Patents

Literature

32results about How to "Reduce process water consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

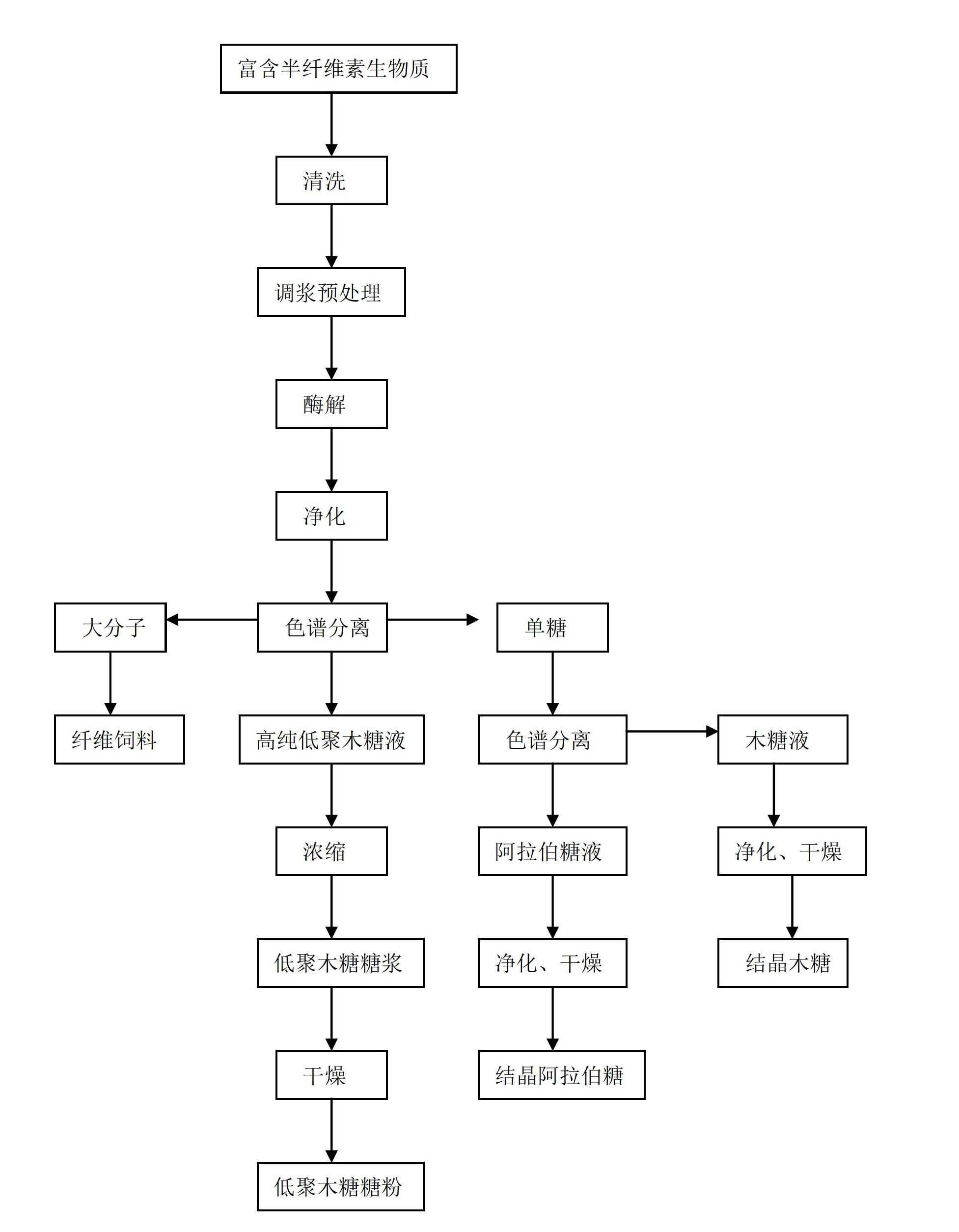

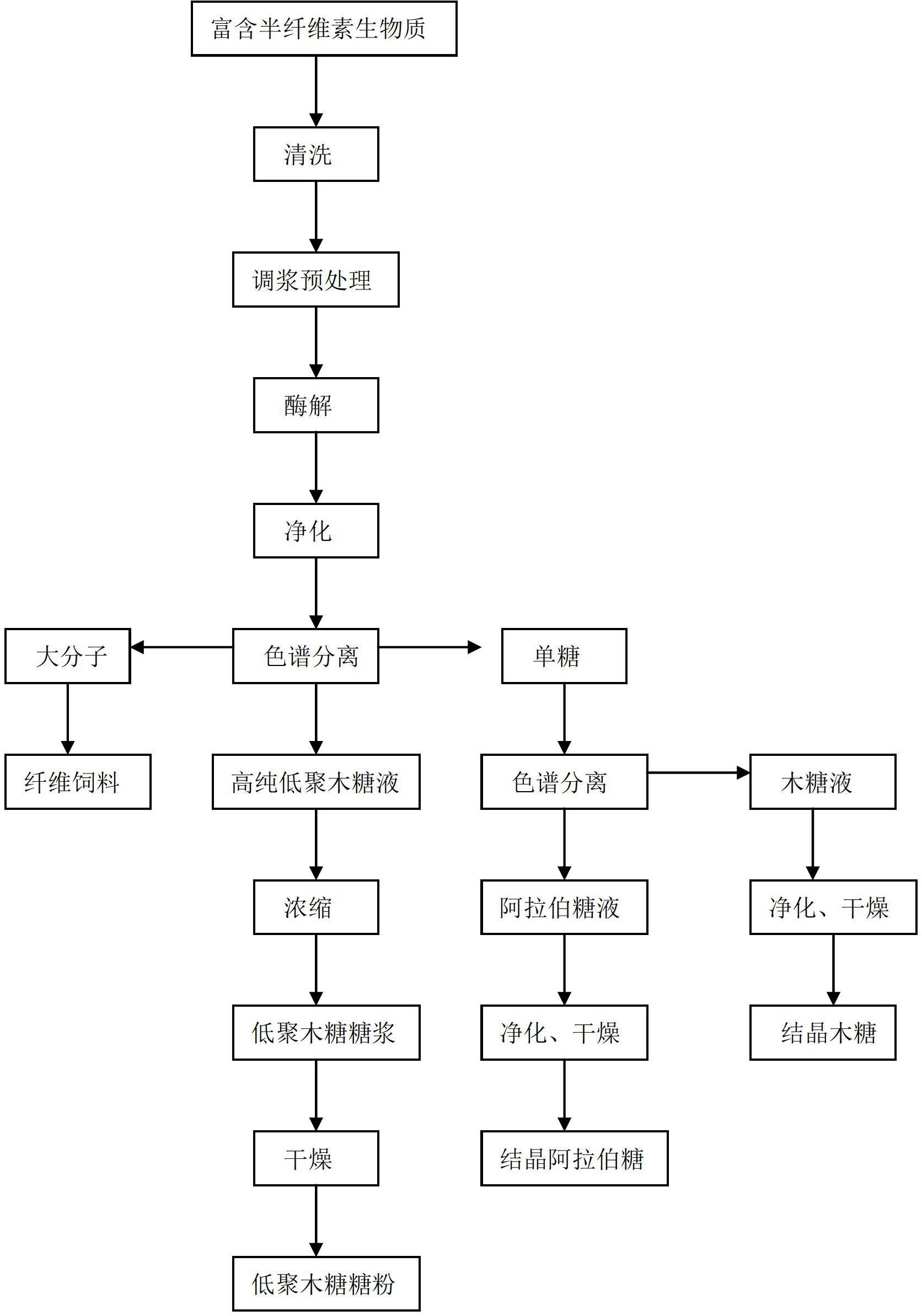

Bio-preparation method for production of high-purity xylo-oligosaccharide and coproduction of arabinose and xylose

ActiveCN102660606AEfficient full value conversionNo churnSugar derivativesSugar derivatives preparationChromatographic separationFiber

The invention discloses a bio-preparation method for production of high-purity xylo-oligosaccharide and coproduction of arabinose and xylose. The method comprises the following steps of: washing hemicellulose-enriched biomass, performing size mixing pretreatment, adding xylanase, performing enzymolysis, and separating and purifying to obtain mixed liquid glucose; concentrating the mixed liquid glucose until the mass concentration is 50 to 70 percent, and performing chromatographic separation to sequentially obtain AD phase, BD phase, CD phase and BD phase, and concentrating the BD phase to obtain a high-purity xylo-oligosaccharide syrup liquid product; concentrating the CD phase, mixing with cellulosic materials, drying, and crushing to prepare fiber feed; performing yeast fermentation on the AD phase to remove glucose, removing impurities, purifying, concentrating and performing chromatographic separation to obtain the high-purity xylose liquid and arabinose liquid; concentrating the xylose liquid, crystallizing, separating and drying to obtain crystallized xylose; and concentrating arabinose liquid, crystallizing, separating and drying to obtain crystallized arabinose. The invention also provides a bio-preparation method for arabinose and xylose.

