Layered pipe column for squeeze packing sand control process

A technology of sand control pipe and filling pipe, which is applied in the direction of production fluid, wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of reducing production cost, etc., and achieve the purpose of increasing oil well production, reducing production cost and labor intensity of workers, and prolonging the production time. The effect of the effective period of sand control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

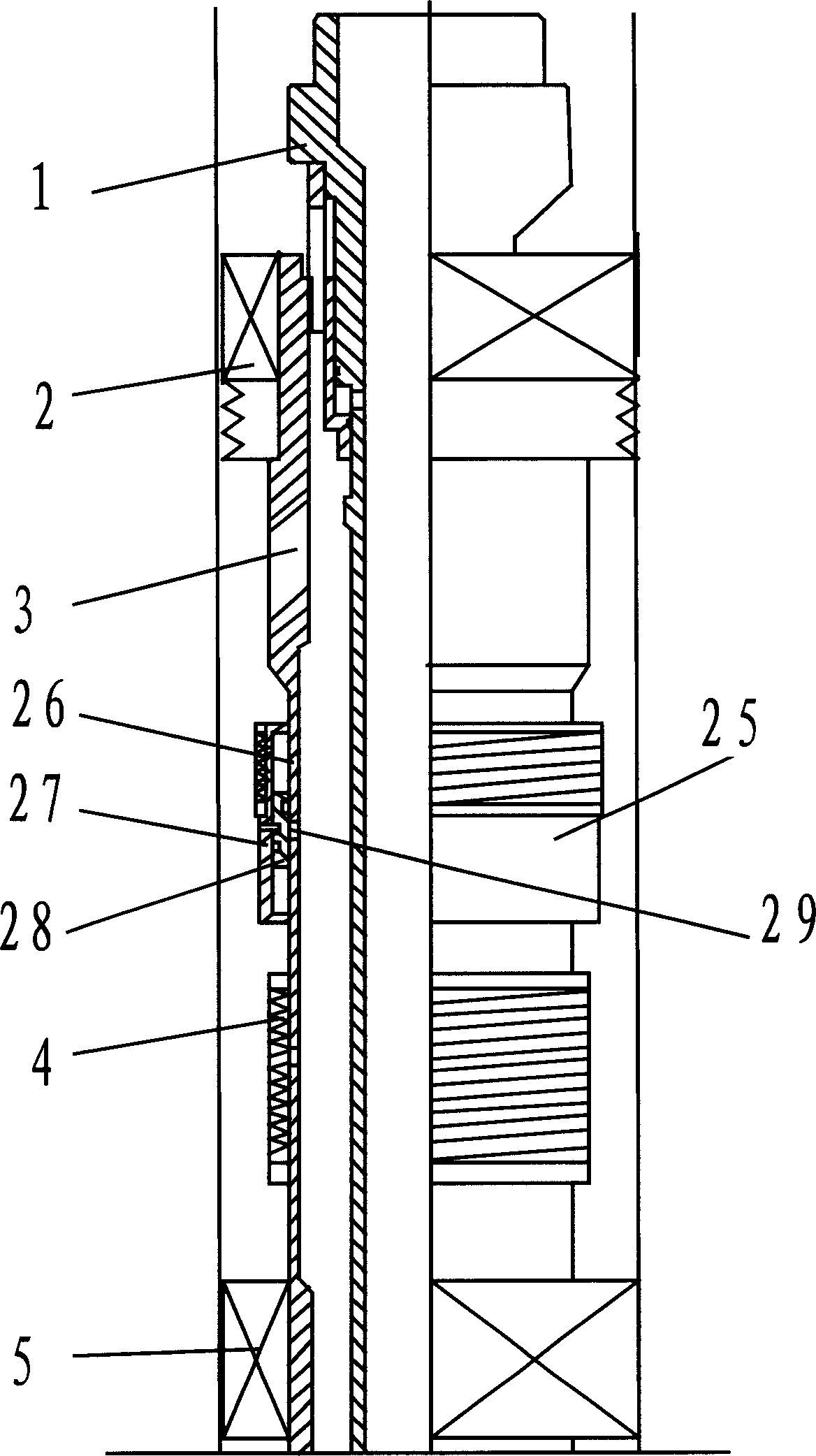

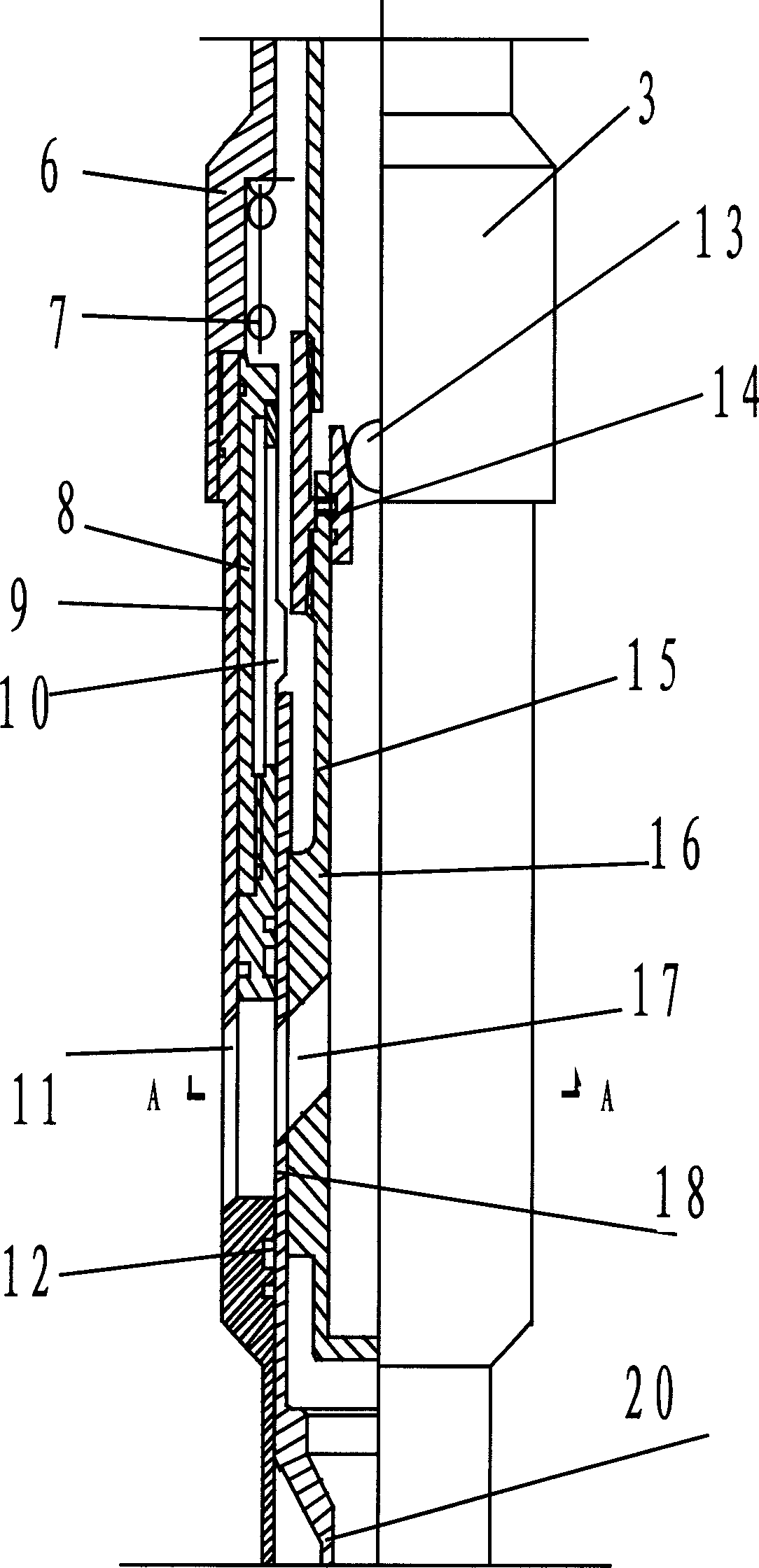

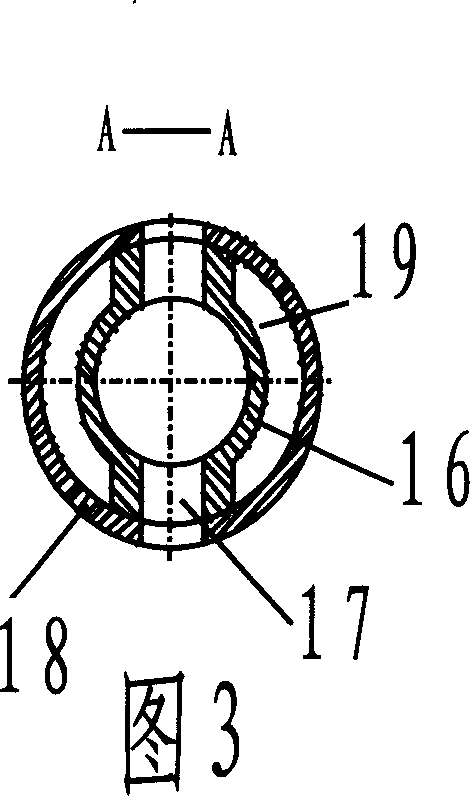

[0012] Below in conjunction with accompanying drawing, the present invention is described in further detail: see appended Figure 1-5 , The layered extrusion packing sand control string is divided into two parts: the inner packing string and the outer packing string. The inner filling pipe string includes setting and dropping hands 1, flushing pipe, inner filling tool 15, extruding and converting inner sliding pipe 21, extruding and filling outer sliding pipe 22, which are threaded in turn, and the extruding and filling outer sliding pipe 22 is suspended and sleeved On the extrusion conversion inner sliding tube 21; wherein the inner filling tool 15 includes a steel ball 13, a ball seat 14, an inner filling conversion head 16, an inner filling port 17, an inner filling outer tube 18, a clamping wall flow chamber 19, an inner filling lower Connector 20. The outer packing string includes a top hanging packer 2, an outer packing tool 3, an annunciator 25, a sand filter pipe 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com