Processing equipment for pulverizing kitchen solid rubbish

A solid waste and treatment device technology, applied in the field of kitchen solid waste crushing and treatment devices, can solve problems such as increasing the difficulty of sewage treatment, unfavorable solid waste resource utilization, and increasing the concentration of sewage pollutants, achieving simple processes and equipment, and convenient Effect of storage, reduction of water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

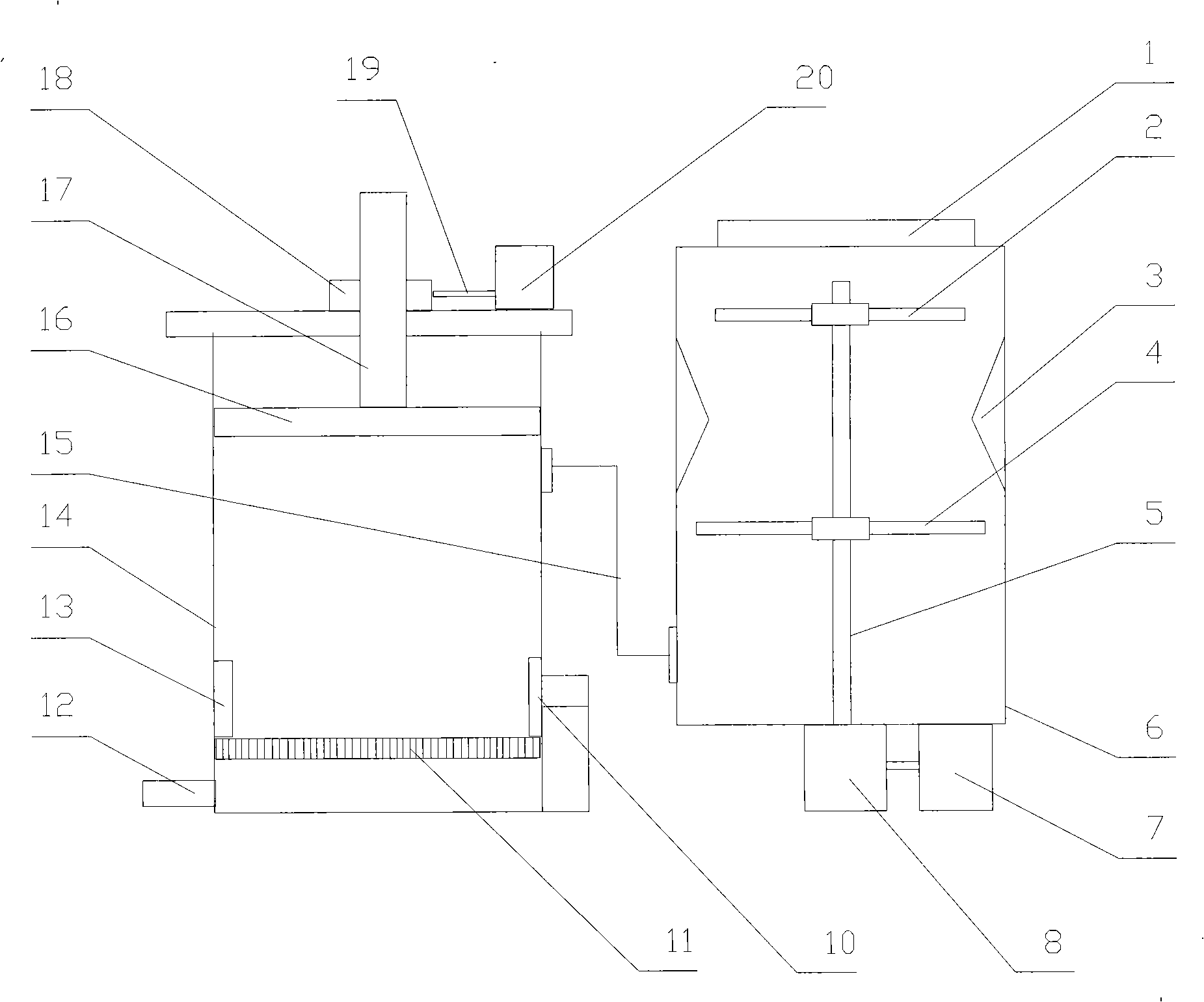

[0009] see figure 1 , the present invention provides a kitchen solid waste crushing and processing device, including a wet crusher and a filter press, the housing 6 of the wet crusher is provided with an upper knife 2 and a lower knife 4, and the upper knife and the lower knife Fixedly installed on the same rotating shaft 5, the housing of the filter press is provided with a fixed orifice plate 11 and a movable pressing plate 16. The pressing plate is located above the orifice plate and is provided with a pressing plate to drive it to move up and down filter driving mechanism, the discharge port of the wet crusher is connected with the feed port of the wet crusher through a connecting pipe 15.

[0010] The upper knife and the lower knife are in the shape of blades, and a certain distance is left between the two to give full play to the effects of each knife. The blade-shaped knife can chop solid objects in the water under the condition of high-speed rotation to achieve the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com