Owner:SHANDONG LONGLIVE BIO TECH CO LTD

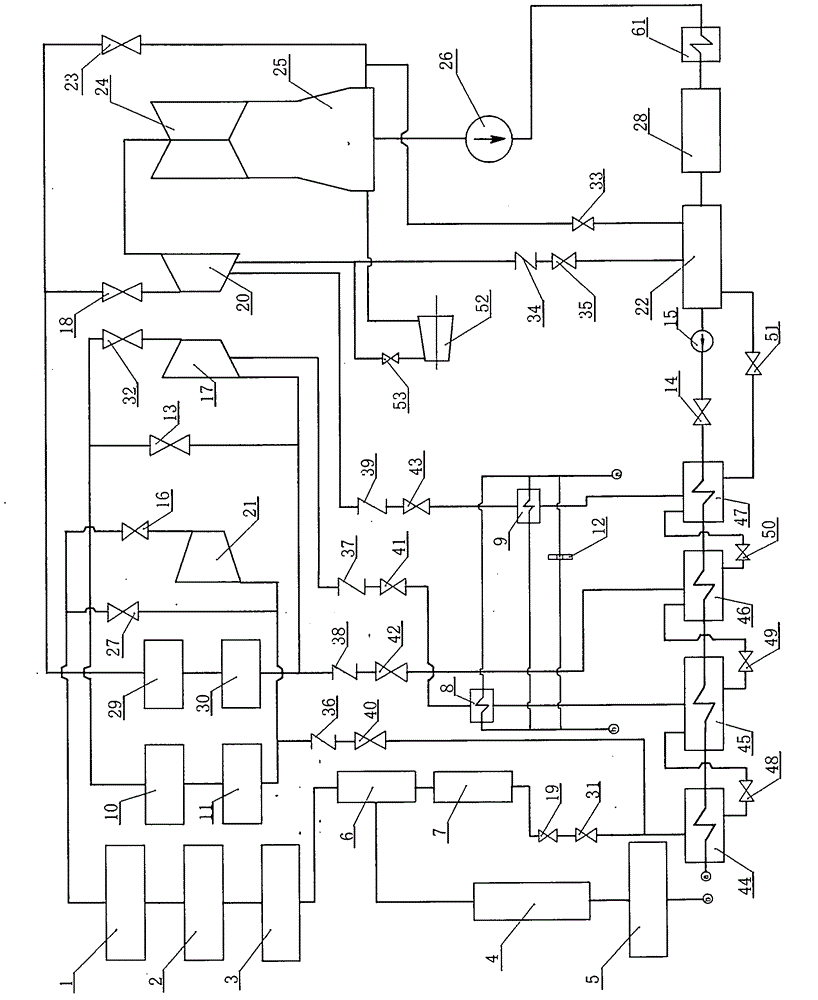

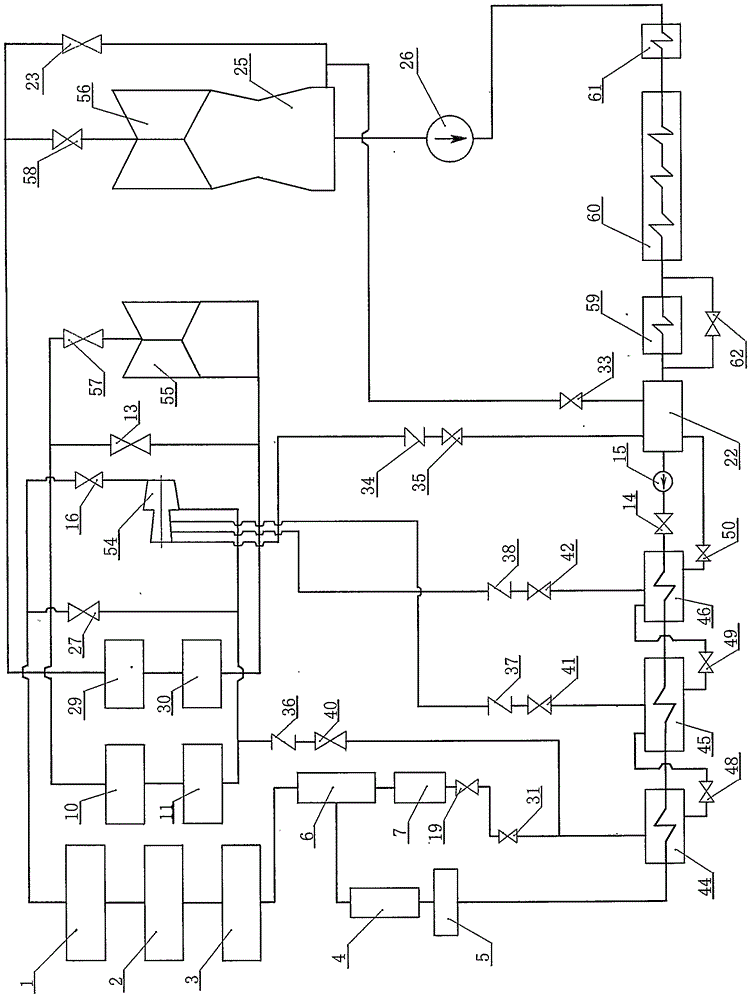

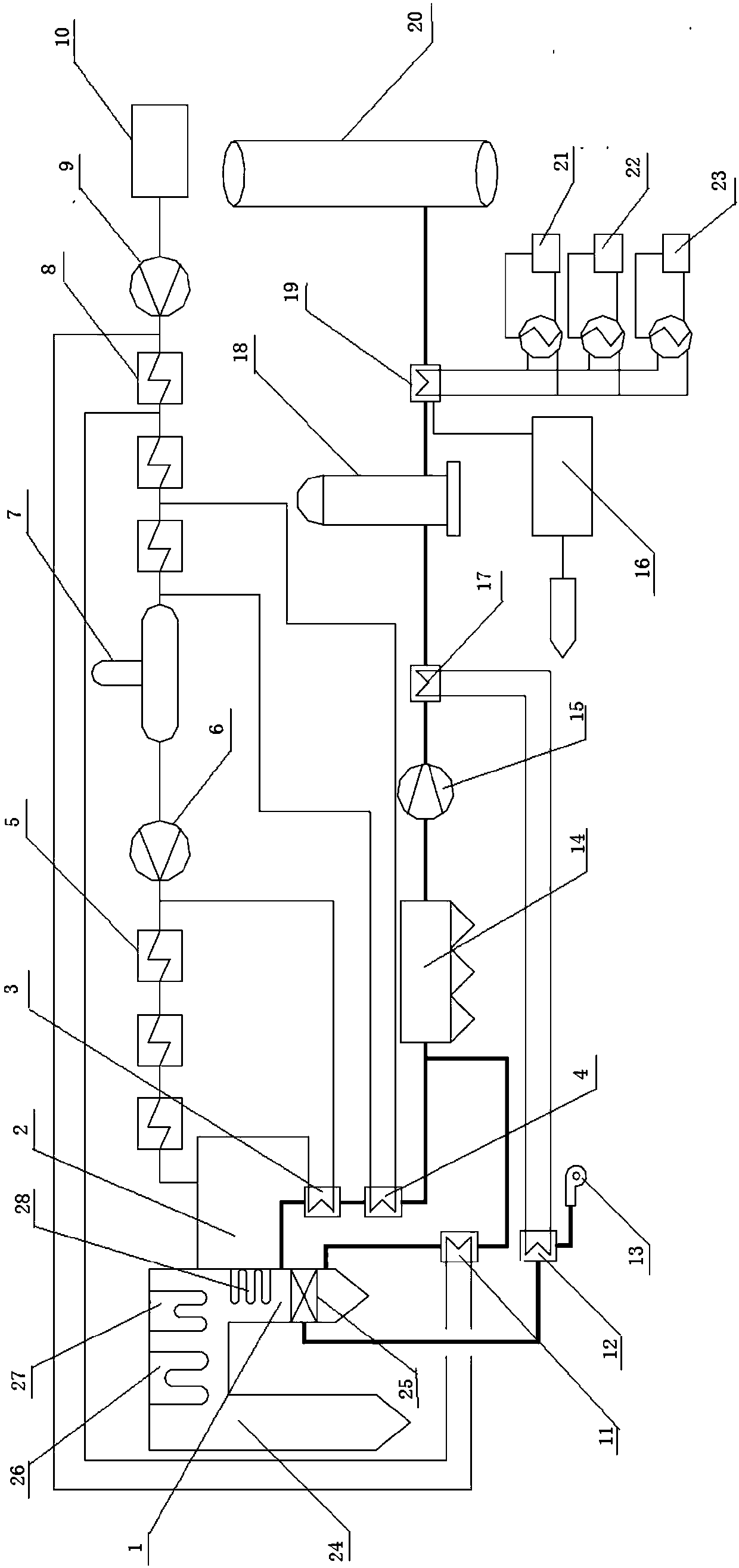

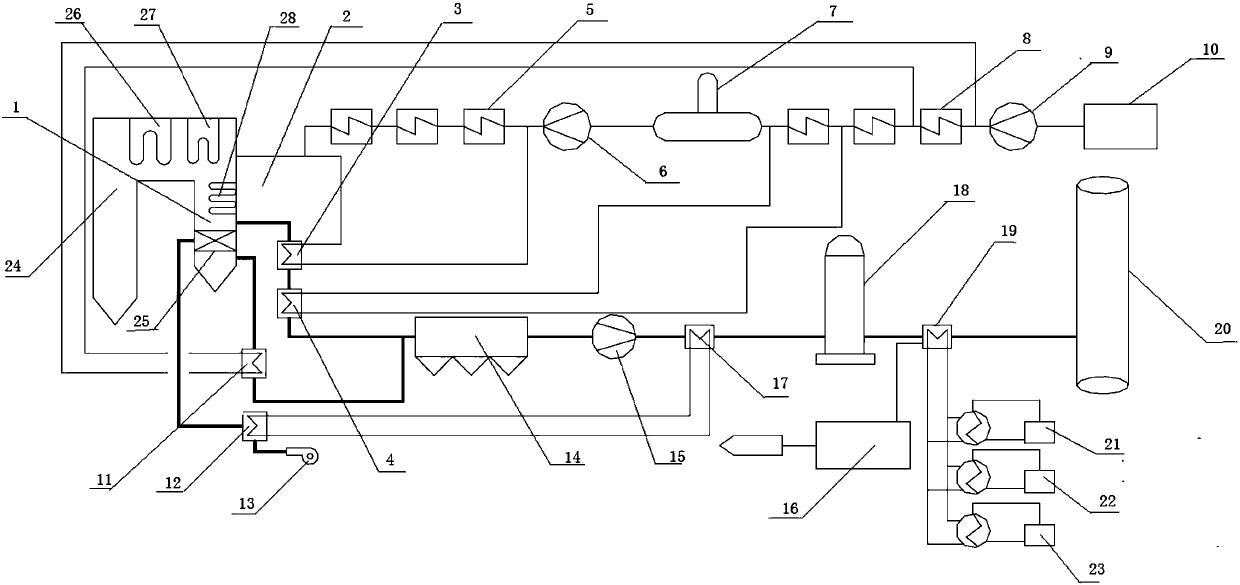

Optimum scheme of ultra-supercritical secondary reheating unit

ActiveCN104806308AIncrease output powerReduce heat consumptionSteam engine plantsUltra high pressureEngineering

The invention discloses an optimum scheme of an ultra-supercritical secondary reheating unit, and refers to a secondary reheating unit of a coal-fired power plant after optimization of a back heating system, parameter optimization of main steam, primary reheating steam, and secondary reheating steam, and structural optimization of a turbine body. The optimum scheme of the ultra-supercritical secondary reheating unit can obviously reduce the heat loss of the secondary reheating unit, and significantly decrease greenhouse gas emission and decreases cost of the ultra-supercritical secondary reheating unit obviously. By taking a 1200 MW grade unit as an example, four mono-axial cylinders are used for gas exhausting, the ultra-supercritical secondary reheating unit is composed of a single-flow ultra-high pressure cylinder capable of completely supplying water, back-heating and pumping gas, a dual-flow high and medium pressure cylinder, and two dual-flow middle and low pressure cylinders; there is no middle pressure cylinder and a middle low pressure linking pipe; no gas pumping opening is arranged on the high middle pressure cylinder and the middle low pressure cylinder; the water supply and back heating are provided by a first pump, a new second pump, a new third pump, and a new fourth pump; a ultra-low temperature coal economizer, and a heat primary wind condensing water heater replace a seventh pump, an eighth pump, a ninth pump, and a tenth pump to heat the condensed water; all low-pressure heaters are canceled.

Owner:章礼道

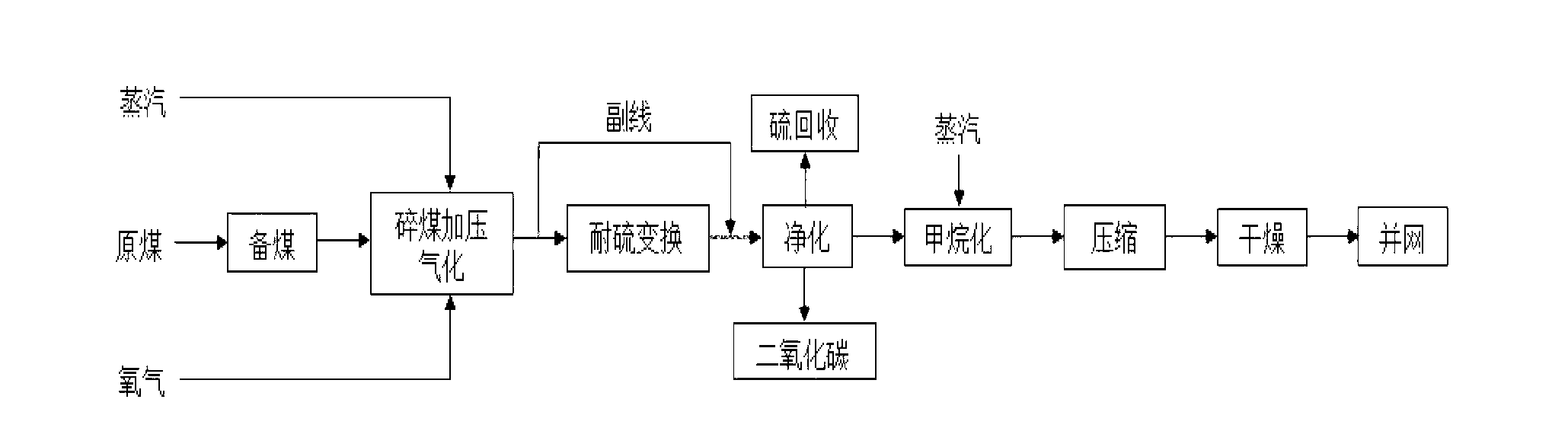

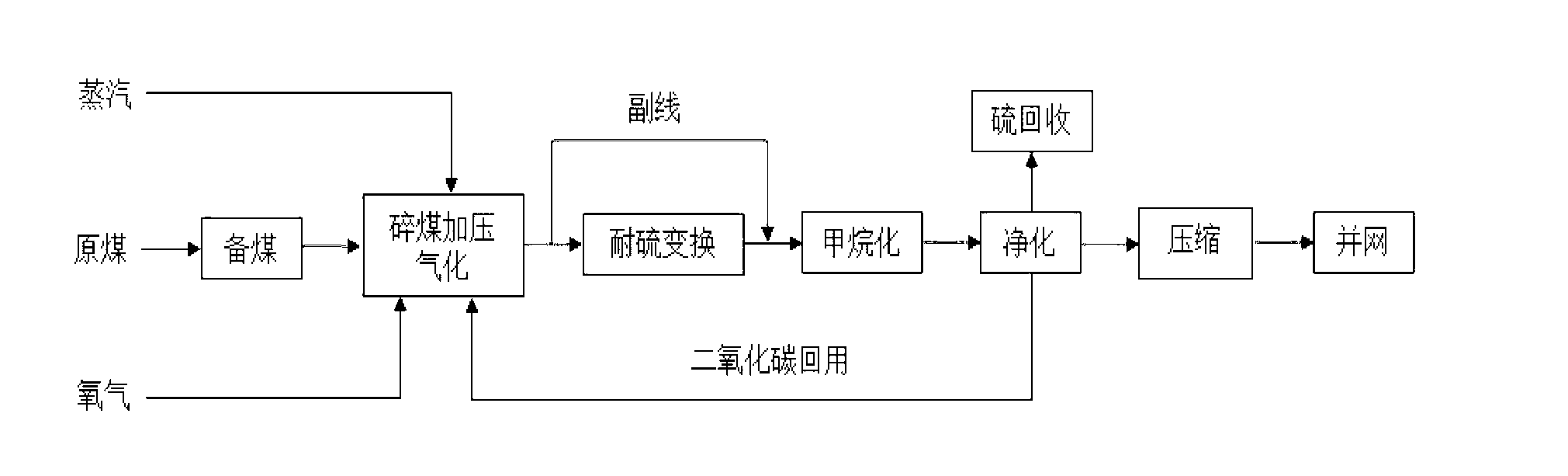

Method for manufacturing natural gas by utilizing low-rank coal

The invention relates to a method for manufacturing natural gas by utilizing low-rank coal. The method comprises the following steps of charging multielement gasifying agent consisting of oxygen, steam and carbon dioxide into a crushed-coal pressurized gasification furnace to gasify the low-rank coal to produce raw gas and obtain the raw gas containing methane gas; charging a part of raw gas into a furnace filled with cobalt-molybdenum sulfur-resistant oil-resistant catalyst to carry out a CO conversion reaction, combining the other part of raw gas with the gas subjected to the CO conversion reaction through a sub-line so that the molar ratio of H2 to CO is within 3.05-3.45 and meets the requirement of a raw material gas for synthesizing the methane; synthesizing the methane in a methanation device filled with a MoSi2 sulfur-resistant catalyst by utilizing the conversed gas; and enabling the methanated mixed gas to pass through cool, dehydrated and deacidified gas to obtain products with high natural gas product quality standard ruled in the national standard GB-17820-1999. The method disclosed by the invention has the advantages of high efficiency, energy conservation and environment protection.

