comprises a cloth feeding mechanism, a cleaning mechanism and a cloth discharging mechanism, the cleaning mechanism is arranged between the cloth feeding mechanism and the cloth discharging mechanism, the cloth feeding mechanism comprises a cloth feeding box, a delivery wheel is arranged at the upper end of the cloth feeding box, a swing wheel is arranged at one side of the delivery wheel, and cloth spreading wheels are arranged at the top of the cloth feeding box. The sanding machine has the advantages of simple structure principle, convenience in use, high automation degree, realization of double-sided sanding treatment of a knitted fabric, high sanding efficiency and good sanding quality.

Owner:南通奇呈印染机械有限公司

A kind of multi-layer furniture board production process

ActiveCN111360951BImprove sanding efficiencyReduce labor intensityGrinding carriagesGrinding drivesAdhesive glueMechanical engineering

The invention relates to the technical field of furniture plate processing. Disclosed is a production process for multi-layer furniture boards, including the following steps: a: preparation; selecting several flat boards, each of which is a group of 11 boards; preparing a sanding device; b: one-time board blank forming; a single group of 11 boards Apply glue on all of them, and then select 7 of them to be cold-pressed, repaired, hot-pressed and sanded successively to obtain a primary slab; After the plate, cold pressing, hot pressing and sanding treatment are carried out successively to obtain the secondary slab; d: furniture board molding; after adding a plate on the upper and lower sides of the secondary slab, cold pressing, hot pressing and sanding are successively carried out Light treatment to obtain furniture boards. This solution mainly solves the problem of low efficiency of the current plate sanding method.

Owner:重庆德沃木制品加工有限公司

Sanding units for the production of furniture parts

The invention discloses a sanding device for producing furniture parts, which includes a base and a sanding mechanism, the sanding mechanism includes a fixed frame and a motor, the base has a fixed seat, the fixed seat has a first cylinder and a sliding rod, and There is a mounting seat on the mounting seat, a clamping mechanism on the mounting seat, a fixed part on the fixed frame, one end of the slide bar is installed on the fixed part, and a first gear, a second gear, a first sanding ring, and a second gear in the middle of the fixed frame. The structure of the second sanding ring and the third sanding ring, the first sanding ring, the second sanding ring and the third sanding ring are consistent. The sanding device for producing furniture parts is simple in structure and ingenious in design. It can drive the gears through the motor to make the first gear and the second gear rotate, and zero-align the first sanding ring, the second sanding ring and the third sanding ring. The sanding of parts can sand parts with shapes such as tubular, square, and polygonal. It has practical functions and high sanding efficiency, which effectively improves work efficiency.

Owner:瑞昌市勤奋实业有限公司

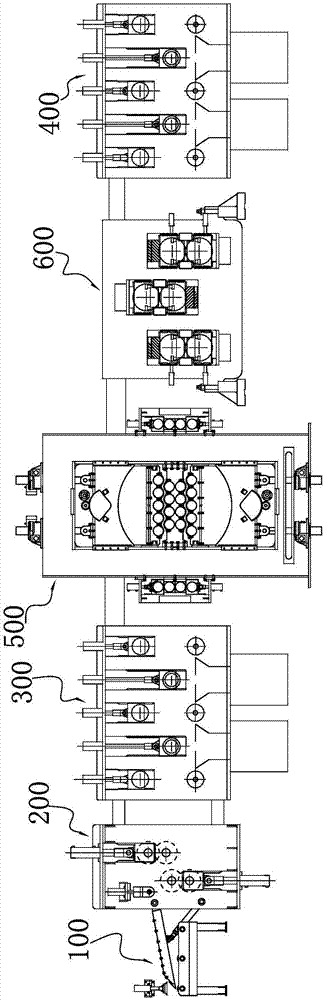

Preparation production line of environment-friendly fireproof waterborne coating

PendingCN110193407AReach replacementRegulation stabilityShaking/oscillating/vibrating mixersTransportation and packagingProduction lineSander

The invention relates to a preparation production line of an environment-friendly fireproof waterborne coating. The preparation production line comprises two sand mills, a sanding feeding pipe, a sieving machine, a sieved material collecting box, a sanded material returning pipe, a sanded material returning pump, a sieving feeding pipe, a sieving feeding pump, a kneading machine, a kneaded material collecting box, a kneaded material feeding pipe and a mixing device. The sieving machine is arranged on one side of the sand mills and is connected to the two sand mills through the sanding feedingpipe; the sieved material collecting box is connected to one sand mill through the sanded material returning pipe; the sanded material returning pump is arranged on the sanded material returning pipe;the kneading machine is connected to the kneading machine through the sieving feeding pump; the sieving feeding pump is arranged on the sieving feeding pipe; the top of the kneaded material collecting box is connected to a kneading discharge port; and the mixing device is connected to the kneading machine through the kneaded material feeding box. By structurally designing equipment, part of assemblies of the equipment can be detached and cleaned, so that the production efficiency of the whole production line is high. The produced waterborne coating is good in performance.

