Multifunctional refining agent, cold batch liquid and cold batch pretreatment method

A refining agent, multi-functional technology, used in fiber processing, biochemical fiber processing, textiles and papermaking, etc., can solve the general trend of not adapting to cleaner production, no solutions, poor fabric adaptability and other problems, to achieve excellent hydrogen peroxide stability Performance, saving water and energy consumption, and the effect of low fabric strength loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The mass of each part is 1g, take 12 parts of nonionic surfactant, 13 parts of anionic surfactant, 0.3 part of antistatic agent, 2 parts of stabilizer, 5 parts of chelating dispersion system, 0.2 part of antibacterial agent, and 4 parts of pH regulator Parts, 6 parts of mixtures of polyether ester and vegetable oil, 1.5 parts of enzyme preparation, appropriate amount of solvent and water to prepare a multifunctional refining agent; wherein: nonionic surfactant is isomerism tridecyl alcohol ethoxylate; anionic surfactant It is alkylbenzene sulfonate; the stabilizer includes 16 parts of sodium gluconate, 33 parts of magnesium sulfate, 5 parts of sodium sulfite, and 12 parts of water; the chelating dispersion system is acrylic acid; the pH regulator is an organic alkaline substance; the solvent is environmentally friendly solvent.

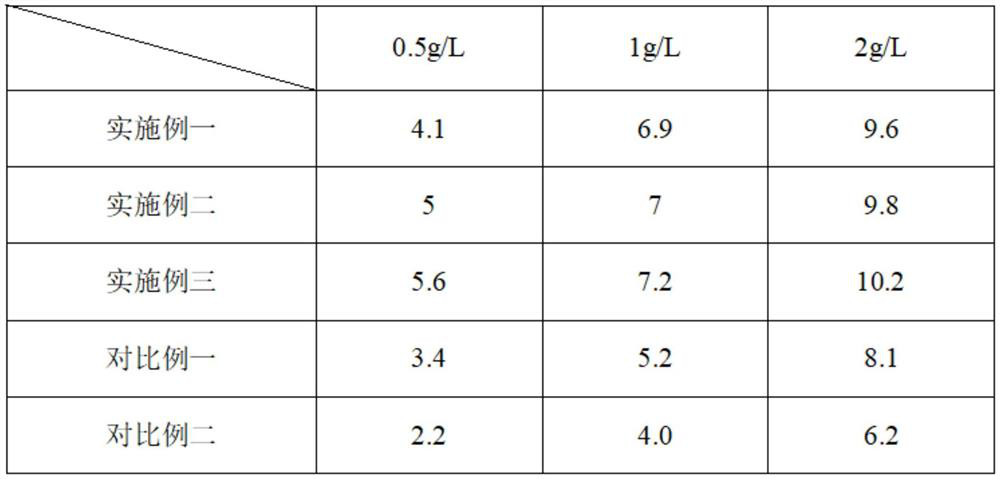

[0036] Take the prepared multifunctional refining agent and add it to water, the ratio of the amount of multifunctional refining agent to wate...

Embodiment 2

[0038] The mass of each part is 1g, take 15 parts of nonionic surfactant, 19 parts of anionic surfactant, 0.6 part of antistatic agent, 5 parts of stabilizer, 7 parts of chelating dispersion system, 0.4 part of antibacterial agent, and 6 parts of pH regulator part, 10 parts of mixture of polyether ester and vegetable oil, 4.2 parts of enzyme preparation, solvent and water to prepare multifunctional refining agent in right amount; Wherein: nonionic surfactant is isomerism tridecyl alcohol ethoxylate; Anionic surfactant It is alkylbenzene sulfonate; the stabilizer includes 18 parts of sodium gluconate, 40 parts of magnesium sulfate, 7 parts of sodium sulfite, and 15 parts of water; the chelating dispersion system is acrylic acid; the pH regulator is an organic alkaline substance; the solvent is environmentally friendly solvent.

[0039] Take the prepared multifunctional refining agent and add it to water, the ratio of the amount of multifunctional refining agent to water is 0.5g / L...

Embodiment 3

[0041] The quality of each part is 1g, take 19 parts of nonionic surfactant, 24 parts of anionic surfactant, 0.9 part of antistatic agent, 7 parts of stabilizer, 9 parts of chelating dispersion system, 0.6 part of antibacterial agent, and 9 parts of pH regulator Parts, 14 parts of mixture of polyether ester and vegetable oil, 7.9 parts of enzyme preparation, appropriate amount of solvent and water prepare multifunctional refining agent; Wherein: nonionic surfactant is isomerism tridecyl alcohol ethoxylate; Anionic surfactant It is alkylbenzene sulfonate; the stabilizer includes 20 parts of sodium gluconate, 48 parts of magnesium sulfate, 9 parts of sodium sulfite, and 17 parts of water; the chelating dispersion system is acrylic acid; the pH regulator is an organic alkaline substance; the solvent is environmentally friendly solvent.

[0042] Take the prepared multifunctional refining agent and add it to water, the ratio of the amount of multifunctional refining agent to water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com