Sand mill circulating pump for production of high-performance metal soft magnetic ferrite

A soft ferrite, high-performance technology, used in liquid variable capacity machinery, pumps with flexible working elements, pumps, etc., can solve the problems of large changes in state and low flow, and reduce cycle time, The effect of enhanced pumping capacity, easy precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

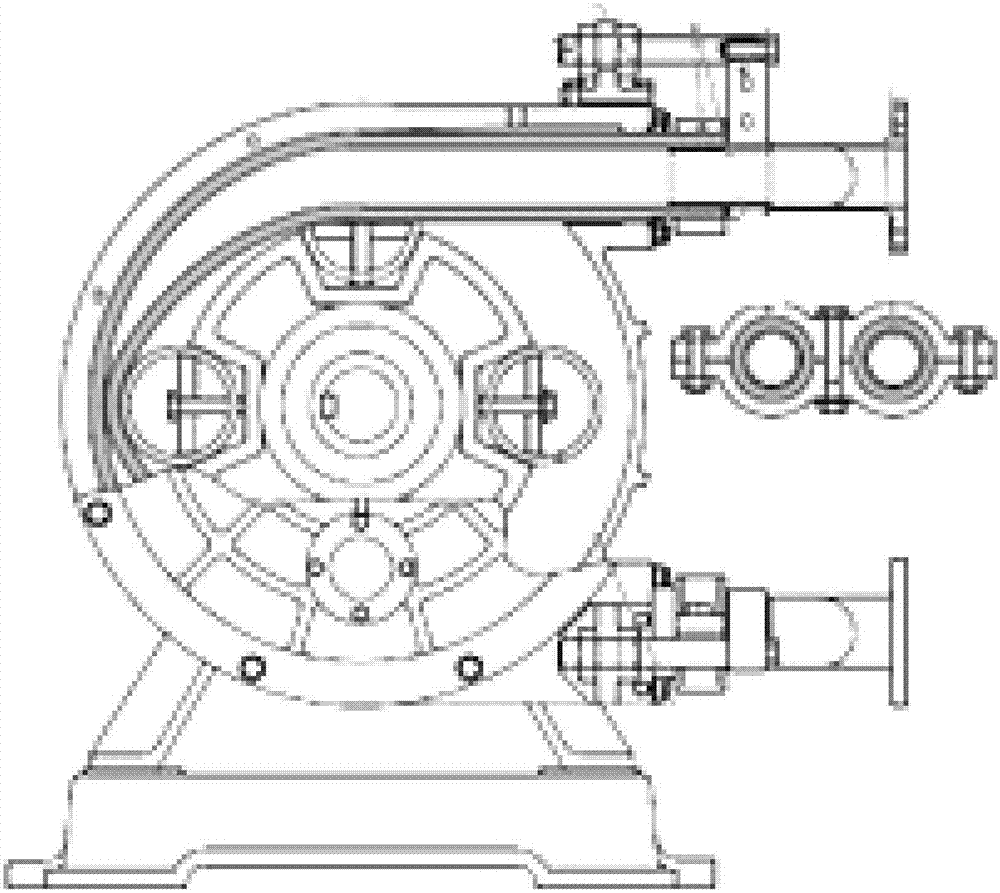

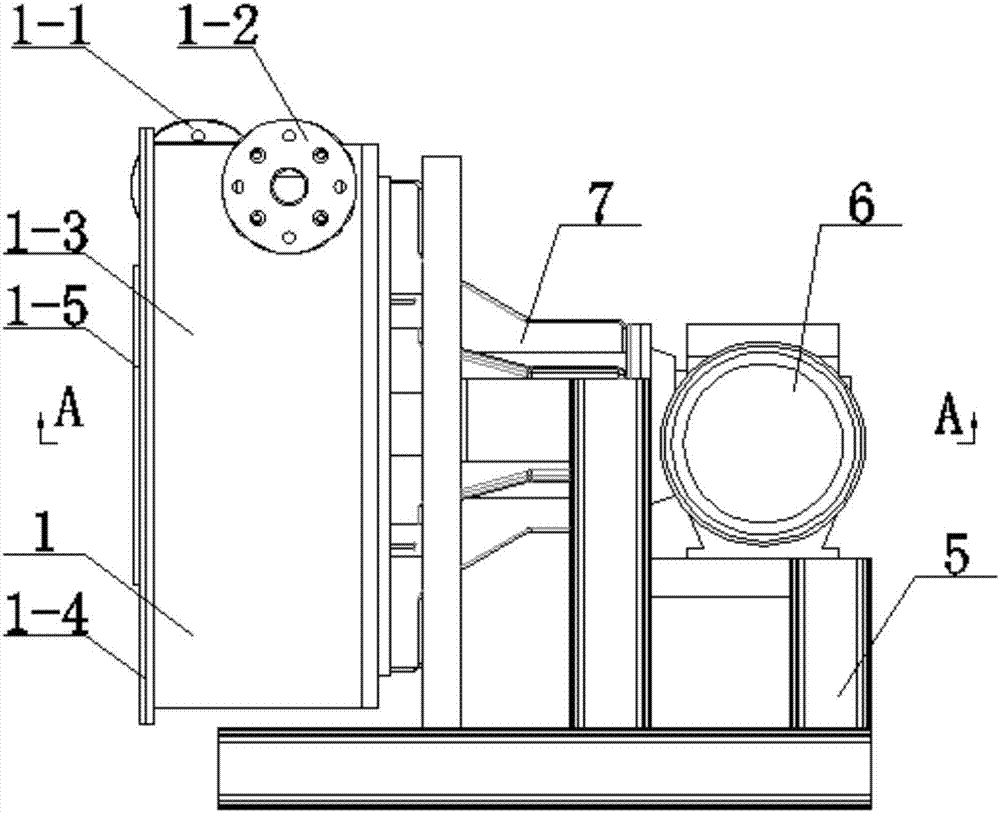

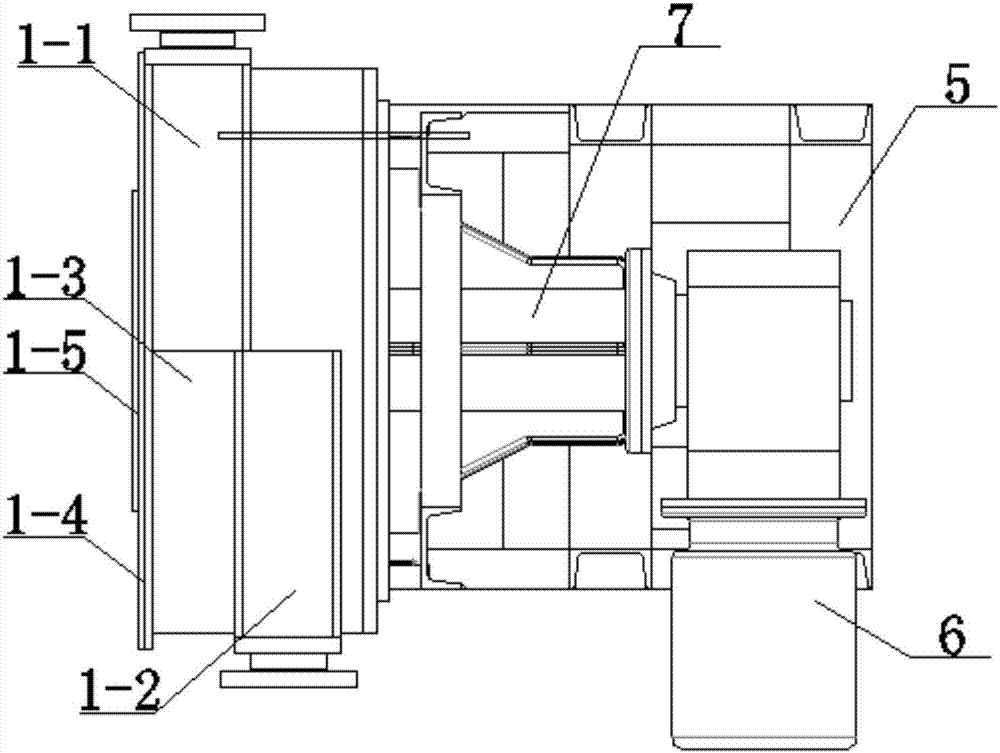

[0040] like Figure 2 to Figure 8 As shown, a sand mill circulation pump for the production of high-performance metal soft ferrite of the present invention includes a pump casing 1, a feed port 1-1 and a discharge port 1-2 arranged on the pump casing 1, and a crankshaft 2. Extrusion roller 3, hose 4, deceleration motor 6 and bearing housing 7 fixedly installed on base 5, feed inlet 1-1 and discharge outlet 1-2 are staggered horizontally by 180°, hose 4 The two ends are respectively connected to the material inlet 1-1 and the material outlet 1-2, and material sensors (not marked in the figure) are arranged in the material inlet 1-1 and the material outlet 1-2, and the center of the hose 4 The axis is located on the spiral surface, the crankshaft 2 is inserted in the bearing seat 7, and connected with the reduction motor 6, the extrusion roller 3 is fixed on the crankshaft 2, and the crankshaft 2 drives the extrusion roller 3 to squeeze the hose 4, which solves the current cycle...