Owner:丹阳市现代实业有限公司

Bottom surface sanding machine

InactiveCN106181697AImprove sanding efficiencySave resourcesGrinding carriagesBelt grinding machinesEngineeringMechanical engineering

The invention belongs to the field of sanding machines, and particularly relates to a bottom surface sanding machine. The bottom surface sanding machine comprises a machine frame, a workbench, sanding racks and sanding rack motors, wherein the workbench, the sanding racks and the sanding rack motors are arranged on the machine frame. The bottom face of the workbench is a working face. A lifting platform capable of moving up and down along the machine frame through a lifting assembly is arranged below the workbench. The sanding racks are fixedly arranged on the lifting platform. The sanding rack motors are erected above the workbench through rack rods with the bottom ends fixedly arranged on the lifting platform. According to the bottom surface sanding machine, the workbench located above is motionless, and the lifting platform located below can drive the sanding racks to move up and down, so that the lifting platform of the sanding machine is directly matched with a workbench located below of an existing top surface sanding machine, and synchronous lifting can be realized; hence, under the premise that there is no need to widen a workshop and to be additionally provided with a transition conveying table, an existing top surface sanding machine manufacturer can achieve direct butt joint with the original top surface sanding machine with low capital investment after the bottom surface sanding machine is additionally arranged, and then the effect of sanding two surfaces with one-time feeding can be achieved.

Owner:ANJI DEMAI BAMBOO & WOOD MACHINERY

A type of steel surface sanding equipment

ActiveCN104440487BNot easy to damageImprove protectionGrinding machine componentsRevolution surface grinding machinesElectric machineryEngineering

The invention discloses a structural steel surface sanding device. The device comprises a machine frame, a grinding machine arranged on the machine frame, and a containing device arranged on one side of the machine frame, wherein the grinding machine comprises a cantilever arranged at the upper end of the machine frame in a rotary mode, a grinding wheel disc and a grinding wheel motor, the grinding wheel disc and the grinding wheel motor are located at the two ends of the cantilever respectively, the grinding wheel disc is located above the containing device, and the output end of the grinding wheel motor is connected with the grinding wheel disc through a belt and is used for driving the grinding wheel disc to rotate. The device is characterized in that a cylinder installation base is further arranged on the side, away from the containing device, of the lower portion of the machine frame, a cylinder is hinged to the cylinder installation base, and a telescopic arm of the cylinder is arranged upwards and is connected with the end, provided with the grinding wheel motor, of the cantilever. The device has the advantages that the structure is simple, operation and control are easy, sanding efficiency is high, the surface of round steel is not damaged easily, grinding wheel protecting effect is good, and safety performance is higher.

