Refining method of caprolactam

A technology of caprolactam and refining method, which is applied in the field of caprolactam refining, and can solve the problems of large process water consumption and complicated process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

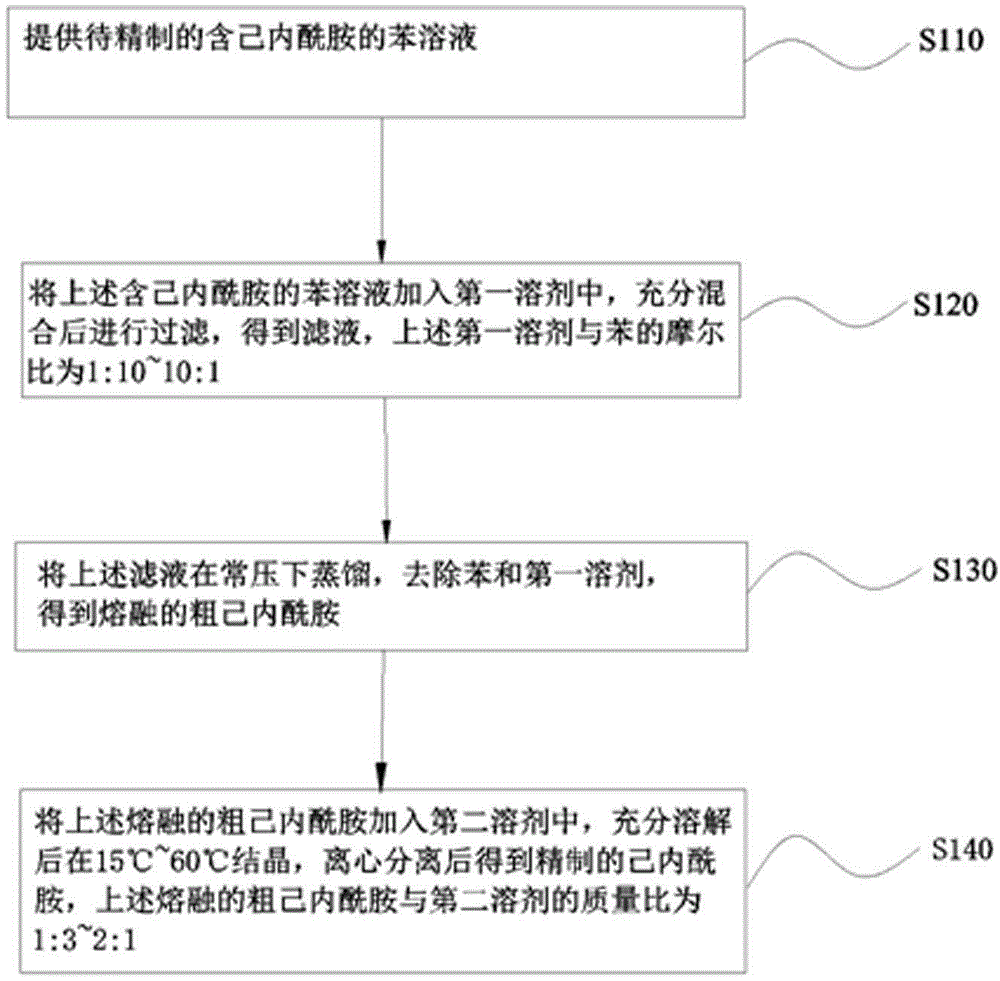

Method used

Image

Examples

Embodiment 1

[0056] Provide the benzene solution containing caprolactam to be refined, add the above-mentioned benzene solution containing caprolactam into methanol, mix thoroughly and then filter to obtain the filtrate, the molar ratio of methanol to benzene is 1:10. The above filtrate was distilled at 75°C under normal pressure to remove benzene and methanol to obtain molten crude caprolactam. Then add the molten crude caprolactam into diisopropyl ether, fully dissolve and crystallize at 15°C, and obtain refined caprolactam after centrifugation. The mass ratio of the above molten crude caprolactam to diisopropyl ether is 1:3.

Embodiment 2

[0058] Provide the benzene solution containing caprolactam to be refined, add the above-mentioned benzene solution containing caprolactam into ethanol, mix thoroughly and then filter to obtain the filtrate, the molar ratio of ethanol to benzene is 10:1. Distill the above filtrate at 100°C under atmospheric pressure to remove benzene and ethanol to obtain molten crude caprolactam. Then add the molten crude caprolactam into cyclohexane, fully dissolve and crystallize at 60°C, and obtain refined caprolactam after centrifugation. The mass ratio of the above molten crude caprolactam to cyclohexane is 2:1.

Embodiment 3

[0060] Provide the benzene solution containing caprolactam to be refined, add the above-mentioned benzene solution containing caprolactam into methanol, mix thoroughly and then filter to obtain the filtrate, the molar ratio of methanol to benzene is 2.2:1. Distill the above filtrate at 80°C under normal pressure to remove benzene and methanol to obtain molten crude caprolactam. Then add the melted crude caprolactam into n-hexane, fully dissolve and crystallize at 40°C, and obtain refined caprolactam after centrifugation. The mass ratio of the above-mentioned molten crude caprolactam to n-hexane is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com