Patents

Literature

37results about How to "Increase seepage area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligent greenhouse used for cultivation of citrus reiculata blanco seedlings

InactiveCN109258217AIncrease seepage areaAvoid standing waterManure treatmentClimate change adaptationGreenhouseEngineering

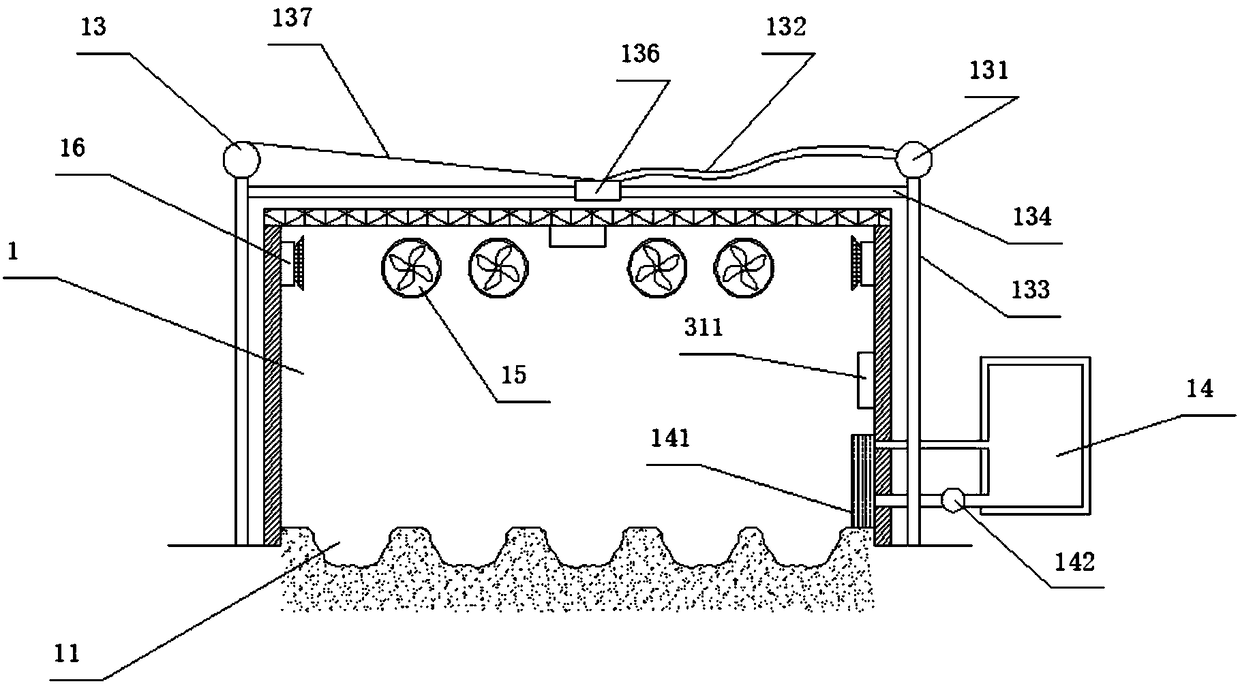

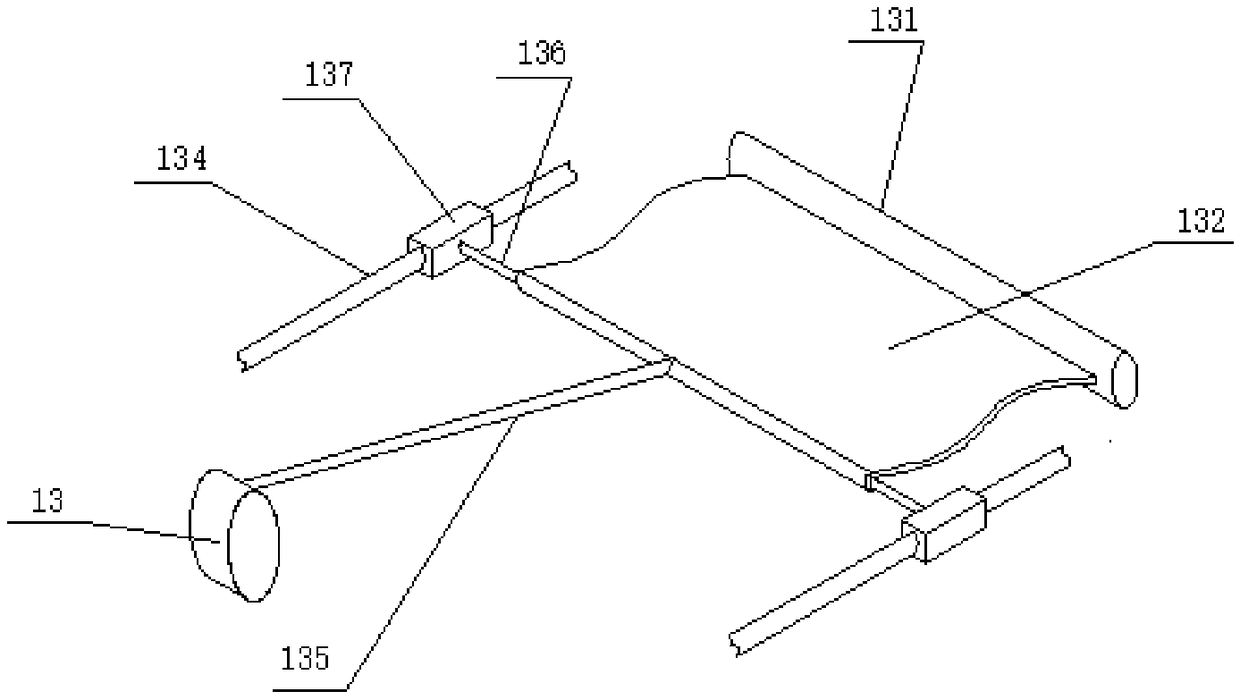

The invention relates to the technical field of agricultural planting, in particular to an intelligent greenhouse used for cultivation of citrus reiculata blanco seedlings. The intelligent greenhousecomprises a planting greenhouse, a water circulating device, a water and fertilizer irrigating device, a controller and a management module, and the planting greenhouse provides a good growing environment for the citrus reiculata blanco seedlings; the water circulating device is used for recycling water drained from soil; the water and fertilizer irrigating device comprises a storage box, a stirring blade, a material discharging pipe and fertilizer applying pipes, the material discharging pipe is communicated with the storage box through a pulp discharging pump, and the fertilizer applying pipes are respectively located on all planting rows and communicated with the material discharging pipe and comprise pipe bodies and spiral material pushing rods; the controller can control the plantinggreenhouse, the water circulating device and the water and fertilizer irrigating device according to the management module. The intelligent greenhouse used for cultivation of the citrus reiculata blanco seedlings can ensure that the citrus reiculata blanco seedlings grow in the environment suitable for growth of the citrus reiculata blanco seedlings and can automatically apply a suitable amount offertilizer to and irrigate citrus reiculata blanco.

