Bottom surface sanding machine

A technology of sanding machine and bottom surface, which is applied in the field of sanding machines, can solve the problems of inability to directly match plates of different thicknesses, increase the cost of purchasing machines, increase production costs of enterprises, and large space limitations, and achieve simple structure, low cost, and matching flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

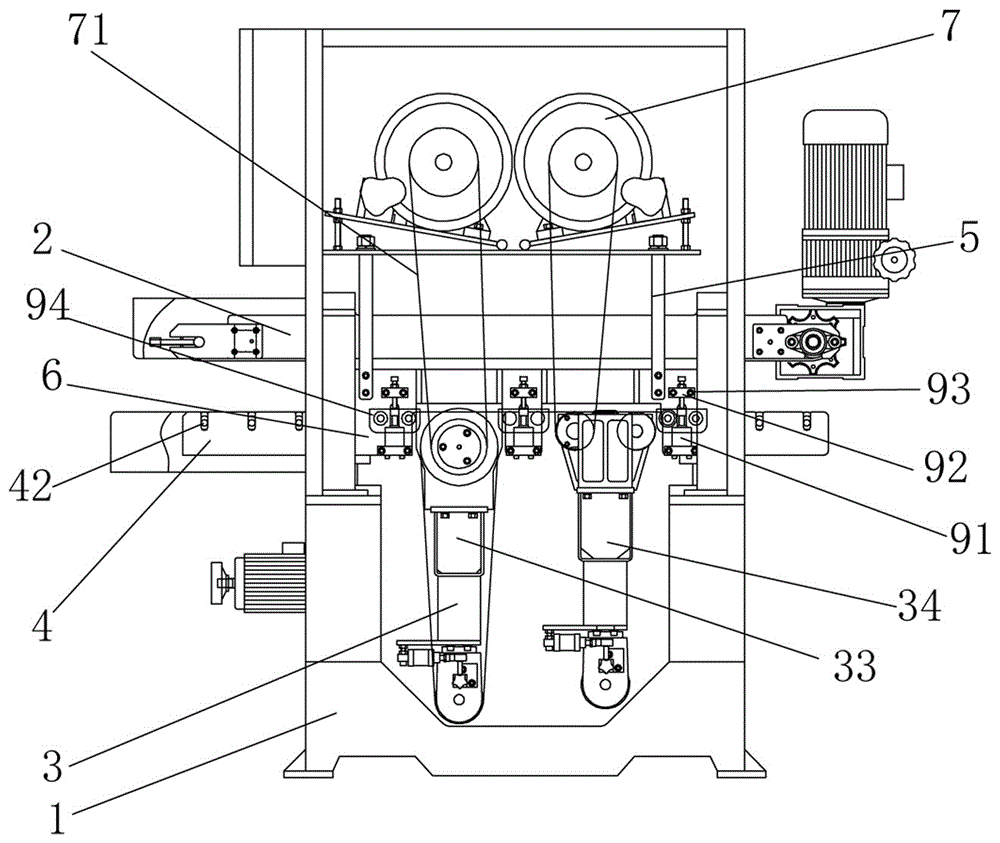

[0031] A bottom surface sanding machine, comprising a frame 1, a workbench 2 arranged on the frame, a sand frame 3 and a sand frame motor 7, the bottom surface of the workbench is a working surface, and a lifting assembly is arranged under the workbench An elevating platform 4 that can move up and down along the frame, and the sand frame is fixed on the elevating platform.

[0032] The sand frame motor is erected on the top of the workbench through the frame rod 5 whose bottom end is fixed on the lifting platform. The sand frame motor is hung on the top of the worktable through the frame rod, so as to save space without increasing the height of the entire lifting platform, and has a compact structure.

[0033] Mounting plates 6 are fixed on both sides of the middle part of the lifting platform, a pressing assembly is arranged on the mounting plate, and the frame rod is fixed on the mounting plate. There is a frame rod on the outer surface of both ends of the mounting plate on...