Owner:宝武特冶航研科技有限公司

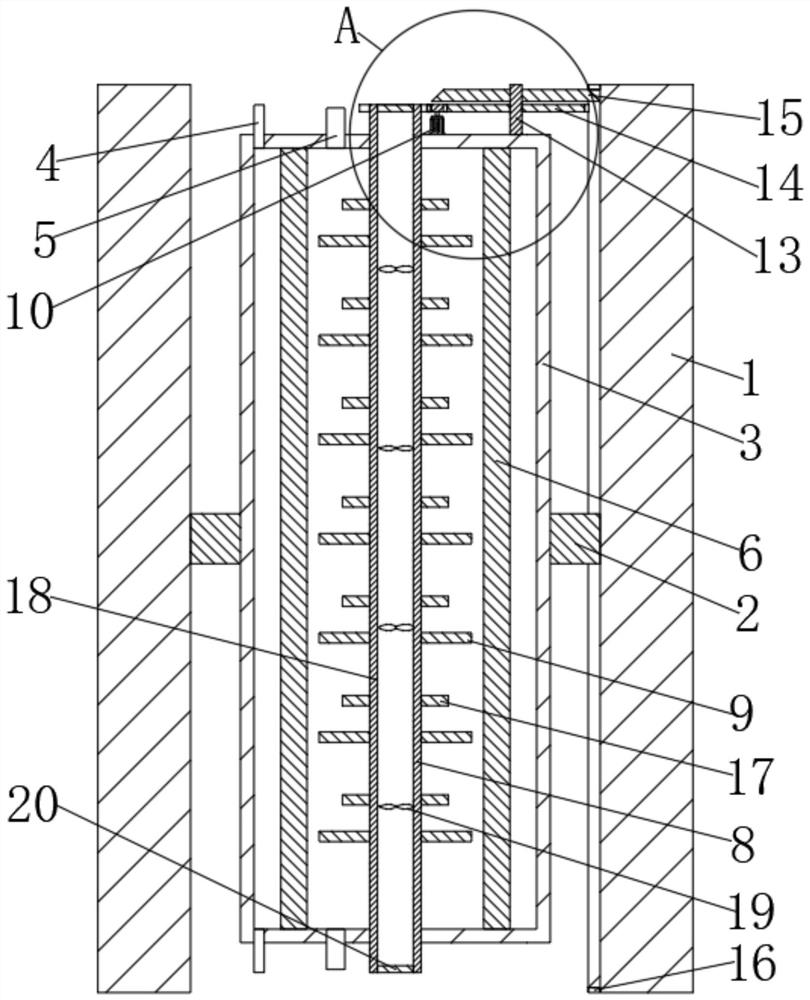

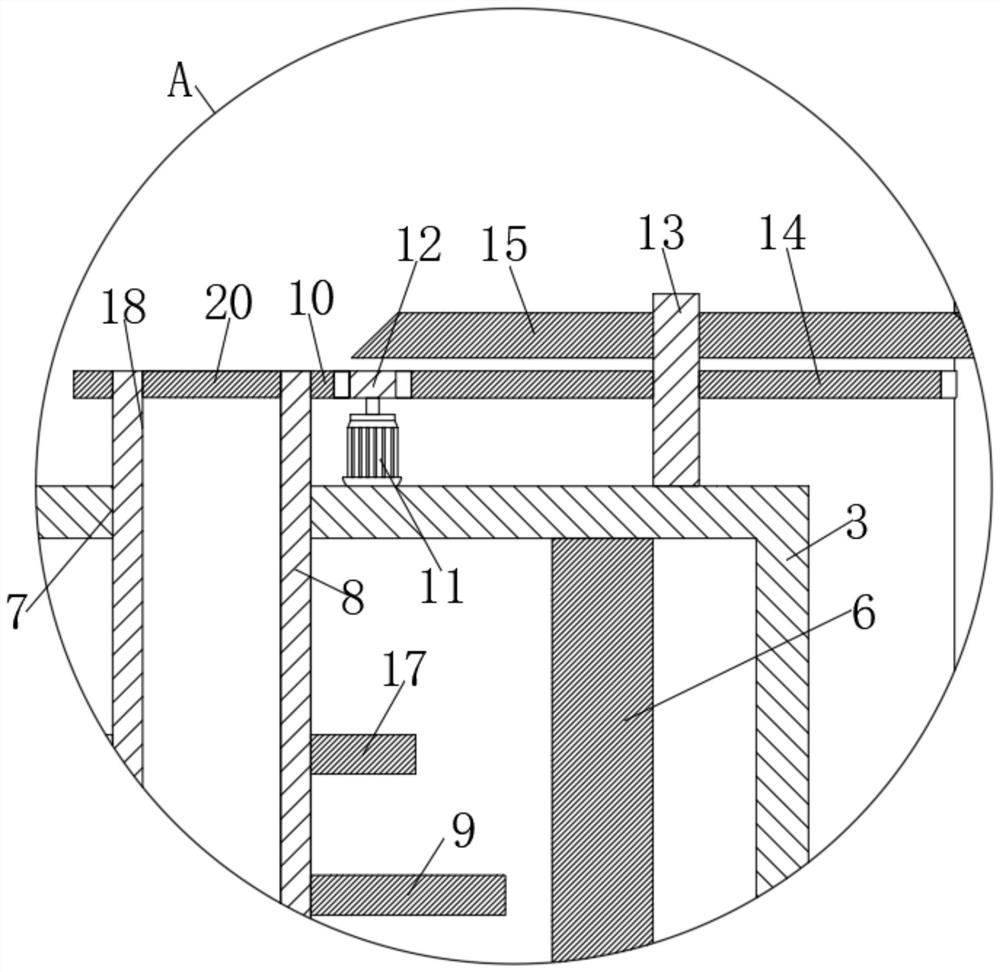

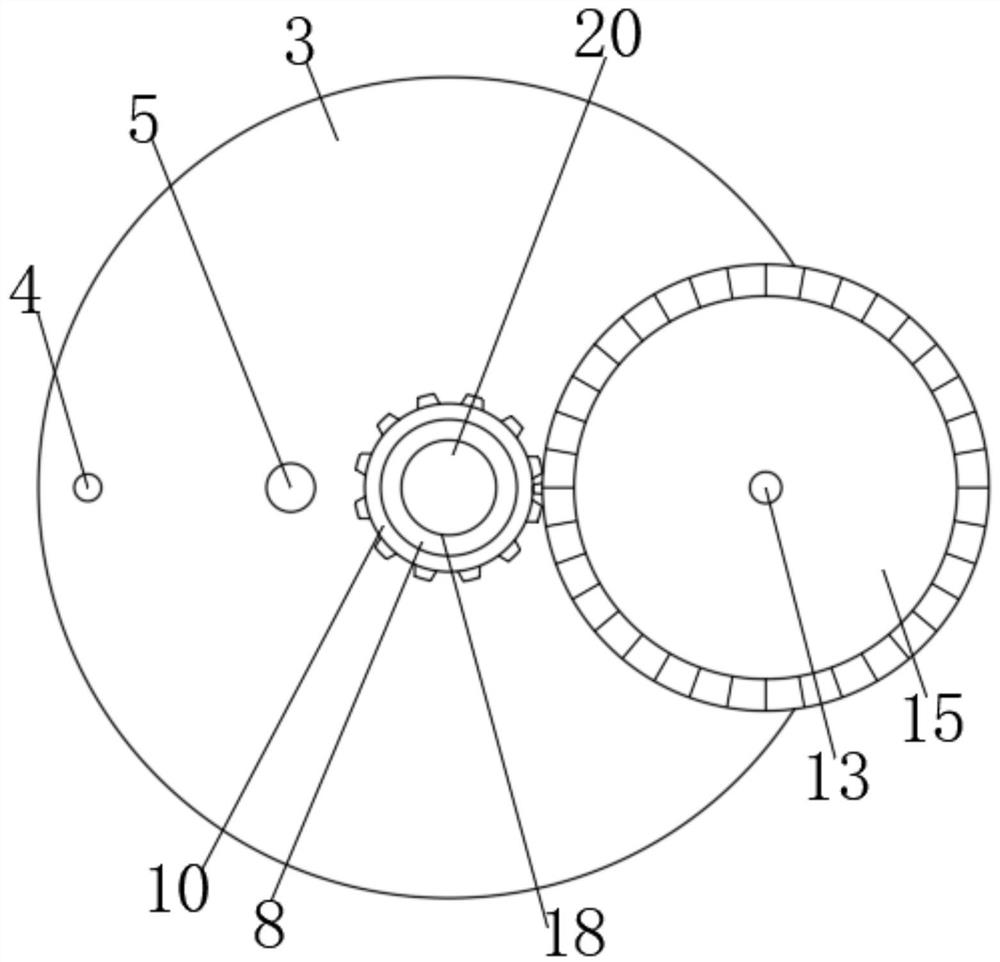

A vertical sanding mechanism for corundum abrasive

ActiveCN110180641BAchieving a sanding effectImprove sanding efficiencyGrain treatmentsCircular discElectric machine

The invention discloses a vertical sanding mechanism for corundum abrasives. The vertical sanding mechanism comprises two supporting plates, wherein the opposite surfaces of the two supporting platesare rotationally connected with rotating shafts; the opposite surfaces of the two rotating shafts are fixedly connected with sanding cylinders; and the top and bottom of each sanding cylinder are respectively provided with a feeding port and a discharging port. By means of the vertical sanding mechanism for the corundum abrasives, a motor drives a pinion to rotate by starting the motor, a rotatingrod is driven to rotate by engagement between the pinion and a ring rack. The rotating rod the dispersing, colliding and other movements of the abrasives and sanding objects in the sanding cylindersare carried out through double-sided sanding discs by the rotating rod; the sanding objects are screened by a cylindrical filter screen and discharged through the discharging ports; at the same time,a bevel gear is driven to rotate through the engagement between the pinion and a main gear; and the sanding cylinders rotates around the rotating shafts through the engagement between the bevel gear and a circular conical rack, so that the abrasives and the sanding objects in the sanding cylinders overturn up and down in the sanding cylinders so as to achieve the effect of improving the sanding efficiency.

Owner:新郑市宝德高技术有限公司

Sanding device for processing fireproof boards

ActiveCN111958362BEasy to useImprove sanding efficiencyGrinding work supportsPlane surface grinding machinesEngineeringHuman power

The invention provides a sanding device for processing fireproof boards, belonging to the technical field of fireproof board processing, comprising a bottom box, a sanding assembly arranged on the upper left side of the bottom box, and a top box arranged on the upper right side of the bottom box There are at least three sets of supporting components for supporting the board from left to right inside the bottom box, and there are also support components inside the bottom box for driving the supporting components to move back and forth along the length of the bottom box. drive components. In the embodiment of the present invention, through the arrangement of at least three sets of support components and support components, the board body can be automatically turned over after sanding treatment on the upper part of the board body, and the turned-over board body can be transported again with the driving assembly Sanding to the inside of the sanding assembly, so as to sand the both sides of the plate body, has the advantages of convenient use and high sanding efficiency. Compared with the existing technology, it reduces human labor and labor costs.

Owner:中材(宜昌)节能新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com