A flue gas desulfurization zero-emission resource processing system and method

A resource treatment and zero-emission technology, which is applied in gaseous discharge wastewater treatment, sludge treatment, filtration treatment, etc., can solve the problems of poor economic benefit of recovered products, insufficient utilization of recovered materials, and high operating costs, and achieve high-efficiency resources. The effect of reducing environmental pollution and resource waste, and reducing process water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

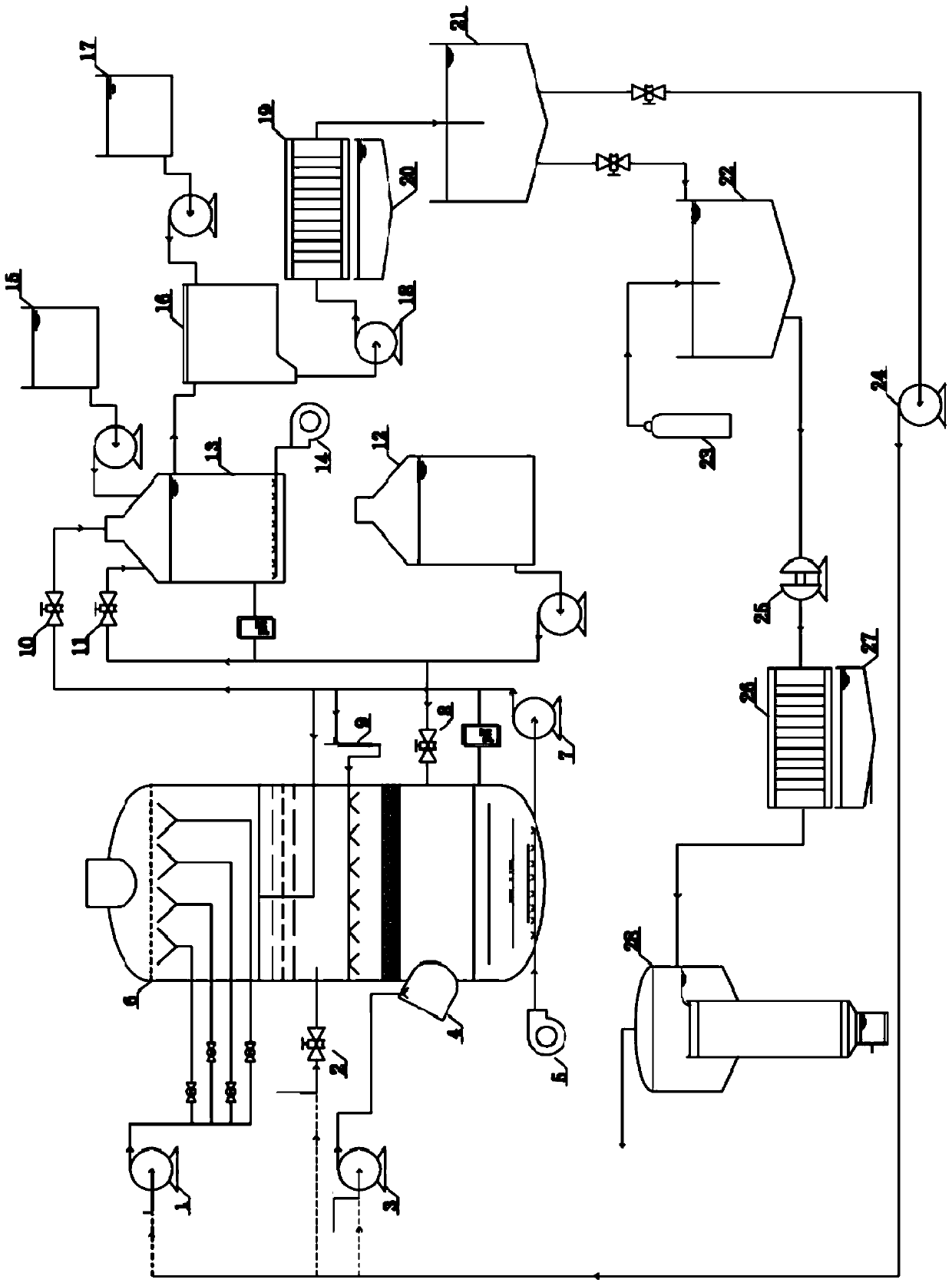

[0042] In order to better illustrate the present invention, the present invention will be described in detail with a preferred embodiment and with accompanying drawings, specifically as follows:

[0043] like figure 1 As shown, the flue gas desulfurization zero-emission resource processing system provided by the present invention includes:

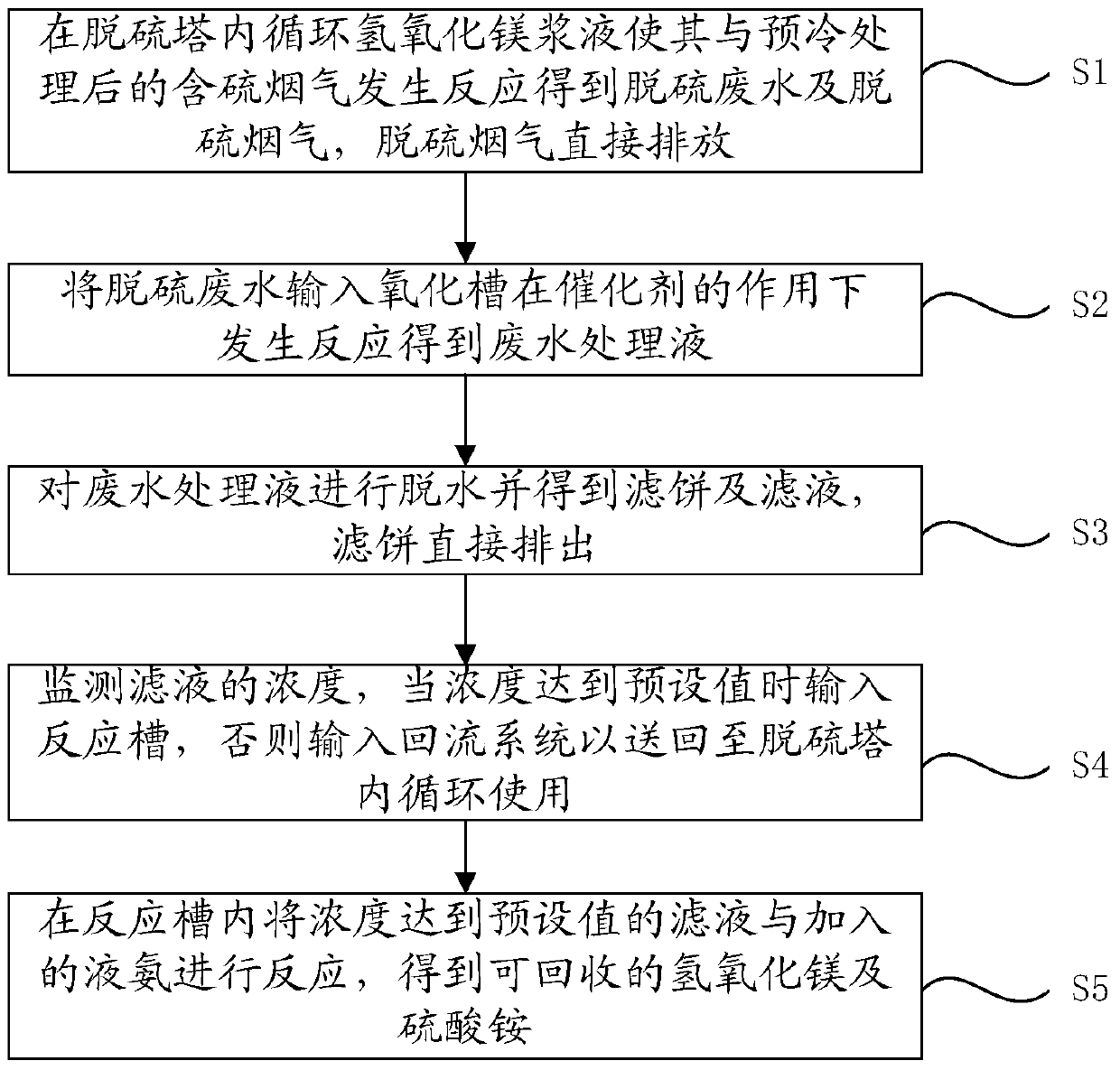

[0044] Desulfurization tower 6, the desulfurization tower 6 is used to store magnesium hydroxide slurry, and circulate the magnesium hydroxide slurry to react with sulfur-containing flue gas to obtain desulfurization wastewater and desulfurization flue gas, wherein the desulfurization flue gas is directly discharged;

[0045] An oxidation tank 13, the oxidation tank 13 is used to obtain the above-mentioned desulfurization wastewater, so that the desulfurization wastewater reacts under the catalysis of the catalyst to obtain a wastewater treatment liquid, and the catalyst improves the conversion efficiency of magnesium sulfite;

[0046] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com