Owner:靖西海越农业有限公司

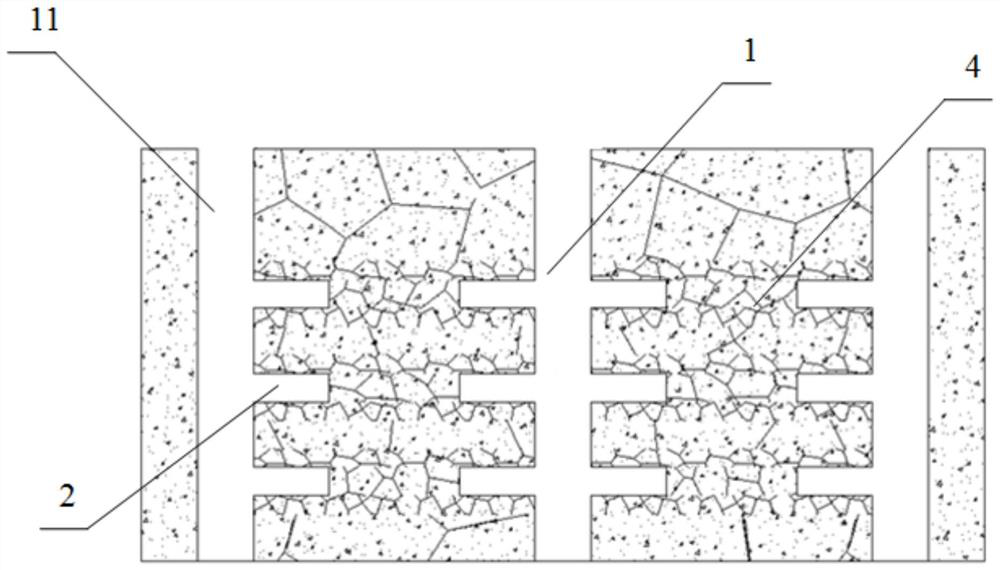

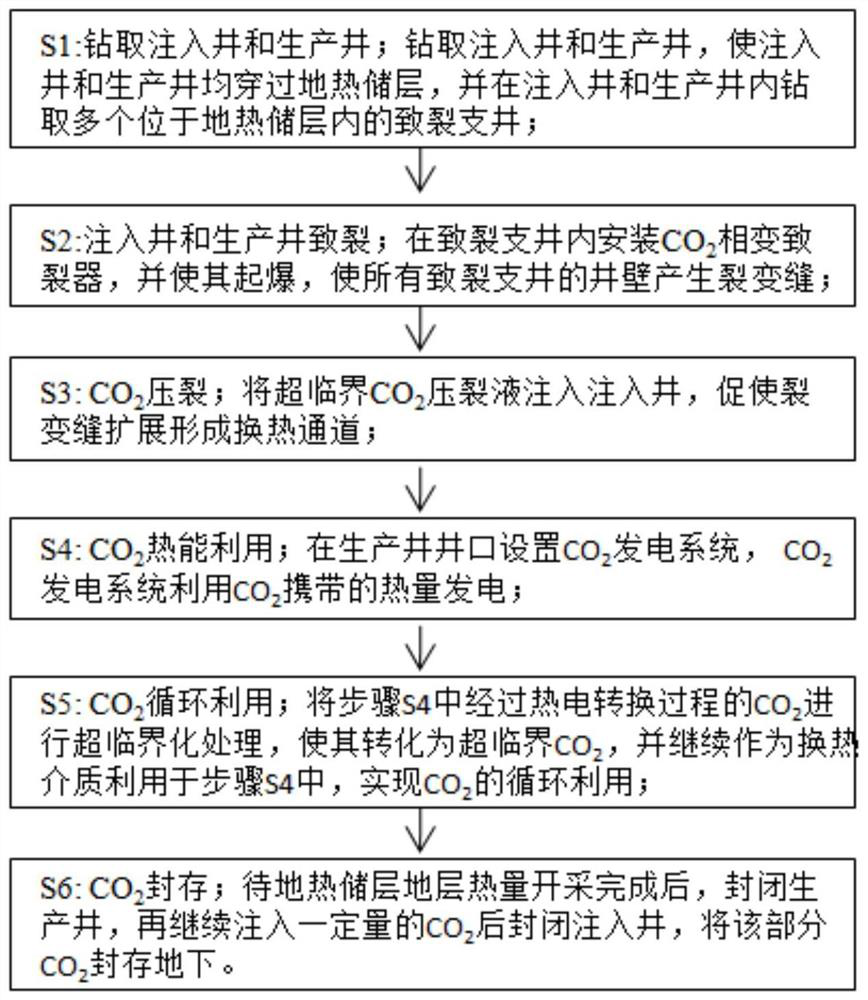

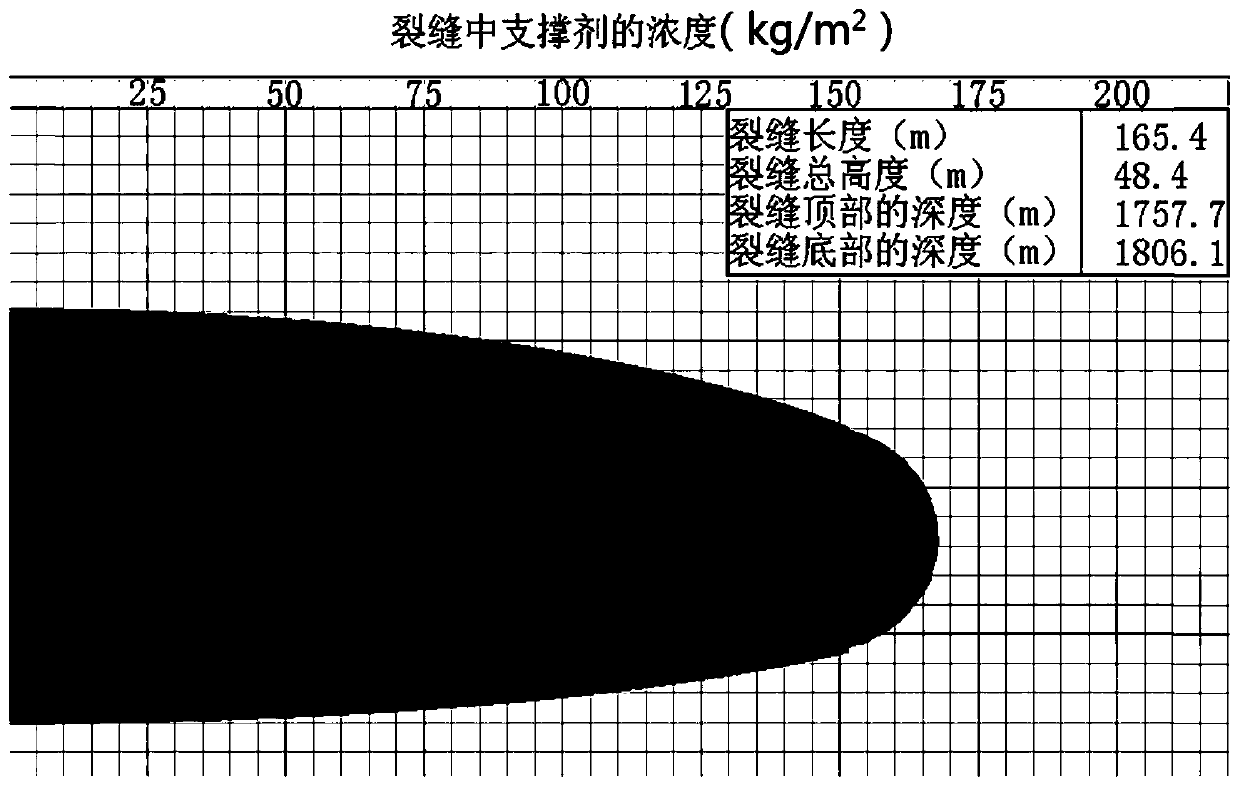

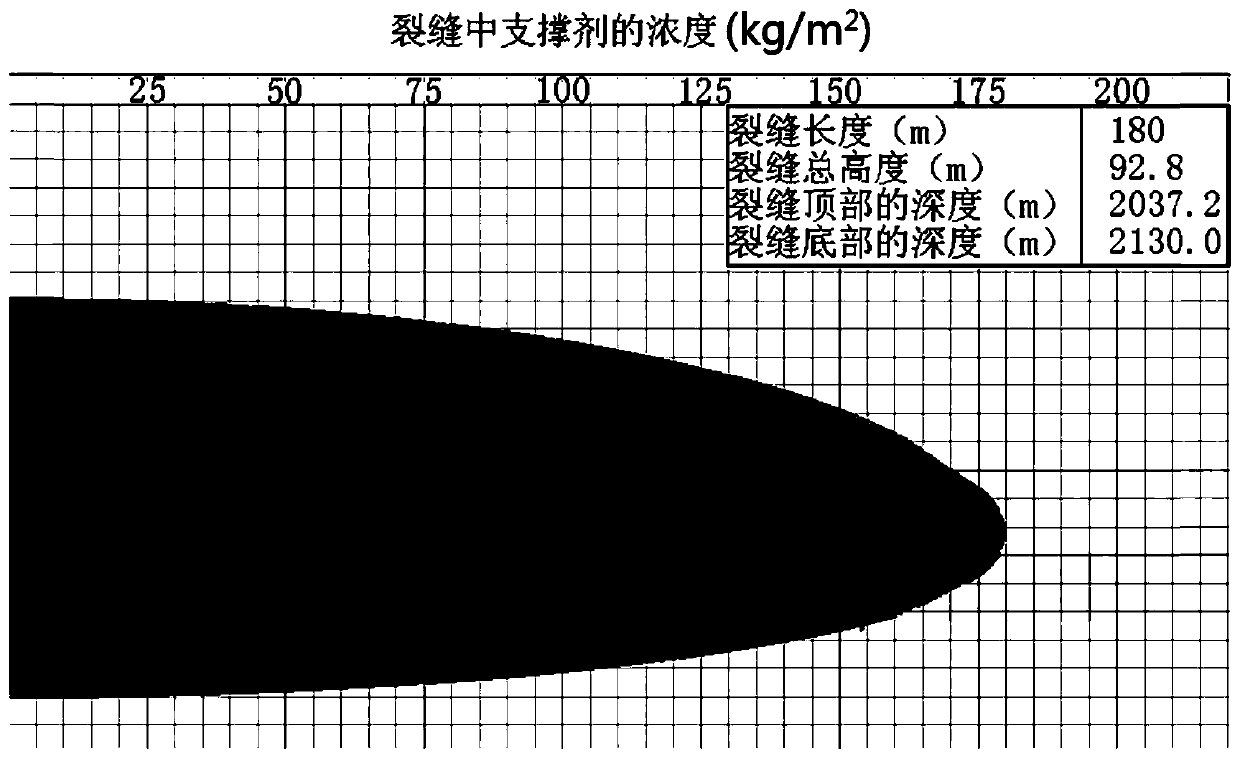

Deep geothermal exploitation method based on carbon dioxide medium

ActiveCN114033346AHigh cracking efficiencyUniform seamGeothermal energy generationFluid removalThermodynamicsFracturing fluid

The invention provides a deep geothermal exploitation method based on a carbon dioxide medium. The deep geothermal exploitation method comprises the following steps that S1, an injection well and a production well are drilled; S2, the injection well and the production well are fractured; S3, CO2 fracturing is carried out; S4, CO2 heat energy utilization is carried out; S5, cyclic utilization of CO2 is carried out; and S6, CO2 storage is carried out. The method is advantaged in that CO2 is adopted as a fracturing medium and a heat exchange medium, pressure loss and fracturing difficulty in the flowing process of fracturing fluid can be reduced by taking CO2 as the fracturing medium, the heat exchange area of a heat storage stratum can be increased, intercommunication of a micro-fracture network system is promoted, and the reservoir transformation time is saved; meanwhile, CO2 serves as a heat exchange medium, the heat extraction capacity of a heat storage stratum can be improved, a large amount of CO2 can be stored in the underground deep part in the heat exchange process and after heat exchange, and carbon peak reaching and carbon neutralization can be achieved easily.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

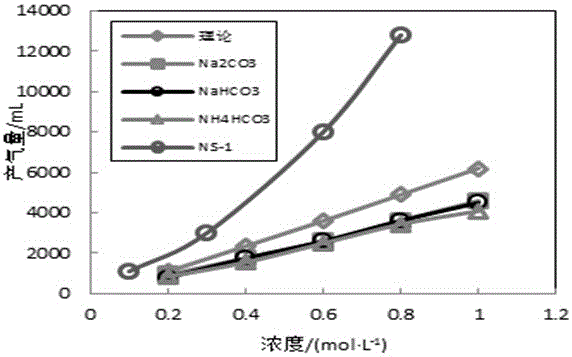

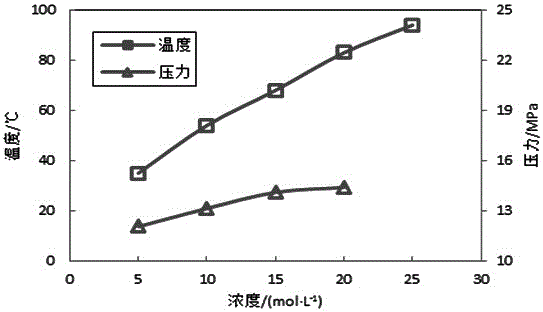

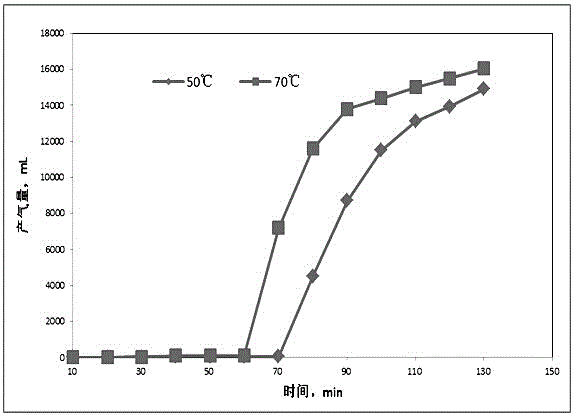

Gas-producing system capable of improving permeability of tight oil reservoir and application thereof

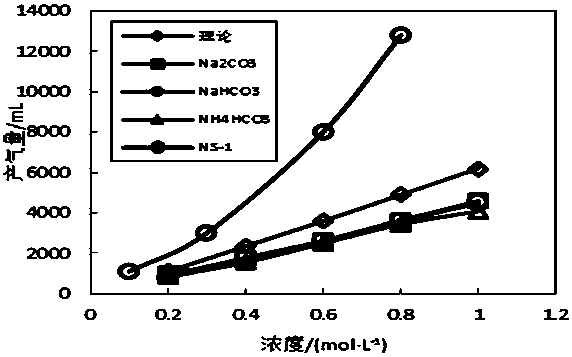

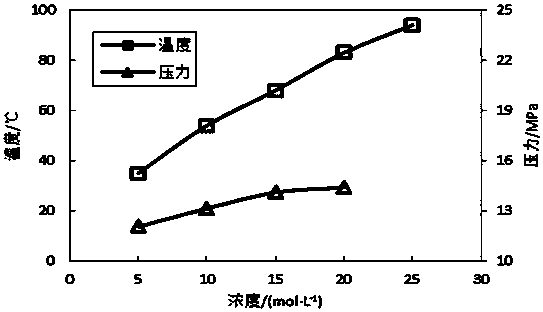

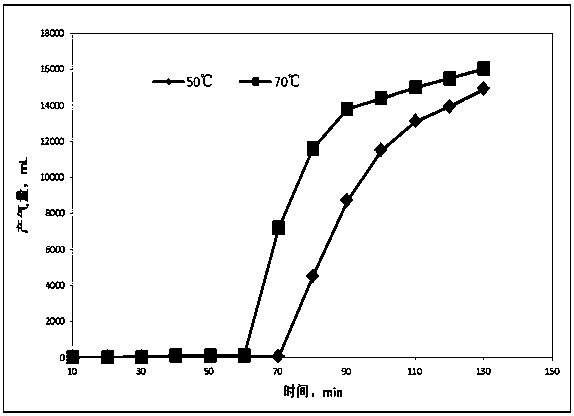

ActiveCN105838347AImprove flowback rateImprove seepage capacityFluid removalDrilling compositionChemical reactionHigh pressure

The invention provides a gas-producing system capable of improving permeability of a tight oil reservoir and application thereof, belonging to the technical field of oilfield development. The gas-producing system comprises a microcapsule and hydrochloric acid; the microcapsule uses a mixture of urea and sodium nitrite as a core material and a mixture of azodiisobutyronitrile, styrene, methyl methacrylate and methacrylic acid as a capsule dressing. In operation, nitrite and the microcapsule are injected into a stratum to a predetermined depth; and the microcapsule undergoes corrosion under stratum conditions and chemically reacts with hydrochloric acid to produce a great amount of gas and release a great amount of heat, so local high pressure is formed in a predetermined part. According to the invention, effective seepage channels of difficult-to-produce reserves such as an ultralow-permeability oil reservoir and the tight oil reservoir are increased so as to improve permeability, increase local energy of reservoirs and the flowback rate of raffinate, and reduce reservoir contamination, so the purpose of improving the recovery efficiency of the difficult-to-produce reserves is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

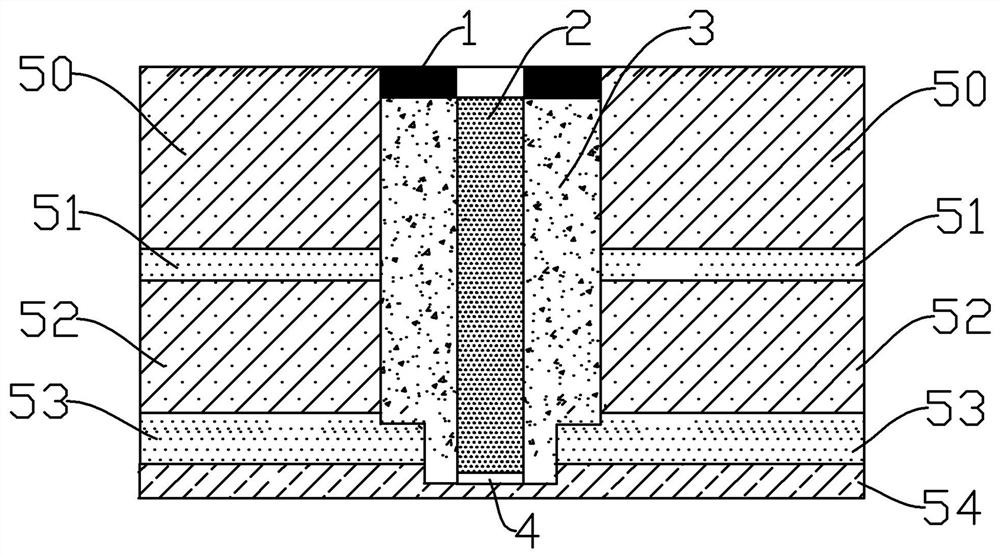

Water draining and pressure relieving structure capable of realizing anti-floating

PendingCN107794954AReduce gapAvoid corrosionProtective foundationWater leakUltimate tensile strength

The invention discloses a water draining and pressure relieving structure capable of realizing anti-floating. The water draining and pressure relieving structure capable of realizing anti-floating comprises a well wall pipe and a slow expansion type hydro-expansive antipriming pipe. The slow expansion type hydro-expansive antipriming pipe is arranged outside the well wall pipe in a sleeving manner. A micro-expansionary fine aggregate concrete layer is arranged between the slow expansion type hydro-expansive antipriming pipe and the well wall pipe. The outer diameter of the slow expansion typehydro-expansive antipriming pipe corresponds to the inner diameter of a water draining hole in which the slow expansion type hydro-expansive antipriming pipe is located. The structure has the advantages that when water leaks out of the well wall pipe, both the slow expansion type hydro-expansive antipriming pipe and the micro-expansionary fine aggregate concrete layer expand, and at the moment, the gap between the slow expansion type hydro-expansive antipriming pipe and the inner side wall of the water draining hole decreases, so that the corrosion to a floor layer due to the outflow, from theexterior of a well wall to the floor layer, of the water under the floor layer can be effectively prevented, the strength of the floor layer is lowered and the function of anti-floating is realized;the water under the floor layer is drained out through the well wall pipe, so that the buoyancy which is applied to the floor layer by the water is reduced and the function of pressure relieving is realized.

