A method and application of biological extractant for treating oily sludge

An extraction agent and biological technology, applied in biological extraction, application of biological extraction agent and treatment method in oil sludge treatment, the application field of extracting crude oil from oil sands, can solve the problem of polluted soil and groundwater resources, high disposal cost, pollution Atmospheric and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

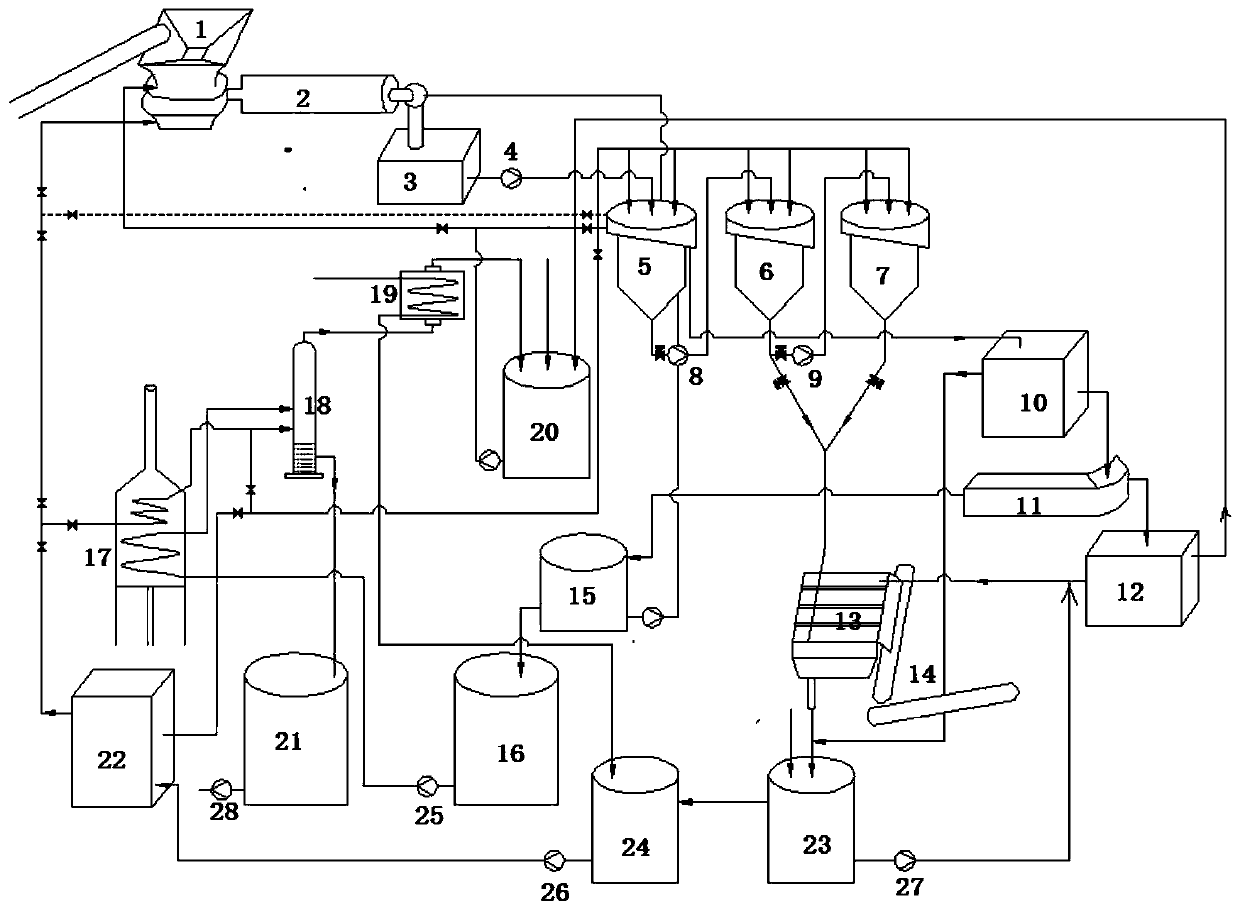

[0080] combine figure 1 , the method of the present invention is specifically:

[0081] 1. The contaminated soil, oil sludge or oil sand is crushed by crusher 1; the crushed soil, oil sludge or oil sand, and limonene washing oil and water are fully stirred, and at the same time, the soil is heated to 50 with steam or hot air ~90 degrees, soil, oil sludge or oil sand: limonene: water = 1:1~3:1~3. The specific ratio needs to be adjusted according to the viscosity of different sludge, oil content, particle size and type of sediment, etc.;

[0082] 2. After preheating and initial stirring, the mixed oil slurry is fully stirred by the spiral agitator 2, so that the mixture is fully stirred, and its viscosity is greatly reduced, and it flows automatically or is transported to the first stage of oil sludge separator 5 by the pump 4 , in the middle of the separator, wash with hot water or steam, sediment and organic petroleum products or crude oil, washed by limonene and hot water, ...

