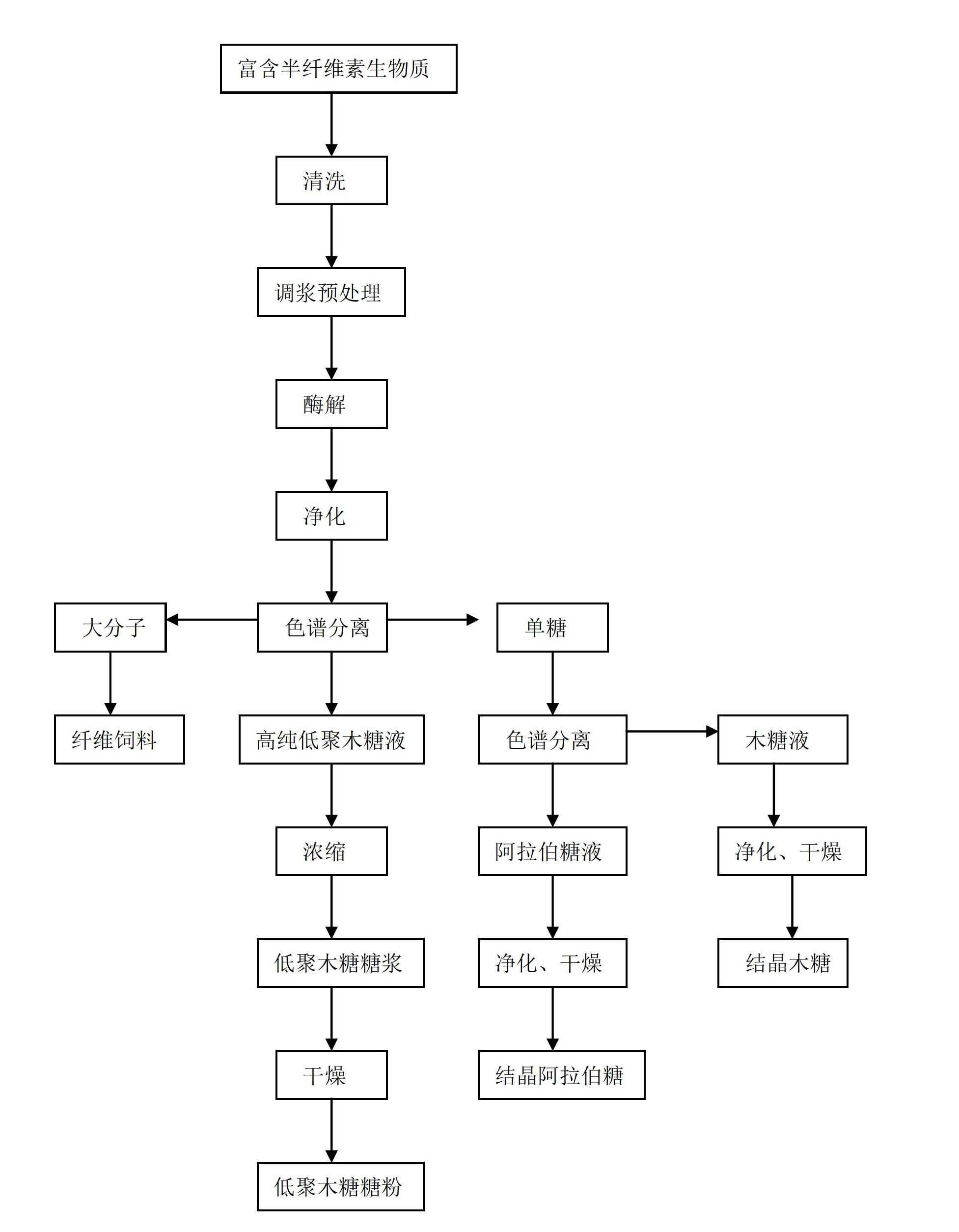

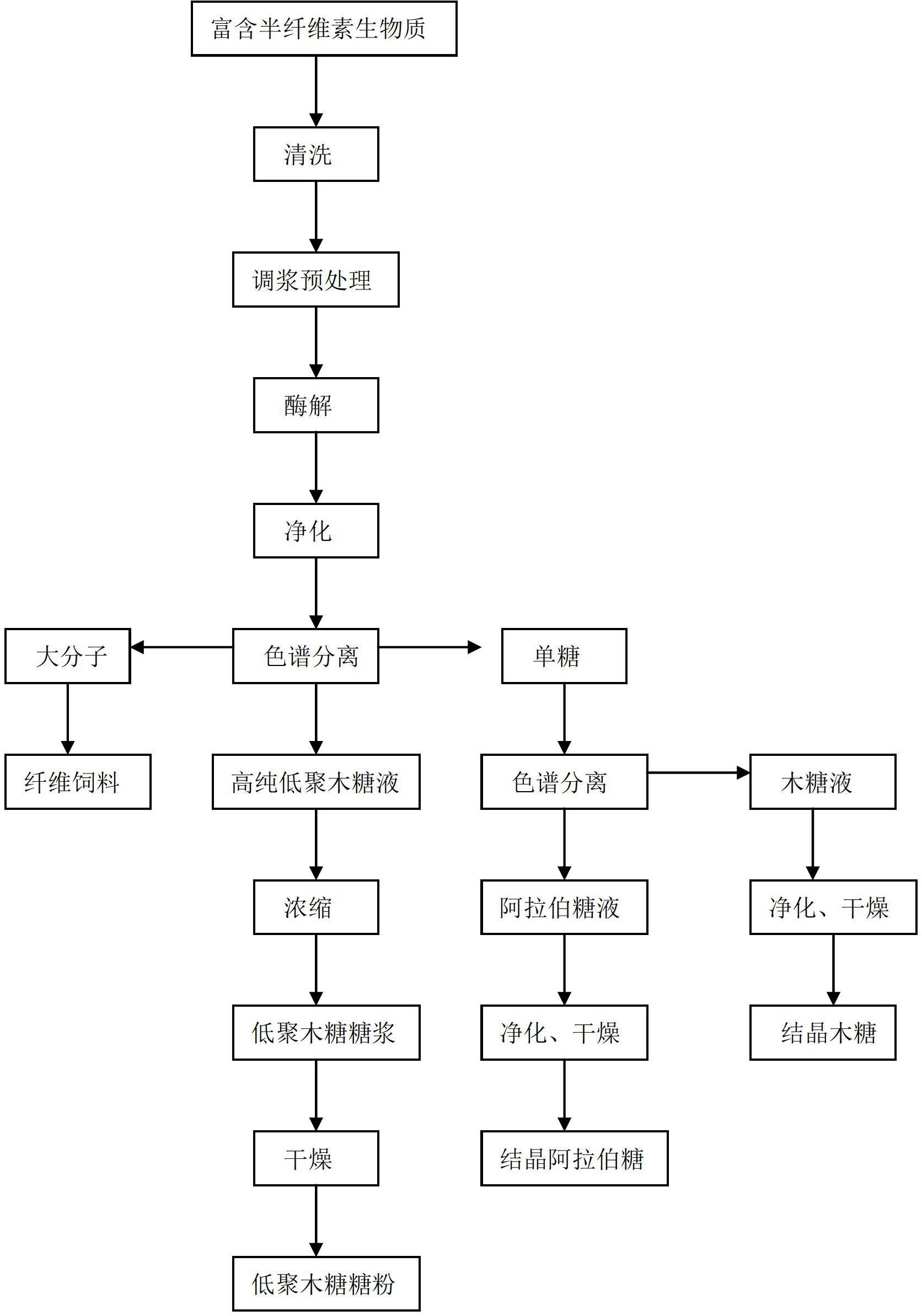

Bio-preparation method for production of high-purity xylo-oligosaccharide and coproduction of arabinose and xylose

A technology of xylo-oligosaccharides and arabinose, which is applied in the preparation of sugar derivatives, sugar derivatives, sugar derivatives, etc., can solve the problems of short service life of membrane, long production cycle, large energy consumption and water consumption, etc. The effect of improving product quality, low production cost and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Wash 2.5 tons of corn cob powder (30 mesh) with 0.1% sulfuric acid at a solid-to-liquid ratio of 1:15 at 80°C for 1 hour under stirring conditions; separate the washing liquid after cleaning;

[0048] (2) After cleaning, mix ingredients according to the solid-liquid ratio of 1:7, stir evenly, and pretreat at 140°C for 2 hours;

[0049] (3) Add xylanase to the pretreated material at a dry matter amount of 30IU / g for enzymolysis. After enzymolysis for 5 hours, separate the slag-liquid, control the slag moisture below 75%, decolorize and concentrate the sugar solution, and then Activated carbon decolorization (decolorization temperature 80°C, carbon addition 0.5%, decolorization time 30min) followed by ion exchange (D301 and 001×7); after ion exchange, the conductivity is controlled to 100us / cm 2 , pH value 2.5 ~ 6.5; light transmittance above 70%;

[0050] (4) The mixed sugar liquid is concentrated to a concentration of 50%, and separated by three-phase chromatograp...

Embodiment 2

[0056] (1) Wash 2.5 tons of bran (30 mesh) with 0.1% hydrochloric acid at a solid-to-liquid ratio of 1:12 at 70°C for 2 hours under stirring conditions; separate the washing liquid after cleaning;

