Technological method for controlling disinfection by-product and pathogenic microorganism risk of drinking water

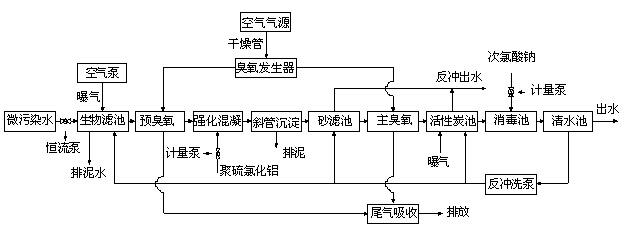

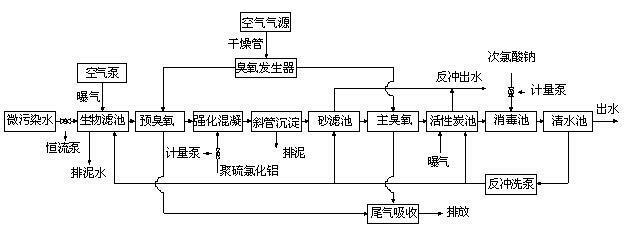

A technology of pathogenic microorganisms and disinfection by-products, applied in chemical instruments and methods, adsorption water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problem that the safety of microorganisms in the effluent cannot be guaranteed, and the removal effect of virus-like microorganisms is not good Ideal, the increase of effluent chemical health risks and other problems, to achieve the effect of overcoming disinfection by-products, improving removal performance, and good flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

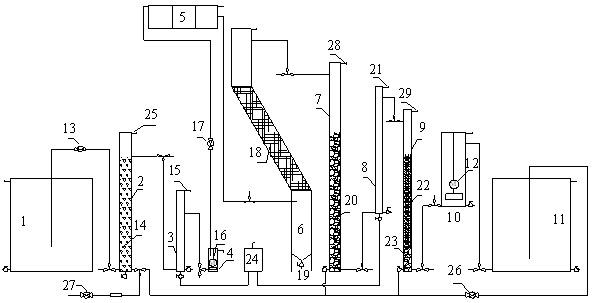

[0039] Experimental research is carried out on the process method of the present invention, the slightly polluted raw water enters the biological pretreatment tank, and the influent flow rate is controlled by a constant flow pump to 0.4 m 3 / d, the aeration air-water ratio in the tank is 1:1; the effluent enters the pre-ozone contact tank, the pre-ozone dosage is 0.5 mg / L, and the contact time is 10 min; the effluent enters the folding plate flocculation tank before adding polysulfide aluminum chloride , dosage 8.9 mg / L (as Al 2 o 3 After 15 minutes of effective flocculation, the effluent enters the inclined tube sedimentation tank, and the effective sedimentation time is 106 minutes; then enters the sand filter and enters the main ozone contact tank after filtration, the main ozone dosage is 2.5 mg / L, and the contact time is 20 minutes ; Then it enters the disinfection pool after being filtered by the activated carbon filter. The amount of chlorine added is 1.5~2.5 mg / L acco...

Embodiment 2

[0043] Experimental research is carried out on the process method of the present invention, the slightly polluted raw water enters the biological pretreatment tank, and the influent flow rate is controlled by a constant flow pump to 0.6 m 3 / d, the aeration air-water ratio in the tank is 1:1; the effluent enters the pre-ozone contact tank, the pre-ozone dosage is 0.5 mg / L, and the contact time is 10 min; the effluent enters the folding plate flocculation tank before adding polysulfide aluminum chloride , dosage 8.9 mg / L (as Al 2 o 3 After 15 minutes of effective flocculation, the effluent enters the inclined tube sedimentation tank, and the effective sedimentation time is 106 minutes; then enters the sand filter and enters the main ozone contact tank after filtration, the main ozone dosage is 2.5 mg / L, and the contact time is 20 minutes ; Then it enters the disinfection pool after being filtered by the activated carbon filter. The amount of chlorine added is 1.5~2.5 mg / L acco...

Embodiment 3

[0047] Experimental research is carried out on the process method of the present invention, the slightly polluted raw water enters the biological pretreatment tank, and the influent flow rate is controlled by a constant flow pump to 0.8 m 3 / d, the aeration air-water ratio in the tank is 1:1; the effluent enters the pre-ozone contact tank, the pre-ozone dosage is 0.5 mg / L, and the contact time is 10 min; the effluent enters the folding plate flocculation tank before adding polysulfide aluminum chloride , dosage 8.9 mg / L (as Al 2 o 3 After 15 minutes of effective flocculation, the effluent enters the inclined tube sedimentation tank, and the effective sedimentation time is 106 minutes; then enters the sand filter and enters the main ozone contact tank after filtration, the main ozone dosage is 2.5 mg / L, and the contact time is 20 minutes ; Then it enters the disinfection pool after being filtered by the activated carbon filter. The amount of chlorine added is 1.5~2.5 mg / L acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com