Method for synthesizing methyl oleate and epoxy methyl oleate in ion liquid medium

A methyl oleate, ionic liquid technology, applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems that have not been widely used, catalyst catalytic performance, stability, cost and operability restrictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

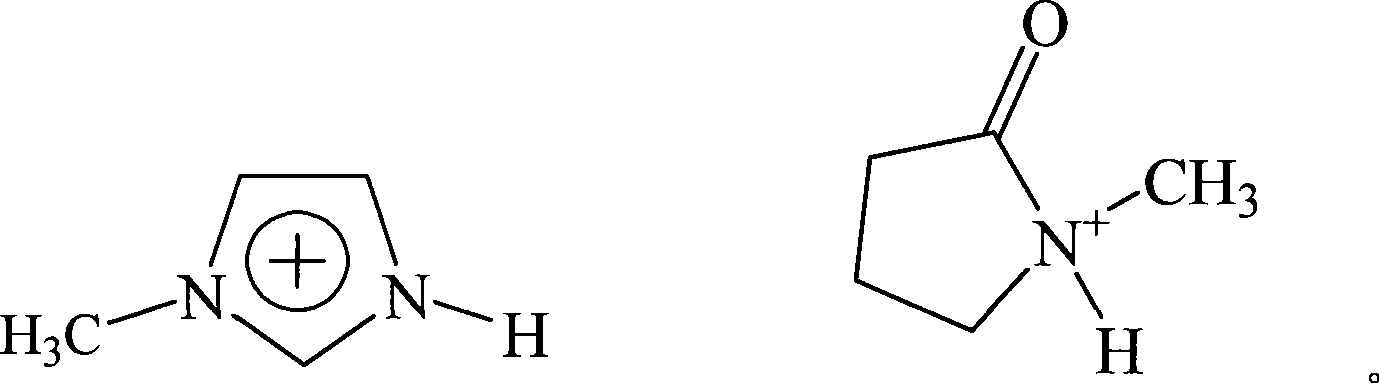

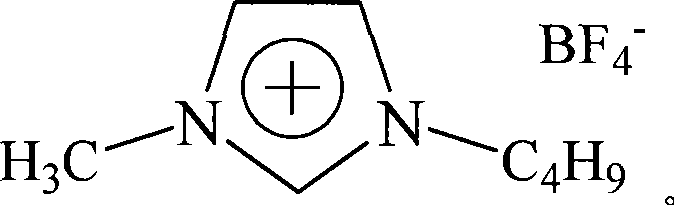

Method used

Image

Examples

Embodiment 1

[0034] 1.57g ionic liquid [Hmim][HSO 4 ], 28.25g oleic acid and 3.2g methanol were put into a three-necked flask, stirred, heated, and the esterification temperature was 70°C, and reacted for 3 hours. The calculated esterification rate was 70.07%.

Embodiment 2

[0036] 5.65g ionic liquid [Hmim][HSO 4 ], 28.25g oleic acid and 6.4g methanol were put into a three-necked flask, stirred, heated, the esterification temperature was 75°C, and reacted for 3 hours. The calculated esterification rate was 96.02%.

Embodiment 3

[0038] 3.30g ionic liquid [Hmim][H 2 PO 4 ], 28.25g oleic acid and 4.8g methanol were put into a three-necked flask, stirred, heated, the esterification temperature was 70°C, and reacted for 2 hours. The calculated esterification rate is 86.34%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com