Graded-discharge sand mill

A sand mill and discharge port technology, applied in the field of grinding, can solve the problems of low production efficiency, difficulty in controlling the peak shape accuracy of particle size distribution, widening of material particle size distribution, etc., and achieve the effect of improving sand grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

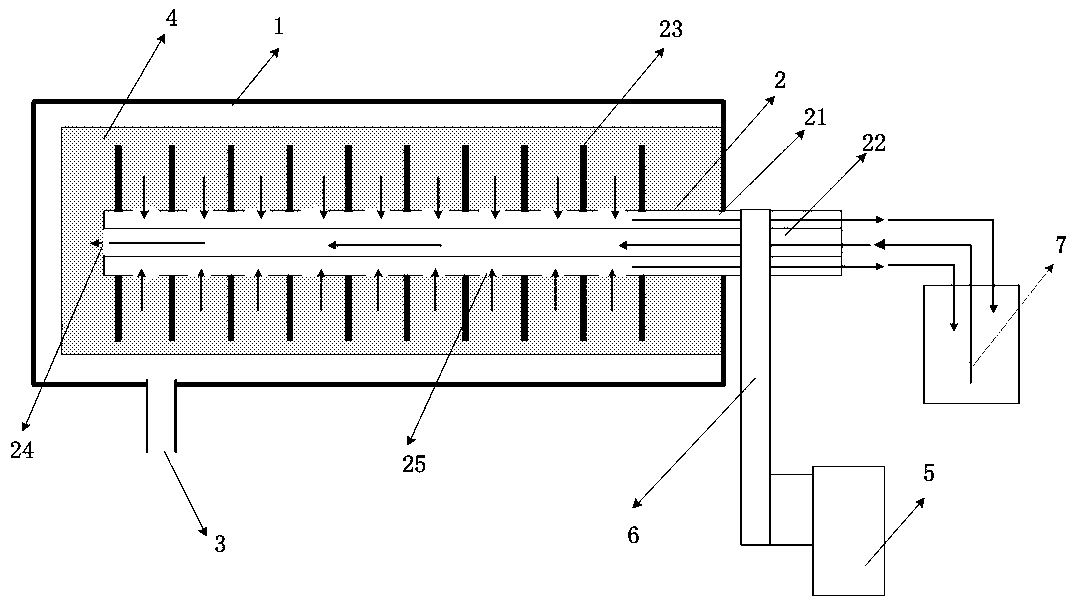

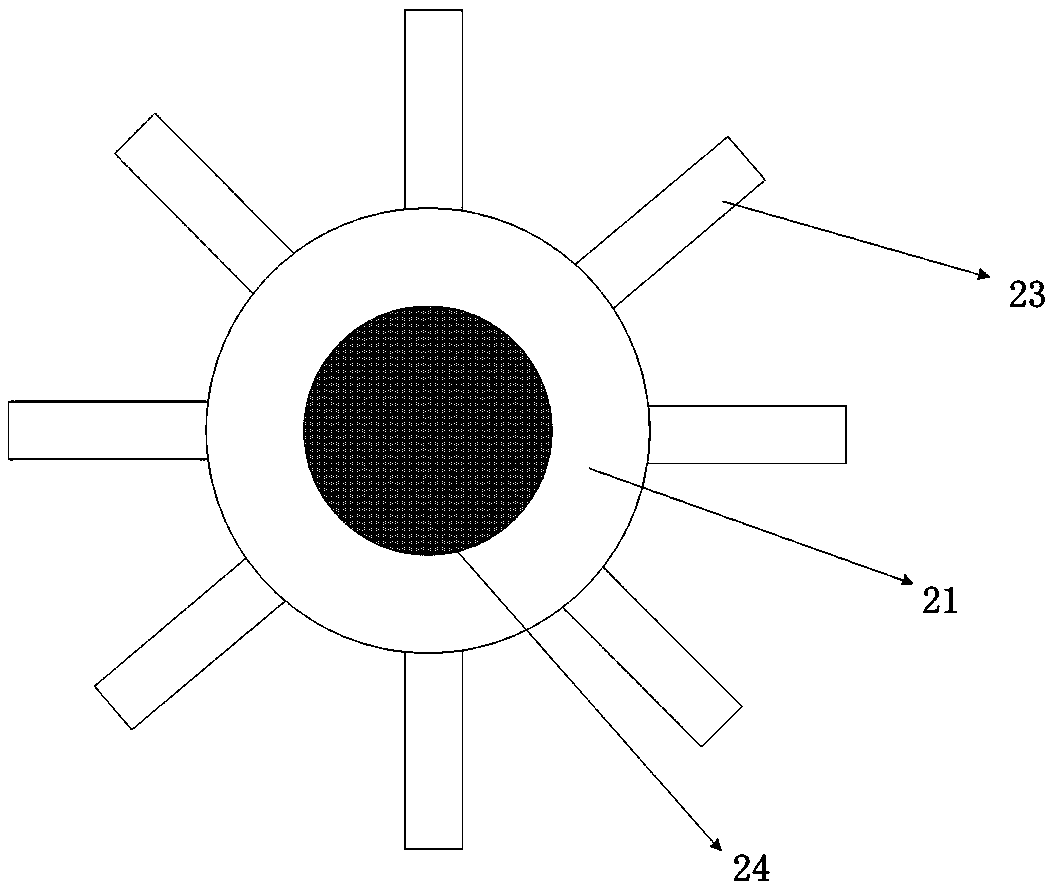

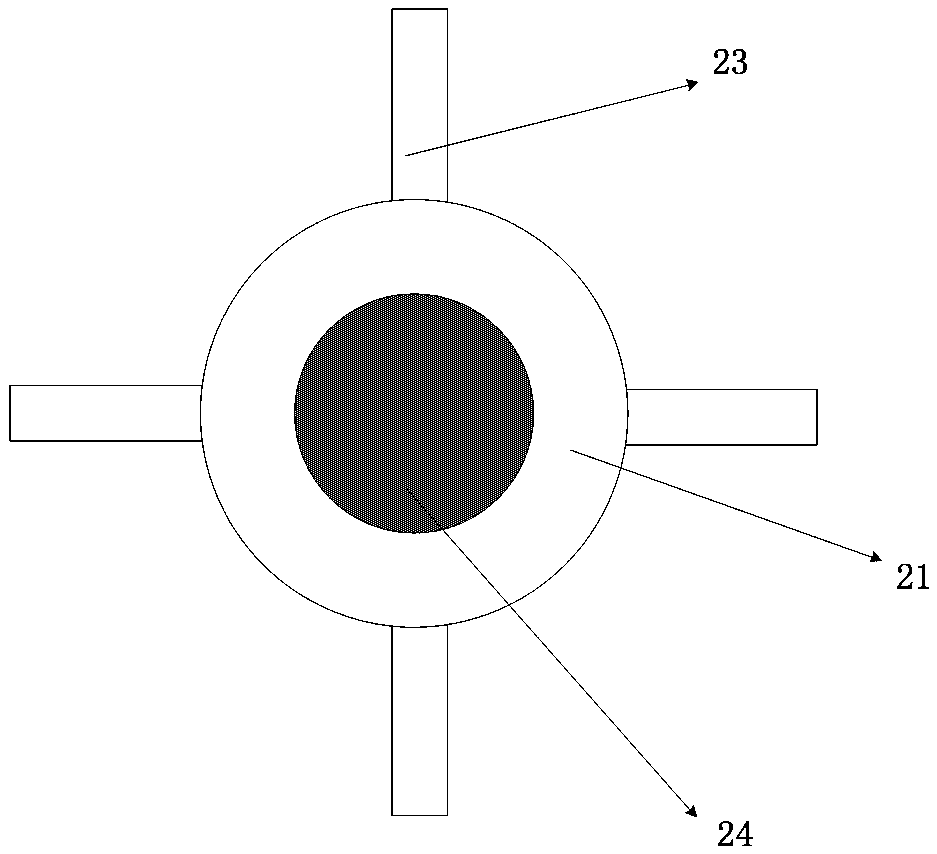

[0019] Such as Figure 1-6 As shown, a graded discharge sand mill includes a sand mill main body 1, a rotor 2, and a motor 5. The lower part of the sand mill main body 1 is provided with a fine material discharge port 3, and the sand mill main body 1 is a hollow structure. A separator 4 is arranged in the cavity of the main body 1 of the mill, and the output end of the motor 5 is connected to the rotor 2 through a transmission device 6. The rotor 2 enters from one end of the main body 1 of the sand mill and is fixedly installed in the cavity of the main body 1 of the sand mill. Among them, the rotor 2 is a hollow interlayer structure, which is composed of a rotor outer interlayer 21, a rotor inner interlayer 22 and a rod pin 23 installed on the outer surface of the rotor. The rotor outer interlayer 21 is provided with a coarse material outlet 25, and the bottom of the rotor inner interlayer 22 is A feed port 24 is provided, and the rotor 2 communicates with the material circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com