Plasma exhaust gas purification device

A technology of waste gas purification and treatment device, which is applied in gas treatment, separation method, dispersed particle separation, etc., and can solve the problems of insufficient treatment, inability to be used repeatedly, and unsatisfactory treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

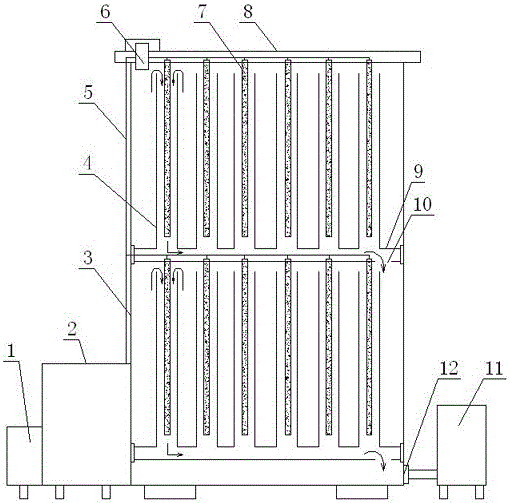

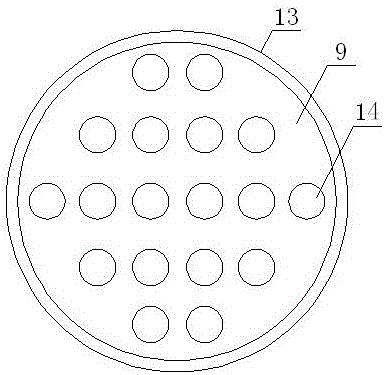

[0020] See attached Figure 1-2 The exhaust gas purification treatment device disclosed in the present invention is a plasma exhaust gas purification treatment device, which includes a power supply 1, a transformer 2, a box body 3, a gas channel 4, a motor wire 5, an air inlet 6, and an electrode rod 7 , Cover plate 8, clapboard 9, air outlet 10, induced draft fan 11, exhaust port 12, clapboard jacket 13, channel positioning hole 14. Among them, the power supply and the transformer work together, the power supply input is high voltage 1.5WV, and the output is low voltage 36V. The power supply is connected with the transformer, the output ends of the transformer are respectively connected with the motor wires, and the power supply and the transformer are respectively arranged outside the box body. The induced fan is arranged outside the other side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com