Owner:HEFEI UNIV OF TECH

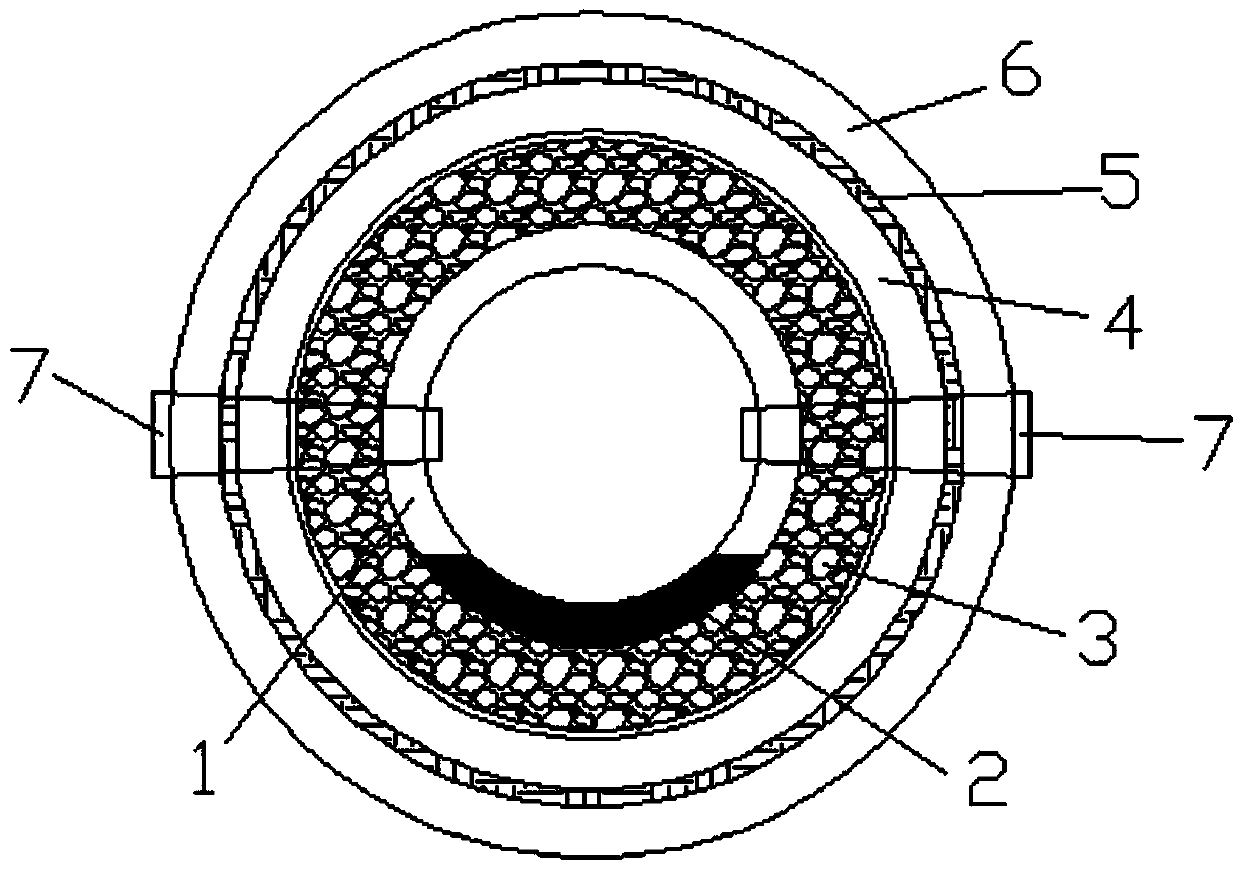

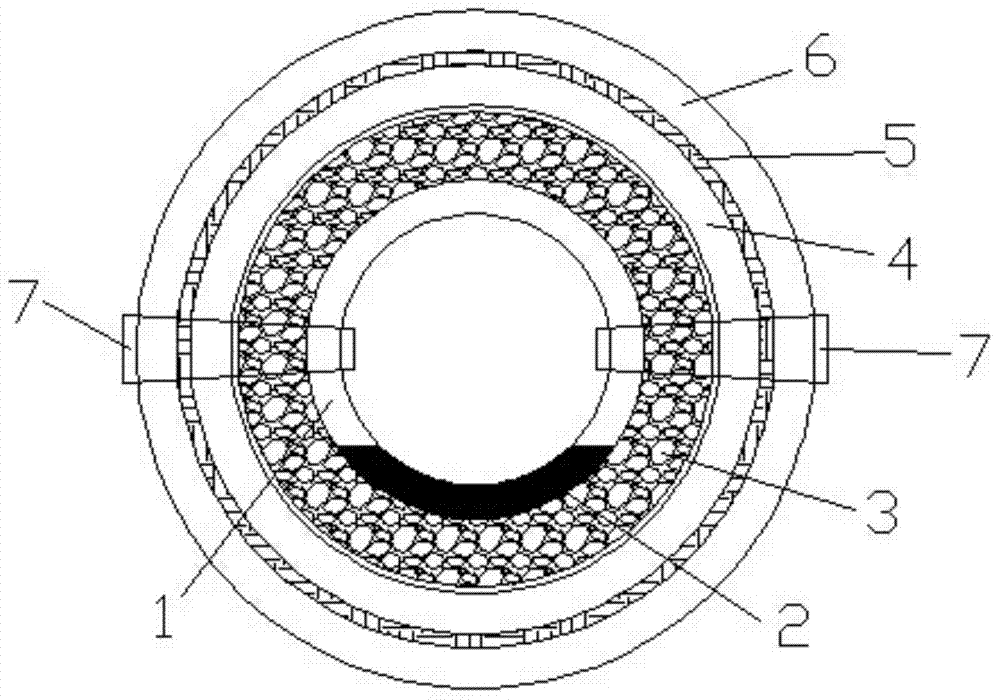

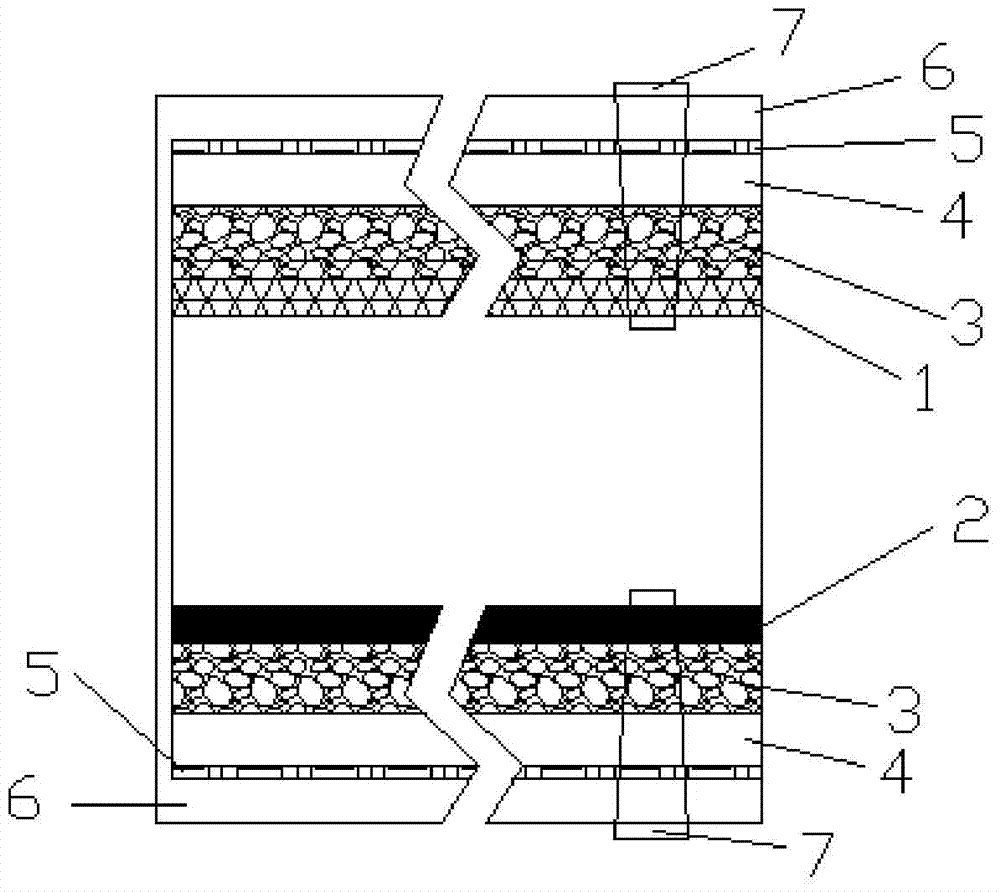

Drainage pipe with replaceable side slope and construction method thereof

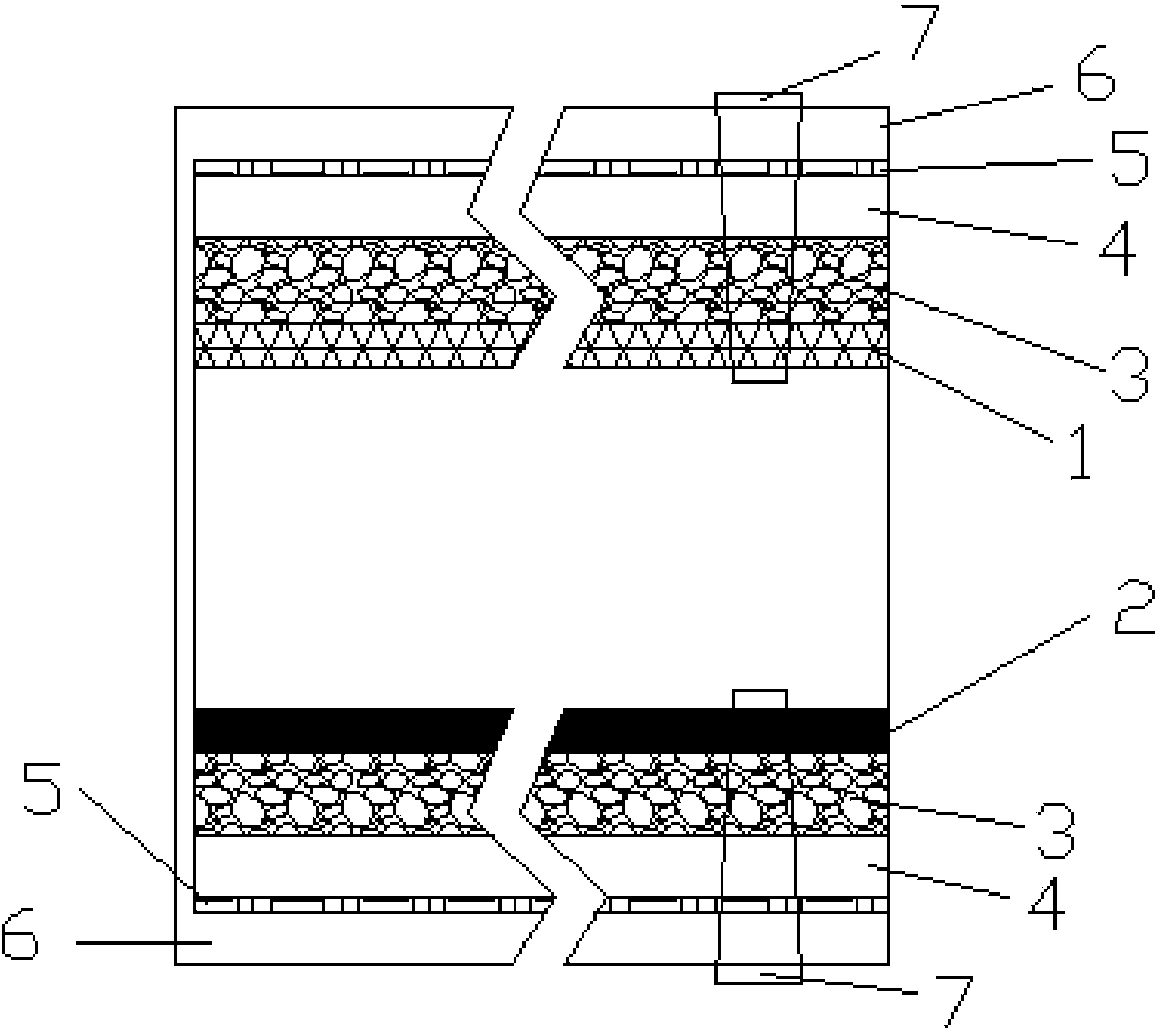

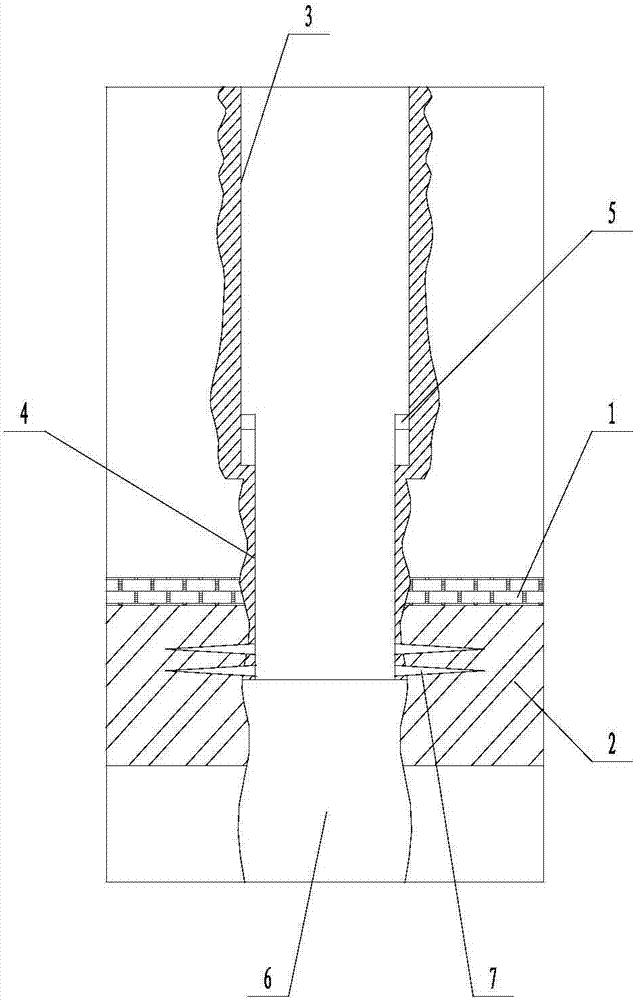

The invention discloses a drainage pipe with a replaceable side slope and a construction method thereof. A sector-shaped drainage pipe (2) is connected to the lower portion of a sector-shaped permeable layer (1) to constitute a circle, and a plastic blind groove pipe filter layer (3) is wrapped on the periphery of the sector-shaped permeable layer (1) and the periphery of the sector-shaped drainage pipe (2). A cylindrical filter sieve (4) is wrapped on the periphery of the plastic blind groove pipe filter layer (3), a through hole is formed in the part above a circle of the cylindrical filter sieve (4), and the part below the circle is sealed. At least one layer of geofabric filter layer (5) is wrapped on the periphery of the cylindrical filter sieve (4), and a rigid supporting layer (6) is wrapped on the periphery of the geofabric filter layer (5). A big through hole is formed in the rigid supporting layer (6) in an all-dimensional mode, and pins (7) are inserted in end openings of all the layers to be fixedly connected. The drainage pipe with the replaceable side slope can prevent plugging, and is durable, quick, capable of preventing secondary seepage and capable of replacing the inside structure of the drainage pipe after being used for a period.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

