Method for manufacturing natural gas by utilizing low-rank coal

A low-rank coal and natural gas technology, applied in the field of natural gas preparation, can solve the problems of immature process technology, high raw material gas requirements, and high operating costs, and achieve the effects of easy grid-connected transportation, reduced impurity content, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

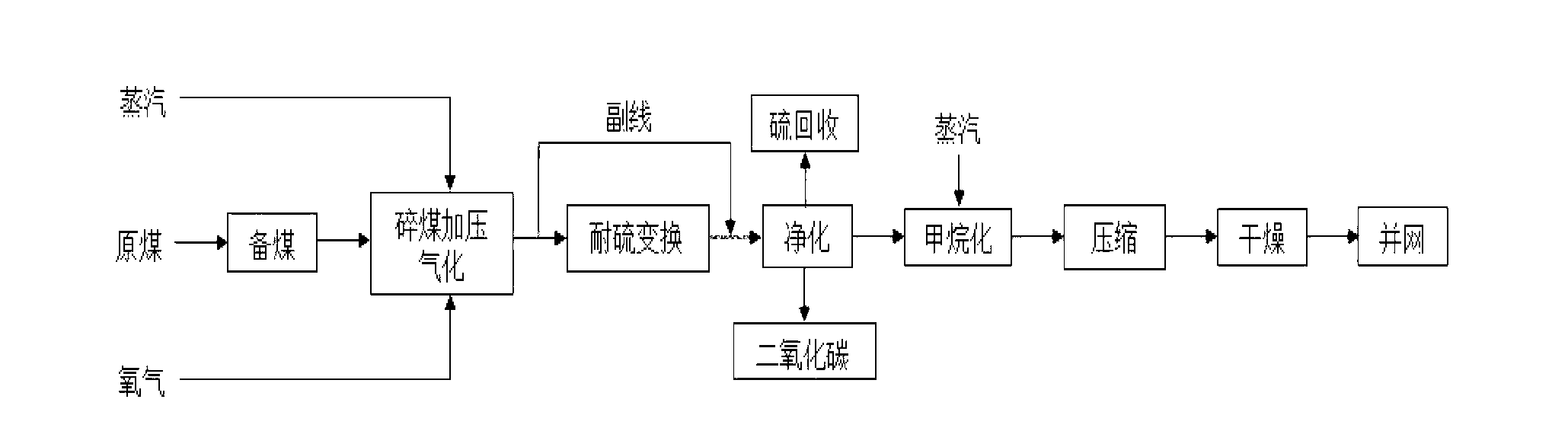

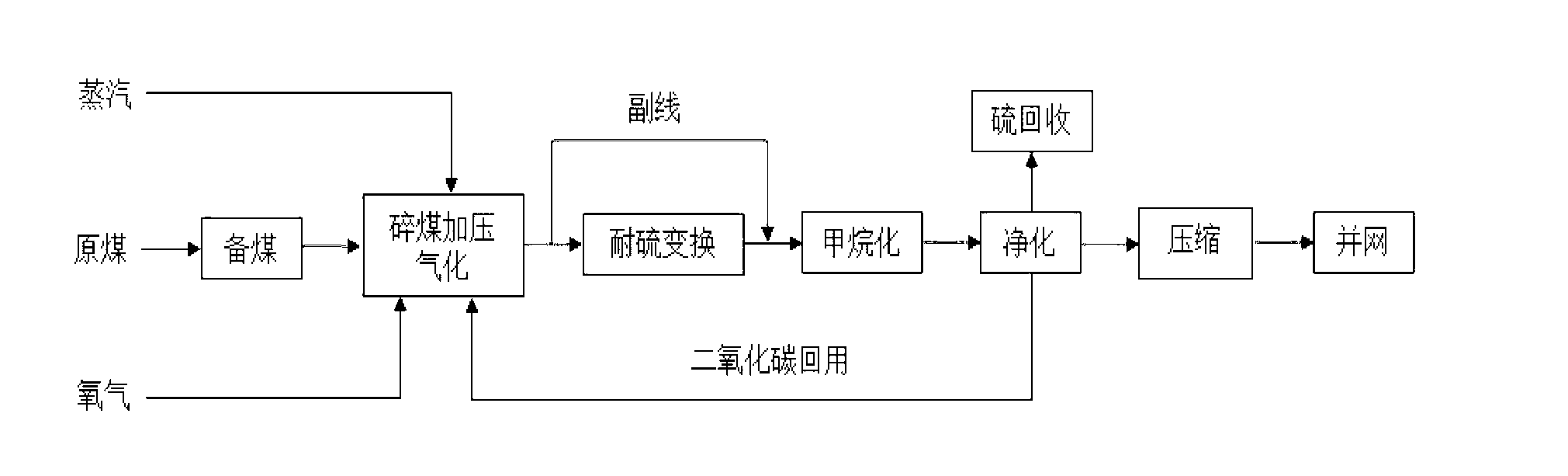

Method used

Image

Examples

Embodiment 1

[0046] Using lignite as raw material, pressurized gasification of crushed coal (gasification pressure 4.0MPa, gasification temperature 1050°C, gasification agent is water vapor, CO 2 and oxygen in accordance with water vapor: CO 2 : Oxygen=7kg: 1Nm 3 : 1Nm 3 Composition of multi-component mixed gasification agent), the composition of the produced gas is (V%):

[0047] h 2 : 37.88, CO: 20.25, CH 4 : 10.65, CO 2 : 30.25, H 2 S: 0.22, N 2 : 0.75

[0048] 27.52% of the above gas is subjected to sulfur-resistant transformation (transformation pressure is 3.85MPa, transformation temperature is 220-385°C, space velocity is 3500h -1 , the catalyst is the QCS-04 sulfur-resistant shift catalyst produced by Keli Chemical Company of Qilu Petrochemical Research Institute in China), which is mixed with the unshifted gas passing through the auxiliary line to obtain the gas composition (V%):

[0049] h 2 : 42.50, CO: 13.90, CH 4 : 8.80, CO 2 : 33.90, H 2 S: 0.20, N 2 : 0.70

[...

Embodiment 2

[0054] The long-flame coal is used as raw material to gasify crushed coal under pressure (gasification pressure is 3.0MPa, gasification temperature is 1020°C, gasification agent is water vapor, CO 2 and oxygen in accordance with water vapor: CO 2 : Oxygen=6kg: 2Nm 3 : 1Nm 3 Composition of multi-component mixed gasification agent), the composition of the produced gas is (V%):

