Method for preparing biodiesel through high-temperature esterification reaction of high acid value oil

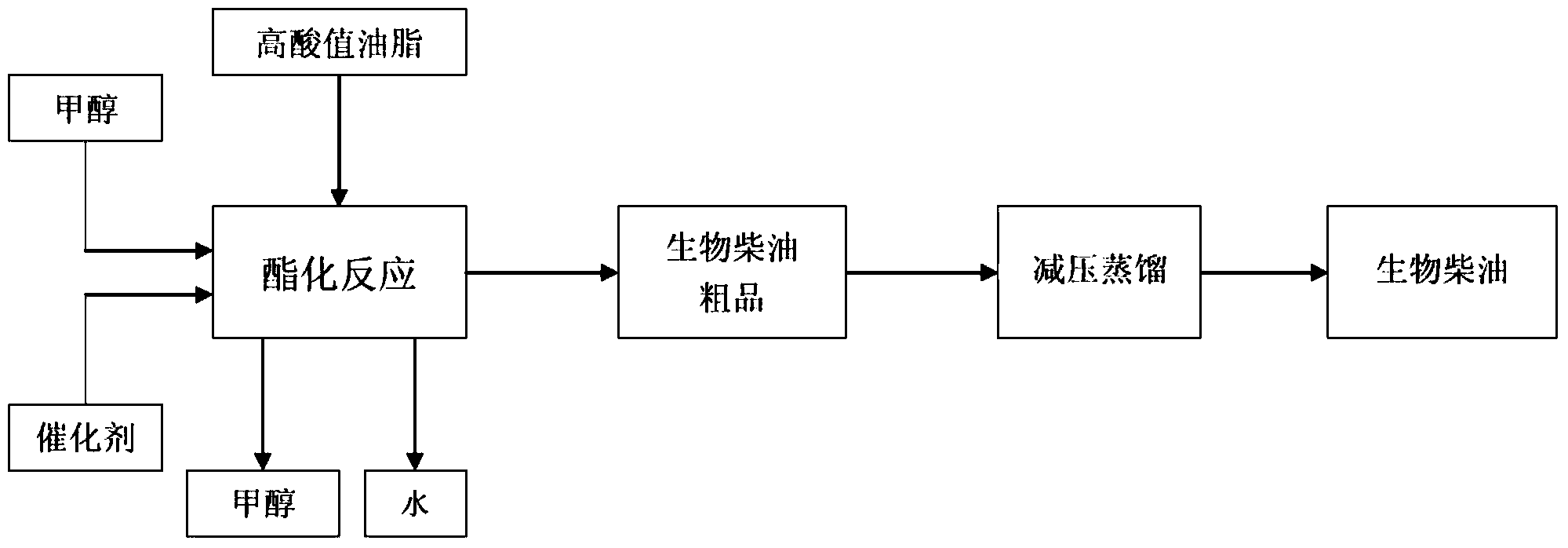

A high-acid value grease and esterification technology, which is applied in fatty acid esterification, biofuel, petroleum industry, etc., can solve the problem of immature biodiesel preparation technology, inability to realize industrial mass production, and low conversion rate of methanol esterification and other problems, to achieve the effect of improving primary esterification capacity, shortening the production cycle, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

