A kind of multi-layer furniture board production process

A production process and furniture board technology, applied in the direction of manufacturing tools, grinding skateboards, wood processing utensils, etc., can solve the problems of low efficiency of board sanding, and achieve the effect of smooth surface of finished products and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of multi-layer furniture board production process, comprises the following steps:

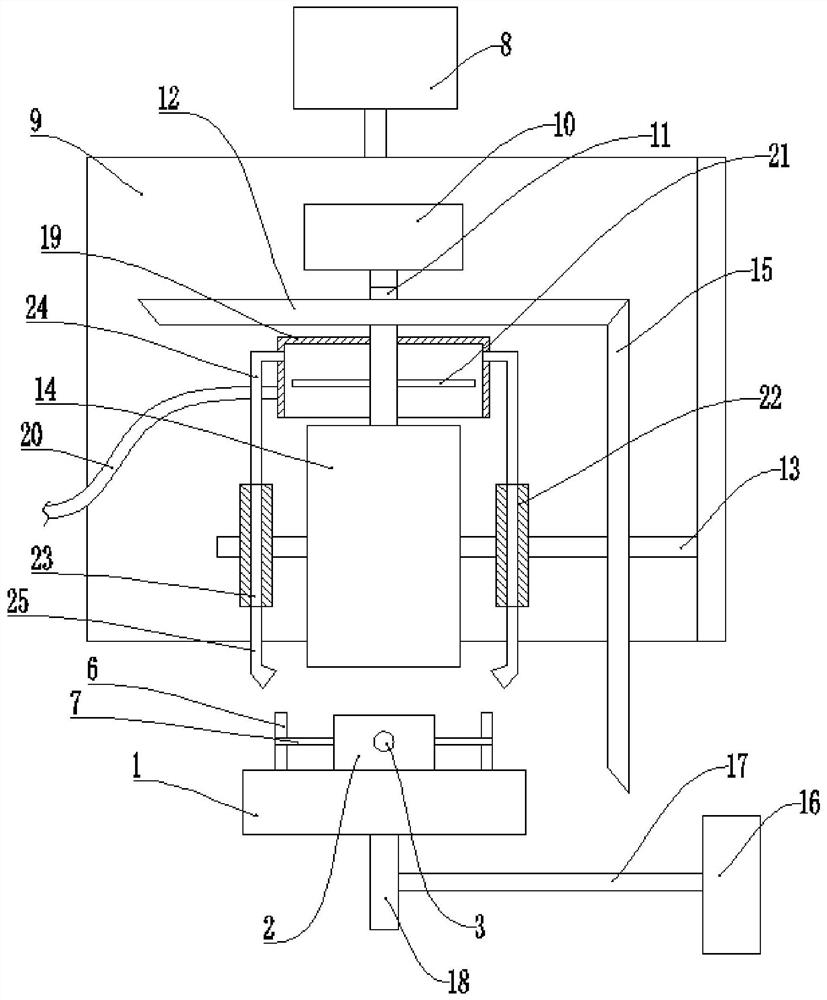

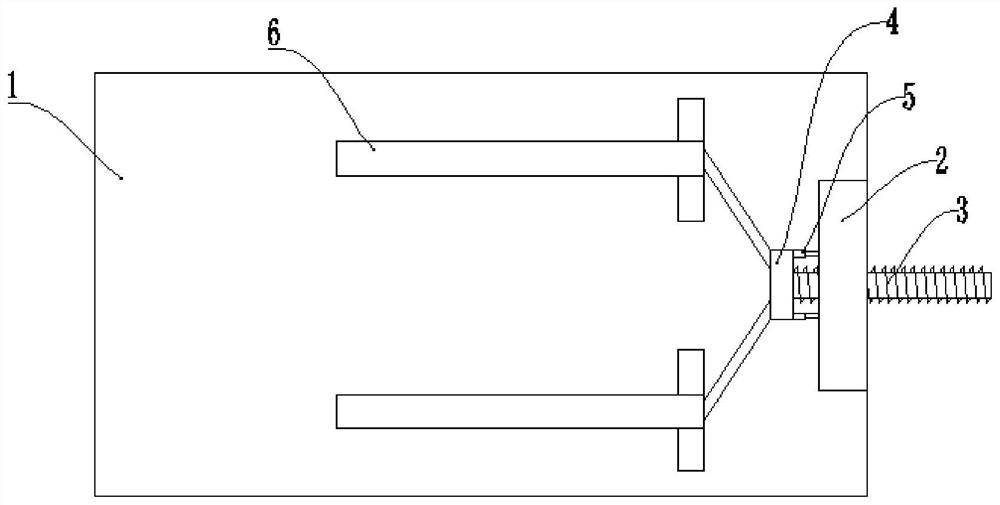

[0035] a: Preparation; select a number of flat plates, each of which is a group of 11 plates, and the 11 plates are numbered in the order of 1 to 11; prepare the sanding device, including the machine base, which is provided with supports for placing the plates Plate 1, a power mechanism for driving the support plate 1 to move horizontally and a sanding mechanism for sanding plates with different thicknesses, the support plate 1 is provided with a positioning mechanism for plate positioning;

[0036] b: one-time slab forming; 11 panels in a single group are all coated with glue, and then the panels numbered 3 to 9 are selected for cold pressing. The cold pressing time is 50min and the pressure is 12mpa to obtain a core; The defects on the board core are repaired. Specifically, check whether there are cracks on the primary board core. If so, use wood chip filling to repair it, and t...

