A kind of tea saponin extraction and refining process

A tea saponin and process technology, applied in the field of tea saponin extraction and refining process, can solve the problems of difficult separation of impurities, high refining difficulty, low tea saponin purity, etc., and achieve the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

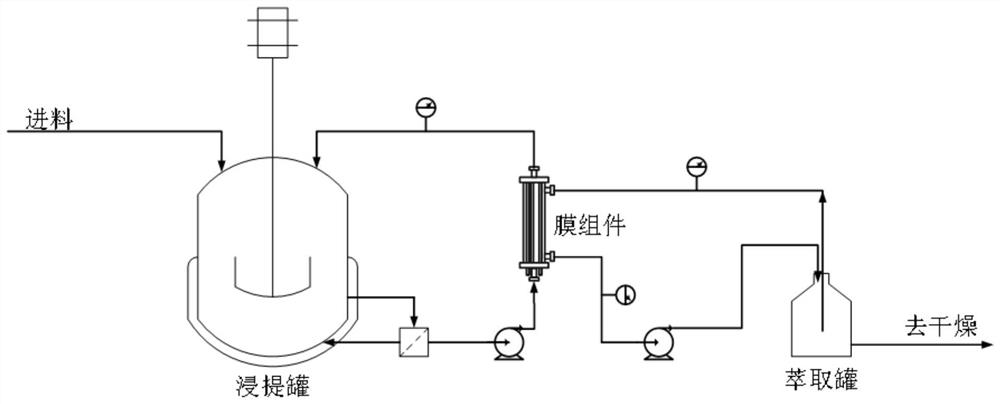

Image

Examples

Embodiment 1

[0023] The present embodiment provides a tea saponin extraction and refining process, and the refining process is carried out according to the following steps:

[0024] (1) Raw material pretreatment: the camellia oleifera seed meal was dried in an oven at 60° C. for 24 hours, and pulverized through a 60-mesh sieve to obtain a raw material powder, and 50 grams of the raw material powder was taken for later use;

[0025] (2) the product obtained in the step (1) is 1:5 (g / mL) and 250 mL of water is added according to the weight-to-volume ratio of the material to liquid, and the mixture is uniformly stirred;

[0026] (3) the temperature of the feed liquid in the adjustment step (2) is 80°C, and the heat preservation treatment (ie, water extraction) is carried out for 2h;

[0027] (4) After the step (3) is kept for another 0.5h, the feed liquid (water extraction solution) is turned on to circulate on the shell side of the membrane module, and a microfiltration device is added to th...

Embodiment 2

[0031] Example 2 (change the ratio of material to water = on the basis of Example 1, change the ratio of extractant and water extract)

[0032] The present embodiment provides a tea saponin extraction and refining process, and the refining process is carried out according to the following steps:

[0033](1) Raw material pretreatment: the camellia oleifera seed meal was dried in an oven at 60° C. for 24 hours, and pulverized through a 60-mesh sieve to obtain raw material powder, and 50 grams of raw material powder was obtained for use;

[0034] (2) the product obtained in the step (1) is 1:3 (g / mL) according to the material-to-liquid weight-to-volume ratio, adds 150 mL of water, and stirs evenly;

[0035] (3) the temperature of the feed liquid in the adjustment step (2) is 80°C, and the heat preservation treatment (ie, water extraction) is carried out for 2h;

[0036] (4) After the step (3) is kept for another 0.5h, the feed liquid (water extraction solution) is turned on to c...

Embodiment 3

[0040] Example 3 (on the basis of Example 1, the ratio of extractant to water extract becomes larger)

[0041] The present embodiment provides a tea saponin extraction and refining process, and the refining process is carried out according to the following steps:

[0042] (1) Raw material pretreatment: the camellia oleifera seed meal was dried in an oven at 60° C. for 24 hours, and pulverized through a 60-mesh sieve to obtain a raw material powder, and 50 grams of the raw material powder was taken for later use;

[0043] (2) the product obtained in the step (1) is 1:5 (g / mL) and 250 mL of water is added according to the weight-to-volume ratio of the material to liquid, and the mixture is uniformly stirred;

[0044] (3) the temperature of the feed liquid in the adjustment step (2) is 80°C, and the heat preservation treatment (ie, water extraction) is carried out for 2h;

[0045] (4) After the step (3) is kept for another 0.5h, the feed liquid (water extraction solution) is tur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com