Embodiment 2

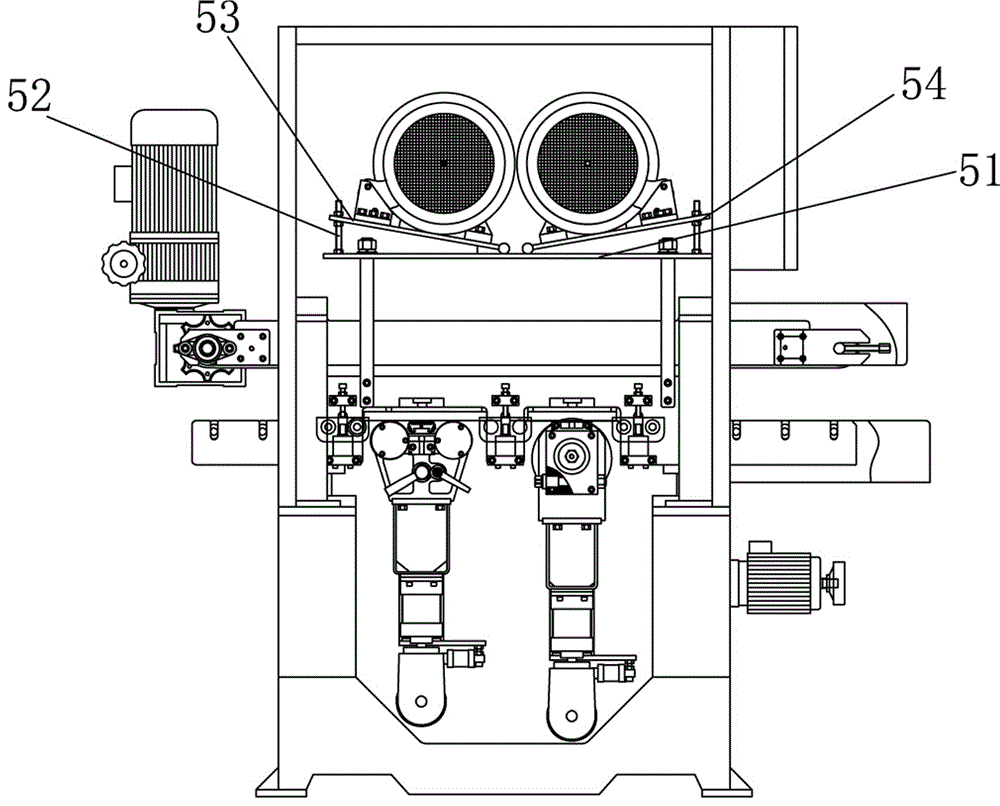

[0037]The difference from the above embodiment is that the sand frame of this embodiment includes a front sand frame 33 and a rear sand frame 34, and the sand frame installation grooves are two for installing the front sand frame and the rear sand frame respectively, and one can also be set according to the requirement Or three or more sand frames and suitable sand frame installation grooves; in the present embodiment, at least one set of pressing assembly is provided between the front side of the front sand frame, the rear side of the rear sand frame, and the front and rear sand frames, so that For the stable transfer of the sheet. A reinforcing connecting plate 611 is also fixedly connected between the connecting hanging plate and the mounting plate; the lifting table includes a feeding section at both ends with several feeding rollers 42, and a feeding section in the middle with The working section of the grinding through hole 43 of the abrasive belt on the sand frame and t...

Embodiment 3

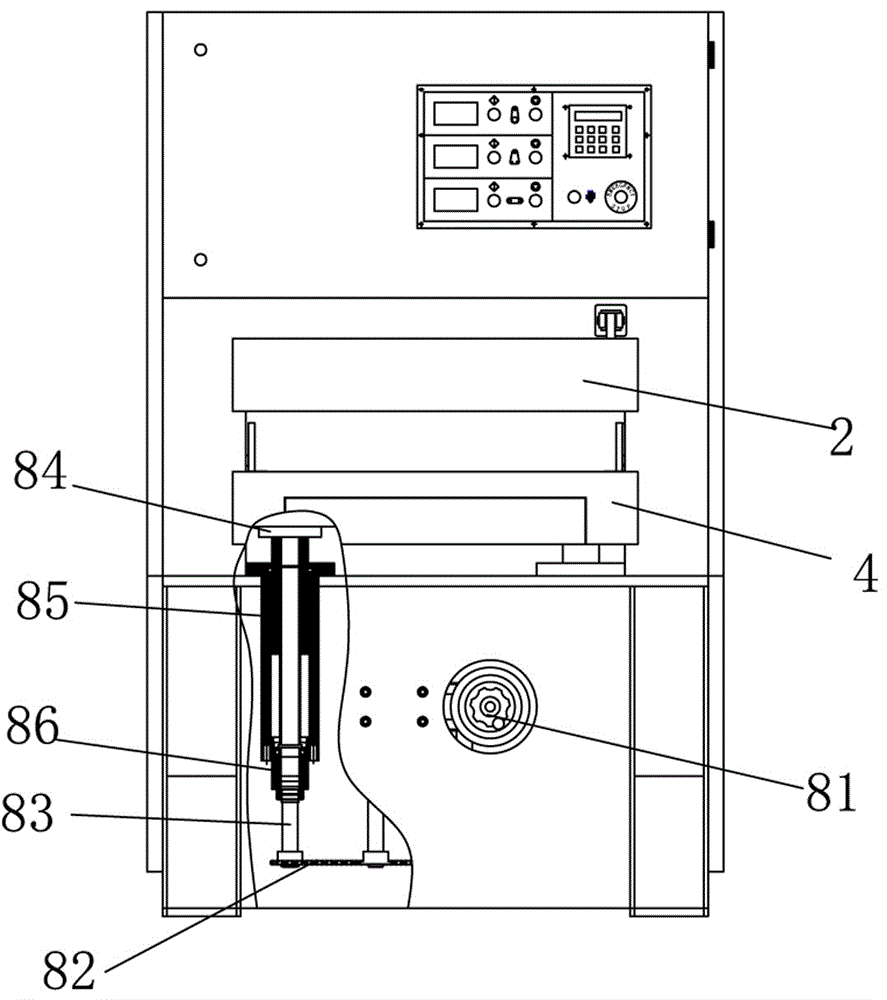

[0041] The difference from the above embodiment is that the lifting assembly includes a lifting motor 81 arranged in the frame, a lifting shaft 83 that is connected to the main shaft of the lifting motor through a transmission chain 82, and a lifting shaft 83 that is screwed to the side of the lifting shaft. The seat 84 is fixed on the frame and is sleeved on the lifting sleeve 85 on the lifting seat.

[0042] The lower end of the lifting sleeve is provided with a stable guide seat 86 that is socketed with the lifting shaft through a bearing. A sleeve between the lifting shafts and having an internal thread screwed with the lifting shaft, the length of the sleeve is less than or equal to the distance from the top of the lifting sleeve to the top of the stable guide seat. The length of the lifting shaft is long and easy to twist, and the upper part is screwed with the bushing to have a torque, and the bottom is connected to the lifting chain and there is another torque. The two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com