Biomass pyrolysis oil refining method

A biomass thermal cracking and refining method technology, applied in the field of biomass energy conversion, can solve the problems of high cost of additives, complex process, incomplete water removal and acid adjustment, etc., and achieves reduced corrosion, high specific surface area, and effective better results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

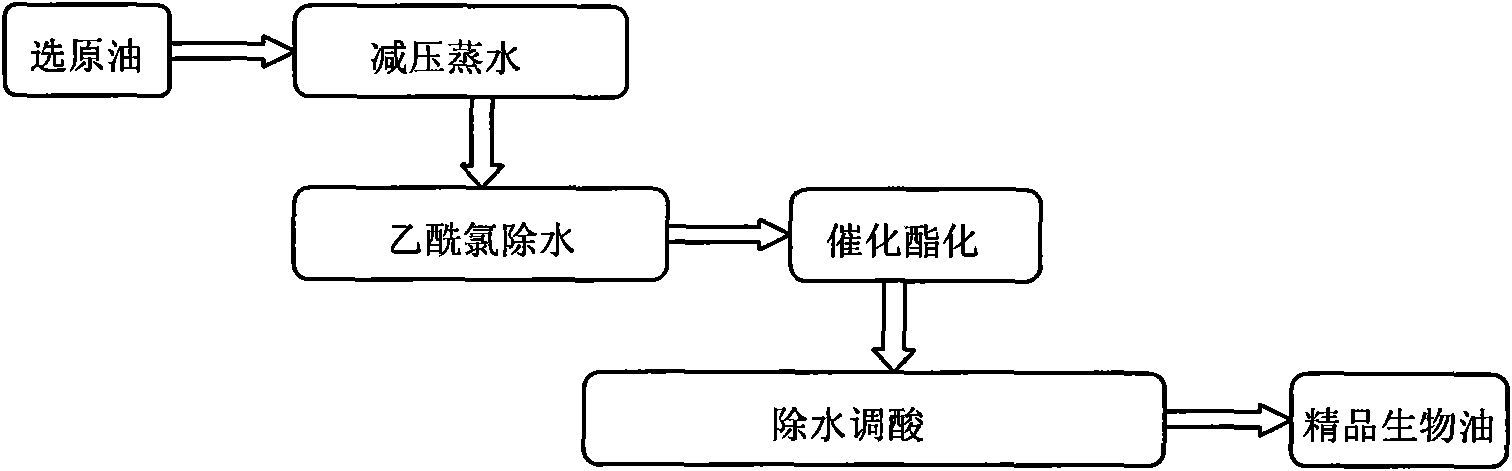

Method used

Image

Examples

Embodiment 1

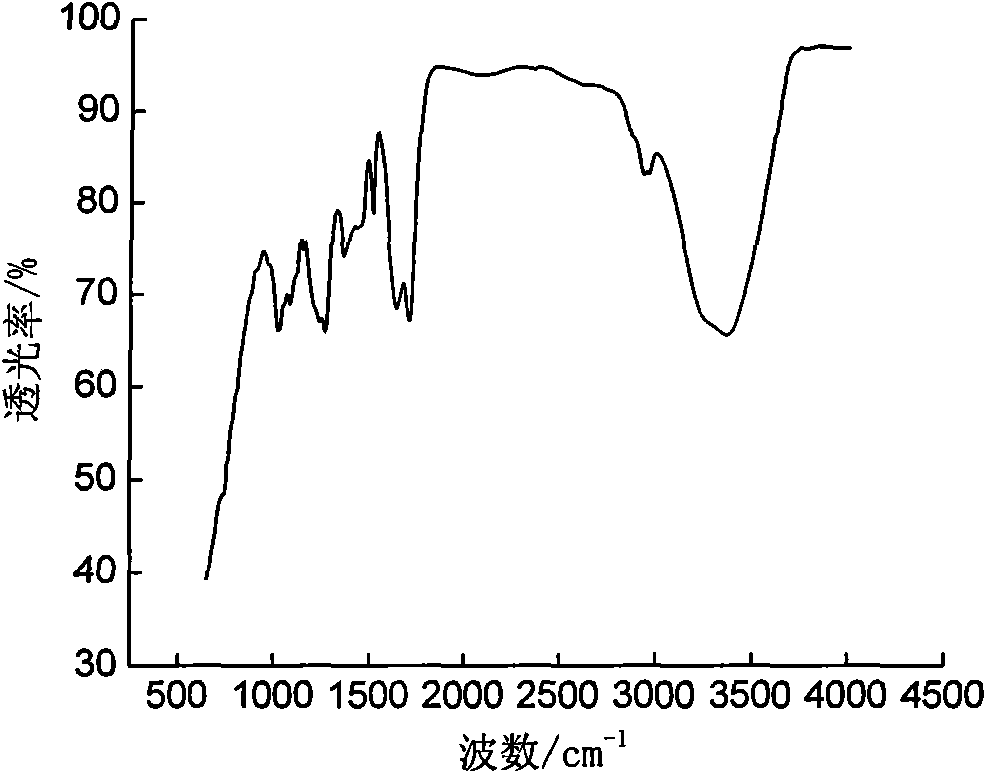

[0024] First do infrared spectrum analysis on the sawdust raw material bio-oil with a water content of about 30wt%. -1 There is a strong absorption peak nearby which is the symmetrical stretching vibration of C-O-C in ethers; at 1300cm -1 There is a strong absorption peak near the stretching vibration of the C-O bond; at 1400cm -1 There is a weaker absorption peak nearby is -CH in alkanes 3 The characteristic absorption peak; 1600cm -1 The absorption peak nearby is the absorption peak of C=C in the aromatic ring, which is the skeleton vibration of the benzene ring; at 1700cm -1 There is a strong absorption peak nearby which is the stretching vibration of C=O, which is the most recognizable absorption peak in infrared; at 3000cm -1 There are several weaker absorption