Method and system for processing desulphurization waste water

A technology for desulfurization wastewater and wastewater, applied in energy wastewater treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of limited climate conditions, high cost, expensive anti-corrosion materials, etc., to reduce water evaporation and reduce water consumption , the effect of low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

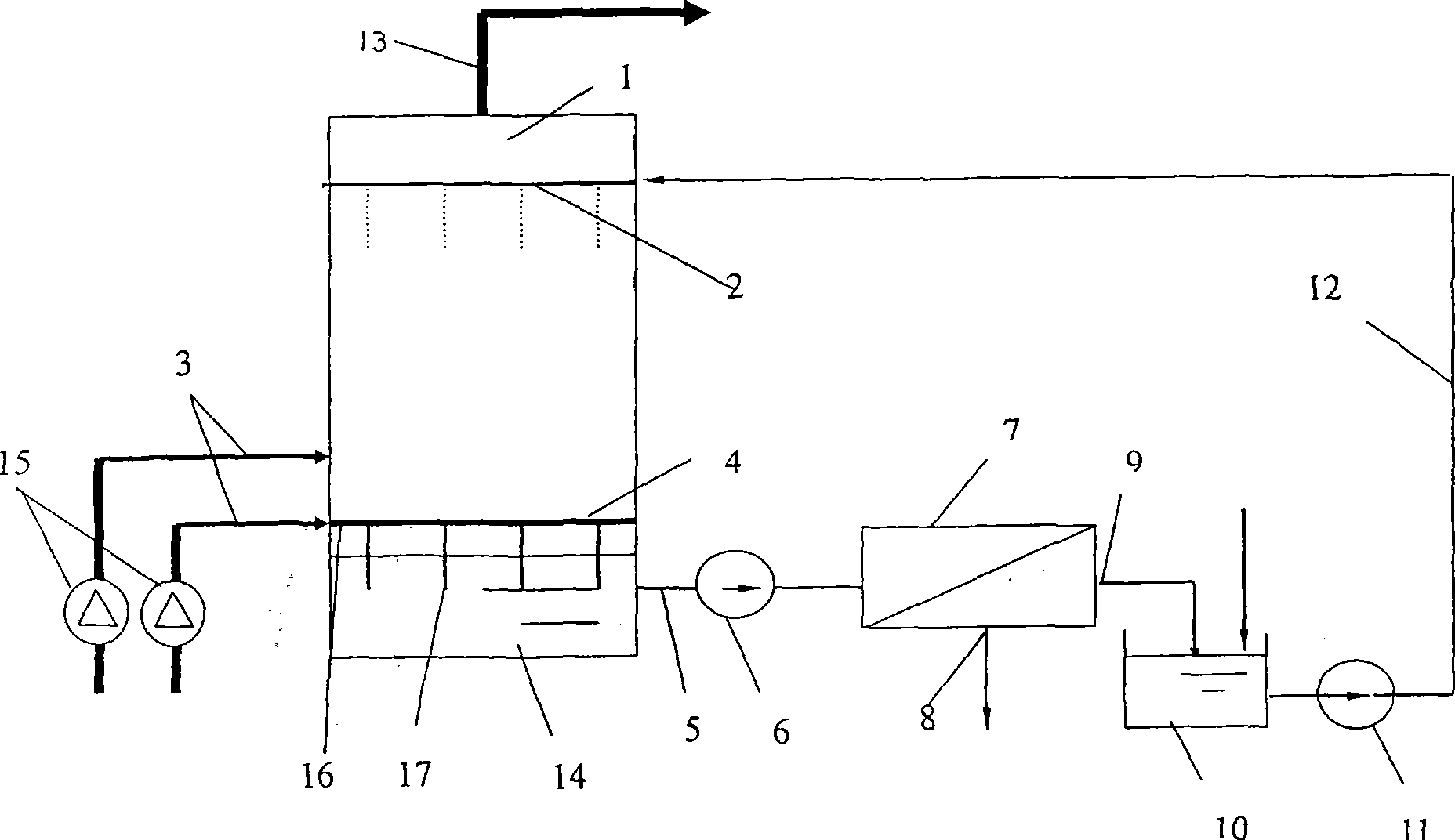

[0057] A 330MW unit adopts the limestone / gypsum desulfurization process for flue gas desulfurization, the desulfurization wastewater volume is about 6T / h, the solid content is 5000-10000mg / L, Cl - 1000~20000mg / L; the average temperature of the flue gas after the electrostatic precipitator is 130°C, and the flue gas volume (wet basis) is 1.25 million Nm 3 / h, 8% of the flue gas is introduced, that is, 100,000 Nm 3 / h (wet basis) enters the drying tower, a small part of which enters the bubbling and stirring device, and the rest enters the lower part of the drying tower. The system operates normally. When the liquid level of the circulating wastewater pool reaches a certain height, increase the input of hot flue gas. Up to 15%. The operation of this system does not affect the work of the desulfurization island.

[0058] In addition, the acid-base wastewater with high salt content discharged from the chemical water treatment workshop of the power plant is usually difficult to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com