Owner:SEDIN ENG

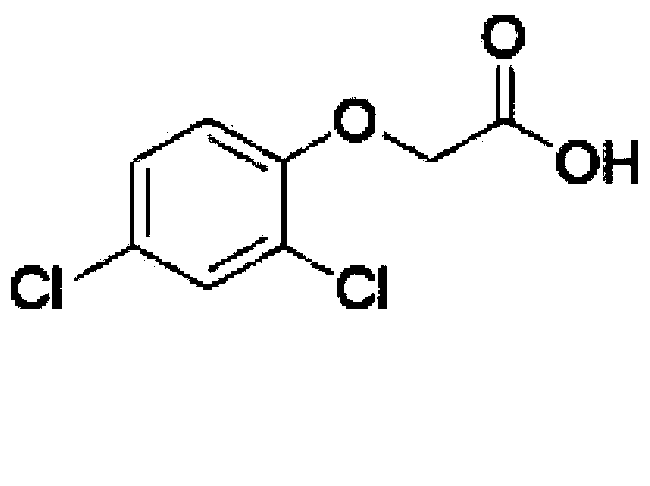

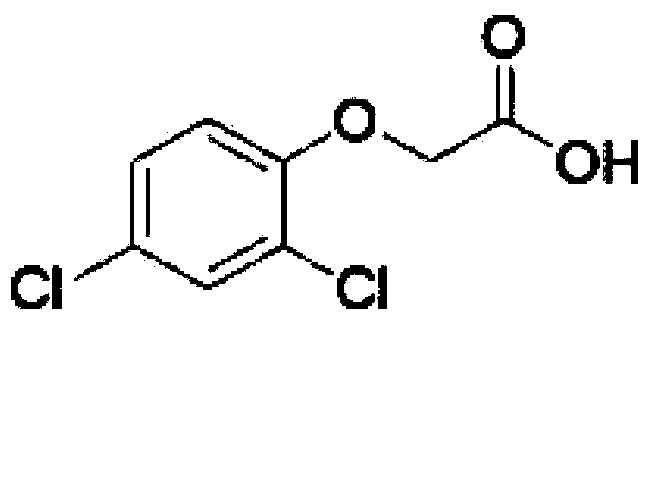

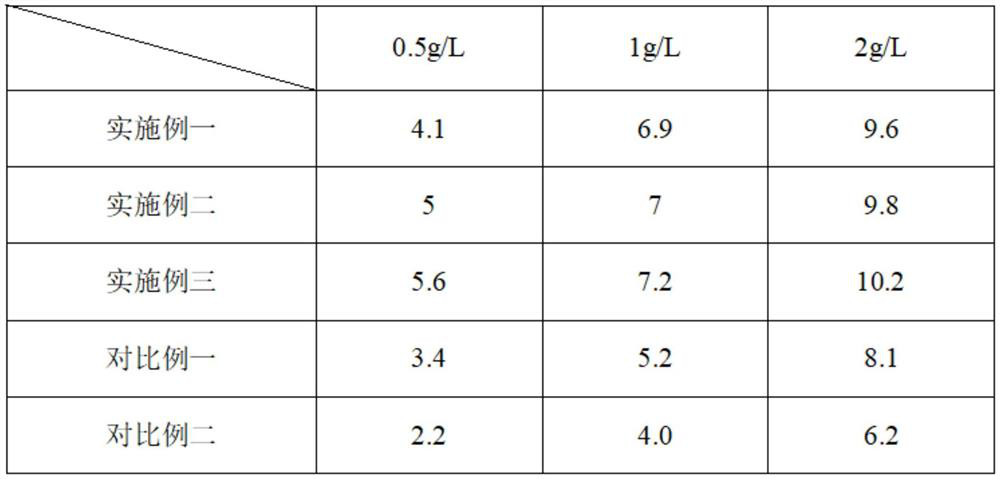

Preparation method of high-purity 2,4-D

ActiveCN103351296AImprove reaction efficiencyReduce Process Water ConsumptionPreparation from carboxylic acid saltsOrganic compound preparationFiltrationChloroacetic acids

The invention discloses a preparation method of high-purity 2,4-D. The preparation method comprises the following steps: (1) preparing 2,4-bitionolate; (2) enabling chloroacetic acid and the 2,4-bitionolate to directly react under the alkaline condition to obtain 2,4-D sodium salt; (3) achieving pressure filtration and acidification of the 2,4-D sodium salt to form a 2,4-D crude product; (4) rinsing- pressure-filtering and drying the 2,4-D crude product to obtained to the high-purity 2,4-D product. The preparation method provided by the invention can effectively reduce the process water consumption, simplify the process steps, greatly shorten the reaction time and improve the product yield.

Owner:山东科源化工有限公司

Acidum folicum production method without sewerage discharge

Owner:JIHENG PHARMA HENGSHUI CITY

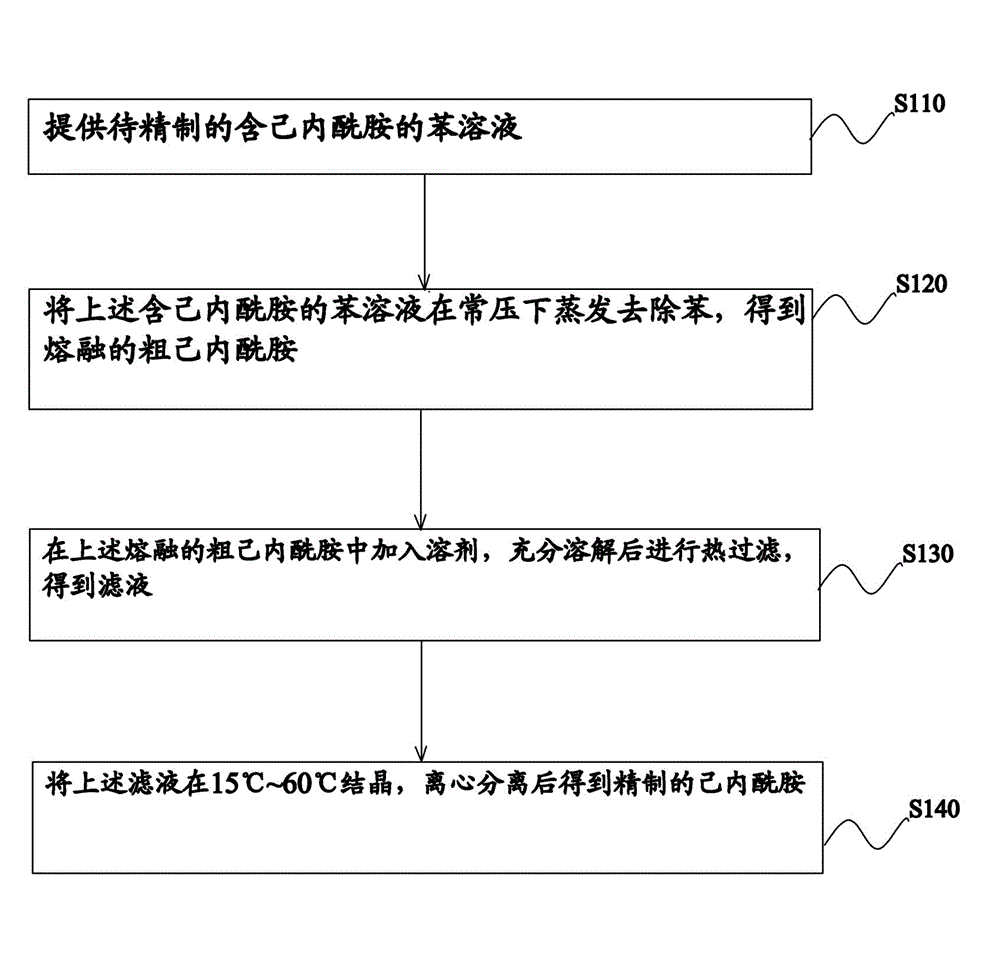

Method for refining caprolactam

InactiveCN105017153ASimple processReduce process water consumptionOrganic chemistry methodsLactams separation/purificationSolventChemistry

The invention provides a method for refining caprolactam. The method comprises the following steps: providing a caprolactam-containing benzene solution to be refined; evaporating the caprolactam-containing benzene solution under normal pressure to remove benzene, thus obtaining molten crude caprolactam; adding a solvent to the molten crude caprolactam, hot filtering after the molten crude caprolactam is completely dissolved, thus obtaining a filtrate; and crystallizing the filtrate at 15-60 DEG C and separating centrifugally to obtain refined caprolactam. The method for refining caprolactam is simple in process flow and moreover the water consumption of the process is reduced greatly.

Owner:CHINA PETROLEUM & CHEM CORP

Desulfurization wastewater treatment method

InactiveCN106986401AAchieve pollutionNo corrosion problemsGeneral water supply conservationWaste water treatment from gaseous effluentsGas phasePhase change

The invention discloses a desulfurization wastewater treatment method, and belongs to the field of desulfurization wastewater treatment. A hot air unit introduces hot air into a phase change generator; meanwhile, a wastewater system conveys desulfurization wastewater to an atomizer in the phase change generator for atomization, hot wind formed by the desulfurization wastewater and the hot air is changed into a gas phase from a liquid phase through mass and heat exchange and the gas phase is discharged from an outlet of the phase change generator along with the hot wind; a solid formed by impurity crystal in the desulfurization wastewater enters the hot air unit at a solid outlet of the phase change generator under the action of gravity. According to the desulfurization wastewater treatment method, hot air in the phase change generator and atomized desulfurization wastewater drops are subjected to mass and heat exchange, and the desulfurization wastewater drops are evaporated and crystallized and then subjected to gas-solid separation. The problems that an original desulfurization balance is broken and equipment corrosion is caused in the desulfurization wastewater treatment process in a flue are solved, so that zero pollution and zero emission of the desulfurization wastewater are achieved.