Embodiment 2

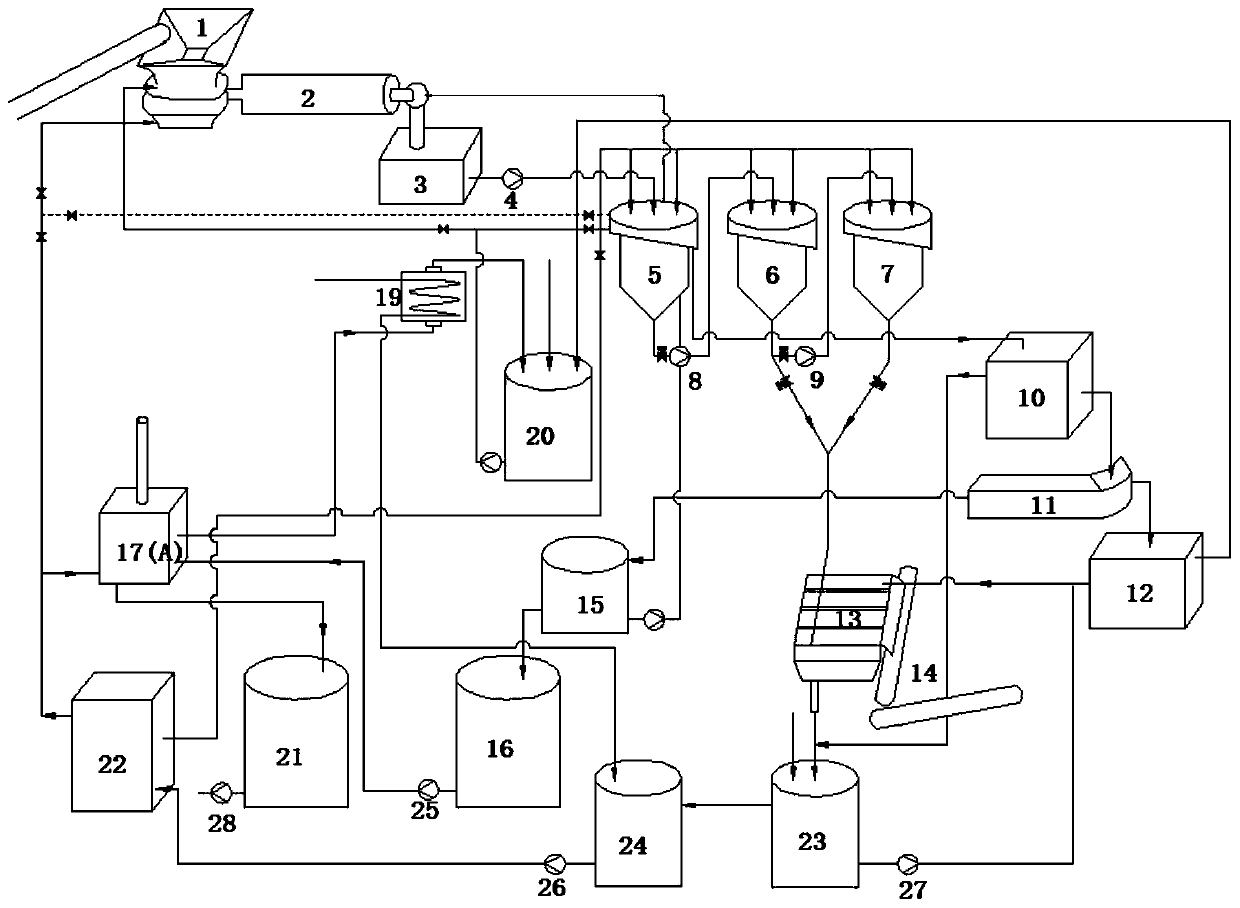

[0098] combined with figure 2 , this process adopts the equipment 17A of the rotary film evaporator / sweeping wall evaporator to replace the tubular heating furnace 17 and the deoiling tower 18, and part of the steam from the boiler directly enters the rotary film evaporator / sweeping wall evaporator, and evaporates from the rotary film evaporator The limonene gas from the upper part of the tank enters the cooler; the petroleum and petrochemical products or crude oil from the bottom enters the product oil tank.

[0099] details as follows:

[0100] combine figure 2 , the method of the present invention is specifically:

[0101] 1. The contaminated soil, oil sludge or oil sand is crushed by crusher 1; the crushed soil, oil sludge or oil sand, and limonene washing oil and water are fully stirred, and at the same time, the soil is heated to 50 with steam or hot air ~90°C, soil, oil sand or oil sludge: limonene: water = 1:1~3:1~3. The specific ratio needs to be adjusted accord...

Embodiment 3

[0118] As in embodiment 2, the instructions are attached figure 2 The equipment in it: the equipment 17A of the rotary film evaporator / sweeping wall evaporator, which is replaced by a still, and other process equipment and processes are all the same as in "Example 2". The process index controls the distillation temperature of the still: 150-190 ℃, other indexes are basically the same as in "Example 2".

[0119] The process is suitable for batch production, suitable for small and medium scale production.

[0120] This invention also belongs to the scope of protection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com