Method for refining caprolactam

A technology of caprolactam and refining method, which is applied in the field of caprolactam refining, and can solve the problems of large process water consumption and complicated process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

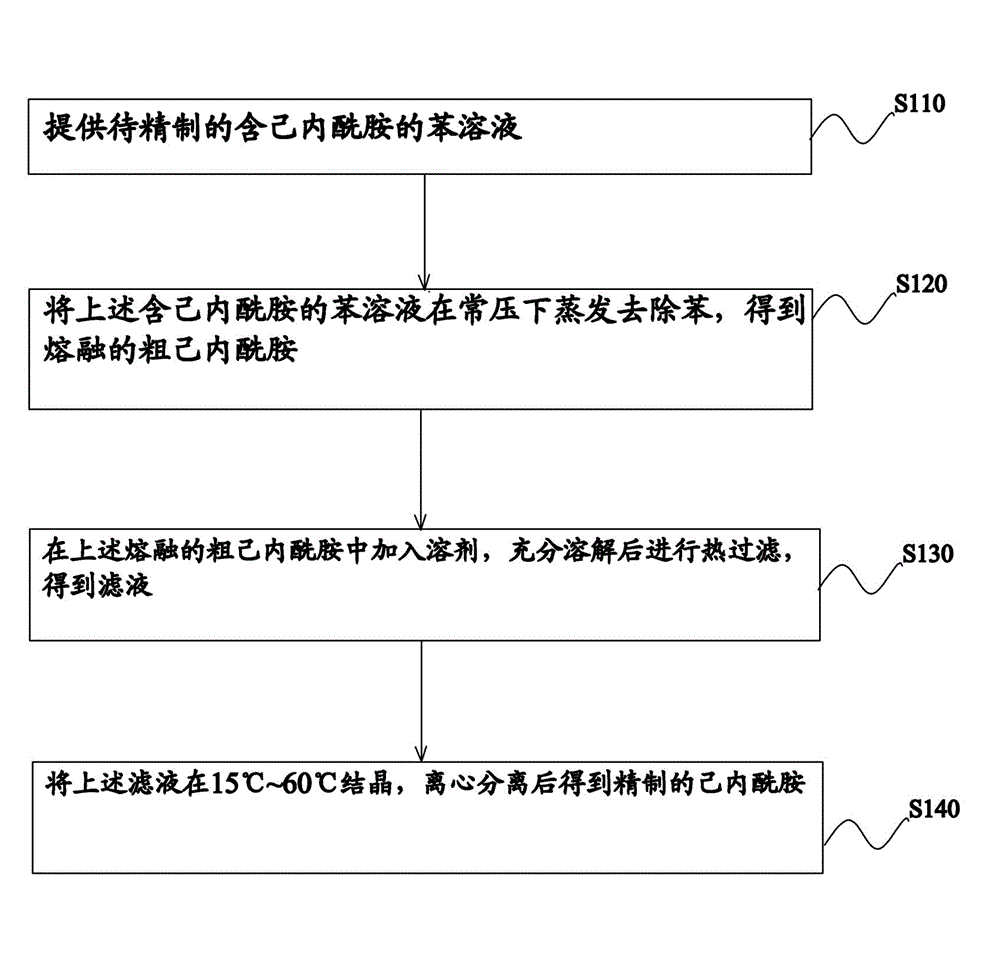

Method used

Image

Examples

Embodiment 1

[0048] The benzene solution containing caprolactam to be refined is provided, the above-mentioned benzene solution containing caprolactam is heated to 75° C., and the benzene is evaporated under normal pressure to obtain molten crude caprolactam. Diisopropyl ether was added to the above molten crude caprolactam, the mass ratio of molten crude caprolactam to diisopropyl ether was 1:3, and after fully dissolved, hot filtration was performed at 40°C to obtain a filtrate. The above filtrate was crystallized at 15°C, and purified caprolactam was obtained after centrifugation.

Embodiment 2

[0050] The benzene solution containing caprolactam to be refined is provided, the above-mentioned benzene solution containing caprolactam is heated to 100° C., and the benzene is evaporated under normal pressure to obtain molten crude caprolactam. Add cyclohexane to the above molten crude caprolactam, the mass ratio of the molten crude caprolactam to cyclohexane is 2:1, fully dissolve and perform hot filtration at 85°C to obtain a filtrate. The above filtrate was crystallized at 60°C, and purified caprolactam was obtained after centrifugation.

Embodiment 3

[0052] The benzene solution containing caprolactam to be refined is provided, the above-mentioned benzene solution containing caprolactam is heated to 80° C., and the benzene is evaporated under normal pressure to obtain molten crude caprolactam. Add n-hexane to the above melted crude caprolactam, the mass ratio of molten crude caprolactam to n-hexane is 1:1, fully dissolve and perform hot filtration at 60°C to obtain filtrate. The above filtrate was crystallized at 40°C, and purified caprolactam was obtained after centrifugation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com