Preparation method of star polycarboxylic acid high-performance water reducing agent

A high-performance, polycarboxylic acid technology, applied in the field of high-performance polycarboxylate superplasticizers, to achieve mild conditions, improve stability, and expand theoretical connotations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

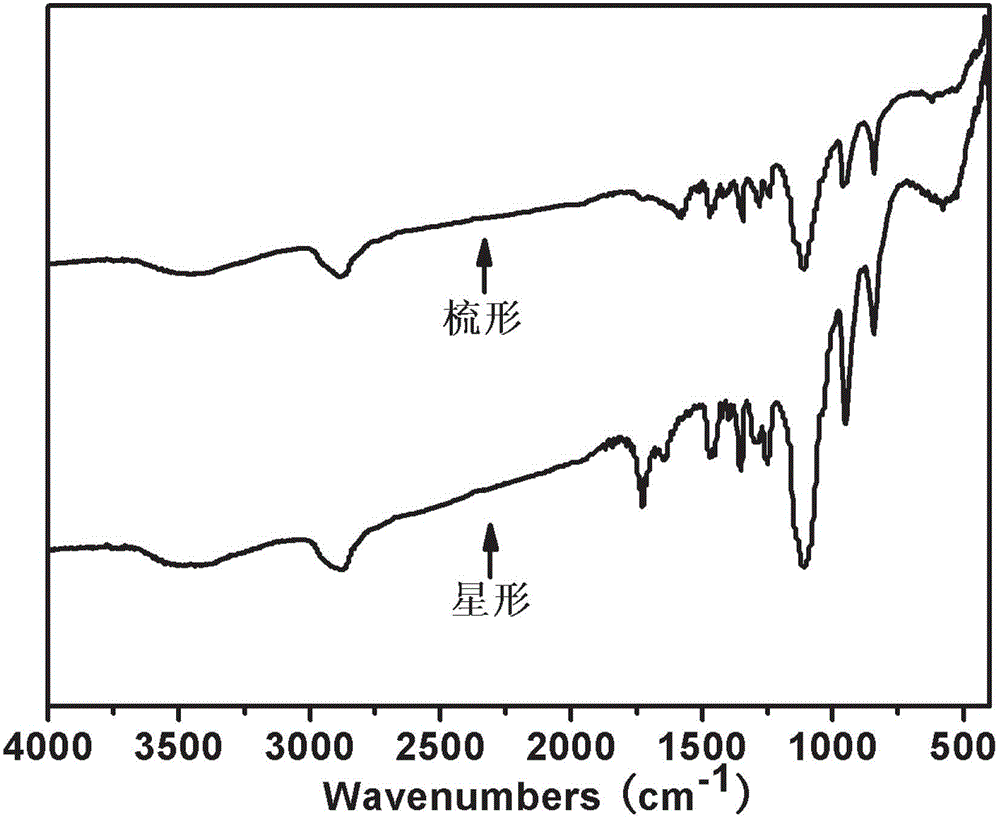

Image

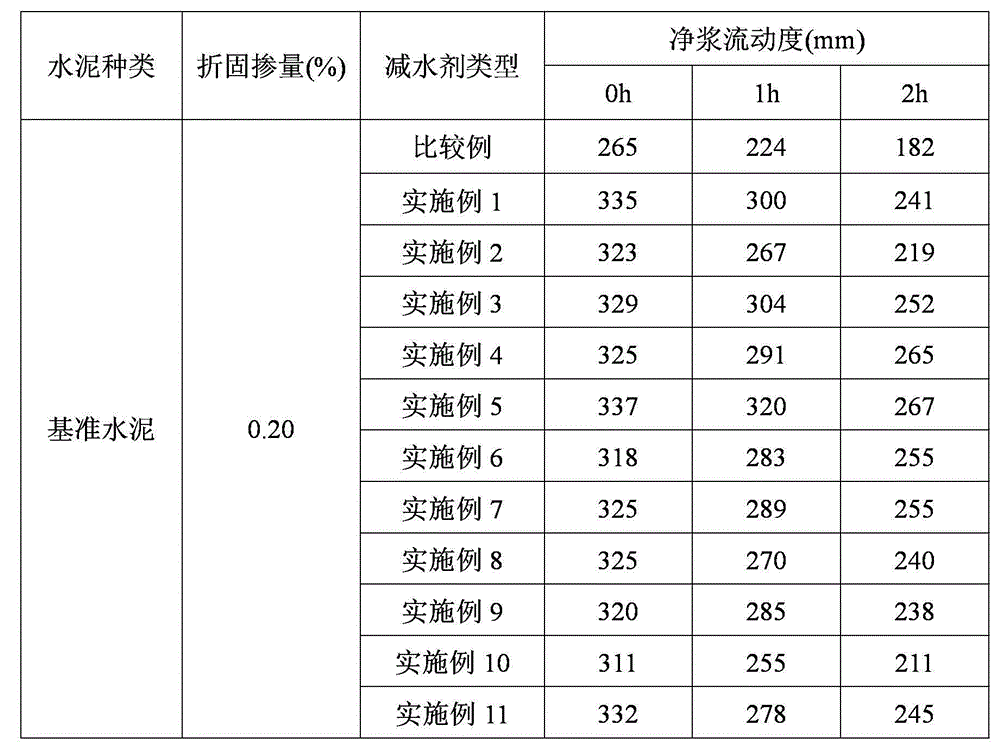

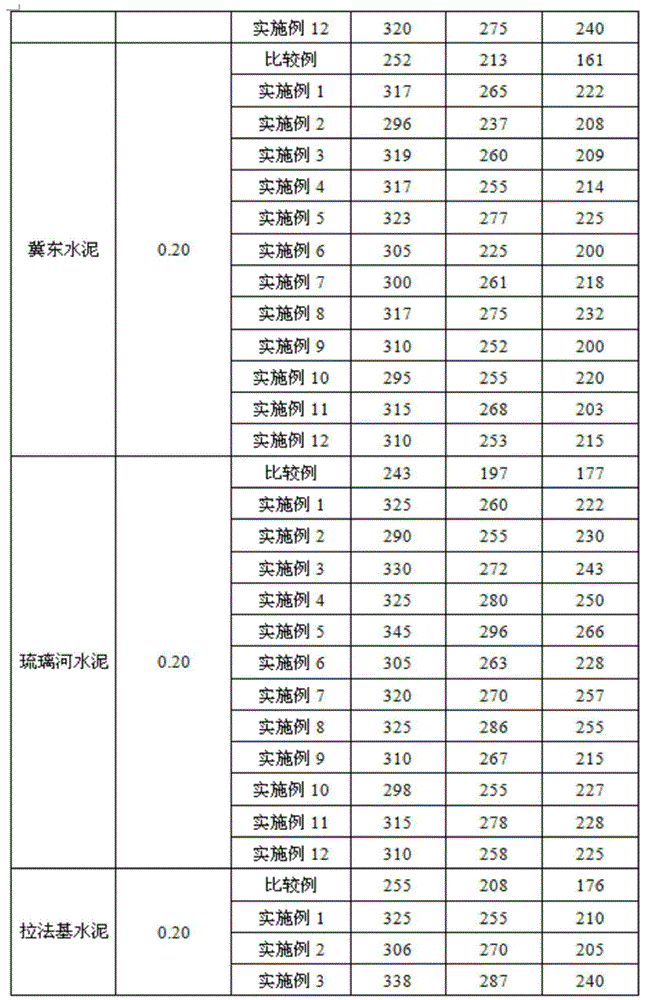

Examples

Embodiment 1

[0025] First, 20.13g of trimethylolpropane was added to the reactor, the temperature was raised to 40°C, 0.02g of hydroquinone methyl ether, 38.74g of methacrylic acid, and 0.88g of sulfamic acid were successively added to the reactor, and each feeding interval Stir for 20 minutes, add 17.66g of toluene when the temperature rises to 80°C, continue to raise the temperature to 150°C for esterification reaction, separate the water obtained during the reaction, and remove the water-carrying agent by vacuuming after 2 hours of reaction , to obtain the esterification reaction product; take 0.23g of the esterification reaction product and add it to the reactor, then add 72.97g of water, raise the temperature to 50°C and stir for 30 minutes until it is evenly mixed, then add 50g of allyl polyoxygen to the reactor in turn Vinyl ether (molecular weight = 500), 0.46g mercaptoacetic acid, 10.81g acrylic acid, 3.8g initiator ammonium persulfate solution with a mass fraction of 30%, and the ...

Embodiment 2

[0027] After the polycarboxylate superplasticizer with a concentration of 40% obtained in Example 1 was stored at 6°C for 30 days, its implementation effect was measured.

Embodiment 3

[0029] First, 10.93g of mannitol was added to the reactor, the temperature was raised to 80°C, 2.16g of hydroquinone, 43.24g of acrylic acid, and 5.42g of p-toluenesulfonic acid were successively added to the reactor, and the stirring time between each addition was 5 minutes. When the temperature rises to 100°C, add 16.25g of cyclohexane, and continue to heat up to 140°C for esterification reaction. During the reaction, the water obtained from the reaction is separated out. After 3 hours of reaction, the water-carrying agent is removed by vacuuming to obtain the ester reaction product; take 0.53g esterification reaction product and join in the reactor, add 51.75g water again, raise the temperature to 65 ℃ and stir for 10 minutes until it is mixed evenly, add 60g isobutenyl polyoxyethylene ether (molecular weight =3000), 3.04g n-dodecyl mercaptan, 0.6g acrylic acid and 4.09g maleic anhydride mixture, 142.87g mass fraction is 1% initiator ammonium persulfate solution, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com