Embodiment 2

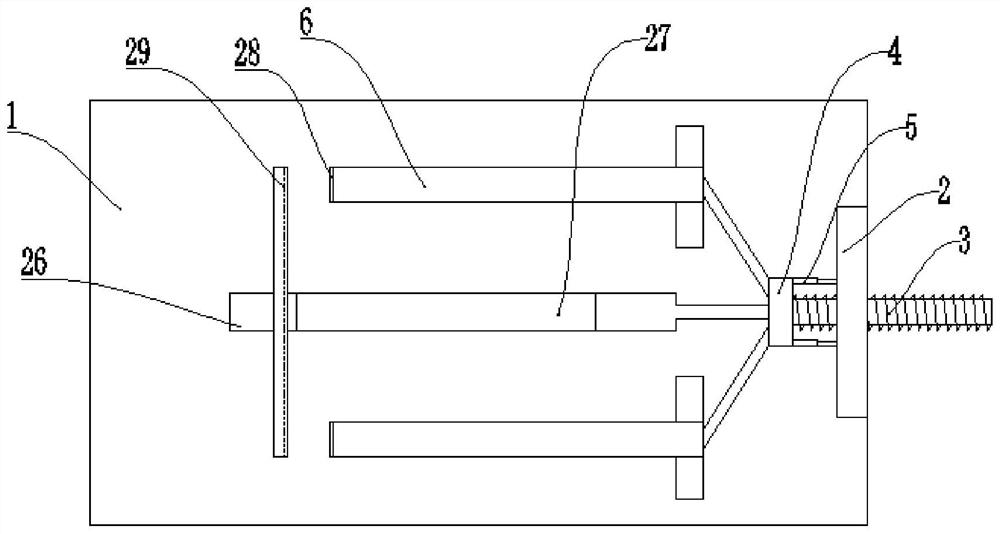

[0048] Basic as attached image 3 Shown: the structure and implementation mode of embodiment two and embodiment one are basically the same, and its difference is:

[0049] The left end of the ring block 4 is fixedly connected with an auxiliary block 26, and the length of the auxiliary block 26 is greater than the length of the clamping arm 6, and the auxiliary block 26 is provided with a groove 27 for placing a plate; on the side walls of the two clamping arms 6 Both are affixed with projections 28; the top of the left end of the auxiliary block 26 is affixed with a top block 29, and the top block 29 is provided with a guide groove 30 for the sliding of the projections 28, and the top block 29 moves to the right, so that the projections 28 stretch into the guide slot 30.

[0050] The specific implementation process is as follows:

[0051] The primary core board is put into the groove 27, and the primary core board can be limited by the groove 27; and when the threaded rod 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com