Method for low-pressure continuous hydrolysis preparation of fatty acid

A fatty acid and crude fatty acid technology, which is applied in the production of fatty acids, chemical modification of fatty acids, preparation/refining of fatty acids, etc., can solve the problems of high production costs of fatty acids, huge investment, and the inability of small and medium-sized enterprises to bear the operating costs, so as to reduce pressure. The effect of level, lower investment amount, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

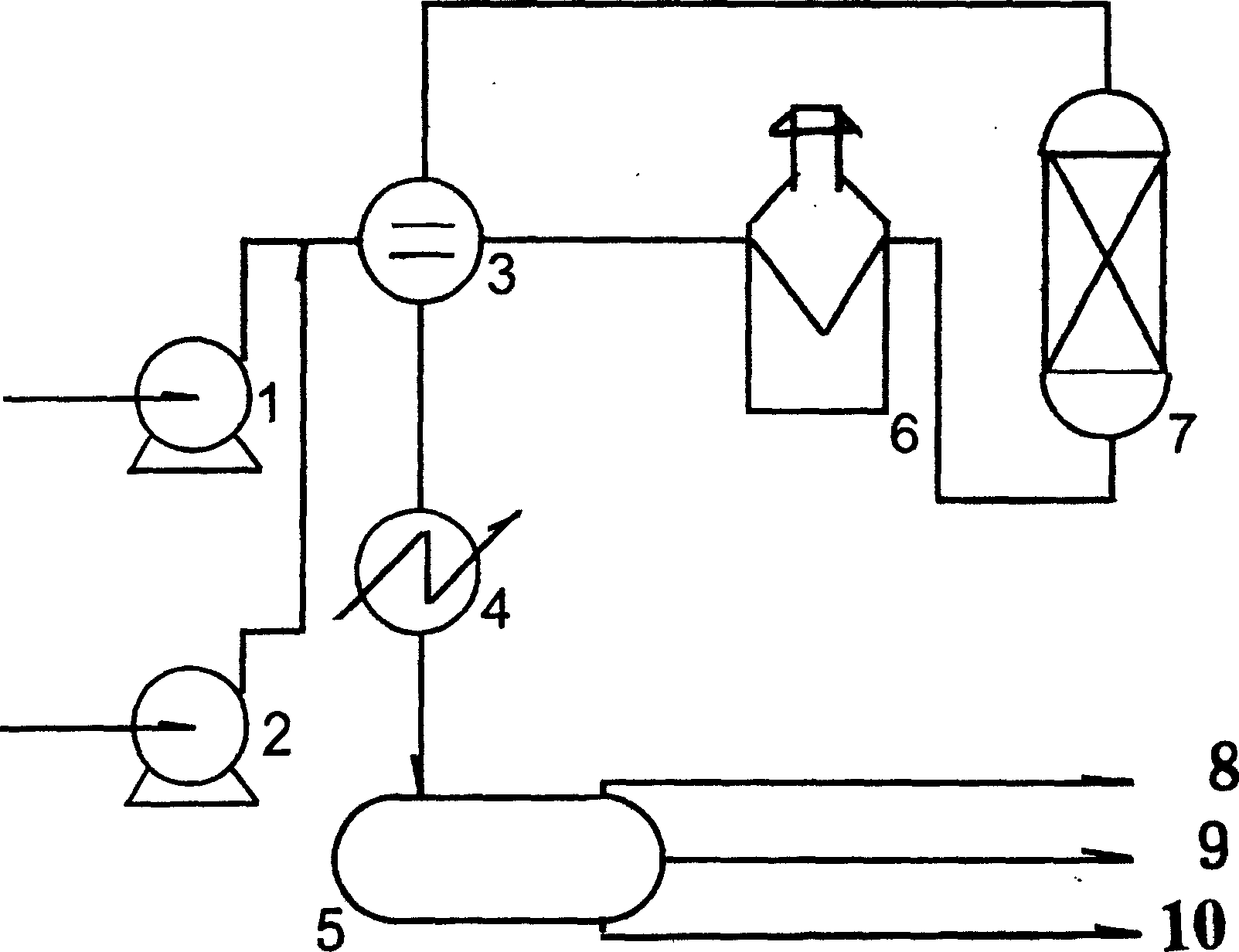

[0018] use figure 1 As shown in the process flow, on a small-scale continuous hydrolysis device with a processing capacity of 20 kg / hour, the acidified oil obtained from the cottonseed oil foot after acidification treatment has an acid value of 68mgKOH / g, and water is metered by a metering pump, and the water oil The ratio is 1:4, the outlet pressure of the pump is 0.4Mpa, it enters the tubular heating furnace and is heated to 380°C and then enters the reactor. After reacting for 6 minutes, it is cooled to normal temperature by the cooler and then enters the separator. After separation, crude fatty acid and fuel gas. The crude fatty acid is distilled to obtain fatty acid, its acid value is: 193mgKOH / g, and its freezing point is 32°C.

Embodiment 2

[0020] Cottonseed oil (edible grade) is used as raw material on the device of Example 1, the operating conditions are: water-oil ratio 28: 100, pump outlet pressure 0.36Mpa, reaction temperature 395 ℃, reaction time is 15 minutes, after cooling, distill, obtain The acid value of fatty acid is 190.5mgKOH / g.

Embodiment 3

[0022] The reaction product obtained by using the raw materials and reaction conditions of Example 1 on the device of Example 1, but directly enters the fractionation system without cooling, can obtain fuel gas from the top, residue from the bottom, and fatty acid from the middle. 196.5mgKOH / g, freezing point 33°C, qualified color.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com