Spade heat-treatment medium recovering device and method for recovering medium using the device

A technology for recovering device and medium, applied in the field of shovel heat treatment medium recovery device, can solve the problems such as overflowing environment of drying pond pharmaceutical industry, inability to dry normally, limitation of natural conditions, etc., and achieve the effects of scientific structure design, small water consumption and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

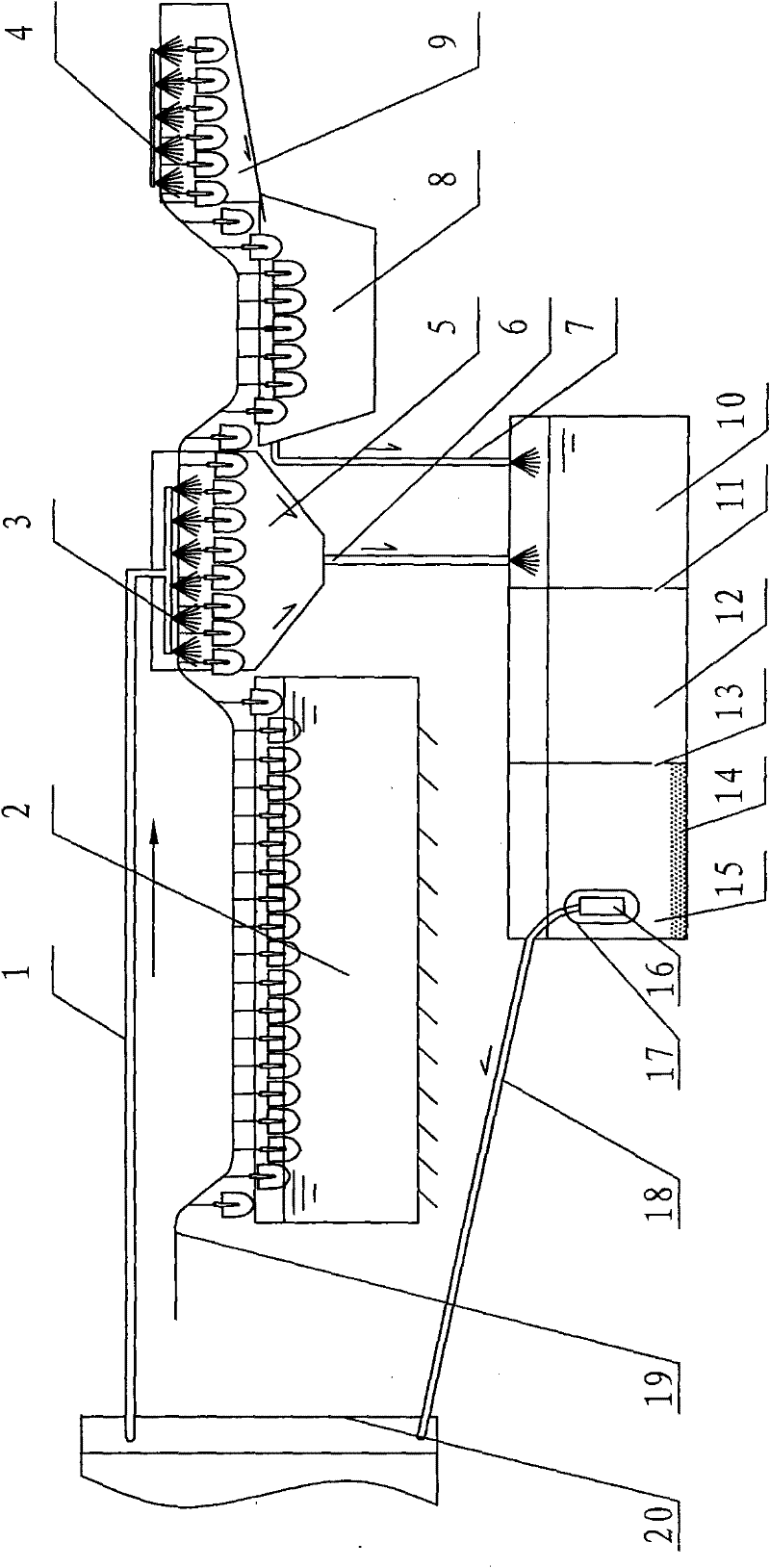

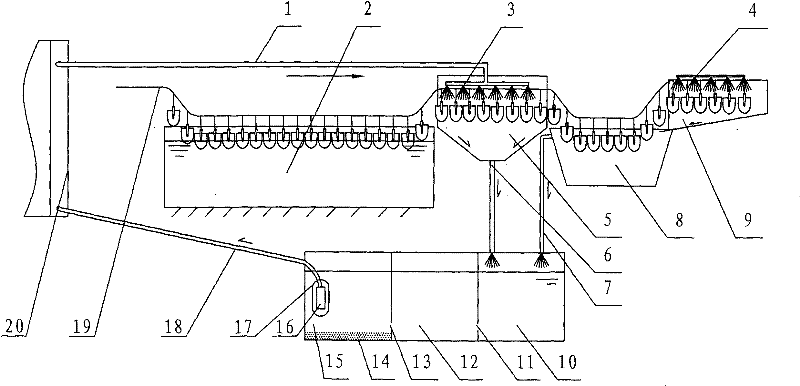

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] The heat treatment medium recovery device in this embodiment is divided into three parts: salt bath, cleaning and recovery. See attached figure 1 , the automatic conveying chain 17 is suspended on the salt bath tank 2, above the dissolution and washing chamber 5, the soaking and dilution chamber 8, and the clear water spray chamber 9, and the top of the dissolution and washing chamber 5 and the clear water spray chamber 9 is provided with a conveyor chain 19 to run through The passage, the workpiece shovel is horizontally suspended on the automatic conveyor chain 17. The cleaning device is composed of a washing room 5, a soaking and diluting tank 8 and a water spraying room 9. The spraying device for cleaning, which is composed of a hot water nozzle 3 and a water nozzle 4, is respectively located in the washing room 5 and the water spraying ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com