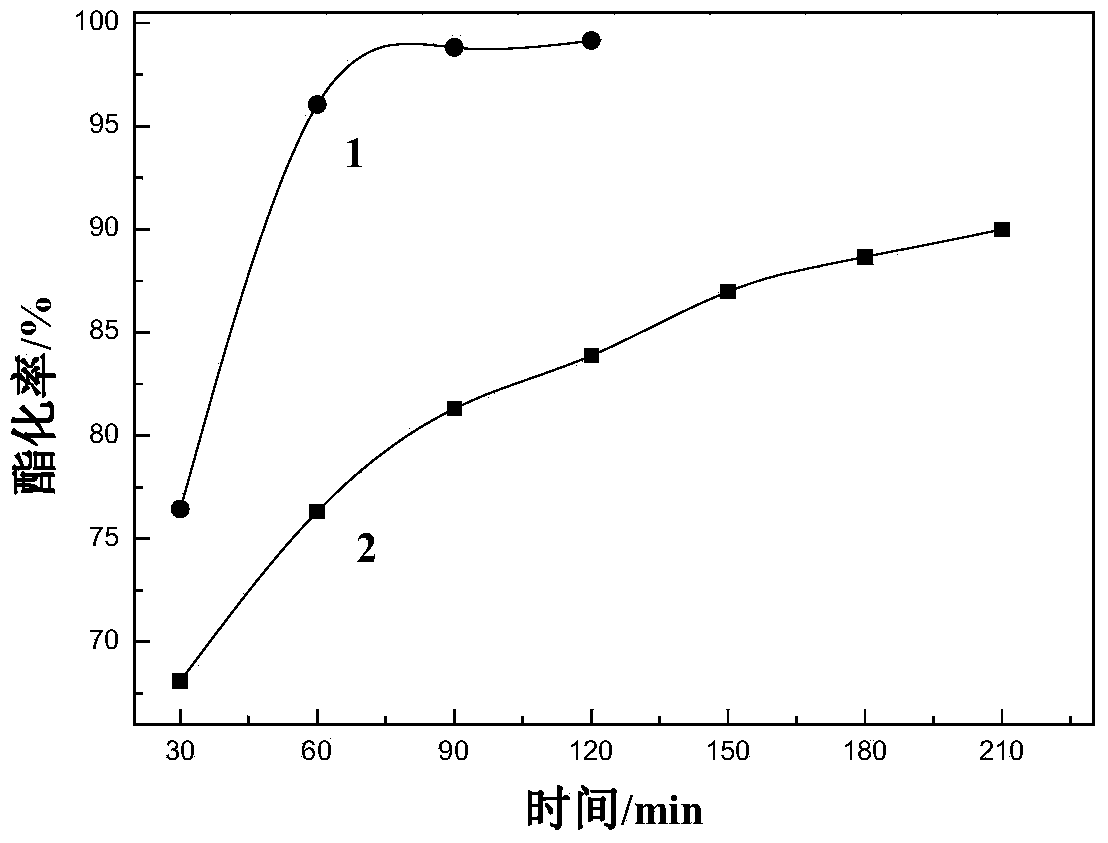

[0031] (1) Esterification reaction: add palmitic acid (acid value 178.8 mgKOH / g) and catalyst concentrated sulfuric acid to the esterification reactor in sequence, the amount of concentrated sulfuric acid is 0.10% of the mass of palmitic acid, turn on the stirring and heating device, and raise the temperature to 125°C After the temperature is constant, methanol is slowly added dropwise to the esterification reactor through a peristaltic pump to carry out the esterification reaction. At the same time, the condensing device cools the unreacted methanol and the moisture generated by the reaction. The amount of methanol is 90.0% of the mass of palmitic acid. The dropping rate of methanol was adjusted so that the whole dropping process was completed within 2.0 h; the reaction was continued for 10 min after the dropping was completed, and the esterification rate was 99.15%. Finally, unreacted methanol and generated water were distilled off to obtain crude biodiesel.

[0032] (2) Dist...

Embodiment 2

[0035] (1) Esterification reaction: add oleic acid (acid value 195.0 mgKOH / g) and catalyst p-toluenesulfonic acid to the esterification reactor in sequence, the amount of p-toluenesulfonic acid is 0.15% of the mass of oleic acid, turn on the stirring and heating device , raise the temperature to 130°C, and after the temperature is constant, slowly add methanol dropwise to the esterification reactor through the dropping device to carry out the esterification reaction. At the same time, the condensing device cools the unreacted methanol and the water generated by the reaction. 75.0% of the mass, and the methanol drop rate was controlled so that the entire dropwise addition process was completed within 4.0 h; after the dropwise addition was completed, the reaction was continued for 15 min, and the esterification rate was 98.96%. Finally, unreacted methanol and generated water were removed by distillation to obtain Crude biodiesel.

[0036] (2) Distillation treatment: Distill the ...

Embodiment 3

[0039] (1) Esterification reaction: add acidified oil (acid value 80.0 mgKOH / g) and catalyst concentrated sulfuric acid to the esterification reactor in sequence. After the temperature is constant, methanol is slowly added dropwise to the esterification reactor through the dropping device to carry out the esterification reaction. At the same time, the condensing device cools the unreacted methanol and the moisture generated by the reaction. The amount of methanol used is 60.0% of the acidified oil quality. The dropping rate of methanol was controlled so that the whole dropping process was completed within 2.5 h; the reaction was continued for 10 min after the dropping was completed, and the esterification rate was 98.54%. Finally, unreacted methanol and generated water were distilled off to obtain crude biodiesel.

[0040] (2) Distillation treatment: Distill the crude biodiesel produced in step (1) under reduced pressure with a vacuum of -0.1 MPa, and collect fractions at a tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com