A biological wastewater inactivation system

A waste water and inactivation technology, applied in water treatment parameter control, heating water/sewage treatment, water/sludge/sewage treatment, etc. Efficient production operation, ensure heat dissipation, ensure the effect of inactivation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

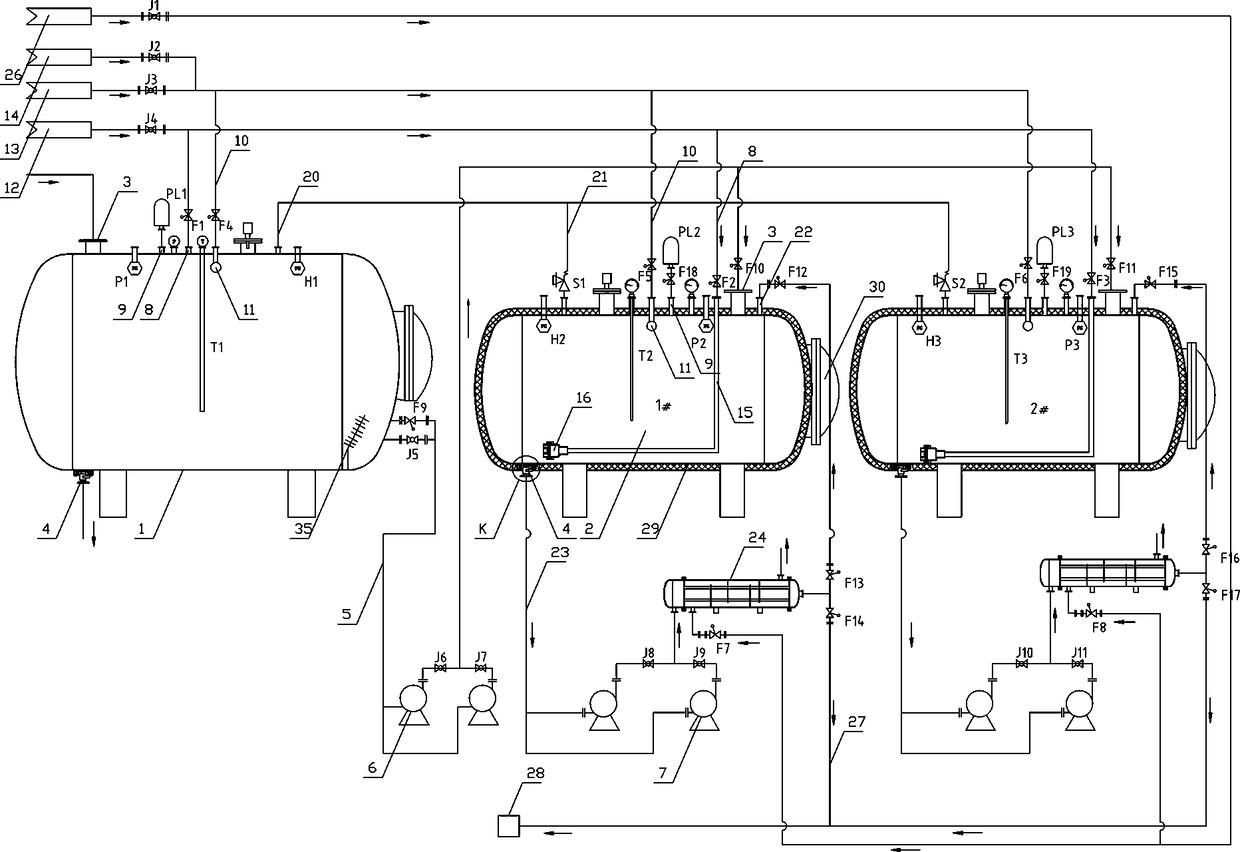

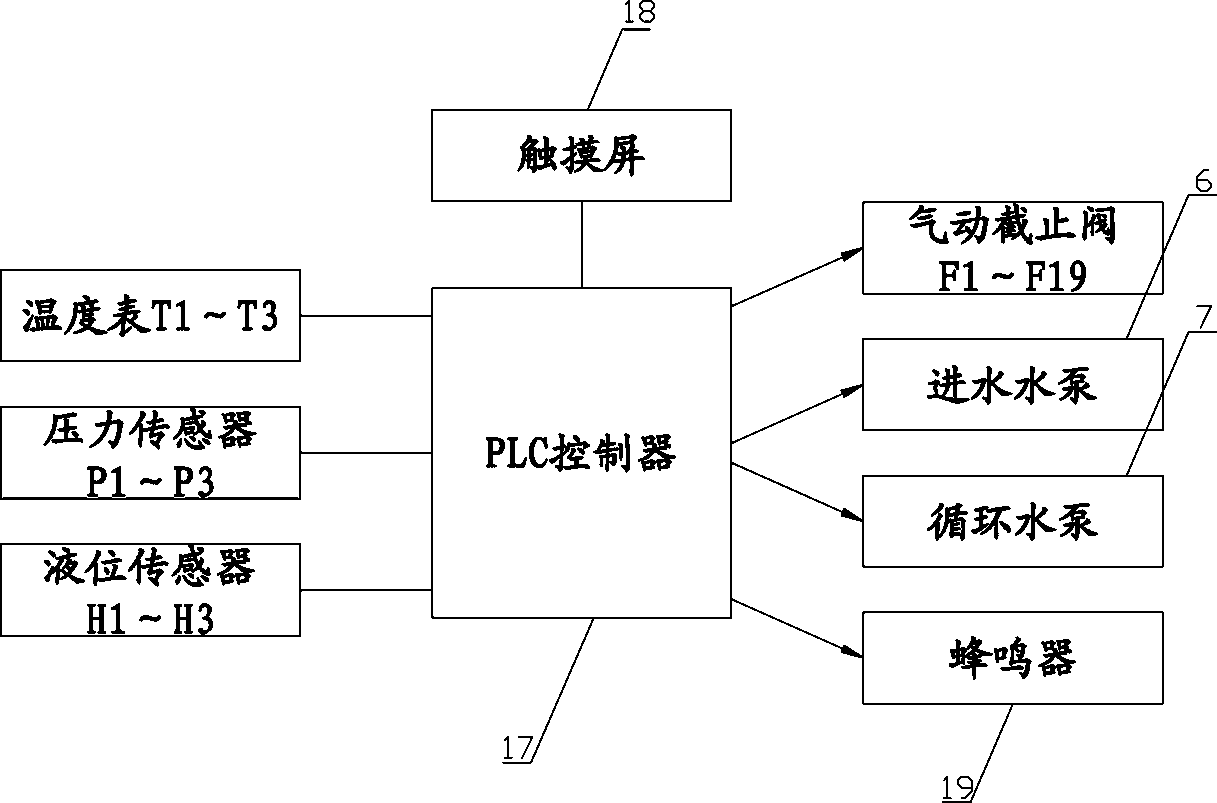

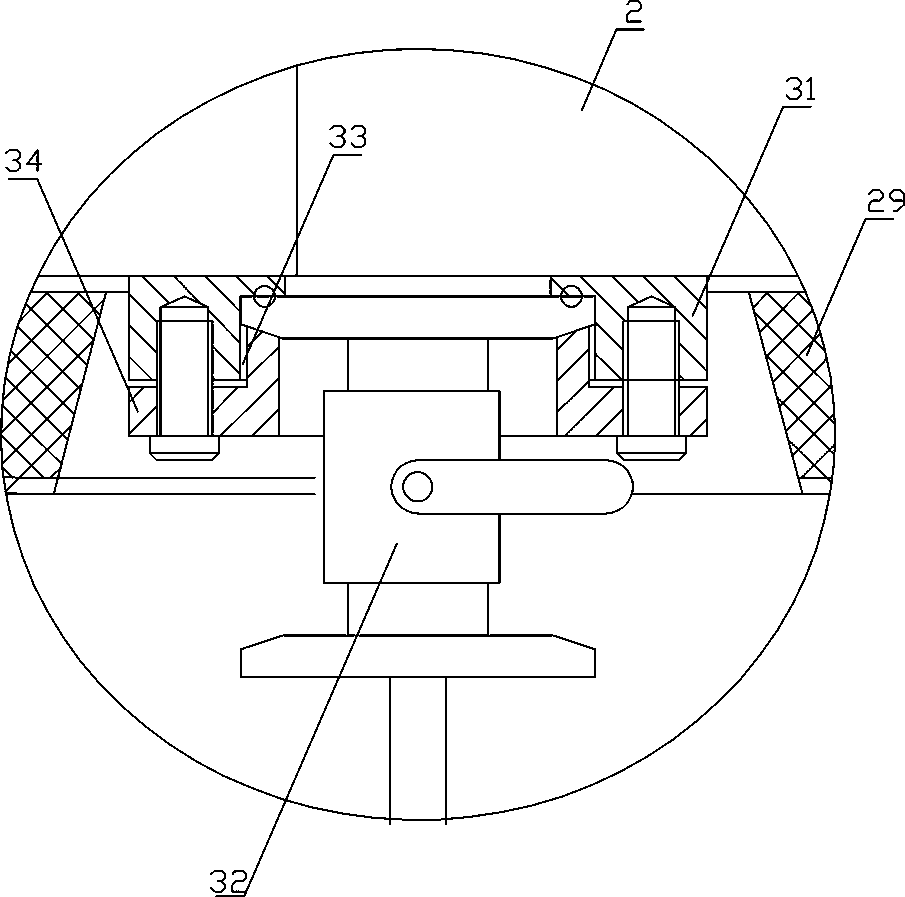

[0026] see Figure 1-2 , the present invention includes a temporary storage tank 1 and two deactivation tanks 2, wherein the two deactivation tanks 2 are respectively marked as 1# deactivation tank and 2# deactivation tank, and the two are used alternately, and the batch mode is adopted to run. Both the temporary storage tank 1 and the inactivation tank 2 are provided with a water inlet 3 and a sewage outlet 4, and a water delivery pipe 5 is set on the temporary storage tank 1 to communicate with the water inlet 3 on the two inactivation tanks, and the water delivery pipe 5 is provided with There are water inlet pumps 6, ball valves and pneumatic stop valves. The specific pipelines are as follows: water inlet pumps 6 are connected in parallel to form one for use and one for standby. Ball valves J6 and J7 are correspondingly installed on the pipelines where the two water inlet pumps are located. , on the water pipe 5 between the temporary storage tank 1 and the water inlet pum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com