Owner:张玉君

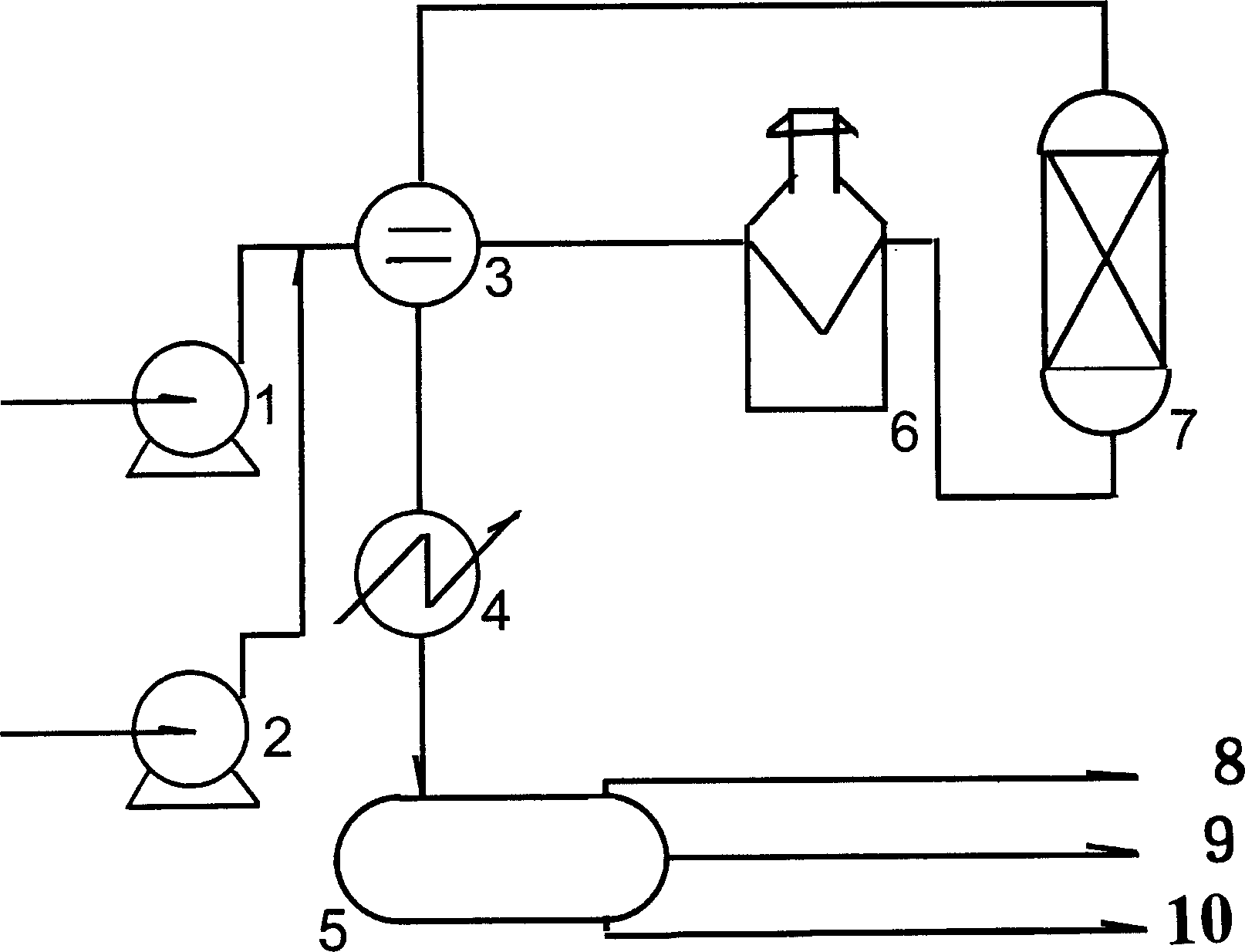

Method for low-pressure continuous hydrolysis preparation of fatty acid

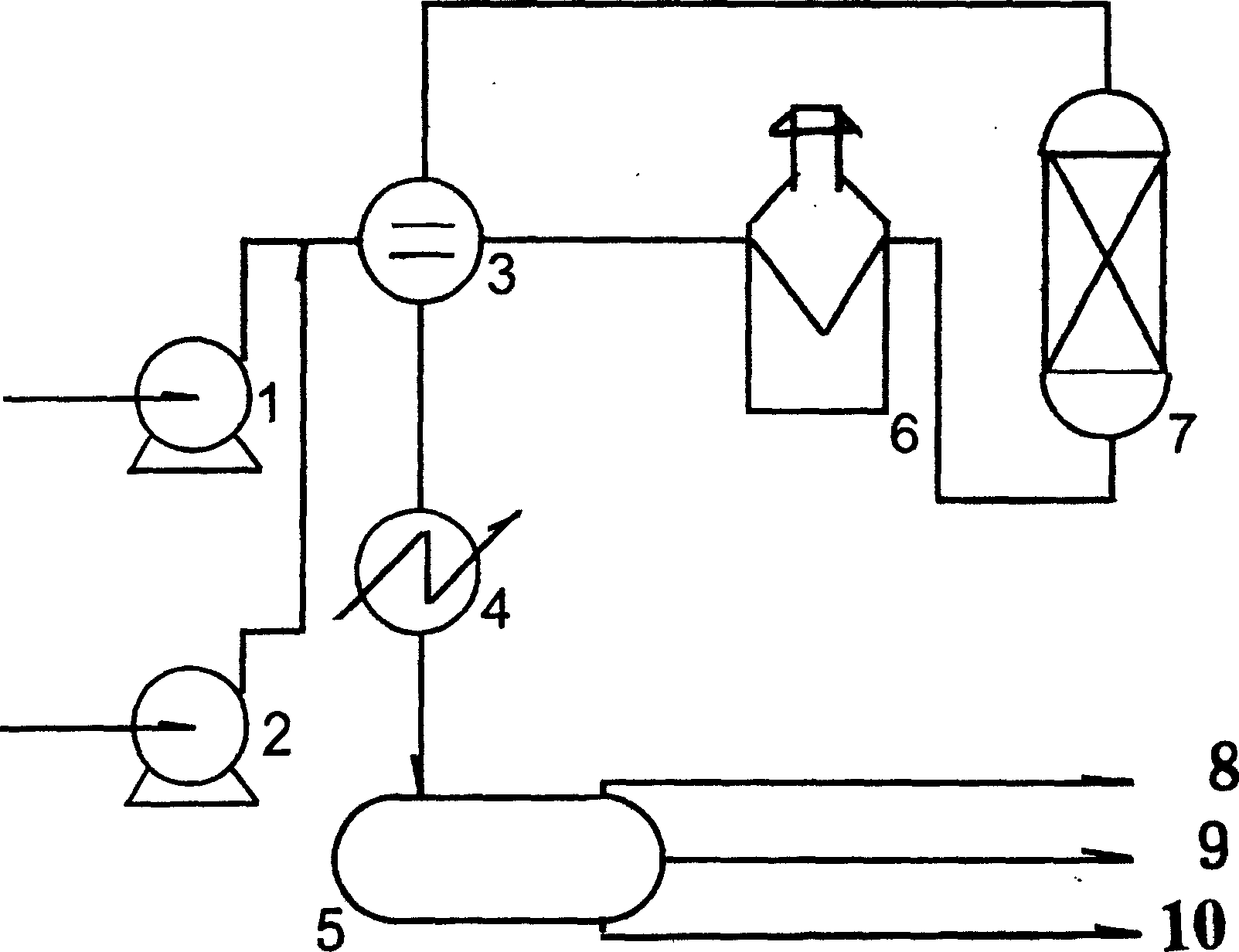

InactiveCN1544595AReduce partial pressureIncrease hydrolysis rateFatty acid chemical modificationIodo fatty acidDecomposition

The invention provides a process for preparing fatty acid through low pressure continuous hydrolytic decomposition, wherein the water-oil weight ratio is 5-30:100, the pump output pressure is controlled between the range of 0.02-0.5MPa, preferably between 0.1-0.4MPa, the raw materials are subjected to heat transfer through heat exchanger and are charged into heating-furnace to be heated to 250-500 deg. C and enter reactor, reacting for 2-30 minutes and the reaction product is led out, the fatty acid is obtained by straight distillation of separated crude fatty acid or fuel gas.

Owner:陈天晓

Novel flue gas waste heat recycling method

PendingCN110030861AReduce the efficiency of SO3 removalImprove the efficiency of SO3 removalRecuperative heat exchangersEmission preventionFlue gasProcess engineering

The invention discloses a novel flue gas waste heat recycling method. The novel flue gas waste heat recycling method is characterized in that flue gas temperatures of all sections of the tail portionof a flue of a boiler are different, so that high-temperature flue gas heat exchangers of corresponding energy levels, medium-temperature flue gas heat exchangers of corresponding energy levels, low-temperature flue gas heat exchangers of corresponding energy levels and low-low-temperature flue gas heat exchangers of corresponding energy levels are additionally arranged at different positions in the flue so as to fully and deeply utilize flue gas waste heat and achieve energy conservation and emission reduction; the different grades of the flue gas waste heat at the tail portion of the boileris comprehensively utilized, moreover, according to flue gas waste heat resources and different use requirements provided by users, different flow division and different proportions of different coldsources and all stages of flue gas waste heat are achieved by virtue of all stages of heat exchange equipment, and finally energy level matching and gradient utilization are achieved; according to thenovel flue gas waste heat recycling method, the flue gas exhaust temperature is effectively reduced, the generating capacity is increased, the coal consumption is reduced, the dust removal efficiencyand the desulfurization efficiency are improved, the desulfurization water consumption is reduced, a chimney is protected, and the problem of environmental protection up-to-standard emission of enterprises is solved to a certain extent.

Owner:NANJING GUONENG ENVIRONMENTAL PROTECTION ENG

Preparation method of high-purity 2,4-D

ActiveCN103351296BImprove reaction efficiencyReduce process water consumptionPreparation from carboxylic acid saltsOrganic compound preparationFiltrationChloroacetic acids

The invention discloses a preparation method of high-purity 2,4-D. The preparation method comprises the following steps: (1) preparing 2,4-bitionolate; (2) enabling chloroacetic acid and the 2,4-bitionolate to directly react under the alkaline condition to obtain 2,4-D sodium salt; (3) achieving pressure filtration and acidification of the 2,4-D sodium salt to form a 2,4-D crude product; (4) rinsing- pressure-filtering and drying the 2,4-D crude product to obtained to the high-purity 2,4-D product. The preparation method provided by the invention can effectively reduce the process water consumption, simplify the process steps, greatly shorten the reaction time and improve the product yield.

Owner:山东科源化工有限公司

A method and application of biological extractant for treating oily sludge

ActiveCN106977064BImprove cleaning rateCause secondary pollutionLiquid hydrocarbon mixture productionSludge treatment with immiscible liquidsPetrochemicalOil sludge

The invention provides an application method and a process for a biological extraction agent in oily sludge treatment. Lemon olefins are adopted for treating oily sludge at the bottoms of tanks for petroleum, petrochemical and coal chemical industries, impurity oily sludge of pipelines and soil polluted by the oily sludge; the application method and the process are used for treating the oily sludge of different types, extracting petroleum from oil sand, and the like. The application method and the process disclosed by the invention are also suitable for extracting crude oil in oil sand, have the characteristics of high recovery rate, low energy consumption and short soil second ploughing time, and have no secondary pollution to environment.

Owner:南京蓝目标生物科技有限公司

Water balance control method based on desulfurization double-tower circulation low load of thermal power plant

PendingCN111991996AAvoid frequent start and stopReduce water consumptionGas treatmentDispersed particle separationProcess engineeringReducer

The invention relates to the technical field of desulfurization double-tower water balance control. The invention further discloses a water balance control method based on the desulfurization double-tower circulation low load of a thermal power plant. A desulfurization process is subjected to technical transformation, a water mechanical seal of a desulfurization slurry pump is changed into a water-free mechanical seal, and the process water supplementing amount of the whole system is reduced. A limestone slurry tank is changed into filtrate water for slurry preparation, cooling water of a slurry circulating pump speed reducer and cooling water of an oxidation fan flow back to an industrial water tank from a process water tank for closed circulation, the liquid level of an absorption tower,all boxes, tanks and pits is reduced, and favorable conditions are created for vigorously flushing a demister. According to the water balance control method based on the desulfurization double-towercirculation low load of a thermal power plant, water balance is controlled through six steps, the problems that flushing of a demister is affected and even the water balance is damaged due to the factthat too much water enters the system are effectively solved, normal operation of the system is guaranteed, the overall steps are simple and convenient, popularization is easy, use is convenient, andthe method is suitable for various conditions.

Owner:宁夏峰业环保科技有限公司

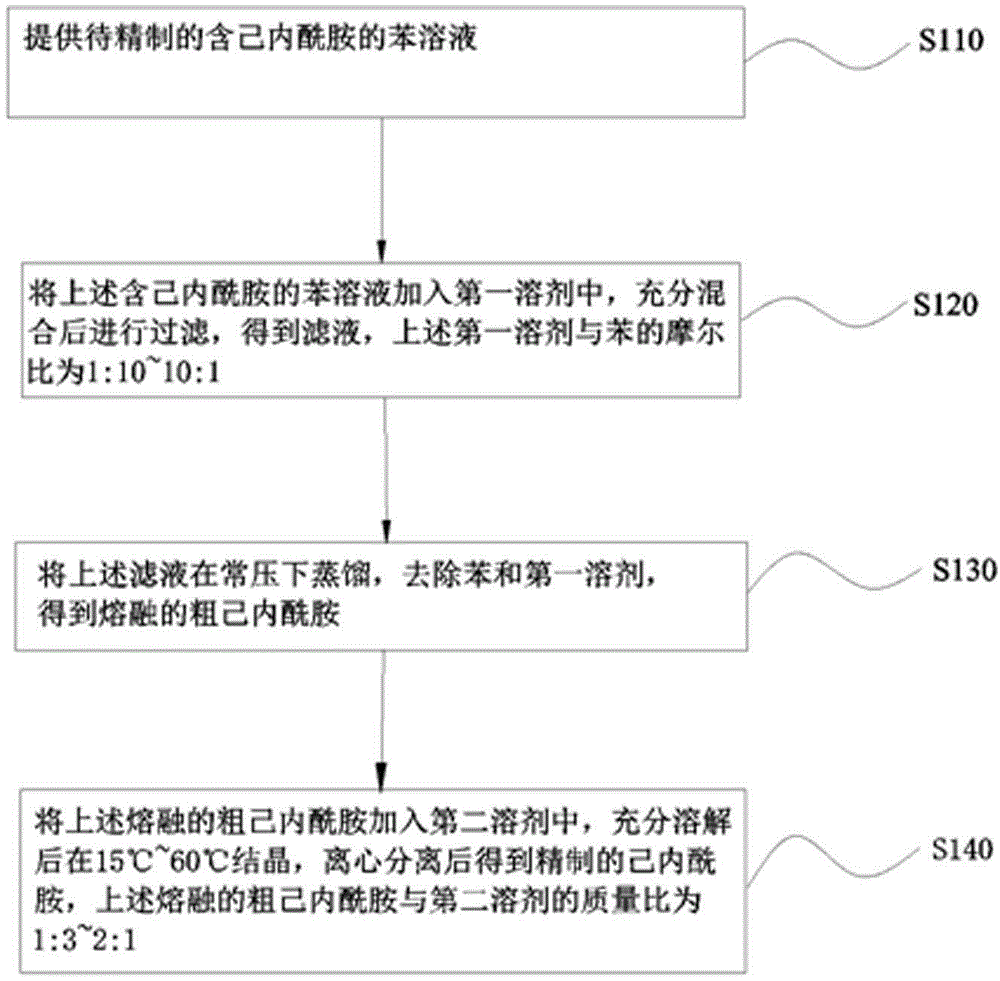

Refining method of caprolactam

InactiveCN105622510ASimple processReduce process water consumptionLactams separation/purificationBenzeneDistillation

The invention provides a refining method of caprolactam. The refining method comprises following steps: a caprolactam-containing benzene solution to be refined is provided; the caprolactam-containing benzene solution is added into a first solvent, and filtering is carried out after full mixing so as to obtain a filtrate, wherein molar ratio of the first solvent to benzene is controlled to be 1:10-10:1; the filtrate is subjected to normal pressure distillation so as to remove benzene and the first solvent and obtain molten crude caprolactam; the molten crude caprolactam is added into a second solvent, crystallization is carried out at 15 to 60 DEG C after complete dissolving, and centrifugal separation is carried out so as to obtain refined caprolactam, wherein mass ratio of the molten crude caprolactam to the second solvent is controlled to be 1:3-2:1. Compared with conventional caprolactam refining methods, the above refining method of caprolactam possesses following advantages: steps such as water reverse extraction and ion exchange are avoided, process flow is simple, and process water consumption is reduced greatly.

Owner:CHINA PETROLEUM & CHEM CORP

Low-cost method for treating waste water

InactiveCN109987772AEasy to useGuaranteed recyclingCombination devicesGas treatmentWater vaporTreated water

The invention discloses a low-cost method for treating waste water. The method comprises the following steps: step 1, preteating the wastewater; step 2, sending the treated waste water into a concentration tower for concentration; step 3, spray drying the concentrated waste water in a spray drying tower; step 4, carrying out pyrolysis and thermal oxidation on that organic toxic components in the waste water; step 5, separating dry salt from flue gas containing water vapor and salt in a dust remover; step 6, desulfurizing and denitrifying the flue gas containing water vapor; step 7, recoveringthat condensed water in the flue gas and removing residual pollutants in the waste water; step 8: using the treated water as circulating water. The low-cost method for treating waste water is convenient for the recycling of water, ensures the recycling of energy, achieves the purpose of treating waste water at low cost, makes the discharged smoke cleaner, purifies the smoke, reduces the dischargeof PM2.5, and reduces the generation of haze.

