A kind of preparation method of mannanase and its extraction and refining device

A technology of mannanase and bacteria strains, applied in the field of mannanase, can solve the problems of only 80% of the finished product hygiene index pass rate, only 70% of the product yield, and poor on-site environment, so as to expand product sales The effect of increasing the scope, enhancing product value, and increasing the qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

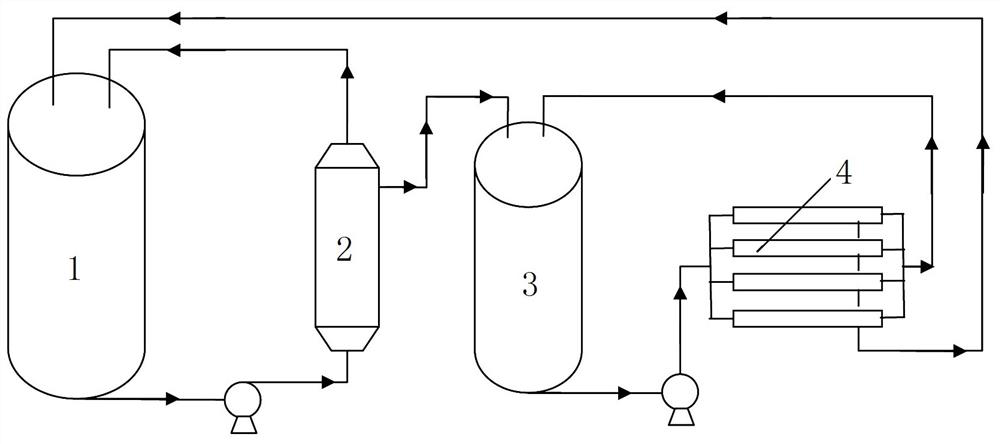

Image

Examples

Embodiment 1

[0032] A method for extracting and refining mannanase, the steps are:

[0033] 1) The fermented liquid is concentrated by circulating filtration with a ceramic membrane, and the temperature of the circulating feed liquid is controlled below 20°C; the pore size of the ceramic membrane is 100nm, the operating pressure difference is 0.40MPa, and the membrane surface flow rate is 3.5m / s. The filtrate was clear and transparent, with a slag content < 0.05%, and a yield of 88.8%.

[0034] 2) After concentrating for 4 hours, the filtrate filtered by the ceramic membrane is circulated and concentrated by ultrafiltration membrane equipment, and the temperature of the circulating feed liquid is controlled below 20°C; the ultrafiltration membrane is an organic membrane with a molecular weight cut-off of 10,000 Daltons. The concentrated solution obtained by ultrafiltration is still clear and transparent, the volume is reduced to 1 / 5 of the filtrate volume, and the yield is 97.5%.

[0035]...

Embodiment 2

[0037] A method for extracting and refining mannanase, the steps are:

[0038] 1) The fermented liquid is concentrated by circulating filtration with a ceramic membrane, and the temperature of the circulating feed liquid is controlled below 20°C; the pore size of the ceramic membrane is 200nm, the operating pressure difference is 0.40MPa, and the membrane surface flow rate is 2.5m / s. The filtrate is clear and transparent, with a slag content < 0.07%, and a yield of 89.3%.

[0039] 2) After concentrating for 8 hours, the filtrate filtrated by the ceramic membrane is circulated and concentrated by ultrafiltration membrane equipment, and the temperature of the circulating feed liquid is controlled below 20°C; the ultrafiltration membrane is an organic membrane with a molecular weight cut-off of 10,000 Daltons. The concentrated solution obtained by ultrafiltration is still clear and transparent, and the volume is reduced to 1 / 7 of the filtrate volume, and the yield is 97.3%.

[0...

Embodiment 3

[0042] A method for extracting and refining mannanase, the steps are:

[0043] 1) The fermented liquid is concentrated by circulating filtration with a ceramic membrane, and the temperature of the circulating feed liquid is controlled below 20°C; the pore size of the ceramic membrane is 500nm, the operating pressure difference is 0.30MPa, and the membrane surface flow rate is 2.5m / s. The filtrate is clear and transparent, with a slag content < 0.08%, and a yield of 89.7%.

[0044]2) After concentrating for 6 hours, the filtrate filtered by the ceramic membrane is circulated and concentrated by ultrafiltration membrane equipment, and the temperature of the circulating feed liquid is controlled below 20°C; the ultrafiltration membrane is an organic membrane with a molecular weight cut-off of 20,000 Daltons. The concentrated solution obtained by ultrafiltration is still clear and transparent, and the volume is reduced to 1 / 8 of the filtrate volume, and the yield is 97.0%.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com