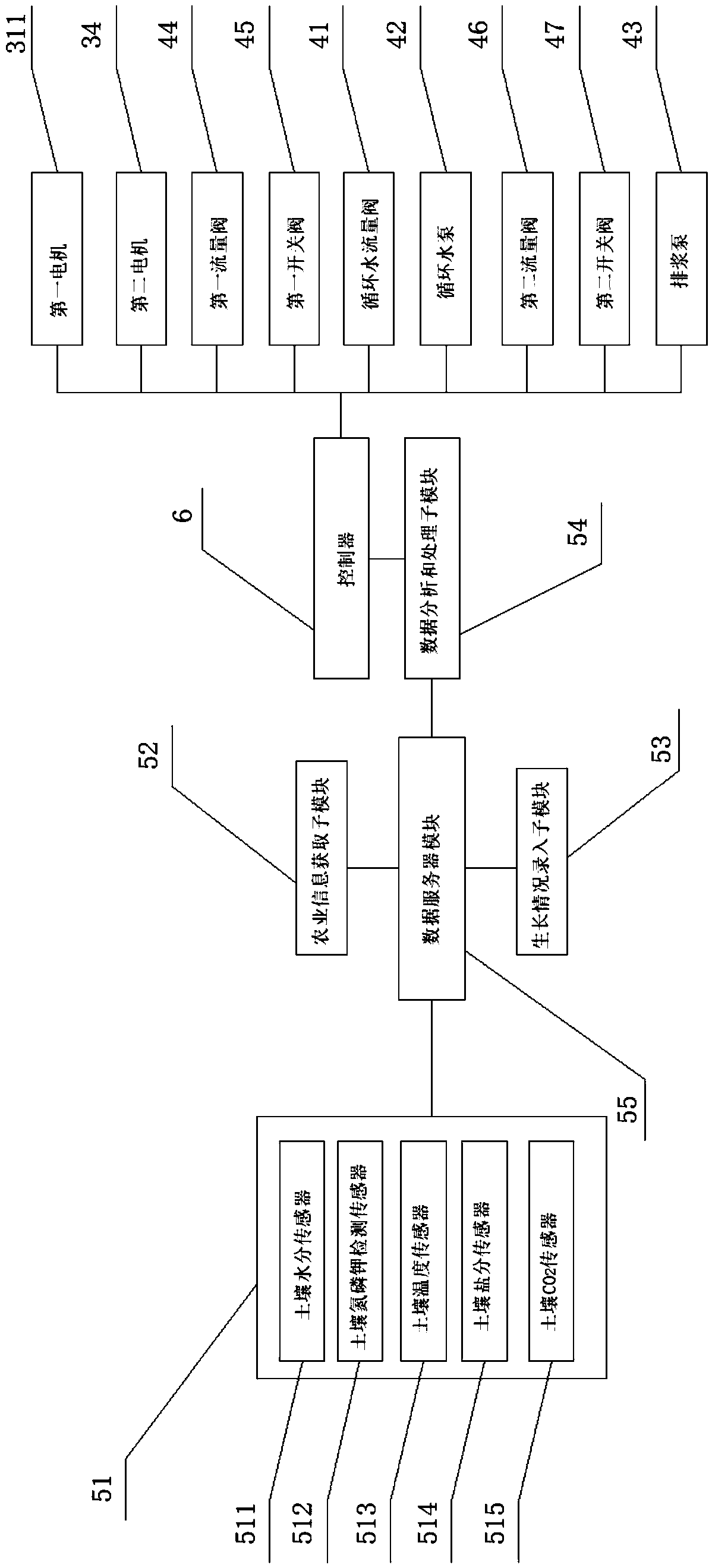

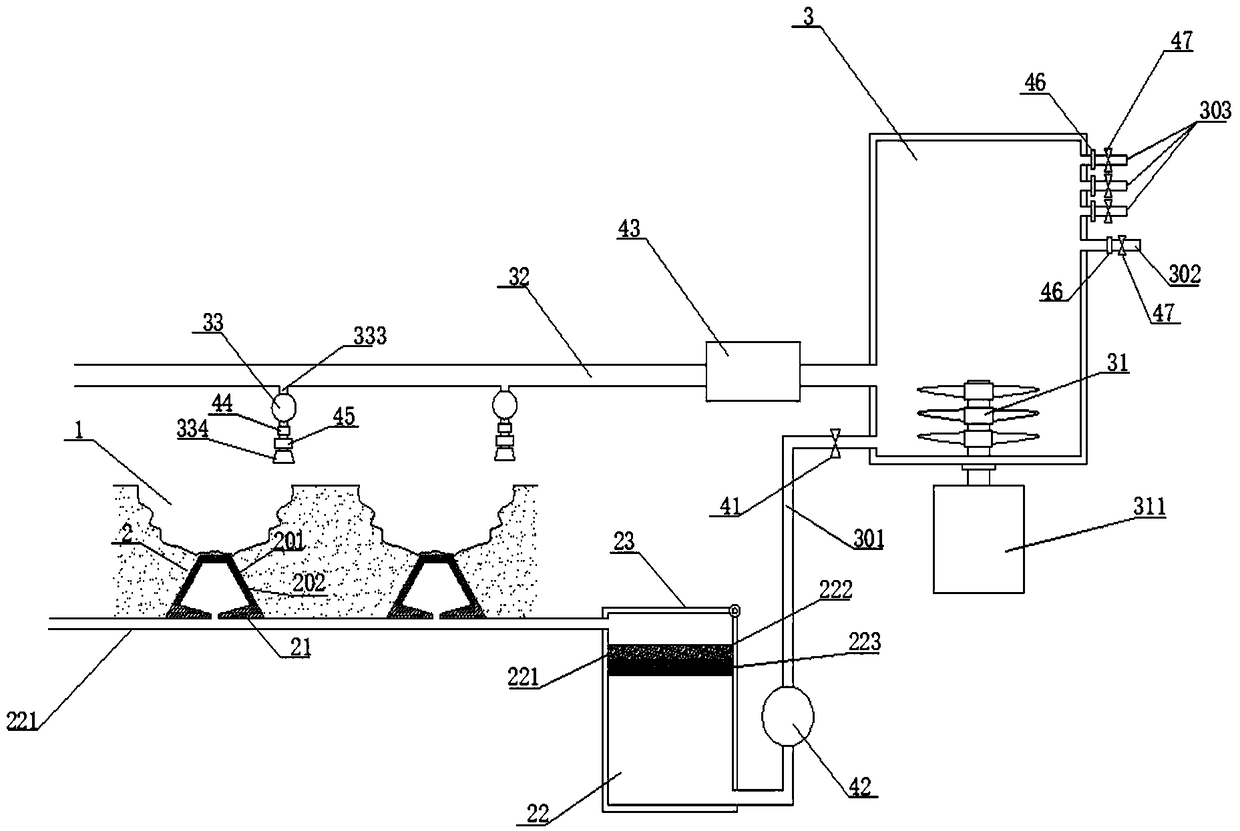

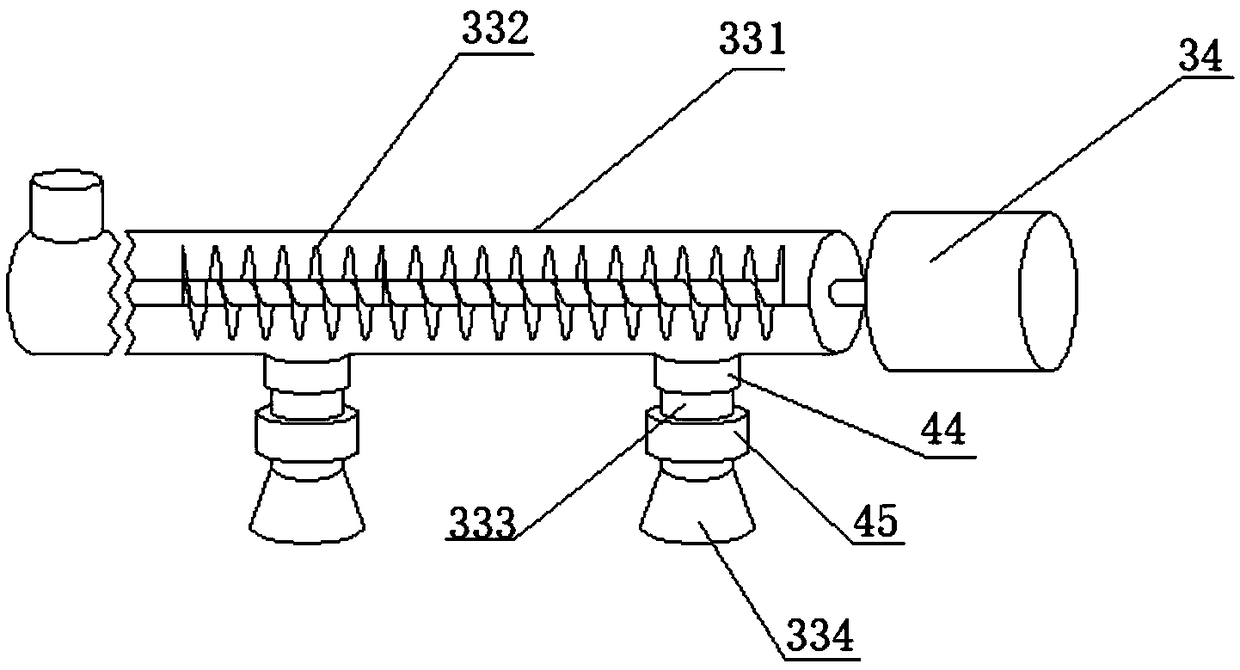

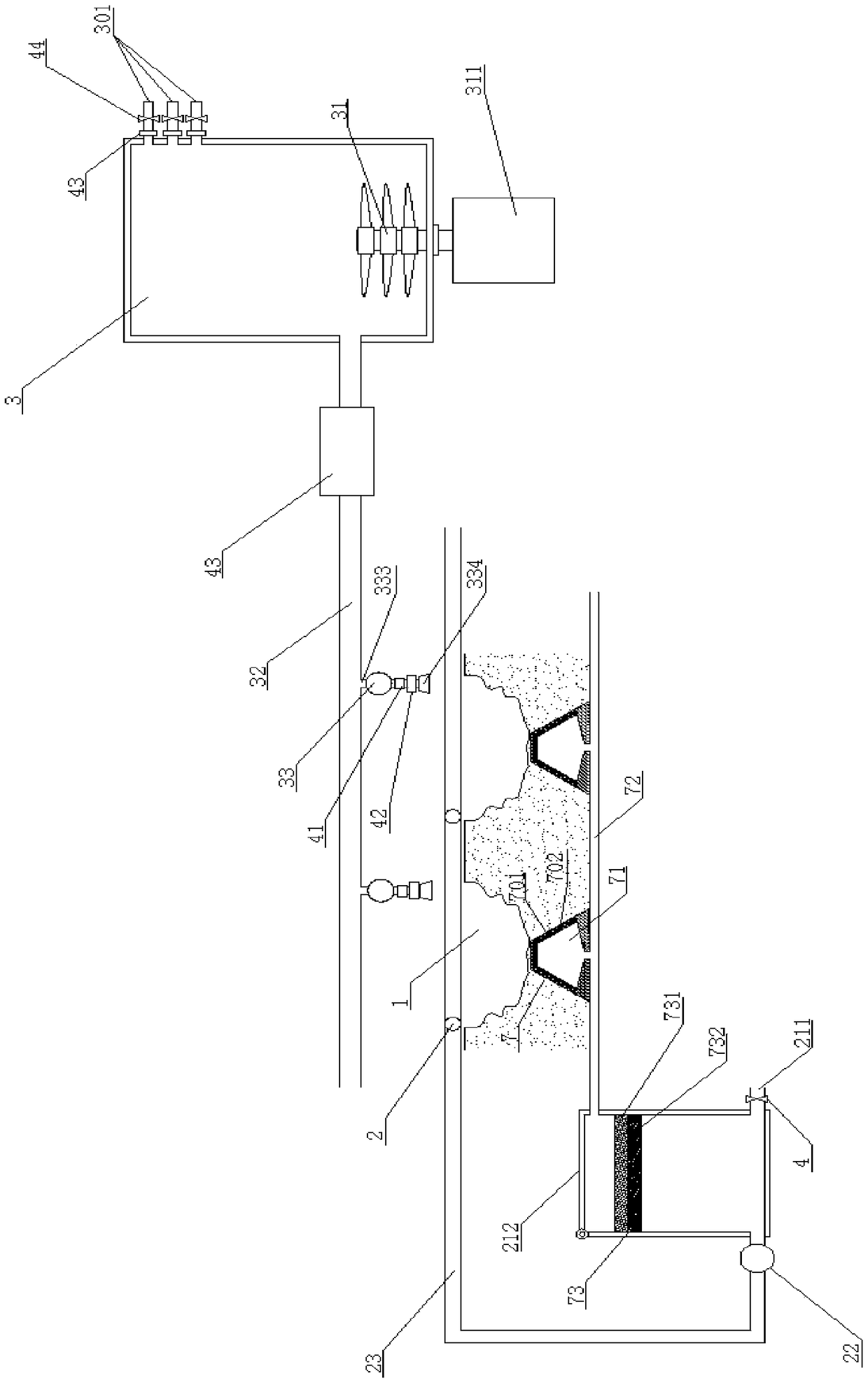

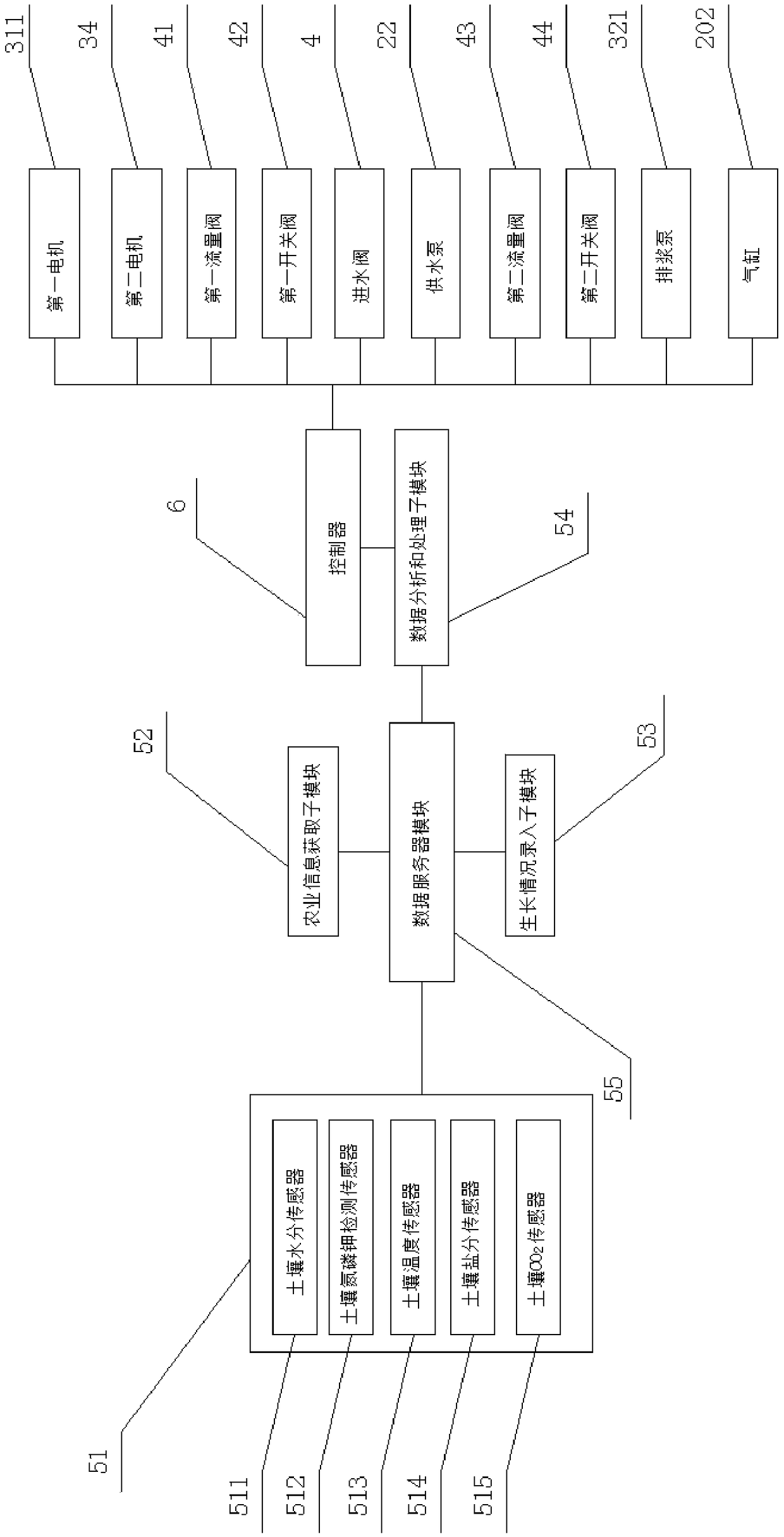

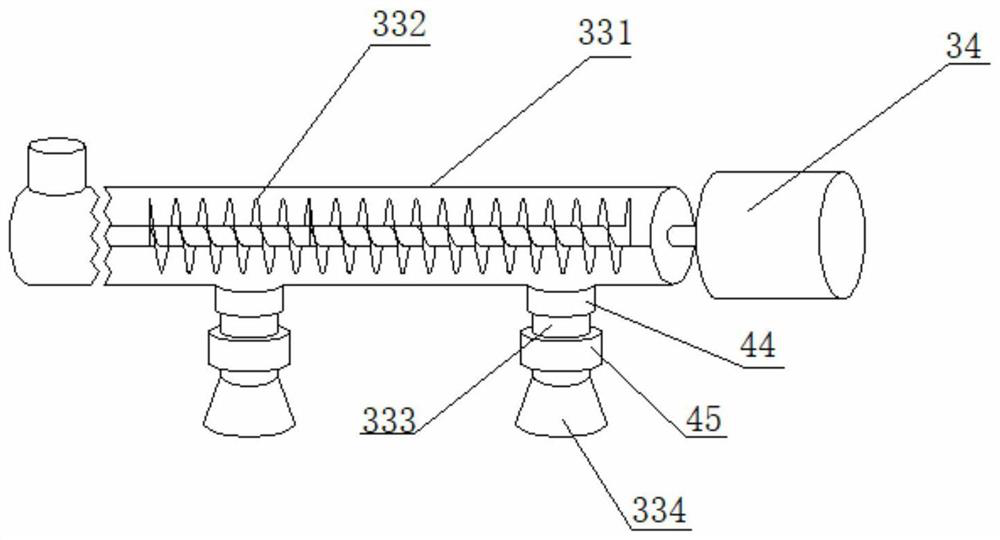

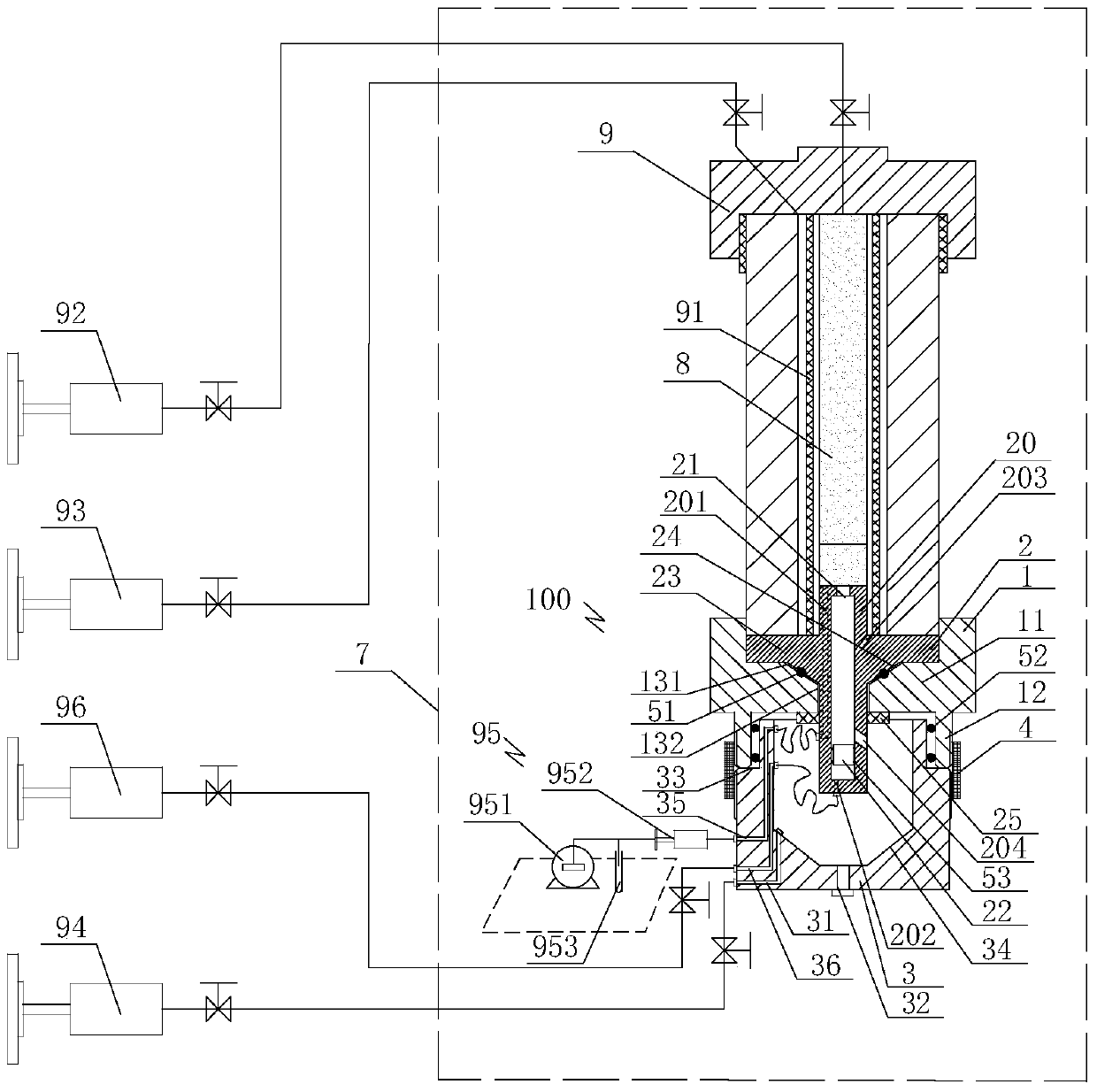

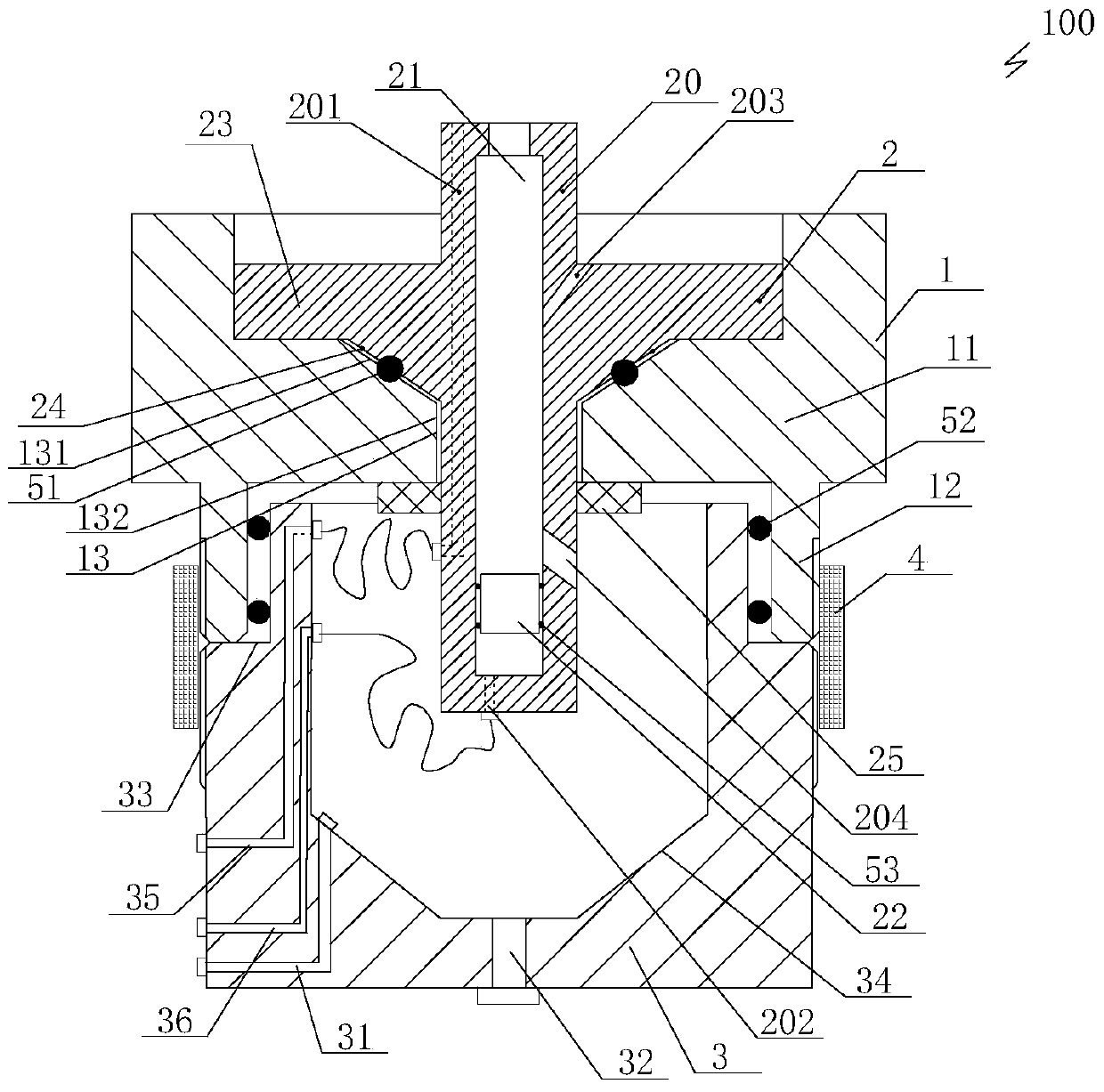

Water fertilizer smart irrigation system

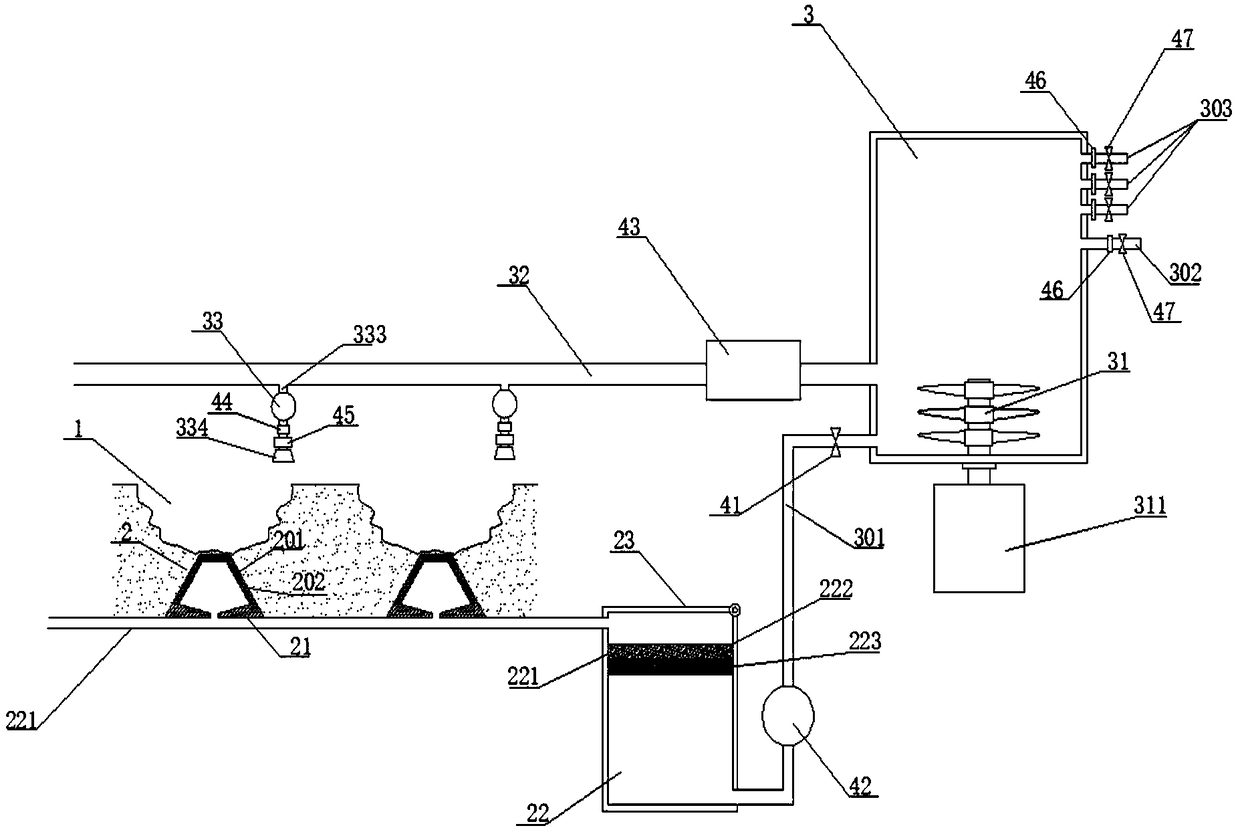

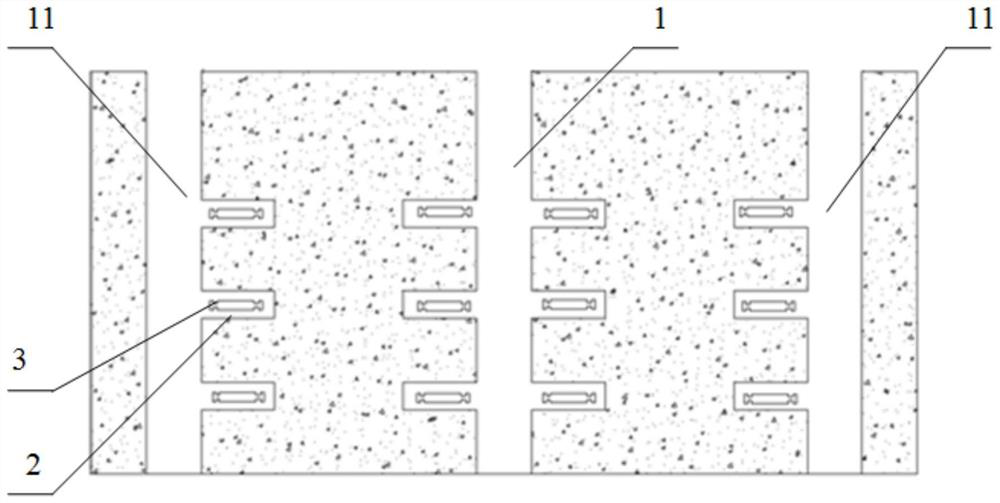

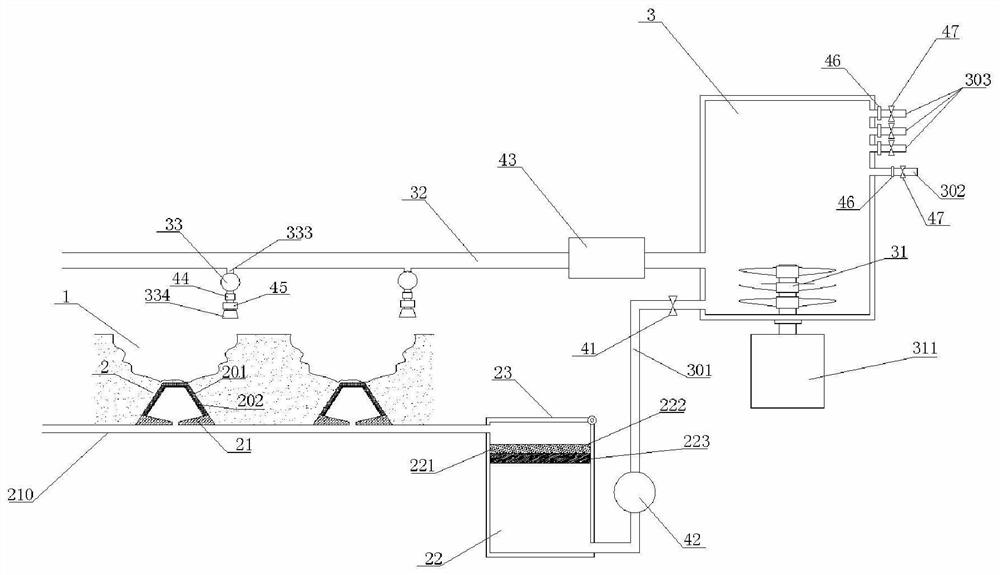

ActiveCN109168528AIncrease seepage areaCause rotManure treatmentLiquid fertiliser regulation systemsWater storage tankWater circulation

The invention relates to the technical field of agricultural planting, and particularly relates to a water fertilizer smart irrigation system. The system comprises planting rows, a water circulation device, a water fertilizer irrigation device, a controller and a management module, wherein the water circulation device is used for recycling water drained from soil; the water fertilizer irrigation device comprises a storage tank, an agitation paddle, a discharge pipe and fertilizing pipes; the storage tank is connected with a water storage tank through a circulating pipe; the discharge pipe is connected with the storage tank through a draining pump; the fertilizing pipes are respectively positioned on each planting row and connected with the discharge pipe; each fertilizing pipe comprises apipe body and a helical push rod; and the controller can be used for controlling the water circulation device and the water fertilizer irrigation device according to the management module. The water fertilizer smart irrigation system can be used for dividing planting into several sections and independently each section of planting rows, so that occurrence of growth difference among W oranges can be reduced.