Owner:江苏正士环保科技有限公司

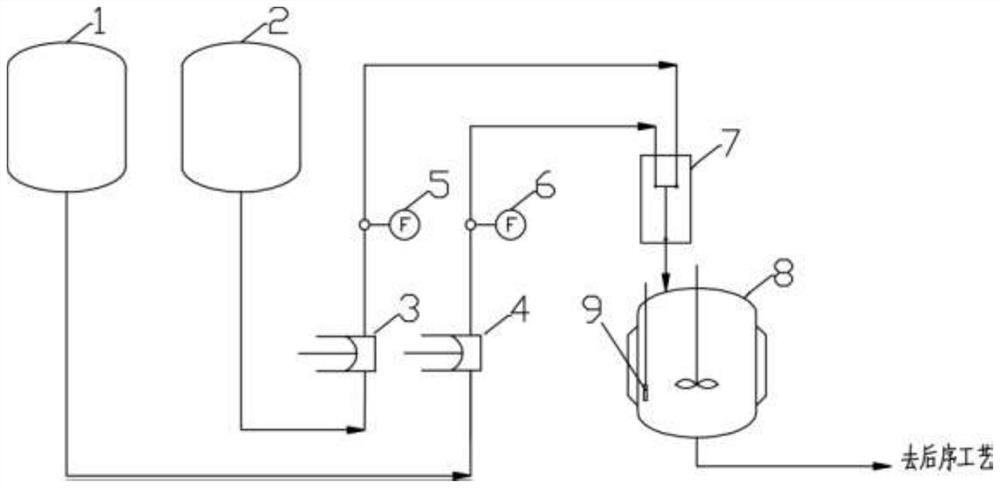

Continuous ammonia neutralization process of 2-methyl-5-nitroimidazole nitration completion liquid

The invention discloses a continuous ammonia neutralization process of 2-methyl-5-nitroimidazole nitration completion liquid. The method comprises the following steps of: respectively conveying nitration reaction completion liquid diluted by water and ammonia water solution for neutralization to a T-shaped mixer by a steady flow conveying metering pump, and carrying out instantaneous mixing and instantaneous neutralization reaction, wherein the flow ratio of the nitration reaction completion liquid to the ammonia water solution for neutralization is subjected to linkage closed-loop regulation through the PH value of the mixed feed liquid in the crystallization kettle; after mixing is completed, entering the crystallization kettle for crystallization; and then, carrying out separation, washing and drying to obtain a finished product. The method has the advantages that the continuous ammonia neutralization of the nitration reaction completion liquid of the 2-methyl-5-nitroimidazole is realized, and the production efficiency is greatly improved; after the neutralized and washed product is dried, the appearance is whiter, and the quality is better; meanwhile, the yield of the product 2-methyl-5-nitroimidazole in the neutralization process is increased by 99.8% or above; and compared with the traditional intermittent neutralization process, the water consumption can be saved by more than 30%.

Owner:西安海泽微流工程技术有限公司

Starch wheat compound enzyme and method of applying same in preparation of starch wheat and vital gluten

Owner:BAIYIN SINO BIOTECH

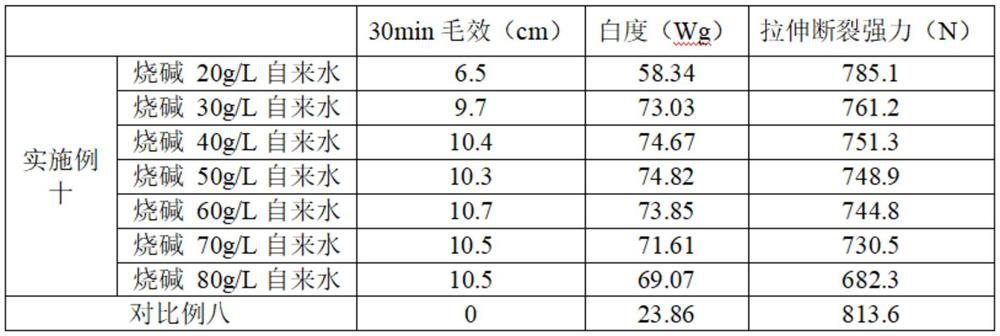

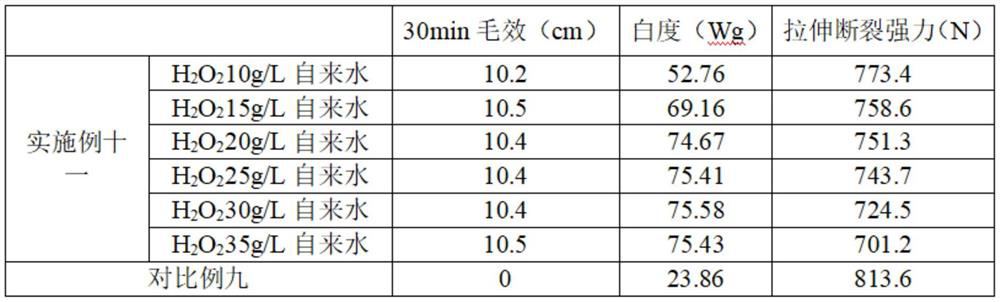

Multifunctional refining agent, cold batch liquid and cold batch pretreatment method

InactiveCN114395924AHas the effect of refining hair effectImprove permeabilityBiochemical treatment with enzymes/microorganismsVegetable oilActive agent

The invention belongs to the field of fabric treatment, and particularly discloses a multifunctional refining agent which is mainly used in a cold batch pretreatment process. Comprising a nonionic surfactant, an anionic surfactant, an antistatic agent, a stabilizer, a chelating dispersion system, an antibacterial agent, an enzyme preparation, a pH regulator, a mixture formed by mixing polyether ester and vegetable oil according to the mass ratio of 1: 3, a solvent and water, the cleaning agent is prepared from components in parts by mass as follows: 12-19 parts of a nonionic surfactant, 13-24 parts of an anionic surfactant, 0.3-0.9 parts of an antistatic agent, 2-7 parts of a stabilizer, 5-9 parts of a chelating dispersion system, 0.2-0.6 parts of an antibacterial agent, 1.5-7.9 parts of an enzyme preparation, 4-9 parts of a pH regulator, 6-14 parts of a mixture of polyether ester and vegetable oil and a proper amount of a solvent and water. The refining agent disclosed by the invention has a refining capillary effect improving effect, relatively good infiltration capacity and excellent hydrogen peroxide stability.

Owner:多恩生物科技有限公司

A kind of method preparing ferrous sulfate

The invention relates to a method for preparing ferrous sulfate, which uses low toxicity and nonflammable methylene chloride instead of highly toxic, flammable and explosive organic reagents such as chlorinated benzene as an extraction agent, and uses a decanter for extraction, which can effectively Improve the efficiency of extraction and separation, reduce the amount of extractant, remove the organic impurities in the acid through extraction, reduce the impurity content in the acid, so that the obtained sulfuric acid solution can be directly used to prepare ferrous sulfate, and the prepared ferrous sulfate product The quality has reached GB10631‑89 industrial superior product.

Owner:SHAOXING JIANG HUA CHEM

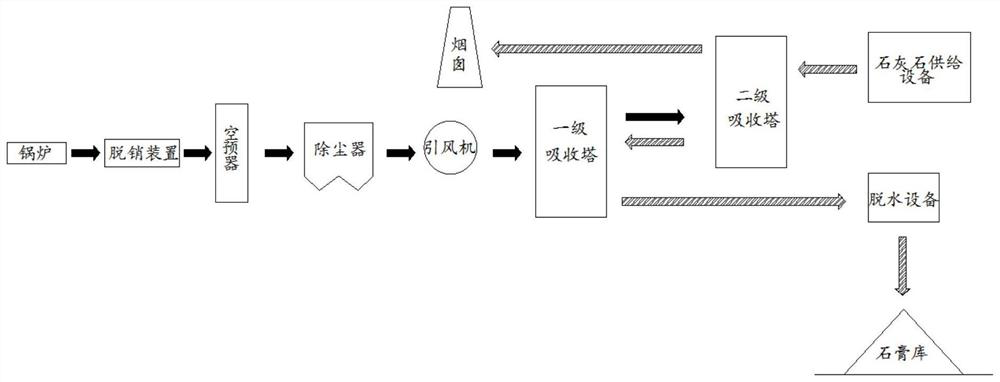

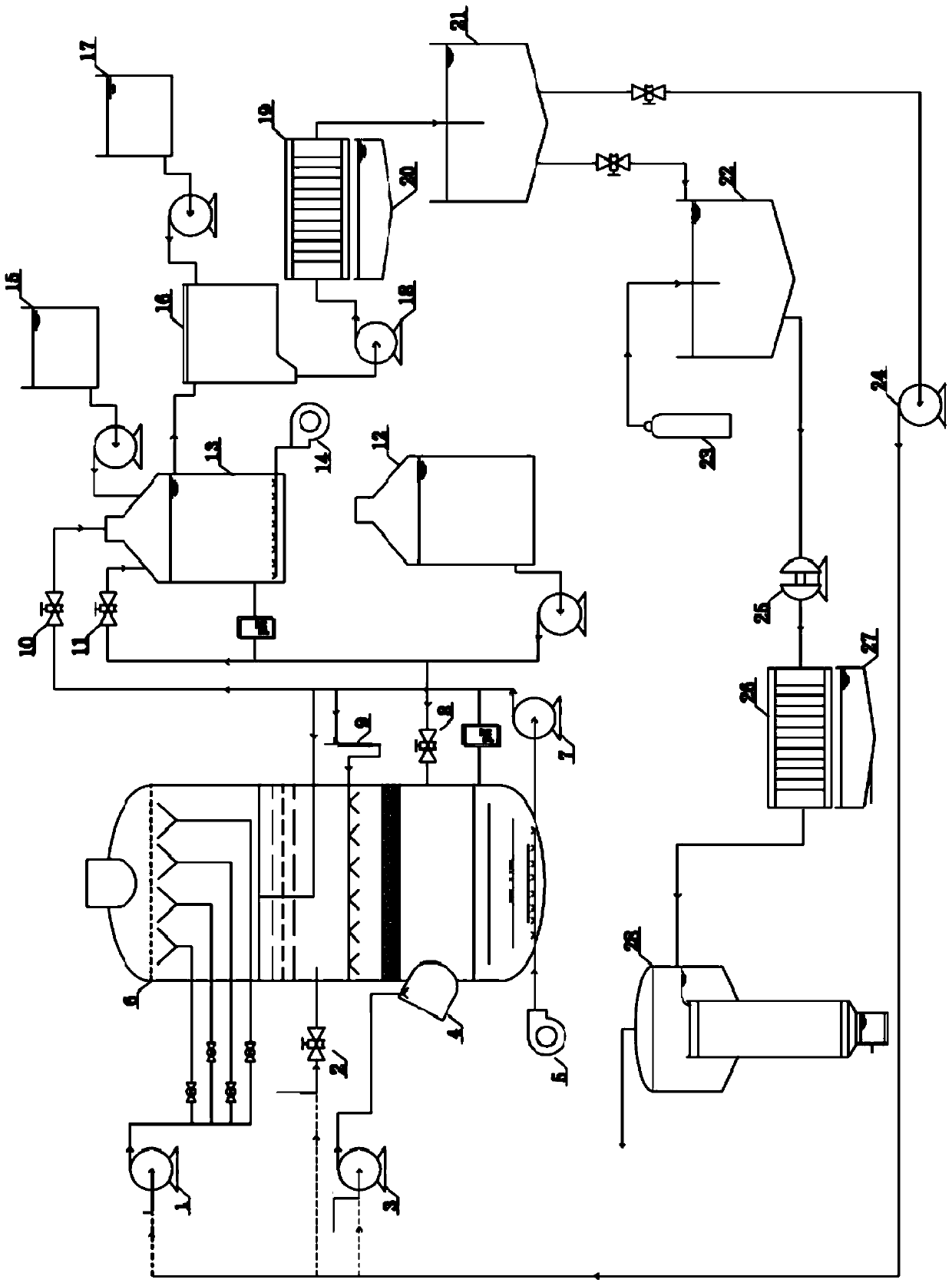

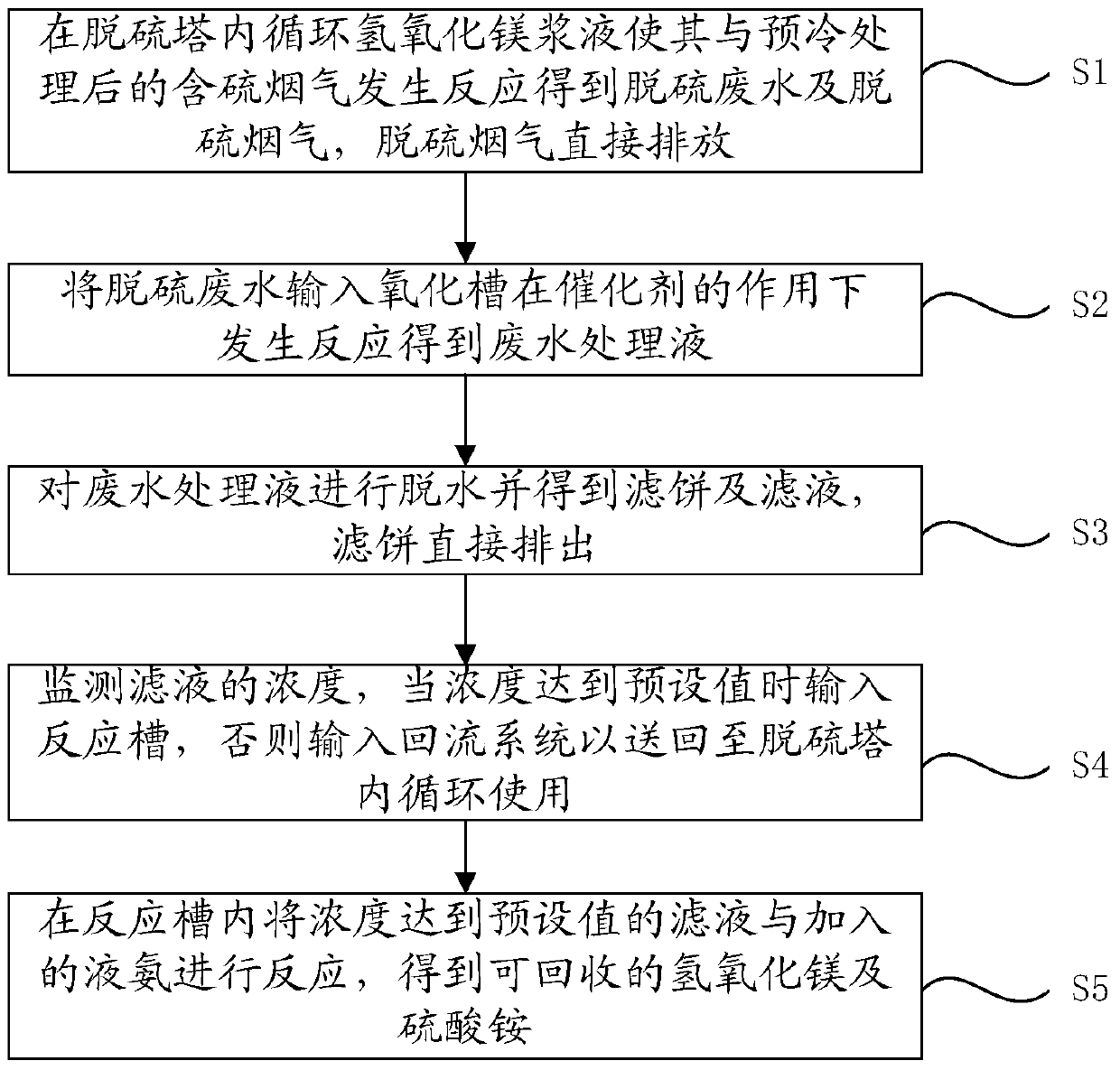

A flue gas desulfurization zero-emission resource processing system and method

ActiveCN105457479BEnable recyclingRealize calcinationSludge treatmentDispersed particle separationSlurrySulfur containing

