Construction method of laminated combined concrete servo formwork

A construction method and concrete technology, applied in the formwork/formwork/work frame, formwork/formwork/workframe connectors, formwork/formwork components, etc., can solve the impact of concrete hydration heat and stress simulation calculation analysis Accuracy, increase the difficulty of controlling the stress release of mass concrete, and the difference in thermal conductivity of concrete, etc., to achieve the effect of not being easy to deform, low cost, and meeting the design size requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

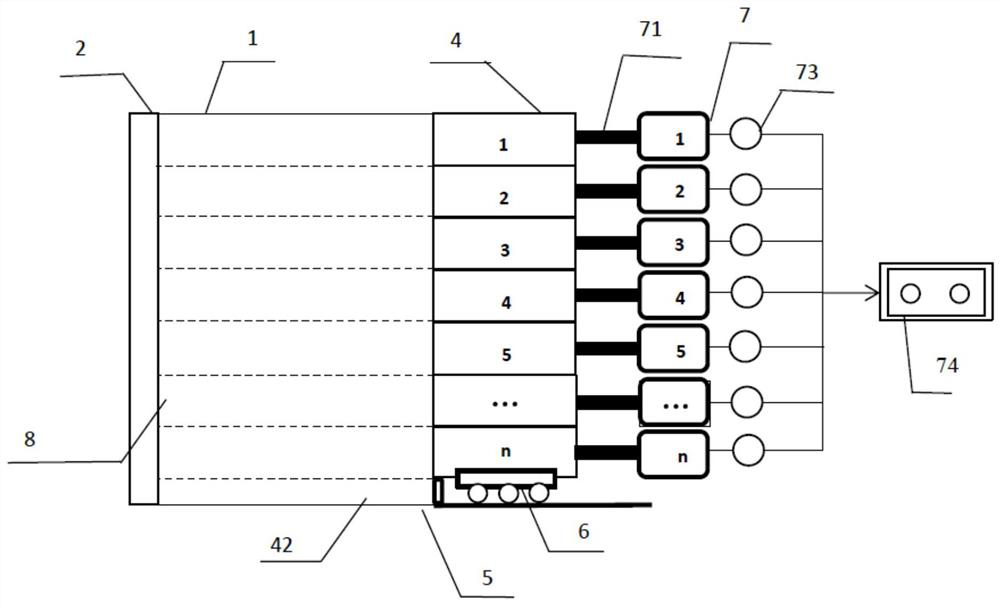

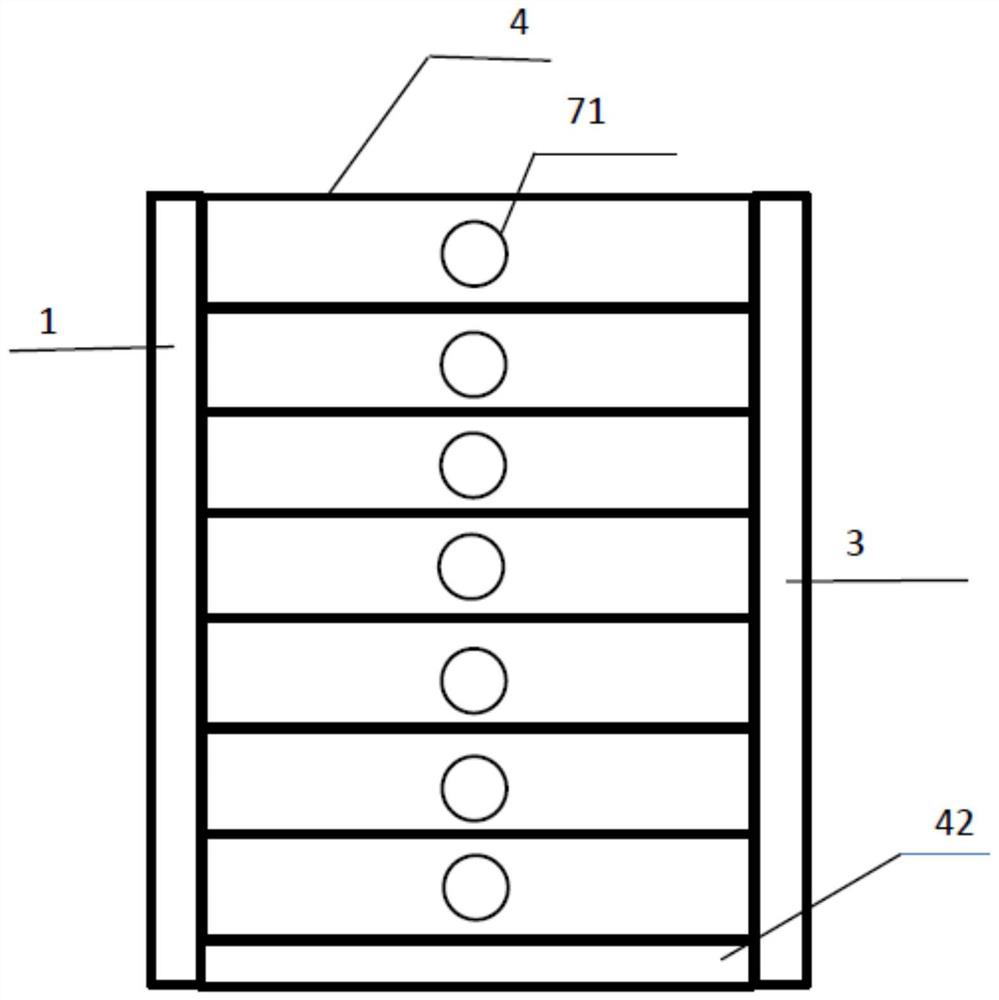

[0035] Combine below Figure 1 to Figure 4 , detailing the structural composition of the laminated combined concrete servo formwork used in the construction method of the present invention.

[0036] Please refer to Figure 1 to Figure 4 , a stacked combined concrete servo formwork, comprising:

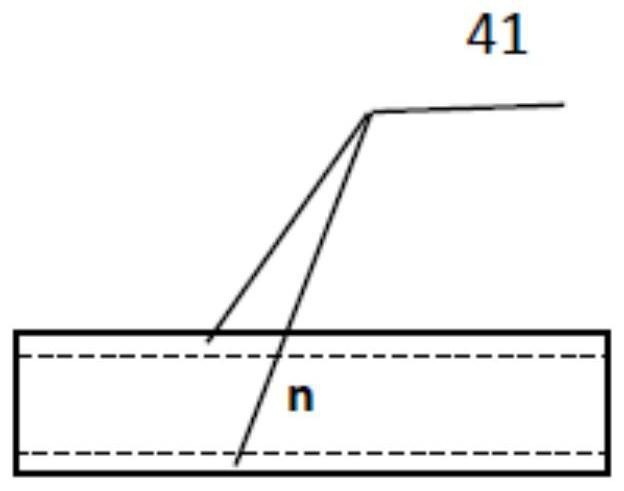

[0037] Bottomless box and displacement control system, the bottomless box includes fixed left side wall layer 2, front side wall layer 1 and rear side wall layer 3, and right stacked formwork set that is movable; right stacked formwork set It can approach or stay away from the bottomless box under the action of the displacement control system; the upper and lower parts of the single-layer right laminated formwork are laid with a high-strength smooth plastic layer 41, which is used to assist the right laminated formwork 4 to move and prevent concrete from leaking; The bottom of the front side wall layer 1 and the rear side wall layer 3 of the bottomless box body are all provided with ...

Embodiment 2

[0045] Please continue to refer Figure 1 to Figure 4 , the present invention also provides a construction method for a stacked combined concrete servo formwork, the construction method adopts the aforementioned stacked combined concrete servo formwork, and the construction method includes the following steps:

[0046] Step S1, erecting and fixing the left side wall layer 2, the front side wall layer 1 and the rear side wall layer 3 of the bottomless box respectively according to the design;

[0047] Step S2, erect n layers of right-side laminated formwork 4 from bottom to top to the design elevation position, and construct a temporary fixed structure to form a right-side laminated formwork group, where n is a natural number;

[0048] Step S3, set up the displacement control system layer by layer at even intervals, so that the ejector rod 71 of the hydraulic jack 7 is evenly and symmetrically close to the stacked formwork 4 on the right side, ensuring that it is stable and doe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com