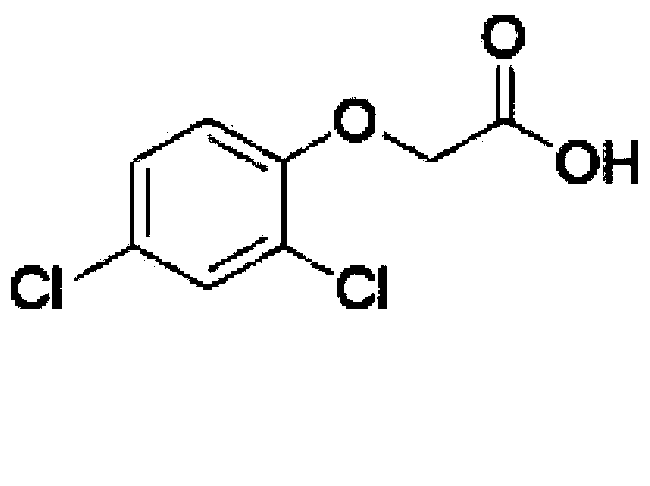

Preparation method of high-purity 2,4-D

A high-purity, 4-D technology, applied in the preparation of organic compounds, carboxylate, carboxylate, etc., can solve the problems of cumbersome operation steps, long reaction time, large process water consumption, etc., and achieve simplified process Steps, increase product yield, shorten the effect of reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of high-purity 2,4-D, comprising the steps of:

[0024] (1) 98.5% 2,4-dichlorophenol 1650kg, and 32% liquid caustic soda, add water 100kg, react at 60°C for 2 hours to make 2,4-dichlorophenol sodium, wherein the 2,4-dichlorophenol and the The molar ratio of said liquid alkali is 1:1.1;

[0025] (2) 1150 kg of chloroacetic acid with a purity of 99% was directly reacted with the 2,4-dichlorophenate sodium at pH=9-11, 100-120°C for 3-4 hours to obtain 2,4-D sodium salt. The mol ratio of said chloroacetic acid and said 2,4-dichlorophenate sodium is 1.3:1;

[0026] (3) The 2,4-D sodium salt is press-filtered and acidified for 2-3 hours to form a 2,4-D crude product; the acidification process is as follows: add 2,4-D sodium salt to water and heat to 80 At 90°C, under stirring conditions, add industrial hydrochloric acid to adjust PH=9-11, stop heating, stir until the crude product of 2,4-D precipitates after cooling, and the mass ratio of 2,4-D sodium s...

Embodiment 2

[0030] A preparation method of high-purity 2,4-D, comprising the steps of:

[0031] (1) Preparation of sodium 2,4-dichlorophenate: react 2,4-dichlorophenol with a concentration of 98.5% and liquid caustic soda with a concentration of 32% at 65°C for 2 hours to prepare sodium 2,4-dichlorophenate ; Wherein the molar ratio of the 2,4-dichlorophenol and the liquid caustic soda is 1:1.2, the yield of the 2,4-dichlorophenol sodium is 99.5%;

[0032] (2) Preparation of 2,4-D sodium salt: react chloroacetic acid with a purity of 99% directly with the 2,4-dichlorophenate sodium at pH=10-11, 120°C for 3-4 hours to obtain 2,4-D -D sodium salt, the molar ratio of the chloroacetic acid to the 2,4-dichlorophenate sodium is 1.4:1, and the yield of the 2,4-D sodium salt is 98%;

[0033] (3) Preparation of 2,4-D crude product: the 2,4-D sodium salt was press-filtered and acidified for 3 hours to form 2,4-D crude product, and the yield of the 2,4-D crude product was 99.5% The acidification pr...

Embodiment 3

[0037] A preparation method of high-purity 2,4-D, comprising the steps of:

[0038] (1) Preparation of sodium 2,4-dichlorophenate: react 2,4-dichlorophenol with a concentration of 98.5% and liquid caustic soda with a concentration of 32% at 50°C for 2 hours to prepare sodium 2,4-dichlorophenate ; Wherein the molar ratio of the 2,4-dichlorophenol and the liquid caustic soda is 1:1, the yield of the 2,4-dichlorophenol sodium is 99.5%;

[0039] (2) Preparation of 2,4-D sodium salt: directly react chloroacetic acid with a purity of 99% with the 2,4-dichlorophenate sodium at pH=9-10,100°C for 3-4 hours to obtain 2,4-D -D sodium salt, the molar ratio of the chloroacetic acid to the 2,4-dichlorophenate sodium is 1.2:1, and the yield of the 2,4-D sodium salt is 98%;

[0040] (3) Preparation of 2,4-D crude product: the 2,4-D sodium salt was press-filtered and acidified for 3 hours to form 2,4-D crude product, and the yield of the 2,4-D crude product was 99.5% ; The acidification proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com