The invention provides a flue gas desulphurization zero-emission resource disposal system and method. The flue gas desulphurization zero-emission resource disposal system comprises a desulphurization tower, an oxidation tank, a dehydration machine, a filtrate tank, a backflow system and a reaction tank. The desulphurization tower stores and circulates magnesium hydrate slurry and enables the magnesium hydrate slurry to react with sulfur-containing smoke so as to obtain desulphurization waste water. The oxidation tank obtains the desulphurization waste water and enables the desulphurization waste water to perform reaction under the catalytic action of a catalyst so as to obtain a waste water treating fluid. The waste water treating fluid is dehydrated by a dehydration machine, a filter cake and filtrate are obtained, and the filter cake is directly discharged out. When the preset concentration is not reached, the filtrate flows into a filtrate tank and is delivered back to the desulphurization tower through the backflow system for cyclic use. When the preset concentration is reached, the filtrate reacts with liquid ammonia in the reaction tank so as to obtain recoverable magnesium hydrate and ammonium sulfate. The system adopts the mode of magnesium hydrate and ammonium sulfate preparation to replace a conventional magnesium desulphurization and recovery process, is high in economic benefit and achieves greater resource recycling and reusing. In addition, calcination is not needed, the process is simpler and more convenient, the cost is lower, and environmental pollution and resource waste are avoided.

Owner:SHANGHAI SHIYUAN ENVIRONMENT PROTECTION TECH

Method for preparing nitryl chlorine solution

InactiveCN109336783AReduce dosageHigh purityCarboxylic acid nitrile purification/separationSulfateMethylene Dichloride

Owner:SHAOXING JIANG HUA CHEM

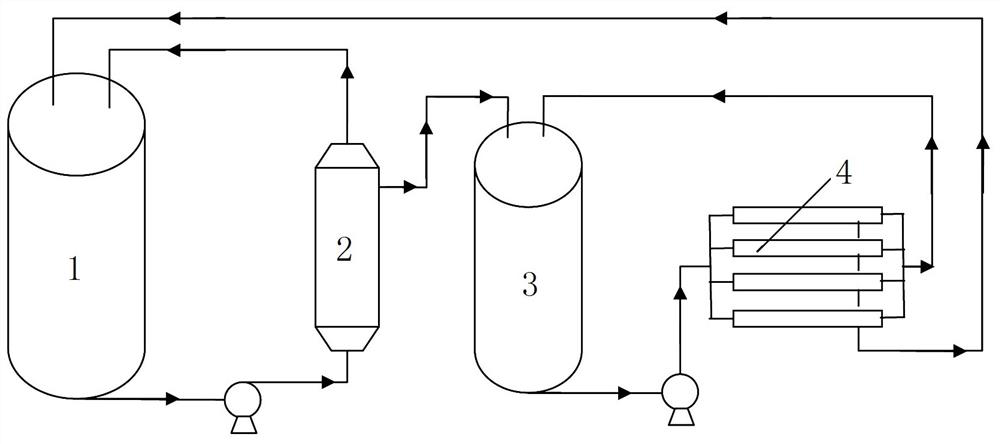

Processing method for recycling wastewater of aluminum industry

ActiveCN101343127BEmission reductionEfficient configurationGeneral water supply conservationDispersed particle separationWater resourcesWastewater

The invention relates to a production wastewater recycling treatment method in the aluminum industry, comprising: firstly, implementing the first pretreatment to wastewater for purifying the wastewater, then concentrating and diluting the wastewater through electrodialysis concentration treatment, and then making the concentrated solution return to the alumina production after the Na2O content therein reaches 100g / l through the low temperature membrane distillation concentration treatment after the concentrated solution is pretreated secondarily, and the produced water serves as washing waterof alumina products. The treated concentrated solution can return to the alumina production, the produced diluted solution can meet the standards of production process water, and can be used as washing water of products, meanwhile, the recovery of Na2O and process water in the production wastewater can be realized, thereby reducing the discharge of wastewater, guaranteeing the clean production, protecting the environment, also reducing the process water consumption, effectively allocating precious water resources, and saving water resources.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Flue gas prewashing method for energy conservation and consumption reduction of wet flue gas desulfurization system

InactiveCN106178763AReduce energy consumptionImprove desulfurization efficiencyGas treatmentUsing liquid separation agentFlue gasBuffer tank

The invention discloses a flue gas prewashing method for energy conservation and consumption reduction of a wet flue gas desulfurization system. The method includes following steps: replenishing water into a prewashing size buffer tank; starting a prewashing size buffer tank stirrer, and continuing replenishing water into the prewashing size buffer tank; starting a prewashing size circulating pump, gathering waste liquid after washing at the bottom of an induced draft fan flue, and enabling the waste liquid to automatically flow into a prewashing drainage pit through a drainage port of the induced draft fan flue; starting a prewashing drainage pit stirrer, and continuing discharging the waste liquid into the prewashing drainage pit; turning off the prewashing size circulating pump, and turning on a prewashing drainage pit pump to discharge washing liquid into the prewashing size buffer tank for recycling use; stopping the prewashing drainage pit pump when liquid level of the prewashing drainage pit lowers to not greater than 2m; repeating the above steps until a flue gas detection index is lower than a designed value, and pumping flue gas into an inlet of an absorption tower. By the flue gas prewashing method, the defect that the flue gas contains much oil dirt and is high in temperature and dust concentration in the prior art is overcome.

Owner:WUHAN LONGKING ENVIRONMENTAL PROTECTION CO LTD

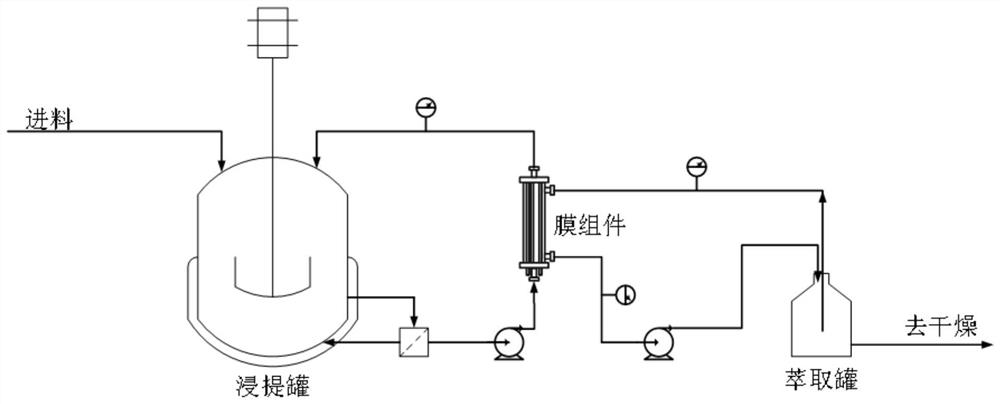

A kind of tea saponin extraction and refining process

The invention discloses a process for extracting and refining tea saponin, which belongs to the technical field of tea saponin extraction. The method is to carry out water extraction on the raw material powder, and make the water extraction solution circulate on one side of the membrane module, and at the same time set the extraction agent on the other side of the membrane module and circulate the extraction agent, and apply pressure on both sides of the membrane module Make the pressure on the side of the extraction agent and the pressure on the side of the water extraction solution both positive. When the membrane module uses a hydrophobic membrane, keep the pressure on the side of the extraction agent lower than the pressure on the side of the water extraction solution for extraction. When the membrane module uses When the film is hydrophilic, keep the pressure on the side of the extractant higher than the pressure on the side of the water extraction solution for extraction. After the extraction is completed, the phase of the extractant is dried, and the solvent is removed to obtain tea saponin. The tea saponin obtained by the refining process has high purity, solves the problem of low purity of the existing tea saponin extraction process, and is suitable for industrial extraction of tea saponin.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Energy-saving and consumption-reducing flue gas pre-scrubbing device for wet flue gas desulfurization system

InactiveCN106178764AReduce energy consumptionImprove desulfurization efficiencyUsing liquid separation agentFlue gasBuffer tank

The invention discloses an energy-saving and consumption-reducing flue gas pre-scrubbing device for a wet flue gas desulfurization system. The flue gas pre-scrubbing device comprises a pre-scrubbing slurry buffer tank, wherein a pre-scrubbing slurry buffer tank stirrer is positioned on the top of the pre-scrubbing slurry buffer tank, two side ends of a pre-scrubbing slurry circulating pump are respectively connected with a spraying device and the pre-scrubbing slurry buffer tank, and two side ends of a pre-scrubbing drain pit pump are respectively connected with a pre-scrubbing drain pit and the pre-scrubbing slurry buffer tank; a pre-scrubbing drain pit stirrer is positioned on the top of the a pre-scrubbing drain pit; the spraying device comprises an induced draft fan flue and a nozzle, two side ends of the spraying device are respectively connected with a boiler induced-draft fan and an absorbing tower inlet, and the lower end of the spraying device is connected with the pre-scrubbing drain pit. According to the flue gas pre-scrubbing device disclosed by the invention, the defects such as too much oil dirt in flue gas, high temperature and high dust concentration in the prior art are overcome.

Owner:WUHAN LONGKING ENVIRONMENTAL PROTECTION CO LTD

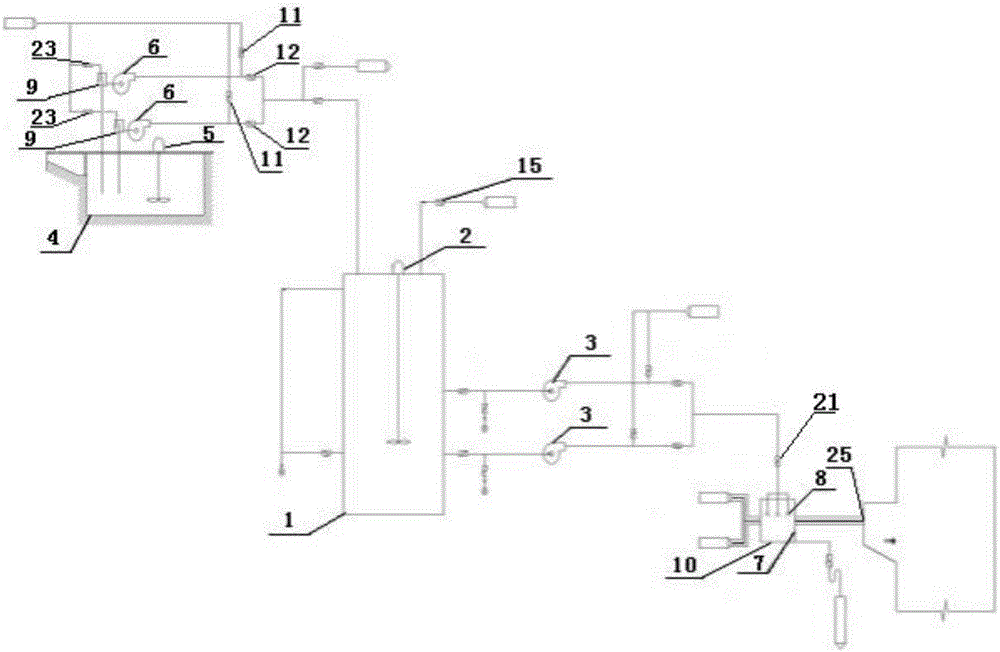

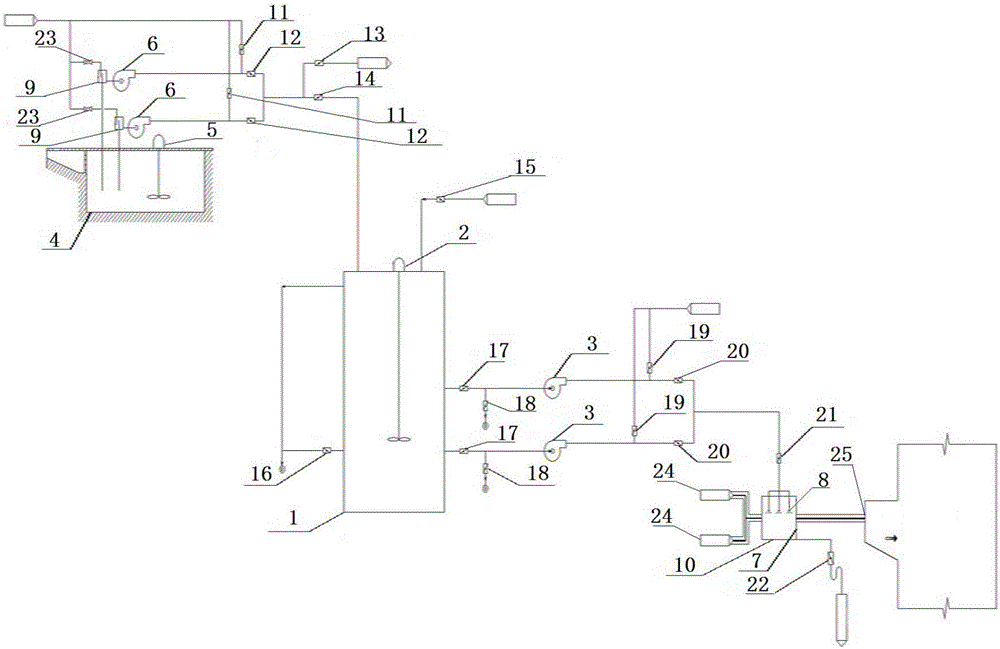

A kind of preparation method of mannanase and its extraction and refining device

ActiveCN107460178BReduce labor intensityImprove working environmentApparatus sterilizationBiomass after-treatmentBiotechnologyPichia pastoris