Embodiment 2

[0047] Because the inner tube 4-1 is made of rubber material, when the hose 4 pump is working, the hose 4 is flattened by the extruding body, the deformation is very large, and the inside bears relatively large pressure and the friction formed by the fluid flow. With the continuous rotation of the extrusion roller 3, these forces are repeatedly applied to the hose 4, and the extrusion deformation and friction of the extrusion body on the surface of the hose 4 will increase the temperature of the hose 4 , which accelerates the aging of the hose 4, so the inner tube 4-1 is set in the protective sleeve 4-2, such as Figure 8 In the structure shown, the extrusion roller 3 is in contact with the protective sleeve 4-2 instead of the inner tube 4-1, and the protective sleeve 4-2 can well protect the inner tube 4-1 and reduce the wear of the inner tube 4-1. Extend the service life of the hose 4.

[0048] The circulation pump of the present invention is installed in the slurry circula...

Embodiment 3

[0050] In the actual use process, in order to facilitate the observation of the internal conditions of the pump casing 1 through the panels 1-5, judge the wear of the hose 4 and the extrusion roller 3, and facilitate the timely replacement of the hose 4 end caps 1-4. The center is provided with an observation hole , A panel 1-5 is installed on the observation hole, and the panel 1-5 is made of transparent toughened glass, wired glass, explosion-proof glass or acrylic material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com