Recycling method of lactic acid fermentation acid-containing wastewater

A technology of lactic acid fermentation and wastewater, applied in microorganism-based methods, fermentation, chemical instruments and methods, etc., can solve problems such as environmental pollution, waste of water resources, increase production costs of enterprises, etc., achieve important environmental benefits, improve recovery rate, The effect of saving process water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

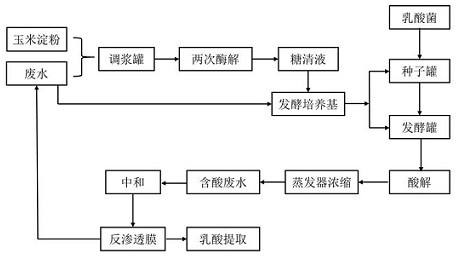

[0022] like figure 1 As shown, 300kg of cornstarch, 637.5kg of lactic acid reverse osmosis wastewater, mixed uniformly in a slurry tank at 50°C, added calcium hydroxide to adjust the pH to 6.0, and added 150g of high temperature resistant α-amylase with an enzyme activity unit of 20000U / g. After the second injection liquefaction, the first injection temperature is 97°C, heat preservation for 60min, the second injection temperature is 110°C, high temperature is maintained for 5min, vacuum flash cooling to 95°C, cooling to 60°C, adding 1000000U / g glucoamylase 60g, using Adjust the pH to 4.8 with lactic acid, and after saccharification at 60°C for 60 hours, filter the sugar solution with a plate frame.

[0023] The sugar clear liquid does not add lactic acid reverse osmosis wastewater, the total sugar of the mixed liquid is 235g / L, add 0.2% ammonium sulfate, 0.05% yeast powder; sterilize at 115 degrees Celsius for 30 minutes, insert lactic acid bacteria for fermentation, and cult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com