Owner:靖西海越农业有限公司

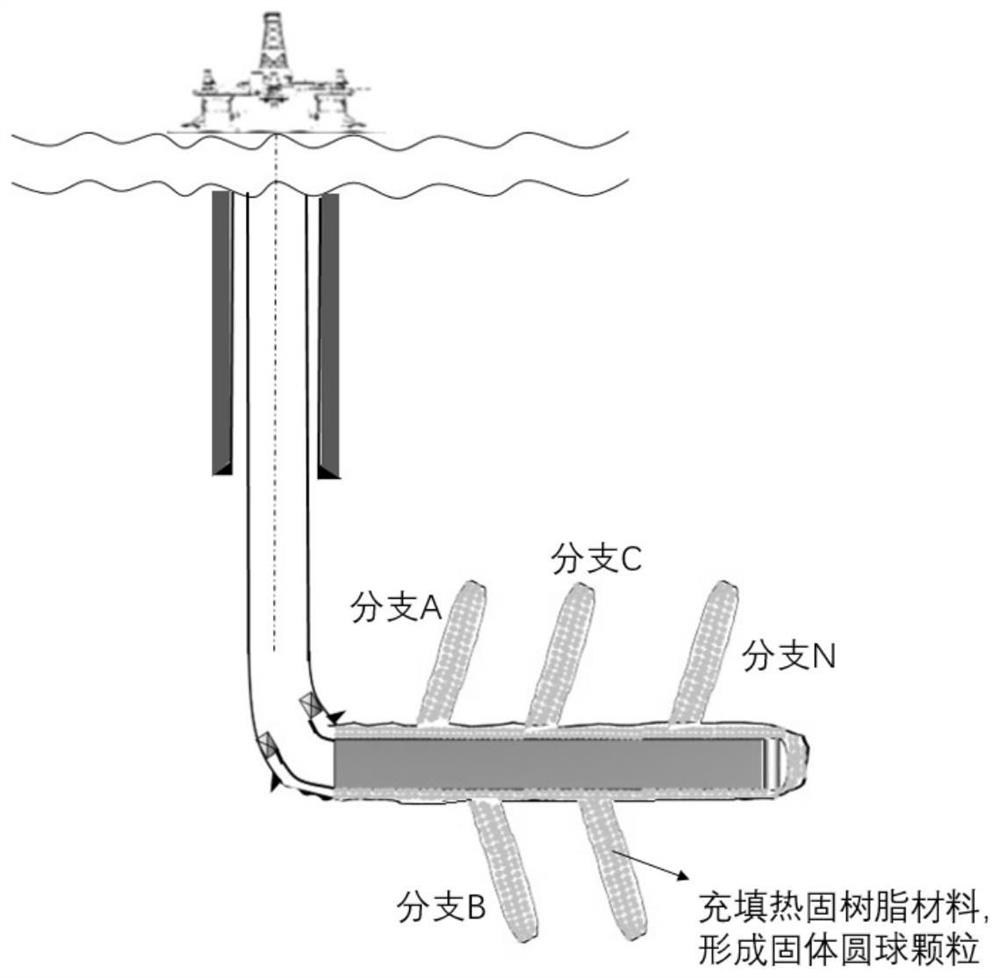

Method for increasing production of horizontal well based on method for filling multi-branch small boreholes with chemical sand

InactiveCN111794721AIncrease seepage areaAvoid sandingFluid removalDrilling compositionFluid phaseGeotechnical engineering

The invention discloses a method for increasing the production of a horizontal well based on a method for filling multi-branch small boreholes with chemical sand, and the method is for a plastic formation. The method comprises the following steps that the multi-branch holes of the horizontal well are drilled, and a heat convertible resin material is injected into the multi-branch open holes, wherein the heat convertible resin material comprises a component X and a component Y which are immiscible, the component X is a solvent, and the component Y is a supermolecular compound material; and thecomponent Y can response to the change of external temperature and can be transformed into the solid phase from the liquid phase. The method can be for the plastic formation instead of a routine staged fracturing technology for the horizontal well, the seepage area of the immediate vicinity of the well is increased, the individual well deliverability is improved, and the formation sand productioncan be prevented while the production is increased. Compared with gravel filling, no sand control liner needs to be placed into the small boreholes, the well completion process is simplified, and themethod is more convenient to implement, safe and reliable.

Owner:SOUTHWEST PETROLEUM UNIV

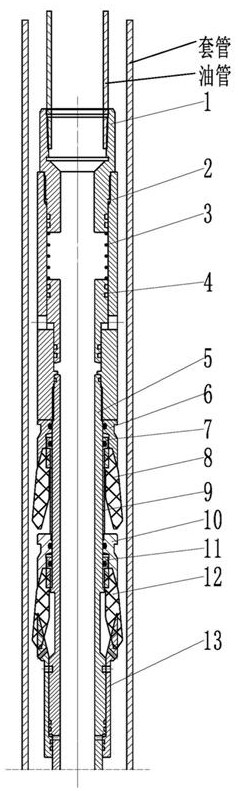

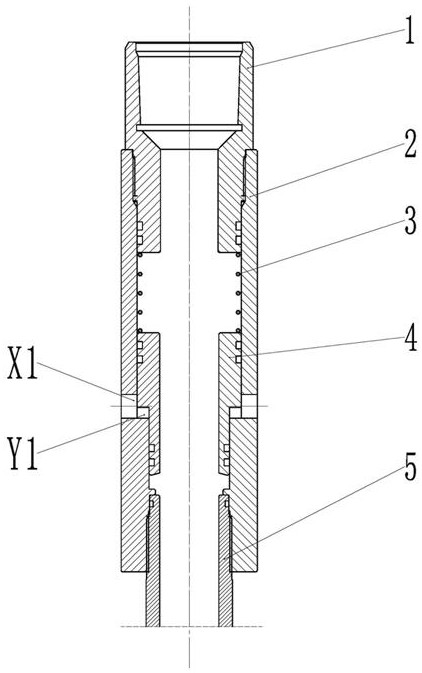

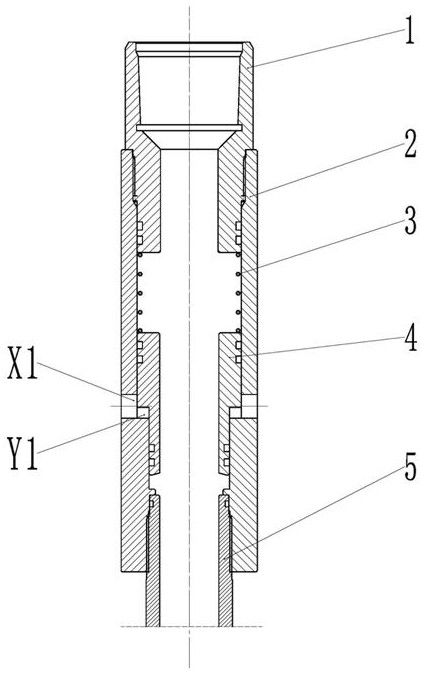

Layered pipe column for squeeze packing sand control process

ActiveCN1294337CIncrease productionUnblock pollutionFluid removalEngineeringUltimate tensile strength

The invention discloses the petroleum use lamination backlog to fill guards against sand pipes the column, was suitable to the multi- oil layers extrusion packing tube column, in was sufficient string of tubing including ram and in fills the tool, outside filled the tube column including the crown hook wall packer, outside filled the tool and the sand filter, outside filled on the tool to be equipped with fills the mouth. In fills the tube column to be equipped with the seat to seal washes one's hands of, outside fills the tube column to be equipped with the level the packer. After the seat seals washes one's hands of is hit the pressure to cause the crown to hang the packer place to seal, the seat seals washes one's hands of prearranges the hook wall packer separation, in fills the tube column to be able to fill in the tube column in outside to reciprocate sits the sealing course gap, fills the tool coordination backlog with outside to fill the stratum. Enhances guards against the granulated substance effect and the term of validity. The next tube column then completes many oil layers lamination backlog to fill guards against the granulated substance the construction, greatly reduced the production cost and worker's labor intensity.

Owner:OIL EXTRACTION TECH INST OF SINOPEC SHENGLI OILFIELD

Geothermal storage layer transformation method

ActiveCN110318725AImproved profileIncrease seepage areaGeothermal energy generationFluid removalWorking fluidEnvironmental geology

The invention relates to a geothermal storage layer transformation method. The method comprises the following steps: 1) anisotropism strengths of geothermal wells are divided according to porosity andpermeability data of each water layer in the geothermal wells; and 2) for the geothermal wells with weak anisotropism, pretreatment liquid is injected in geothermal storage layers, then, acid fracturing prepad fluid and acid fracturing working fluid are repeatedly injected in sequence, and then, replacement liquid is injected; and for the geothermal wells with strong anisotropism, temporary blockage acid is firstly injected in the geothermal storage layers for temporary blockage, then, the pretreatment liquid is injected, then, the acid fracturing prepad fluid and the acid fracturing workingfluid are repeatedly injected in sequence, and then, the replacement liquid is injected. The geothermal storage layer transformation method performs the acid fracturing transformation according to properties of the geothermal storage layers, can form earthworm holes after transformation to communicate with natural cracks, improves the sections of heat storage layers, enlarges the seepage area, andachieves the purpose of increasing the water yield of mining wells and the water injecting quantity of reinjection wells.

Owner:SINOPEC SSC +1

Liquid collecting device for rock core fluid full-surface saturation and full-surface saturation method

ActiveCN107620592AIncrease percolation fluxAccurate measurementBorehole/well accessoriesRock corePiston

The invention provides a liquid collecting device for rock core fluid full-surface saturation and a full-surface saturation method. The upper portion of the liquid collecting device is connected witha rock core clamping device with the open bottom in fixed and sealed modes, a rock core is fixed into an inner cavity of the rock core clamping device, and the liquid collecting device comprises a pressure-bearing connector connected with the bottom of the rock core clamping device in sealed and fixed modes. The lower portion of the pressure-bearing connector is in sealed connection with a constant-pressure liquid collecting cylinder, a piston type connector is sealed in the pressure-bearing connector in a penetrating mode, and the top of the piston type connector extends into a bottom openingof the rock core clamping device and connected into the inner cavity of the rock core clamping device in a sealed mode. The bottom of the piston type connector extends into an inner cavity of the constant-pressure liquid collecting cylinder. A center passage is formed in the piston type connector, and a piston is slidably arranged in the center passage. The side wall of the constant-pressure liquid collecting cylinder is provided with a saturation oil passage, and the bottom of the constant-pressure liquid collecting cylinder is provided with a liquid discharging outlet capable of being closed. According to the liquid collecting device for rock core fluid full-surface saturation and the full-surface saturation method, the full surface of the rock core can make contact with water / oil, theflow seepage speed is high, and the volumes of the saturated water and the saturated oil can be accurately measured.

