Continuous ammonia neutralization process of 2-methyl-5-nitroimidazole nitration completion liquid

A technology of nitroimidazole and methyl, which is applied in the field of continuous ammonia neutralization process, can solve the problems of increased washing water consumption, long neutralization process time, and decreased yield of final products, so as to achieve improved production efficiency, good quality, The effect of white appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

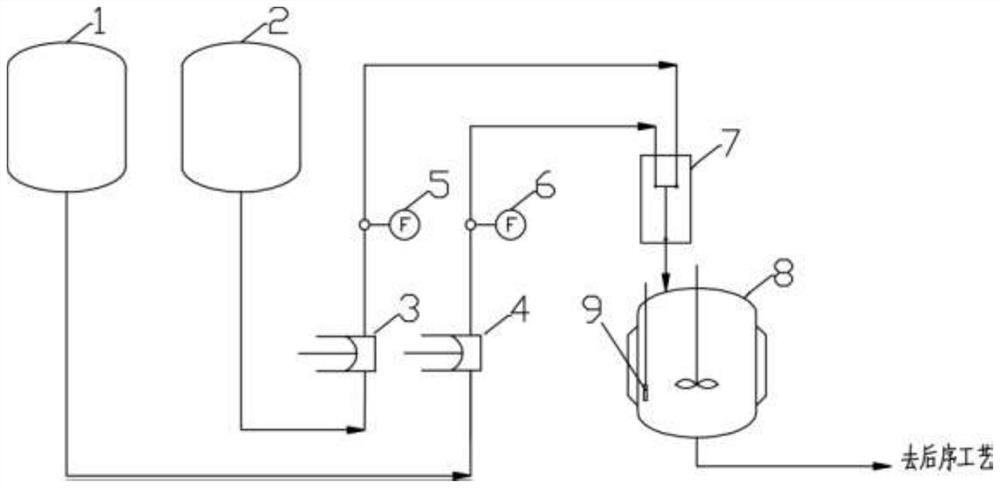

[0031] Embodiment 1: a kind of continuous ammonia neutralization process of 2-methyl-5 nitroimidazole nitration reaction completion liquid, it comprises the following steps: 2-methyl-5 nitroimidazole nitration reaction completion liquid is loaded into nitration reaction completion liquid In the tank 1, put the ammonia solution with a concentration of 27% into the ammonia solution tank 2, turn on the steady flow metering pump 4 of the nitrification completed liquid, set the flow rate of the nitrification completed liquid flowmeter 6 to 17300g / min, and turn on the steady flow metering of the ammonia water Pump 3, adjust the flow rate of ammonia water through the ammonia water flow meter 5 so that the pH value of the material entering the crystallization kettle 8 from the outlet of the T-type mixer 7 is 3, and open the interlocking adjustment of the pH value of the mixed liquid and the ratio of the flow rate of ammonia water to the flow rate of the nitrification completed liquid, a...

Embodiment 2

[0032] Embodiment 2: a kind of continuous ammonia neutralization process of 2-methyl-5 nitroimidazole nitration reaction completion liquid, it comprises the following steps: 2-methyl-5 nitroimidazole nitration reaction completion liquid is loaded into nitration reaction completion liquid In the tank 1, put the ammonia solution with a concentration of 31% into the ammonia solution tank 2, turn on the steady flow metering pump 4 of the nitrification completed liquid, set the flow rate of the nitrification completed liquid flow meter 6 to 17300g / min, and turn on the steady flow metering of the ammonia water Pump 3, adjust the flow rate of ammonia water through the ammonia water flow meter 5 so that the pH value of the material entering the crystallization kettle 8 from the outlet of the T-type mixer 7 is 5, and open the interlocking adjustment of the pH value of the mixed liquid and the ratio of the flow rate of ammonia water to the flow rate of the nitrification completed liquid, ...

Embodiment 3

[0033] Embodiment 3: a kind of continuous ammonia neutralization process of 2-methyl-5 nitroimidazole nitration completion liquid, it comprises the following steps: 2-methyl-5 nitroimidazole nitration reaction completion liquid is loaded into nitration reaction completion liquid In the tank 1, put the ammonia solution with a concentration of 29% into the ammonia solution tank 2, turn on the steady flow metering pump 4 of the nitrification completed liquid, set the flow rate of the nitrification completed liquid flow meter 6 to 17300g / min, and turn on the steady flow metering of the ammonia water Pump 3, adjust the flow rate of ammonia water through the ammonia water flow meter 5 so that the pH value of the material entering the crystallization kettle 8 from the outlet of the T-type mixer 7 is 4, and open the chain adjustment of the pH value of the mixed liquid and the ratio of the flow rate of ammonia water to the flow rate of the nitrification completed liquid, and always maint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com