Method and device for continuously producing terephthalic acid-1,3-propylene glycol ester

A technology of polyterephthalic acid and terephthalic acid, which is applied in the field of organic synthesis, can solve the problems affecting the spinning effect and achieve the effects of reduced residence time, high esterification rate and excellent product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

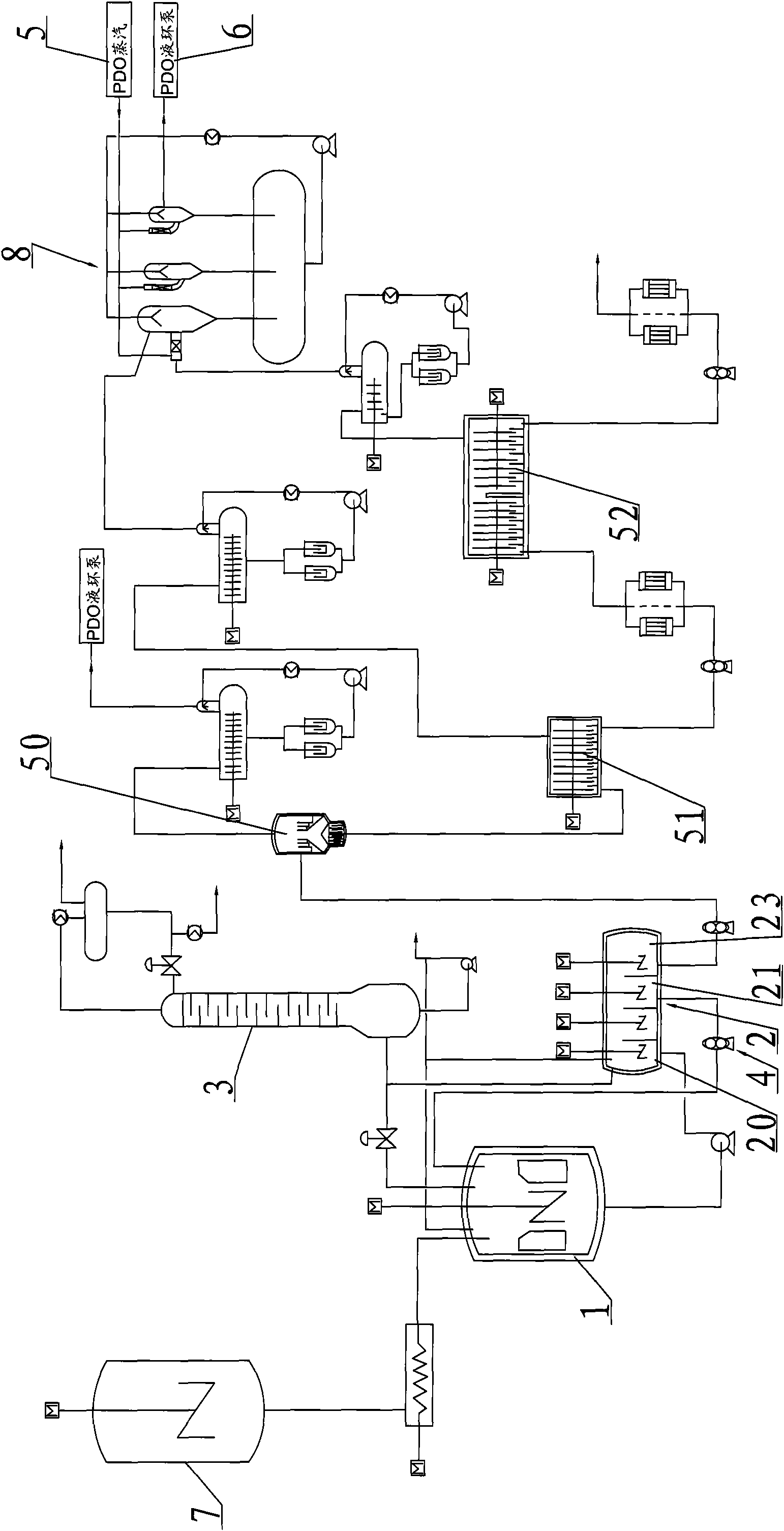

[0038] Such as figure 1 As shown, according to the present invention, the device for continuous production of PTT mainly includes beating kettle 7, the first esterification reactor 1, the second esterification reactor 2, esterification rectification tower 3, the first polymerization reactor 50, the second The polymerization reactor 51, the third polymerization reactor 52 and the supporting vacuum system 8. In addition, the device also includes some other supporting facilities such as auxiliary modulation and recovery equipment, all of which are well-known technical contents in the field, and conventional technologies can be used, and will not be described in detail here. In addition, it should also be understood that any reaction in the production of PTT polyester is carried out under stirring conditions or conditions equivalent to stirring, so the supporting facilities should at least cover stirring devices or provide similar stirring devices.

