Energy-saving and consumption-reducing flue gas pre-scrubbing device for wet flue gas desulfurization system

A wet flue gas desulfurization and pre-washing technology, which is applied in the direction of separation methods, chemical instruments and methods, and the use of liquid separation agents, can solve the problems of low pH value of the slurry in the absorption tower, prolonged running time of the ball mill, and increased power consumption of the fan. , to achieve the effect of little impact on power generation tasks, reduce process water consumption, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

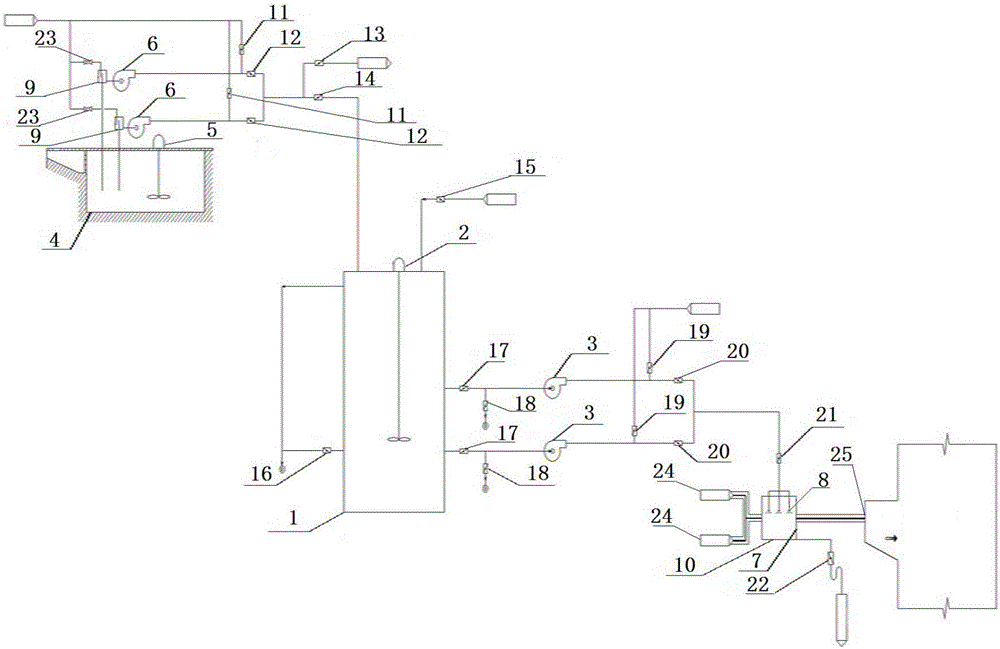

[0022] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

[0023]Referring to the accompanying drawings, it can be seen that the flue gas pre-washing device for energy saving and consumption reduction of wet flue gas desulfurization system is characterized in that it includes a pre-washing slurry buffer tank 1; a pre-washing slurry buffer tank agitator 2 is located in the pre-washing slurry At the top of the buffer tank 1, both ends of the pre-washing slurry circulating pump 3 are respectively connected to the spray device 10 and the pre-washing slurry buffer tank 1, and both ends of the pre-washing drainage pit pump 6 are respectively connected to the pre-washing drainage pit 4 and the pre-washing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com