Owner:PETROCHINA CO LTD

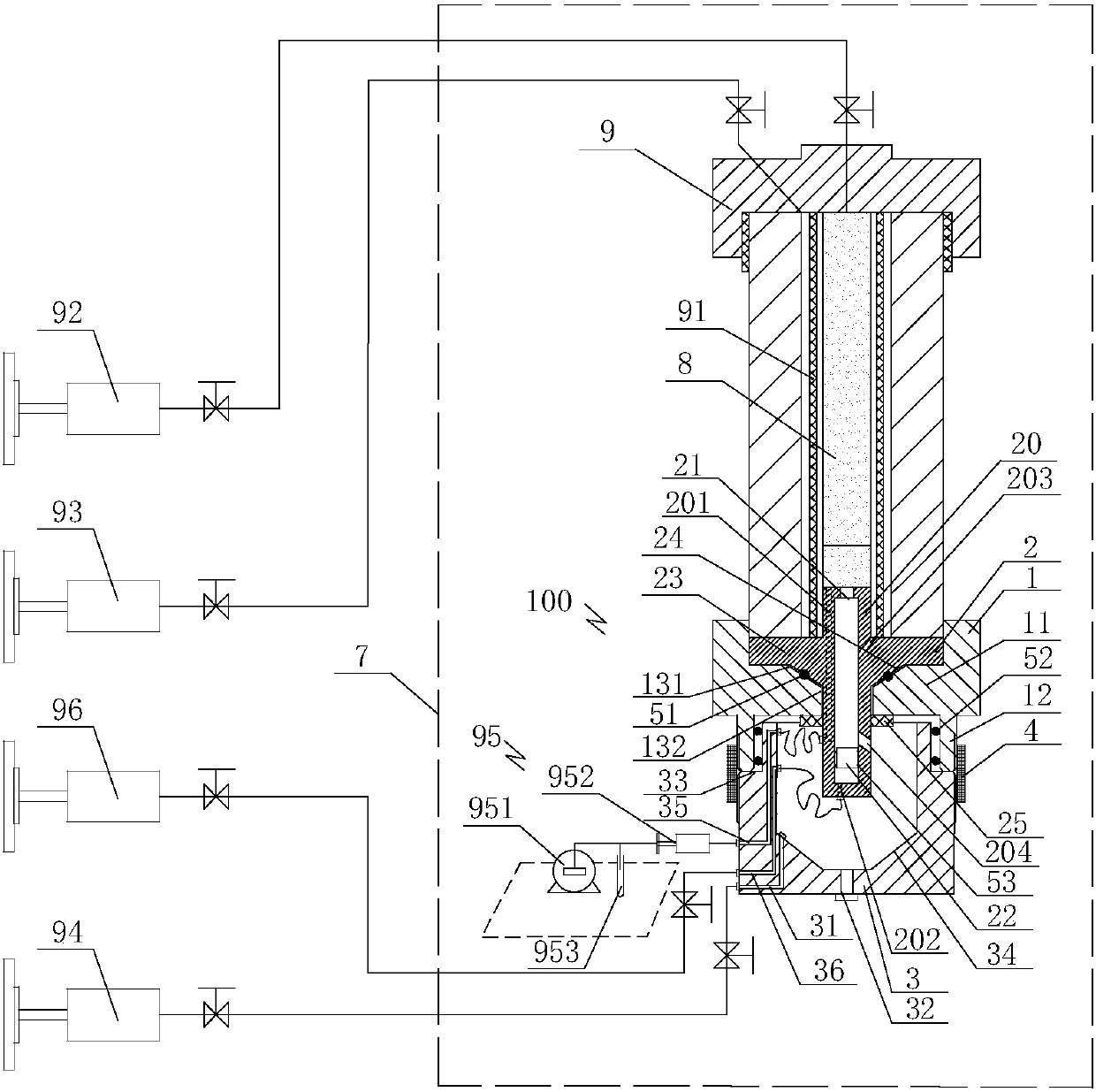

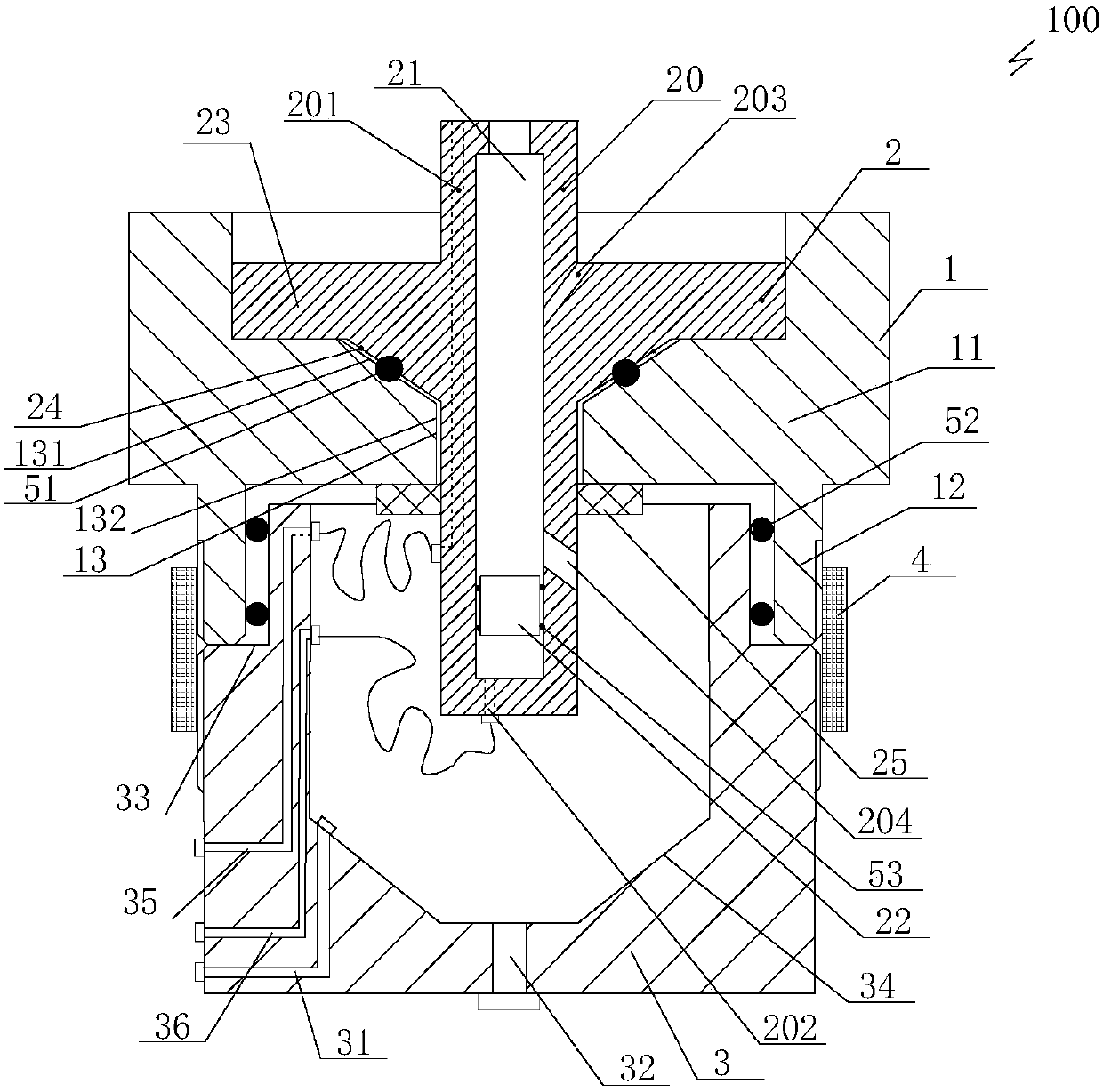

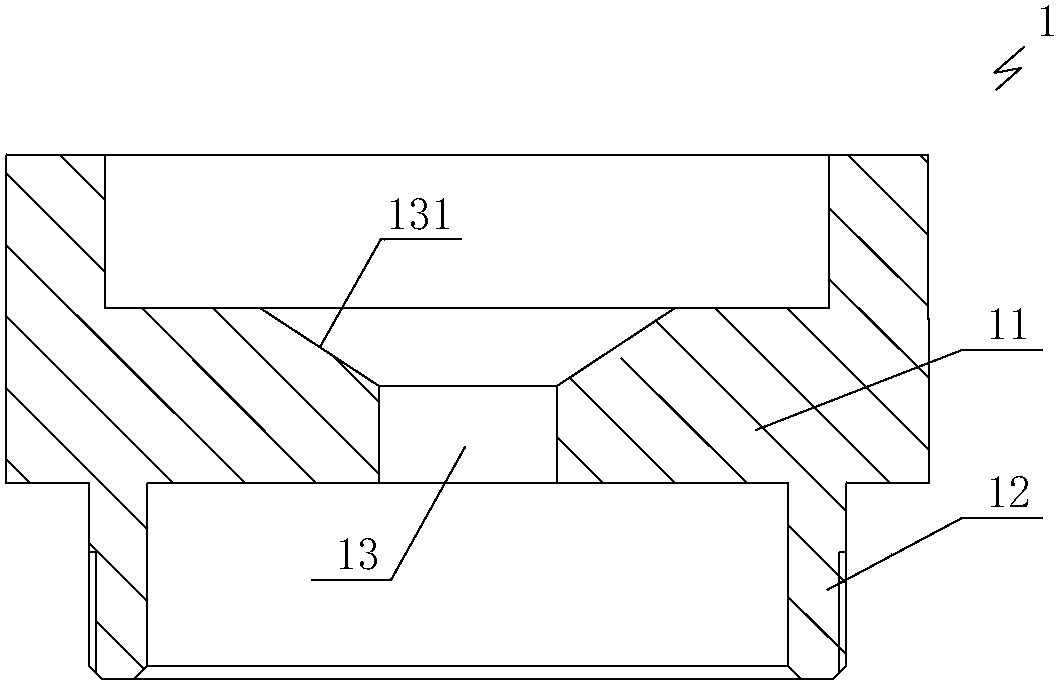

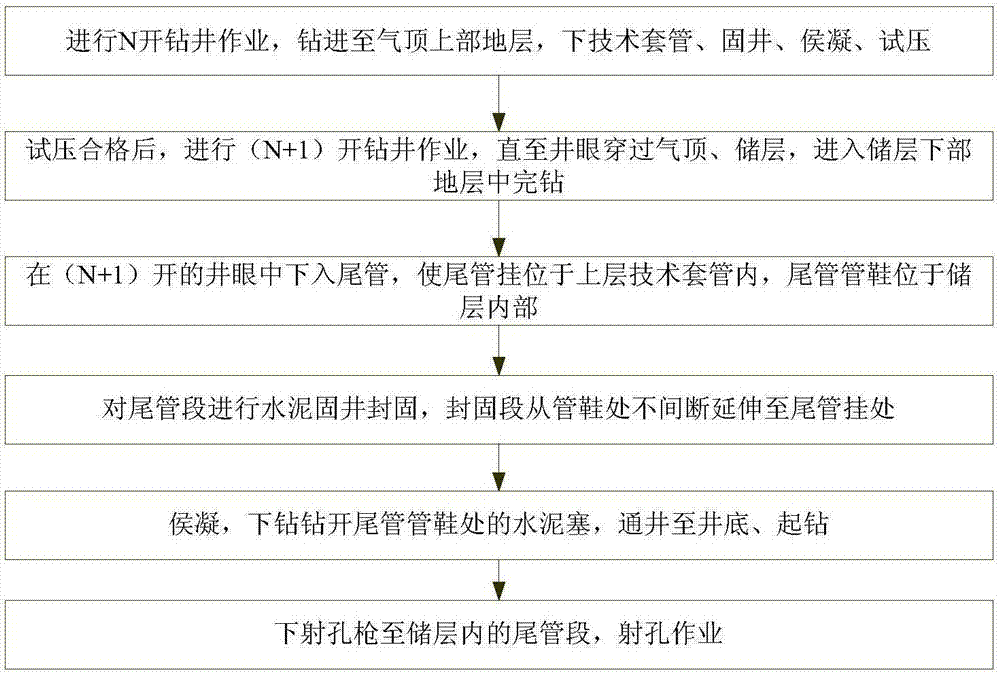

Gap cap entrapment composite well completion method

ActiveCN106996282AIncrease seepage areaStreamline straightFluid removalSealing/packingWell drillingWell cementing

The invention discloses a gap cap entrapment composite well completion method. The method comprises the following steps of (a) performing an Nth well drilling operation to the upper stratum of a gas cap, running in technical casing pipes, performing well cementation, cementation waiting and pressure test, wherein N>=1; (b) after pressure is tested to be qualified, performing an (N+1)th well drilling operation until penetrating the gas cap and a reservoir and reaching the lower stratum of the reservoir to finish drilling; (c) in the (N+1)th well, running a tail pipe into an upper casing pipe, and running the pipe shoe of the tail pipe into the reservoir; (d) cementing the tail pipe section for well cementation to extend the cemented section to the tail hanger of the tail pipe; (e) performing cementation waiting, drilling a cement plug at the tail shoe of the tail pipe until reaching the well bottom, and pulling out of hole; (f) running a perforating gun into the tail pipe section inside the reservoir to performing perforating operation. The gap cap entrapment composite well completion method is applied to solving the problem that gas cap entrapment well completion manners in the prior art are prone to lead to low productivity, and achieving the aim of increasing the seepage area and improving the single well productivity.

Owner:CHENGDU NORTH OIL EXPLORATION DEV TECH

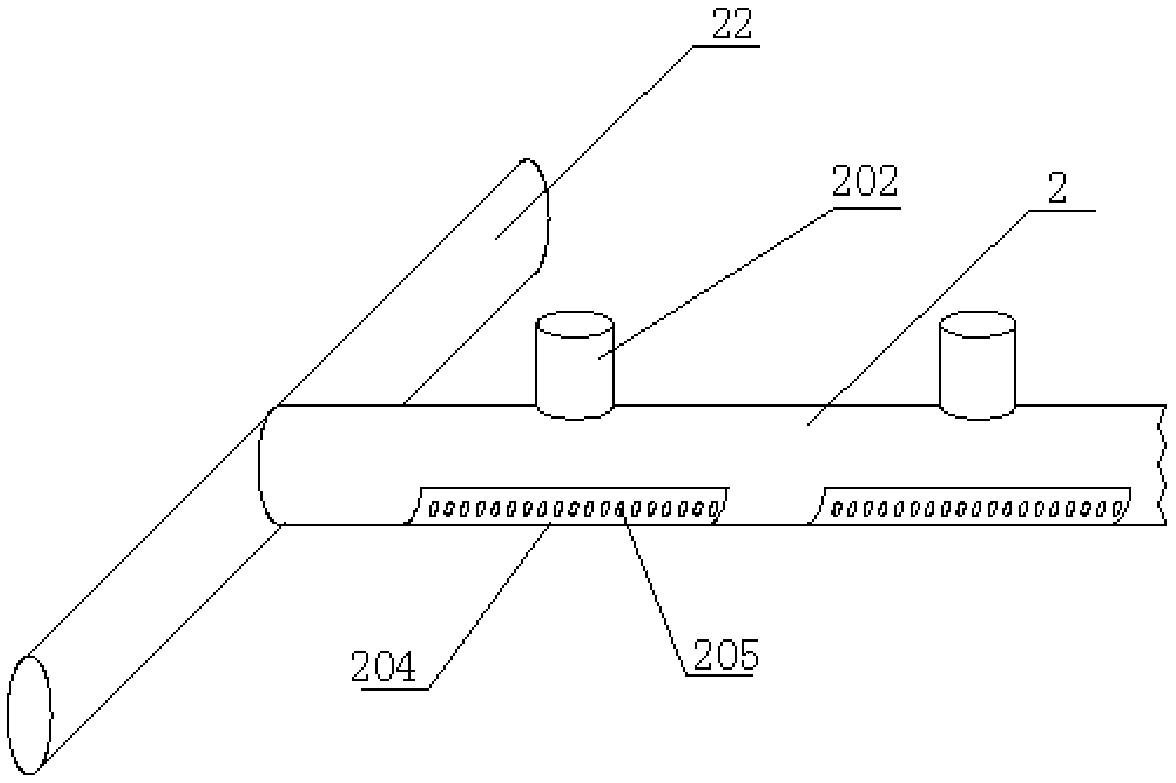

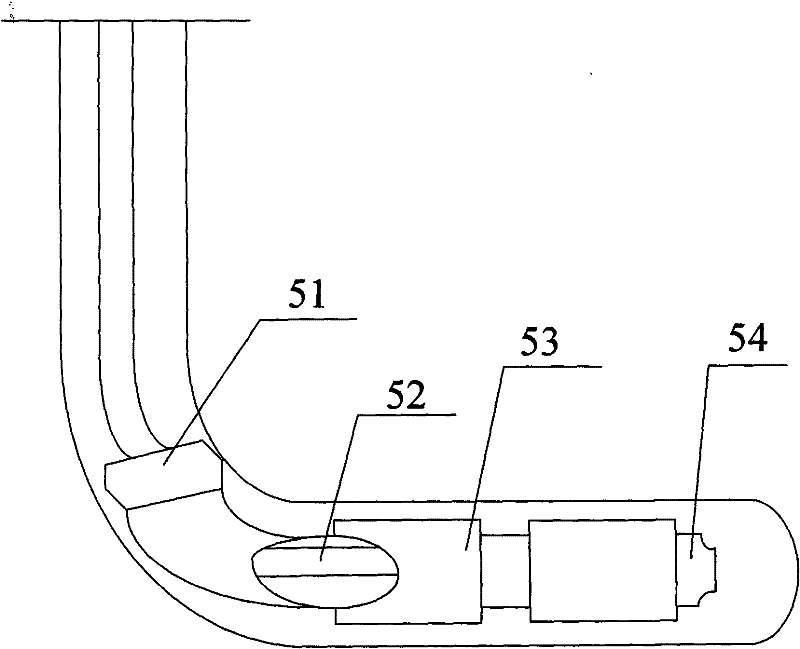

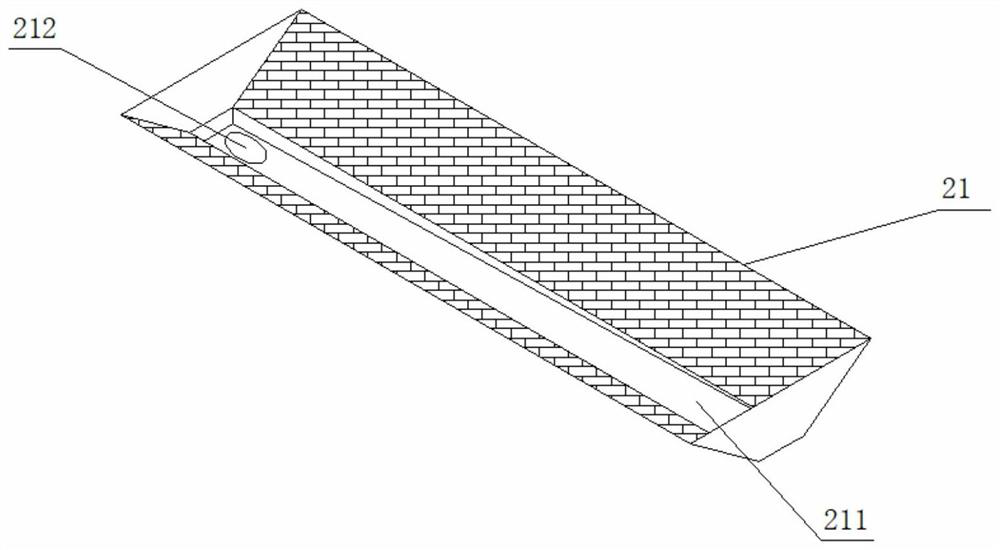

Citrus Orah drip irrigation system

InactiveCN109122220AIncrease seepage areaCause rotMeasurement devicesClimate change adaptationWater storage tankDrip irrigation

