Sanding device and method using zirconium balls in different sizes

A technology of zirconium balls and sanding, which is applied in the direction of grain processing, etc., can solve the problems of difficult to achieve particle size, large step-by-step range of particle size, low efficiency, etc., and achieve simple device structure and sanding process, excellent cycle performance, and sanding high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

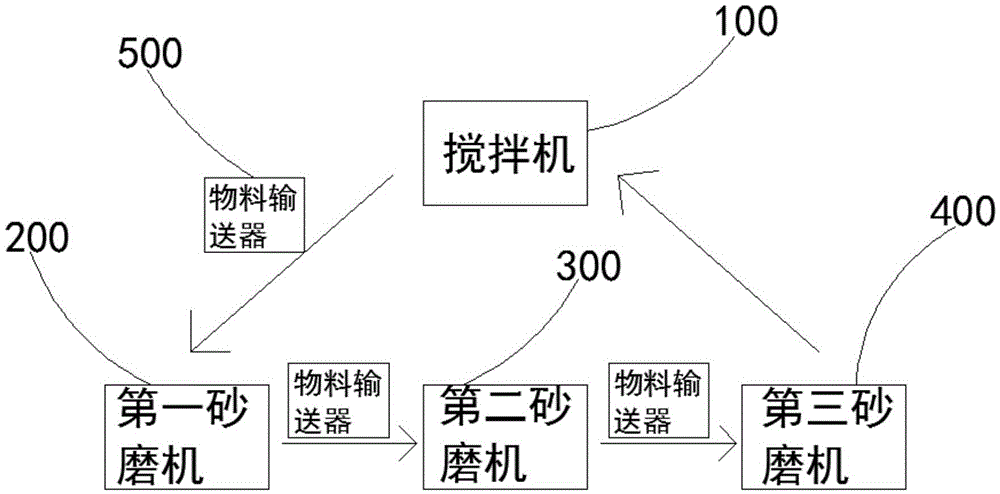

[0038] For the first embodiment, refer to figure 1 , the sand milling device using zirconium balls of different sizes comprises a stirrer 100, a first sand mill 200, a second sand mill 300 and a third sand mill 400 connected in sequence, the stirrer 100 and the first sand mill 200 Between, between the first sand mill 200 and the second sand mill 300 and between the second sand mill 300 and the third sand mill 400, a material conveyor 500 is arranged, and the first sand mill 200 is set There are multiple large zirconium balls, multiple medium zirconium balls are set in the second sand mill 300 , and small zirconium balls are set in the third sand mill 400 .

[0039] Among them, the agitator 100 is mainly used for uniform mixing of the materials to be processed, the first sand mill 200, the second sand mill 300 and the third sand mill 400 are mainly used for sand grinding of the materials to be processed, and the material conveyor 500 is mainly used for It is used for the trans...

no. 2 example

[0067] The second embodiment, the device provided by the embodiment of the present invention, its realization principle and the technical effect produced are the same as those of the previous embodiment. For brief description, for the parts not mentioned in the device embodiment, please refer to the corresponding content in the previous embodiment .

[0068] In this embodiment, an active synchronous wheel is provided on the output shaft of the stirring motor, a driven synchronous wheel is provided on the output shaft of the rotating shaft, and a synchronous belt is set between the active synchronous wheel and the driven synchronous wheel.

[0069] Among them, the synchronous pulley is generally made of steel, aluminum alloy, cast iron, brass, and other materials. The inner hole has round hole, D-shaped hole, tapered hole and other forms. Surface treatment includes natural color oxidation, blackening, galvanizing, color galvanizing, high-frequency quenching and other treatment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com