The invention discloses a mannase preparation method and an extraction and refining device of mannase. The mannase preparation method comprises the following steps: firstly, performing liquid fermentation to pichia pastoris engineering strain to obtain a fermented liquor, then extracting and refining, the specific extracting and refining steps are as follows: 1) circularly filtering and concentrating the fermented liquor through a ceramic film, wherein the temperature of the cyclic liquor is controlled to be below 20 DEG C; 2) after concentrating for certain time, taking clear filtrate filtered by the ceramic film, and circularly concentrating through an ultrafilter membrane equipment, wherein the temperature of the cyclic liquor is controlled to be below 20 DEG C; and 3) when the volume of concentrated liquor in the step 2) is reduced to 1 / 5-1 / 10 of the clear filtrate, adding starch and evenly mixing, and finally performing spray granulation, to obtain mannase. Adopting the ceramic film for filtering not only can hold up producing strains, but also realize filtration sterilization, and through coupling with the concentration of the ultrafiltration membrane, the technological time can be shortened, the proliferation risk of microorganism can be reduced, the hygienic index pass percent of the obtained finished product is greatly improved to 99%, and the yield of the product is improved to 83% or above.

Owner:HEC PHARM

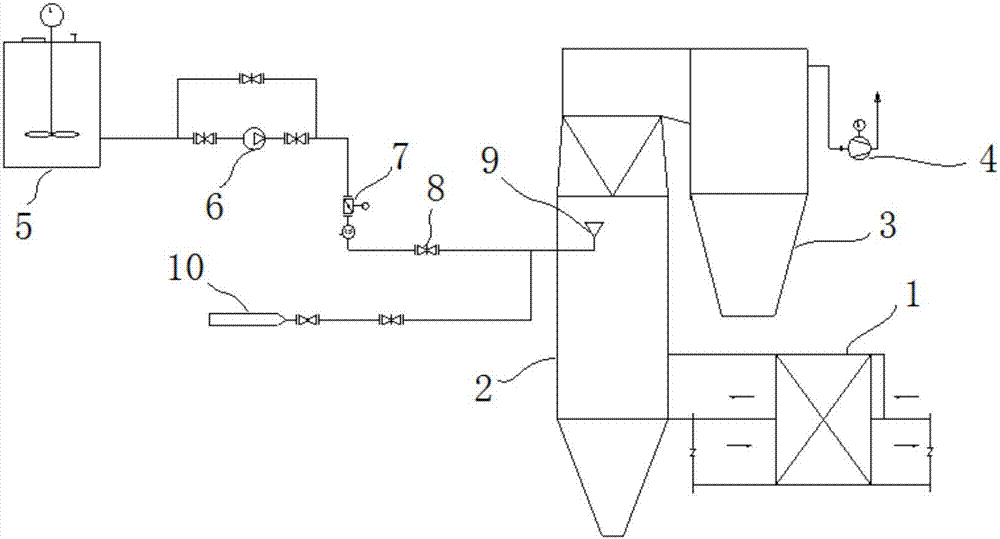

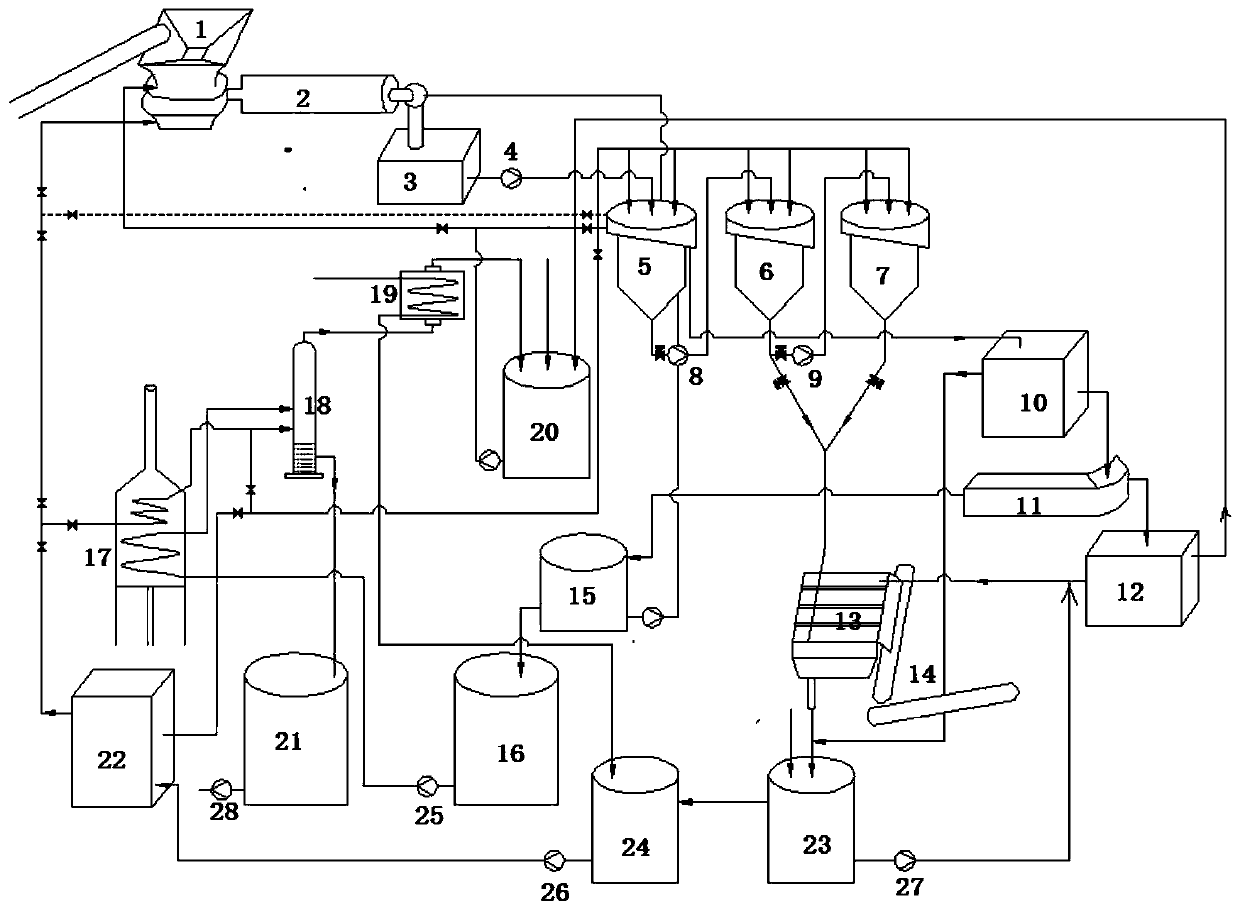

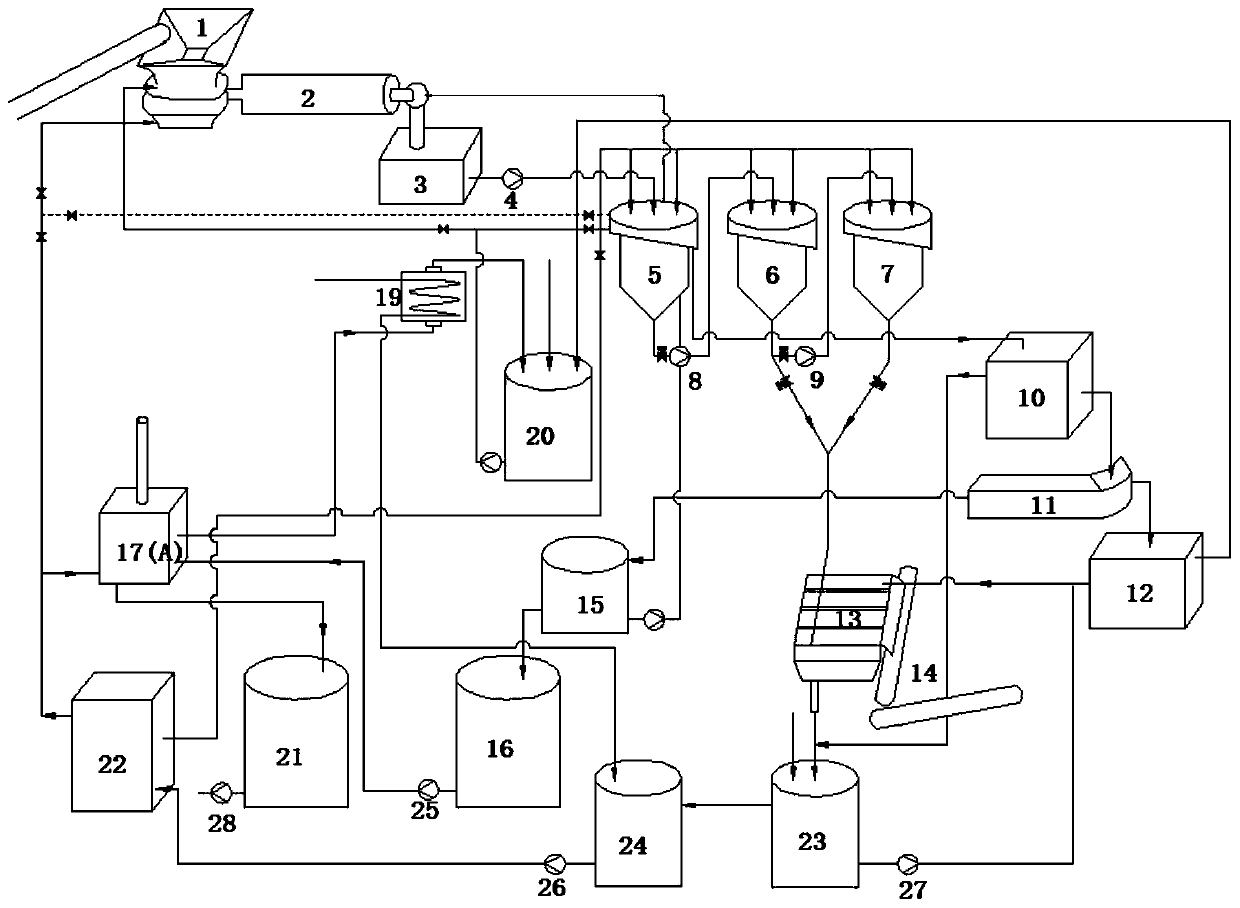

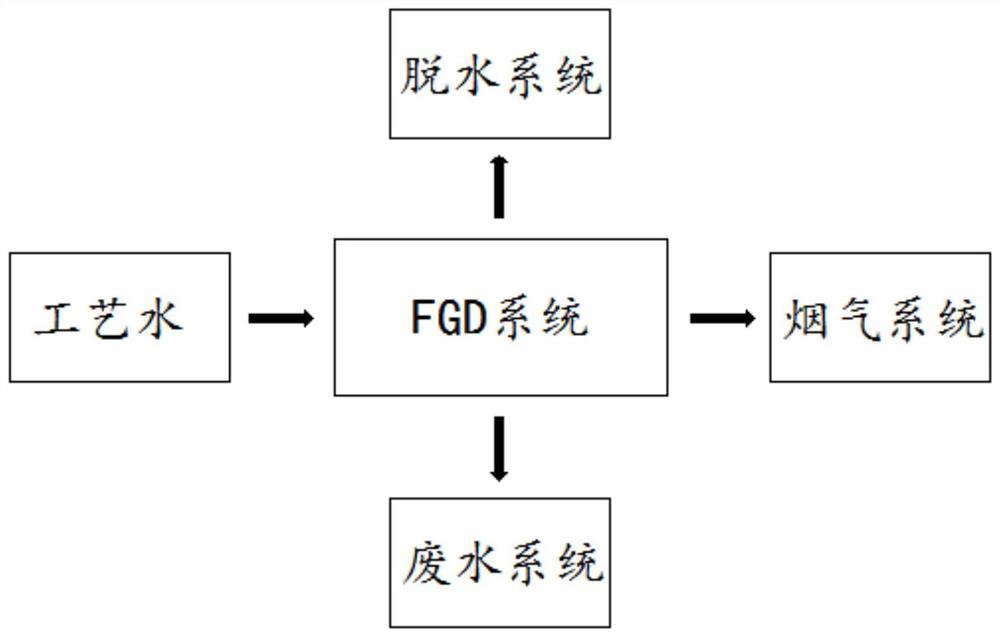

Method and system for processing desulphurization waste water

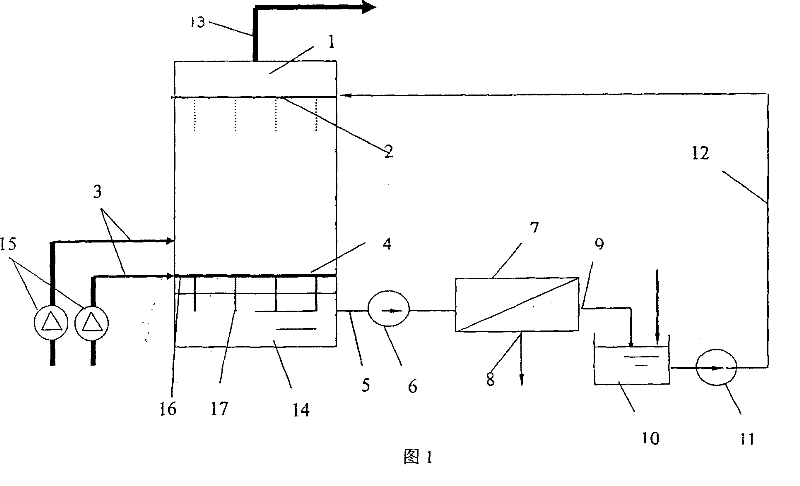

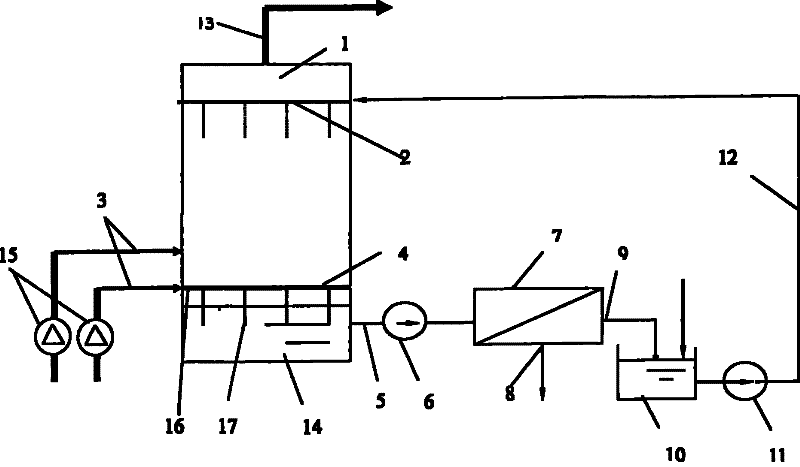

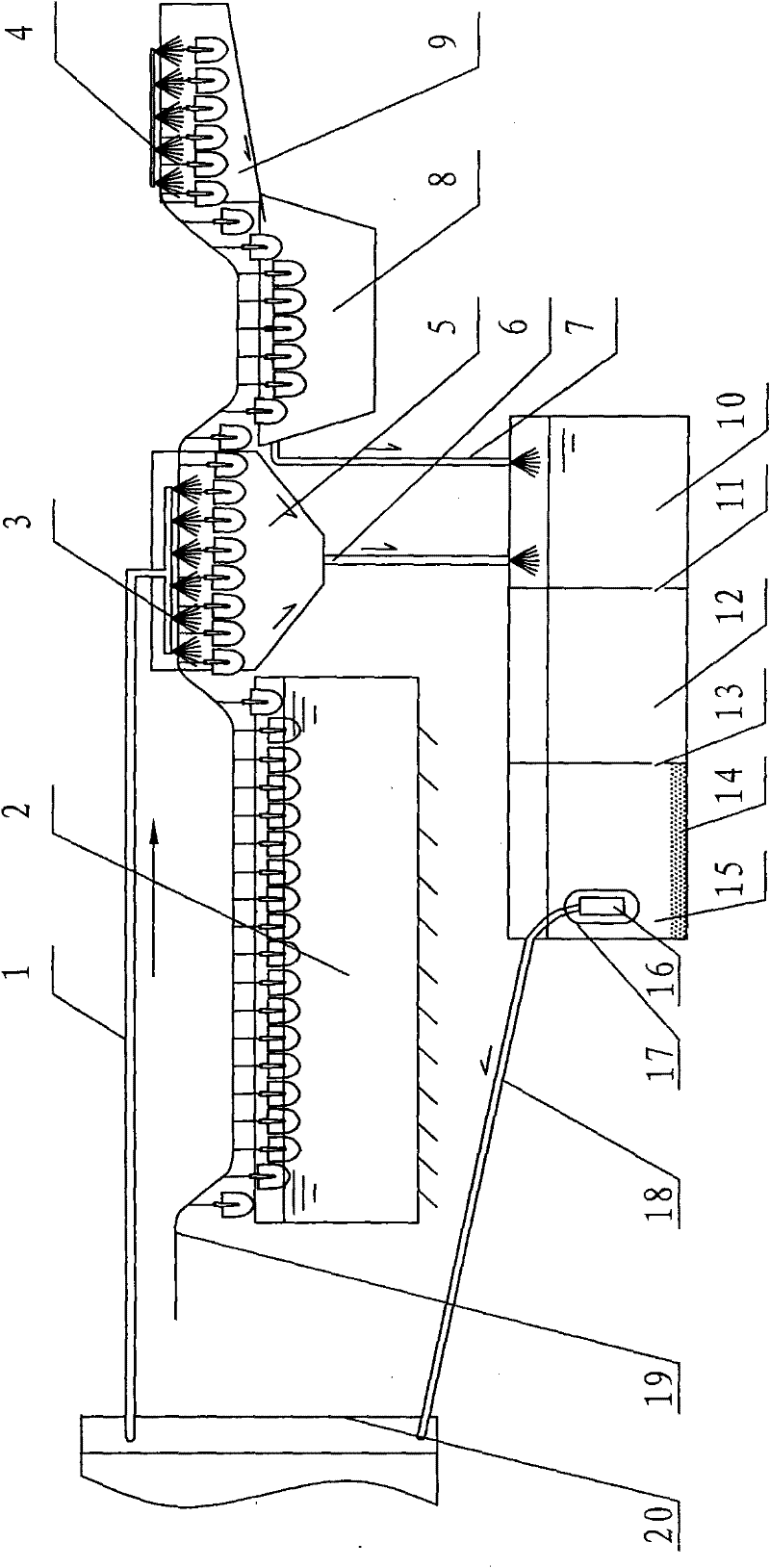

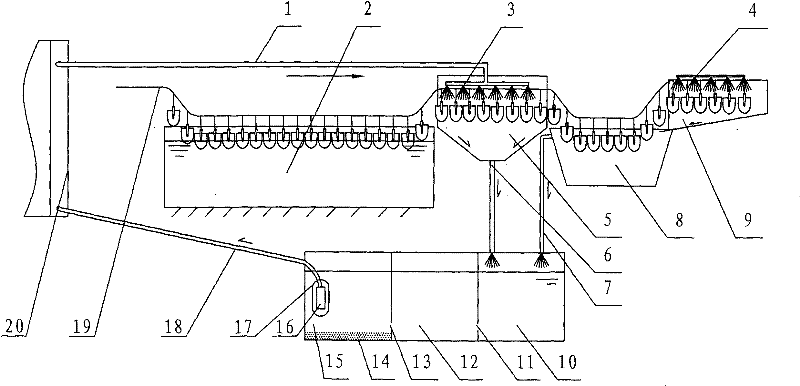

ActiveCN101417826BReduce process water consumptionReduce energy consumptionWater/sewage treatmentEnergy based wastewater treatmentFlue gasWastewater

The invention discloses a method and a system for treating desulfurization wastewater, which are applied to treating the wastewater generated from limestone-plaster wet flue gas desulfurization and other wastewater with high salt content. The system comprises a drying tower, a circular spray system, a flue gas stirring device and a filter press. The method comprises the steps: in the drying tower, hot flue gas and desulfurization wastewater exchange heat through convection contact so as to lead the wastewater to evaporate and concentrate to generate crystal; the filter press is adopted to carry out solid-liquid separation; and mother liquor continually refluxes and is treated. The method and the system have the advantages of low cost, little area occupation and low energy consumption, which can realize zero discharge of the wastewater of the limestone-plaster wet flue gas desulfurization technology and improve contribution.

Owner:CHENGDU RAISE ENVIRONMENTAL PROTECTION TECH CO LTD

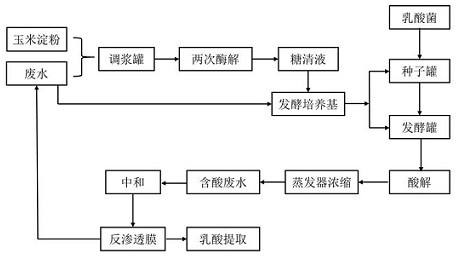

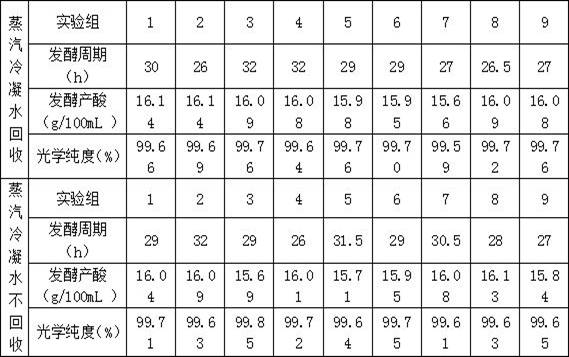

Recycling method of lactic acid fermentation acid-containing wastewater

PendingCN113278659AReduce processing costsHigh recovery rateWater treatment compoundsMicroorganism based processesCALCIUM LACTOBIONATEReverse osmosis

The invention discloses a recycling method of lactic acid fermentation acid-containing wastewater, which comprises the following steps: (1) uniformly mixing corn starch and reverse osmosis wastewater, and carrying out slurry mixing; (2) dissolving the prepared corn starch, performing enzymolysis twice, and performing plate frame filtration to obtain liquefied sugar clear liquid; (3) respectively supplementing the liquefied sugar clear liquid, ammonium sulfate, yeast powder and other nutrients to the reverse osmosis wastewater to adjust the concentration, continuously killing bacteria to obtain a microbial culture medium, and carrying out strain fermentation; (4) after fermentation, separating thalli out through solid-liquid separation, obtaining lactic acid through acidolysis, increasing the concentration of the lactic acid through concentration of an evaporator to generate a large amount of lactic acid-containing wastewater in the evaporation process; (5) neutralizing the lactic acid-containing wastewater through calcium hydroxide to produce calcium lactate, and enabling a calcium lactate solution to penetrate through a reverse osmosis membrane to obtain a calcium lactate concentrated solution and reverse osmosis wastewater; and returning the generated wastewater to the step (1) and the step (3), and circulating in this way. According to the method, the sewage treatment cost is relatively saved, the recovery rate of lactic acid is increased, and the method has important environmental benefits and economic benefits.