[0057] (2) After cleaning, mix according to the solid-to-liquid ratio of 1:6, stir evenly, and pretreat at 130°C for 2.5 hours;

[0058] (3) Add xylanase to the pretreated material at 20 IU / g of dry matter for enzymolysis. After 6 hours of enzymolysis, separate the slag-liquid, control the moisture content of the slag below 75%, decolorize and concentrate the sugar solution, and then Activated carbon decolorization (decolorization temperature 80°C, carbon addition 0.7%, decolorization time 30 min ) after ion exchange (D301 and 001*7); after ion exchange, control conductivity, 100us / cm 2 2.5~6.5; transmittance over 70%;

[0059] (4) The mixed sugar liquid is concentrated to a concentration of 50%, and separated by three-phase chromatography. The chromatographic conditions: the st...

Embodiment 3

[0065] (1) Take xylose mother liquor with similar components to AD liquor, with xylose content of 49%, arabinose content of 19%, and glucose content of 16%; the liquor is diluted to 23% and added with 0.5% yeast for fermentation to remove glucose, and decolorized by activated carbon , ion exchange, concentrated to 57%. Carry out two-phase chromatographic separation, chromatographic conditions: the stationary phase is calcium-type resin, the mobile phase is water; the instantaneous flow rate of step A is 0.412 m 3 / h, setting time 1130 S; step B instantaneous flow 0.412 m 3 / h, set time 108 S; step C instantaneous flow 0.121 m 3 / h, setting time 616 S; step D instantaneous flow rate 0.321 m 3 / h sets the time to 516 s. Through the adjustment of the Z column, the content of xylose phase reaches more than 80%, and the content of arabinose reaches more than 80%;

[0066] (7) Negative pressure crystallization of concentrated xylose solution with a concentration of 68%; centrifu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com