High-efficient antisticking lubricant for drilling fluid

An anti-sticking lubricant and drilling fluid technology, applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve problems such as good lubrication effect, achieve good lubrication effect, low fluorescence level, and simple and easy preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

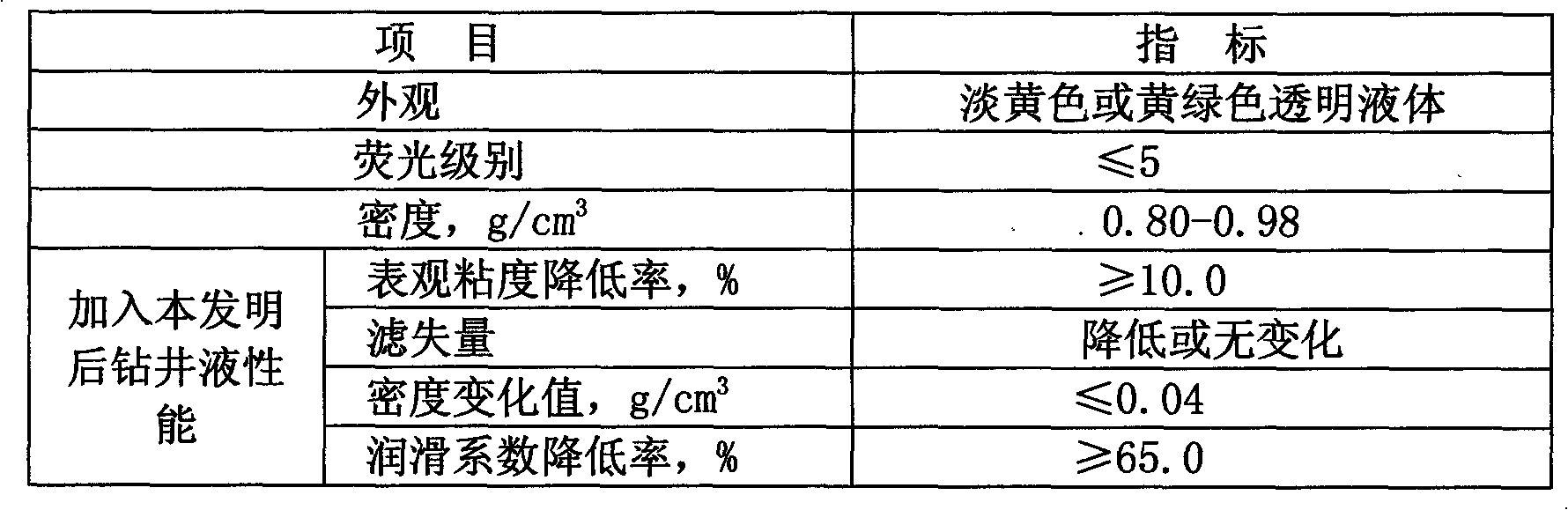

Embodiment 1

[0024] Embodiment 1: the lubricant of the present invention is to take white oil as main raw material, and oleic acid, methyl oleate are auxiliary materials, and defoamer, extreme pressure agent are five kinds of components that regulator mixes, wherein each component The percentage by weight is: white oil 55%, oleic acid 25%, methyl oleate 13%, defoamer 5%, extreme pressure agent 2%. The above-mentioned defoamer adopts a silicone type defoamer, that is, a silicone oil type defoamer (which can be simethicone). The above-mentioned extreme pressure agent adopts sulfurized olefin. The specific preparation method of the lubricant of the present invention is to take 55 kilograms of white oil, 25 kilograms of oleic acid, 13 kilograms of methyl oleate, 5 kilograms of defoamers, and 2 kilograms of extreme pressure agents, and put them into (conventional) stirring reactors respectively In, stir evenly to get the product. The appearance of the product is light yellow or yellow-green t...

Embodiment 2

[0025] Embodiment 2: The lubricant of the present invention is formed by mixing white oil as the main raw material, oleic acid and methyl oleate as auxiliary materials, and defoamer and extreme pressure agent as regulator.

[0026] Wherein the weight percentage of each component can be: 30% of white oil, 30% of oleic acid, 20% of methyl oleate, 10% of defoaming agent, 10% of extreme pressure agent.

[0027] Wherein the weight percent of each component can also be: white oil 70%, oleic acid 18%, methyl oleate 10%, defoamer 1%, extreme pressure agent 1%.

[0028] Wherein the weight percent of each component can also be: white oil 50%, oleic acid 28%, methyl oleate 12%, defoamer 5%, extreme pressure agent 5%.

[0029] Wherein the weight percentage of each component can also be: white oil 40%, oleic acid 20%, methyl oleate 20%, defoamer 10%, extreme pressure agent 10%. Of course, the weight percentage of each component can also take other values within the range.

[0030] The sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com