[0055] h 2 : 38.77, CO: 20.68, CH 4 : 9.79, CO 2 : 30.06, H 2 S: 0.25, N 2 : 0.45

[0056] 29.89% of the above gas is subjected to sulfur-resistant transformation (transformation pressure is 2.85MPa, transformation temperature is 255-385°C, space velocity is 5300h -1 , the catalyst is a sulfur-resistant shift catalyst with high hydrolysis function disclosed in Chinese patent 200410008740.6), mixed with the unshifted gas passing through the auxiliary line to obtain the gas composition (V%):

[0057] h 2 : 42.30, CO: 13.60, CH 4 : 9.20, CO 2 : 34.10, H 2 S: 0.20, N 2 : 0.40

[0058] The abov...

Embodiment 3

[0062] The long-flame coal is used as raw material to gasify crushed coal under pressure (gasification pressure is 6.0MPa, gasification temperature is 1250°C, gasification agent is water vapor, CO 2 and oxygen in accordance with water vapor: CO 2 : Oxygen=3kg: 4Nm 3 : 1Nm 3 Composition of multi-component mixed gasification agent), the composition of the produced gas is (V%):

[0063] h 2 : 33.61, CO: 32.25, CH 4 : 8.69, CO 2 : 24.64, H 2 S: 0.15, N 2 : 1.16

[0064] 58.00% of the above gas is subjected to sulfur-resistant transformation (transformation pressure is 5.85MPa, transformation temperature is 285-480°C, space velocity is 7100h -1 , the catalyst is the QDB series sulfur-resistant shift catalyst produced by Qingdao Lianxin Chemical Industry Co., Ltd.), mixed with the unshifted gas passing through the auxiliary line to obtain the gas composition (V%):

[0065] h 2 : 43.02, CO: 12.48, CH 4 : 6.90, CO 2 : 36.50, H 2 S: 0.10, N 2 : 1.00

[0066] The above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com