WO3@mSiO2 microballoon sphere with nuclear shell hollow structure as well as preparation method and application thereof

A core-shell structure and microsphere technology, applied in the field of nanomaterials, to achieve the effects of less by-products, high catalytic efficiency and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

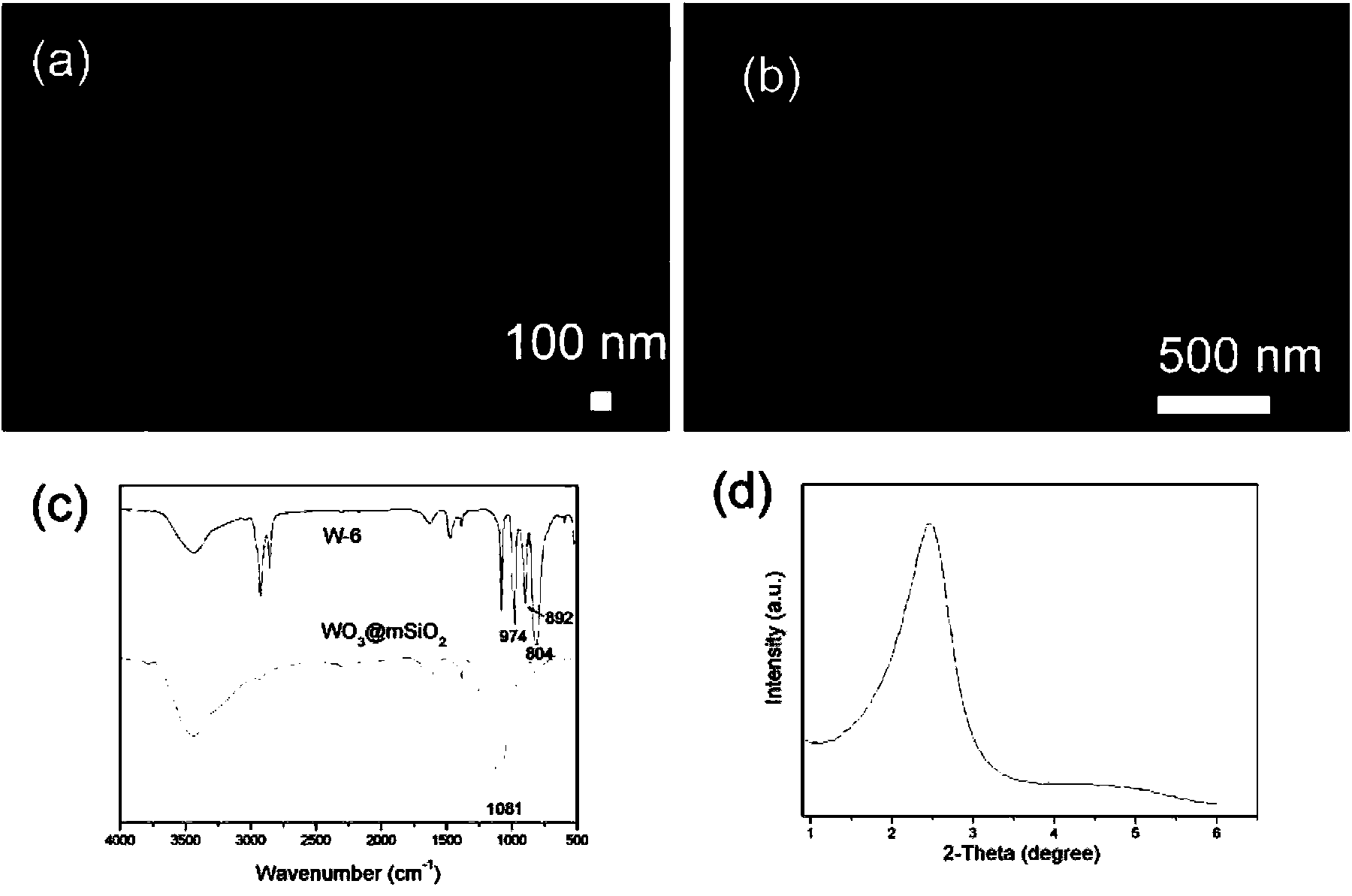

[0037] 1# core-shell hollow structure WO 3 mSiO 2 The concrete preparation steps of catalyst are as follows:

[0038] (1) Preparation method of cetyltrimethylammonium phosphotungstate:

[0039] Measure 100mL of absolute ethanol into a beaker, add 0.44g of cetyltrimethylammonium bromide (CTAB), stir until CTAB is completely dissolved, measure 50mL of absolute ethanol into another beaker, add 1.15g For phosphotungstic acid, stir with a glass rod until the phosphotungstic acid is completely dissolved. While stirring, use a dropper to add the phosphotungstic acid solution to the CTAB solution dropwise. After the addition is complete, continue to stir for half an hour to make it fully react. After filtering and drying, the product hexadecyltrimethylphosphotungstic acid quaternary ammonium was obtained, which was designated as W-6.

[0040] (2) W-6SiO2 2 Microsphere preparation method:

[0041] Weigh 200mg of W-6 and 110mg of CTAB into a round bottom flask, add 20mL of absolut...

Embodiment 2

[0045] 2# core-shell hollow structure WO 3 mSiO 2 The concrete preparation steps of catalyst are as follows:

[0046] (1) Preparation method of W-6:

[0047] With the preparation method of W-6 among the embodiment 1.

[0048] (2) W-6SiO2 2 Microsphere preparation method:

[0049] Weigh 200mg of W-6 and 110mg of CTAB into a round bottom flask, add 20mL of absolute ethanol, disperse in ultrasonic wave for 30min, until the solid is completely dispersed, add 50mL of distilled water dropwise, and keep stirring at 28°C. After stirring for 6h, add 0.3mL ammonia water and 0.6mL TEOS, continue stirring at constant temperature for 16 hours, filter and dry to obtain W-6SiO 2 Microspheres. WO prepared in embodiment 2 3 mSiO 2 The SEM pictures of the microspheres are shown in figure 2 .

[0050] (3) WO 3 mSiO 2 Preparation of microspheres

[0051] Same as the preparation method of step (3) in Example 1.

Embodiment 3

[0053] 3# core-shell hollow structure WO 3 mSiO 2 The concrete preparation steps of catalyst are as follows:

[0054] (1) Preparation method of W-6:

[0055] With the preparation method of W-6 among the embodiment 1.

[0056] (2) W-6SiO2 2 Microsphere preparation method:

[0057] Weigh 200mg of W-6 and 110mg of CTAB into a round bottom flask, add 20mL of absolute ethanol, disperse in ultrasonic wave for 30min, until the solid is completely dispersed, add 60mL of distilled water dropwise, and keep stirring at 28°C. After stirring for 6h, add 0.3mL ammonia water and 0.6mL TEOS, continue stirring at constant temperature for 16 hours, filter and dry to obtain W-6SiO 2 Microspheres.

[0058] (3) WO 3 mSiO 2 Preparation of microspheres

[0059] Same as the preparation method of step (3) in Example 1.

[0060] WO prepared in embodiment 3 3 mSiO 2 The SEM pictures of the microspheres are shown in figure 1 . Depend on figure 1 It can be seen that the dispersion and unifo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com