Double-layer composite plate finishing unit

A finishing unit and composite panel technology, applied in the field of double-layer composite panel finishing unit, can solve the problems of laborious and laborious, low production efficiency, increased production cost, etc., and achieve the effect of reducing production cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

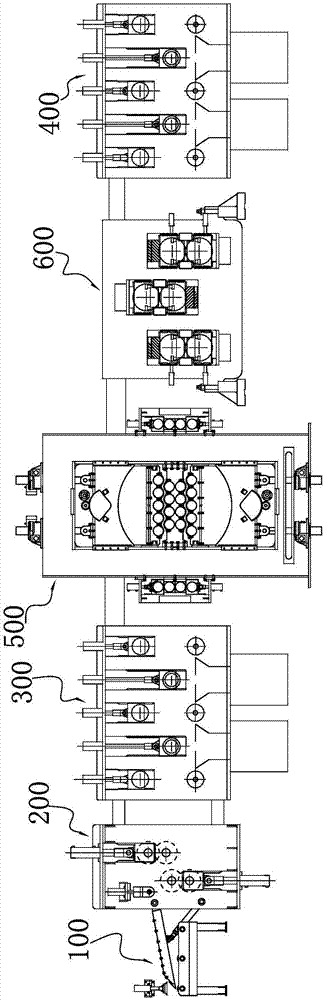

[0049] Such as figure 1 As shown, a double-layer composite board finishing unit includes a double-layer composite board shoveling device 100 connected in sequence, a double-layer composite board bidirectional turtle back straightening machine 200, a double-layer composite board slag cleaner 300, a double-layer composite board Board leveling machine 500, double-layer composite board light finishing machine 600, double-layer composite board sand mill 400.

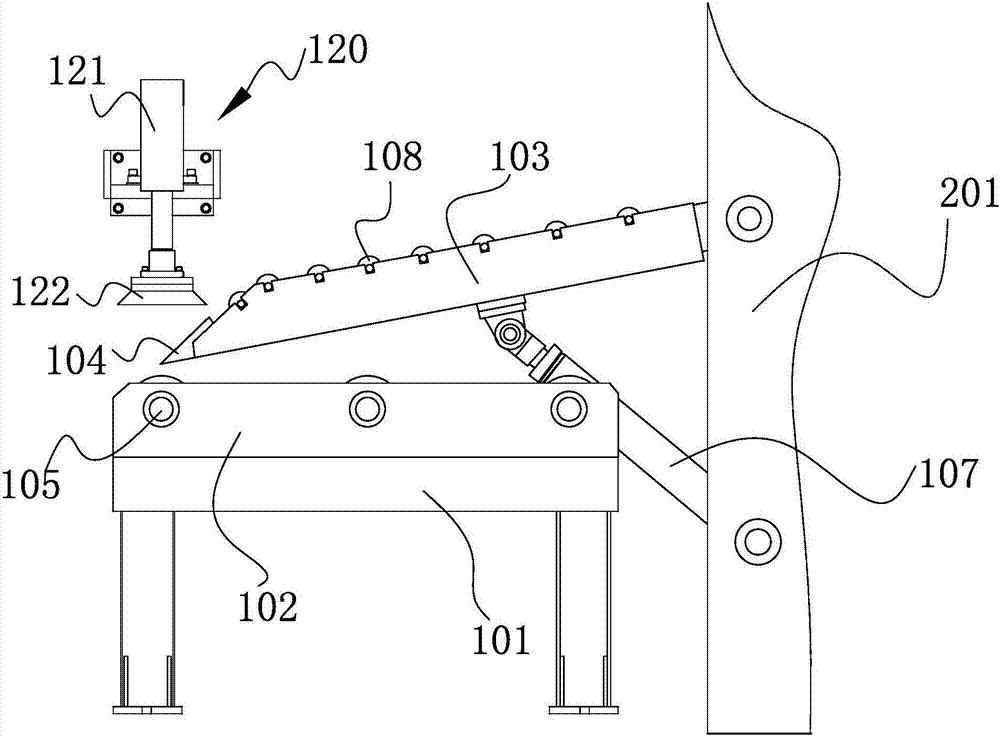

[0050] Such as figure 1 , figure 2 with Figure 4Commonly shown, the double-layer composite board shoveling device 100 includes a bracket 101, a power conveying roller table 102 is arranged on the bracket 101, a power roller 105 is arranged on the power conveying roller table 102, and a swinging roller table is arranged above the power conveying roller table 102 The guide table 103, the front end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com