peaks nearby are C-H and -CH in the benzene ring 3 ,-CH 2 Stretching vibration absorption peak of middle C-H; at 3400cm -1There is a strong absorption peak nearby, which is the -OH stretching vibration associ...

Embodiment 2

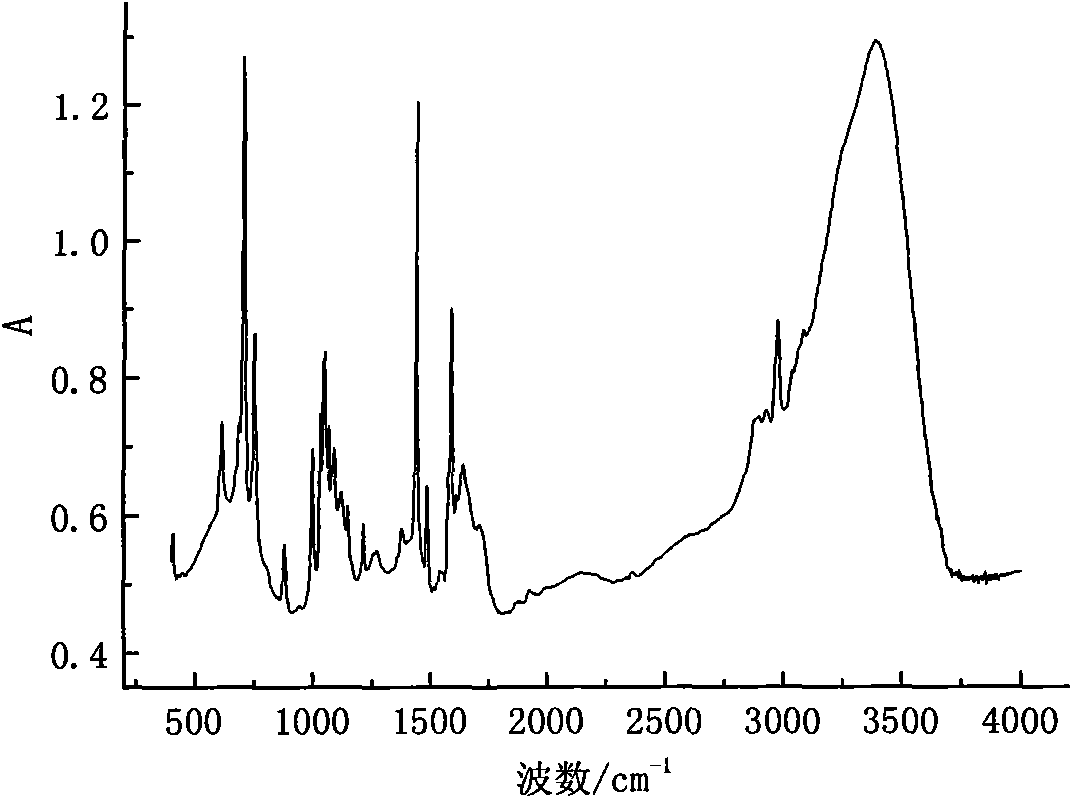

[0030] In this embodiment, straw raw material bio-oil with a water content of about 50% is taken, and the composition is more complex, containing a large amount of organic carboxylic acids (such as formic acid and acetic acid), which makes the pH of the bio-oil lower (1 to 3); Take 80mL of slow-speed oil and pour it into a distillation bottle, add 1 / 5 volume of isooctyl alcohol (which can delay the aging of oil at high temperature) and a few zeolites, use the vacuum pump to maintain a low vacuum of 0.02Mpa, and put it in a water bath at 80°C Distill under reduced pressure until basically no fraction flows out. This process can be completed within one hour, and most of the water (about 80%) and low-boiling components can be distilled out, because the distilled low-boiling components are very less, and the oxygen content is very high, so there is no need to re-separate and recover; the acetyl chloride dewatering method is to measure about 20mL of bio-oil after decompression disti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com