Owner:郑州运维生物技术有限公司

Method for low-pressure continuous hydrolysis preparation of fatty acid

InactiveCN1256412CReduce partial pressureIncrease hydrolysis rateFatty acid chemical modificationFatty acids production/refiningDistillationHydrolysis

The invention provides a method for producing fatty acid by continuous hydrolysis at low pressure. The weight ratio of water to oil is 5-30:100. After exchanging heat, enter the heating furnace to heat to 250-500°C and then enter the reactor. After reacting in the reactor for 2-30 minutes, the reaction product is drawn out, and the crude fatty acid and fuel gas are obtained after separation or directly distilled to obtain fatty acid. The present invention reduces the operating pressure by changing the temperature conditions of hydrolysis, thereby reducing the pressure level of the whole system equipment, shortening the process route, reducing process water consumption, reducing the water system load and sewage discharge intensity; removing the glycerin recovery system, reducing energy consumption and production costs ; Shorten the reaction time and greatly increase the production capacity of the device.

Owner:陈天晓

Method for preparing oral solution of poplar flower

ActiveCN103142742BReduce processing timeReduce heat consumptionAntibacterial agentsPlant ingredientsWater useCellulose

The invention discloses a method for preparing an oral solution of the poplar flower and belongs to the technical field of veterinary medicaments. The method comprises the following steps of: (1) putting the poplar flower into an extraction tank, adding water into the poplar flower, stirring, and increasing the temperature to 45-50 DEG C, wherein the water is 4-6 times of the mass of the poplar flower; (2) adding cellulose into the extraction tank, adjusting the pH value of the materials to 5.0-5.5, and hydrolyzing under the action of the cellulose for 90-120 minutes at the temperature of 45-50 DEG C, wherein the mass of the cellulose is 3-7% of that of the poplar flower; and (3) filtering a solution of enzymolysis, and collecting a filtrate to obtain the poplar-flower oral solution. The poplar flower is extracted by adopting the technology of hydrolyzing under the action of the cellulose, and a novel process for extracting the poplar flower is developed, thus the time spent in extracting the poplar flower is shortened, the heat consumption is reduced, the amount of water used in the process is reduced, and the purposes of saving energy, reducing emission, improving the work efficiency and the extraction efficiency are achieved. The method has good social and economic benefits.

Owner:河北康利动物药业有限公司

Spade heat-treatment medium recovering device and method for recovering medium using the device

InactiveCN101812569BEnsure no emissionsEnsure no emissionWater/sewage treatmentQuenching agentsThree levelNitrate

The invention relates to a spade heat-treatment medium recovery device. The device comprises a conveying chain, a sprinkler device, a salt bath groove, a bleaching chamber, an immersing and diluting tank, a fresh water spray chamber and a three-level cooling pool. The salt bath groove is a heat-treatment iso-quenching bath provided with nitrate; the bleaching chamber for washing and diluting work pieces, the immersing and diluting tank and the fresh water spray chamber are arranged in a triangular shape, wherein the bottom of the bleaching chamber and the upper part of the immersing and diluting tank are provided with osculums of tail water in turn, and a washing recovery pipeline is communicated with an one-level recovering pool; three recovery pools constitute the three-level cooling pool which is arranged under the ground. The recovery steps are as follows: hoisting the work pieces on the conveying chain and entering the work pieces to the salt bath groove provided with the nitrate to carry out heat-treatment iso-quenching; then carrying out three-level washing and leading the fresh water tail water to enter the one-level recovery pool to be naturally cooled; and at last, recovering the medium in the three-level recovery pool. The device can use the residual heat of a heating furnace, and has the advantages of convenient operation, saved energy, simple recovery process, closed circulated process and no pollution.

Owner:付长智

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com