[0039] The second esterificat...

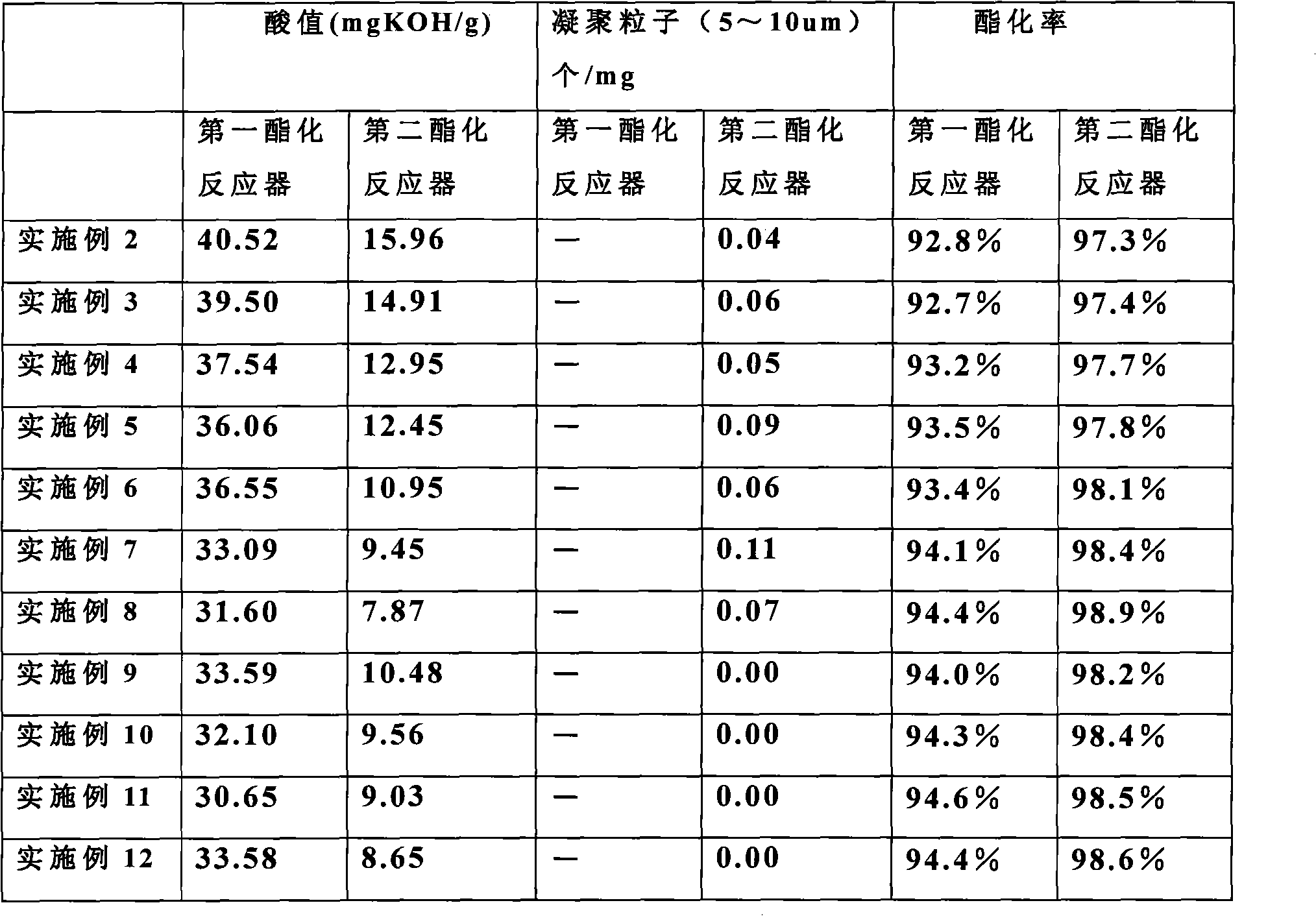

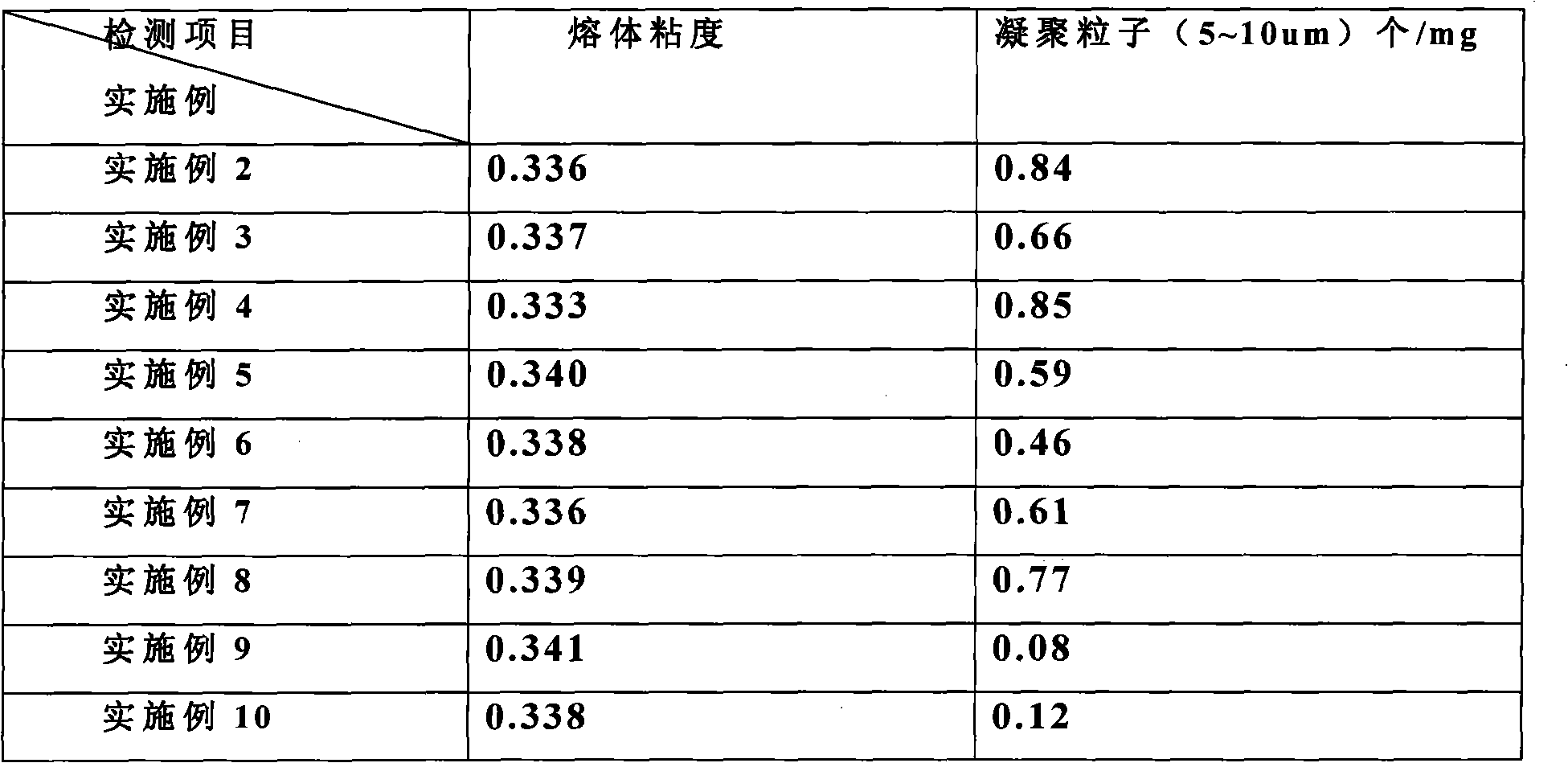

Embodiment 2

[0043] A method for continuous production of PTT, using figure 1 As shown in the apparatus, the method is as follows:

[0044] 1) In the beating tank, 1,3-propanediol and terephthalic acid were mixed at a molar ratio of 1.12:1, and then the mixed slurry was transported to the first esterification reactor 1 at a flow rate of 7.918 tons / hour.

[0045] 2) A titanium-tin-cobalt composite system is used as an esterification catalyst and a polymerization catalyst, and the titanium-cobalt-nickel composite system is composed of isopropyl titanate, titanium ethylene glycol, tin oxide dilaurate, and cobalt chloride.

[0046] 3) The above-mentioned titanium-tin-cobalt composite catalyst is made into a preparation liquid according to the following method: the titanium-tin-cobalt composite catalyst is mixed with 1,4-cyclohexanedicarboxylic acid and neopentyl glycol, heated and dissolved to obtain a preparation liquid, The requirements for each component in the formulated liquid are: the c...

Embodiment 3

[0055] A method for continuous production of PTT, using figure 1The device shown is basically the same as in Example 1, except that the molar ratio of 1,3-propanediol to terephthalic acid is 1.25:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com