The invention relates to the technical field of agricultural planting, and particularly relates to a citrus Orah drip irrigation system. The drip irrigation system comprises planting rows, a water supply device, a fertilizer applying device, a controller and a management module; the water supply device comprises drip irrigation pipes, a water storage tank and a water supply pump, and is used for carrying out drip irrigation on the planting rows; the fertilizer applying device comprises a material storage tank, stirring paddles, a discharging pipe and fertilizing pipes; the discharging pipe isin conducting connection with the storage tank through a slurry discharging pump; the fertilizing pipes are respectively positioned above the planting rows and are in conducting connection with the discharging pipe; each fertilizing pipe comprises a pipe body and a spiral pushing rod; each of fertilizing openings is provided with a first flow valve, a first switch valve and a fertilizer nozzle; and the controller can be used to control a water circulation device and the fertilizer applying device according to the management module. Through the citrus Orah drip irrigation system provided by theinvention, intelligent drip irrigation and fertilization can be carried out according to the growth condition and the soil condition of the citrus Orah, and the influence of manual factors is greatlyreduced.

Owner:靖西海越农业有限公司

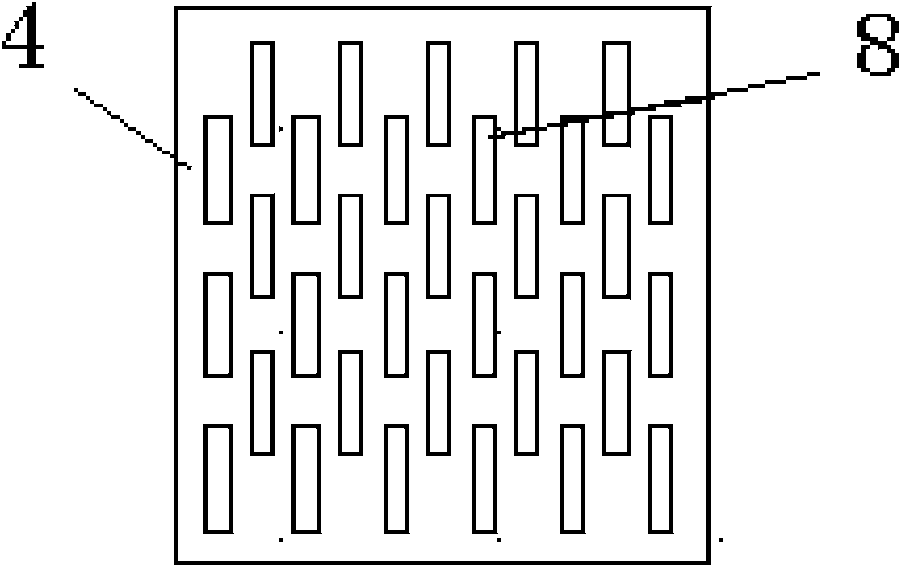

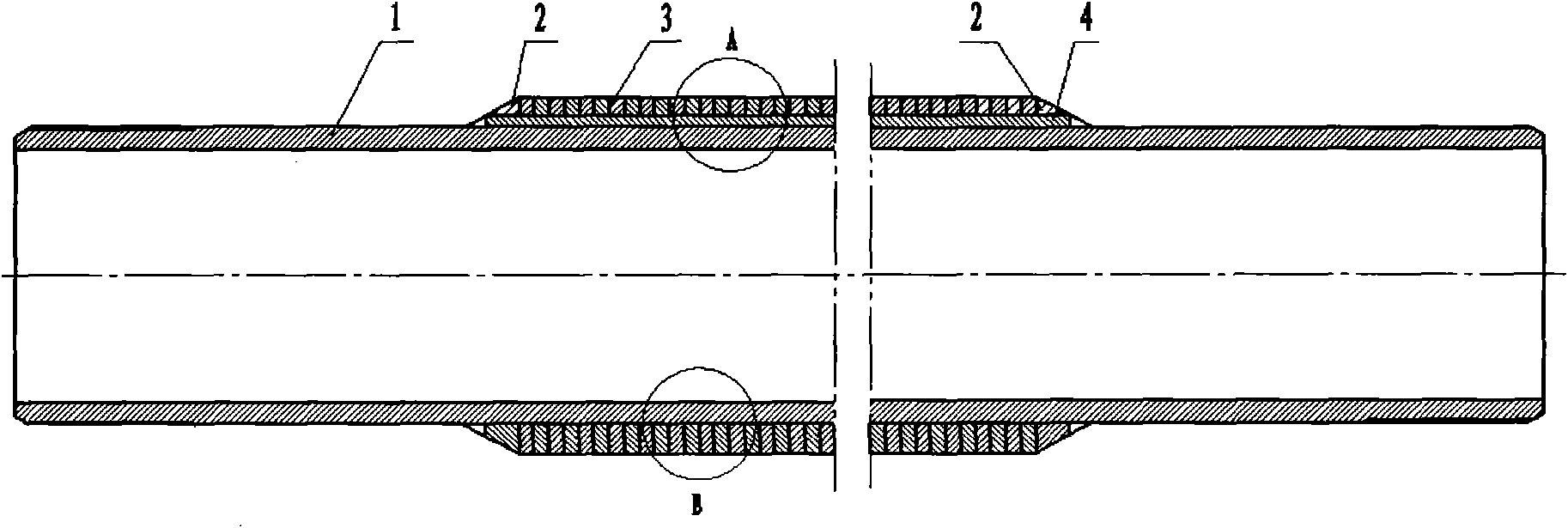

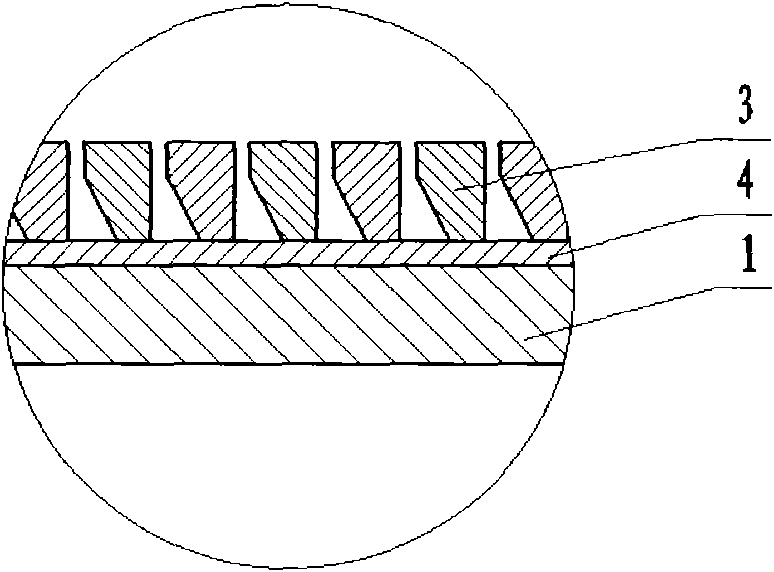

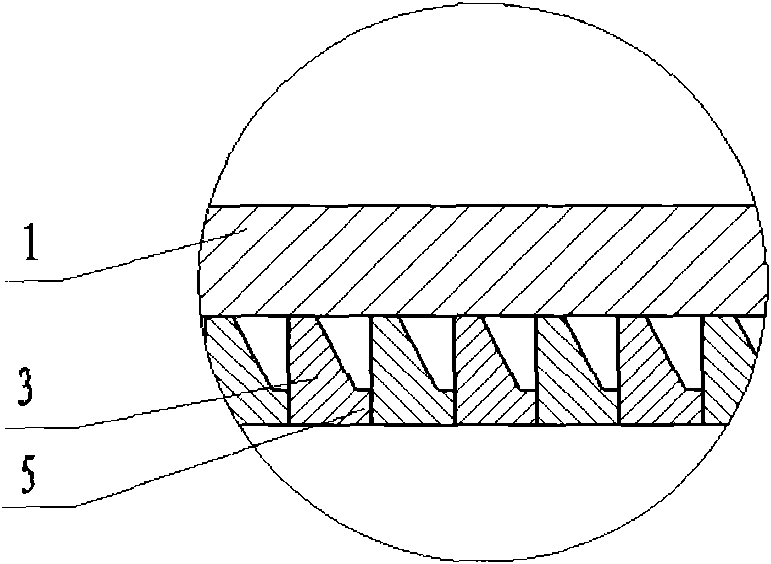

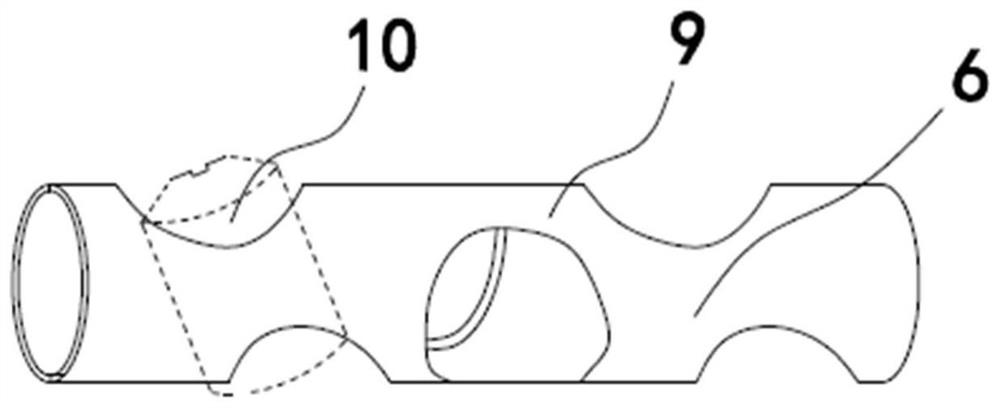

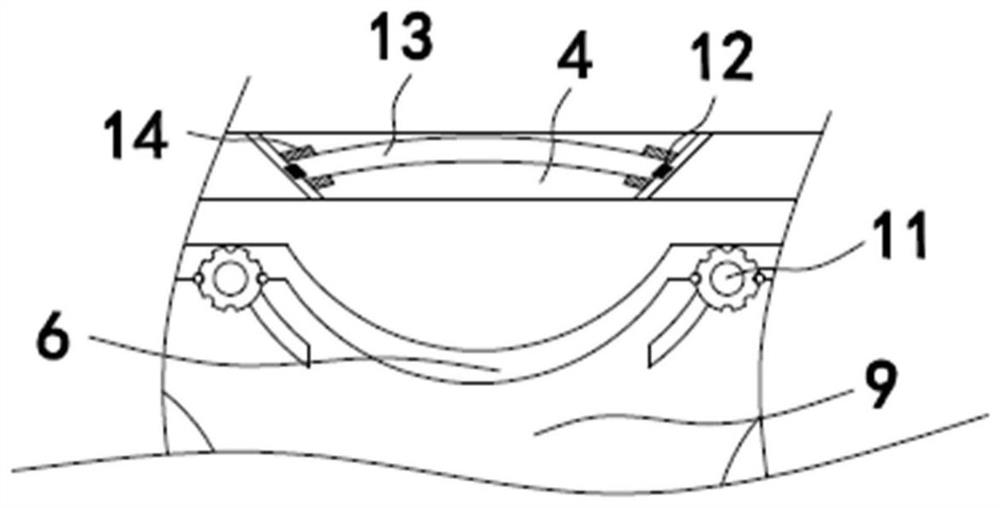

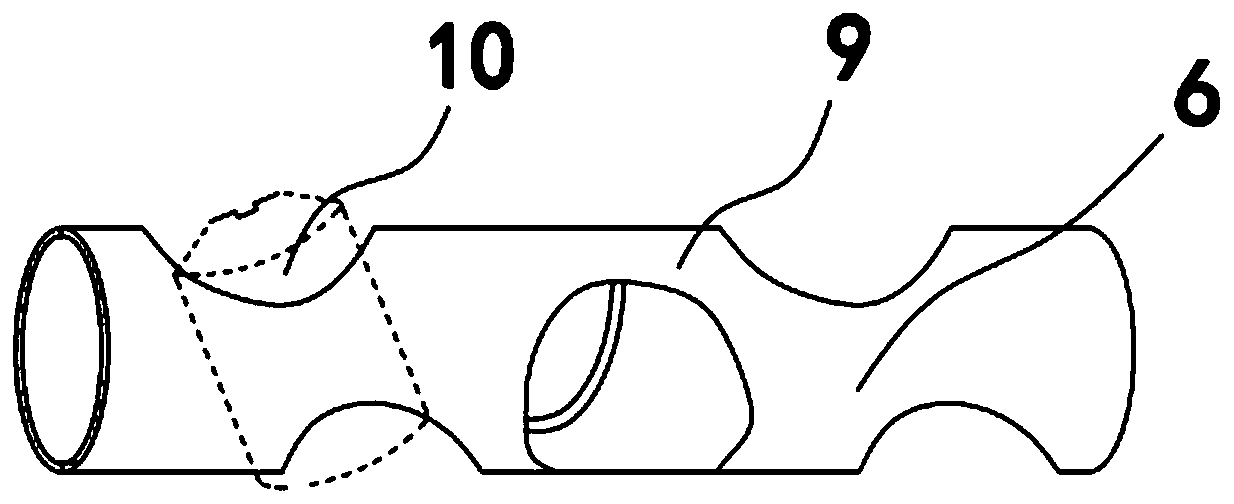

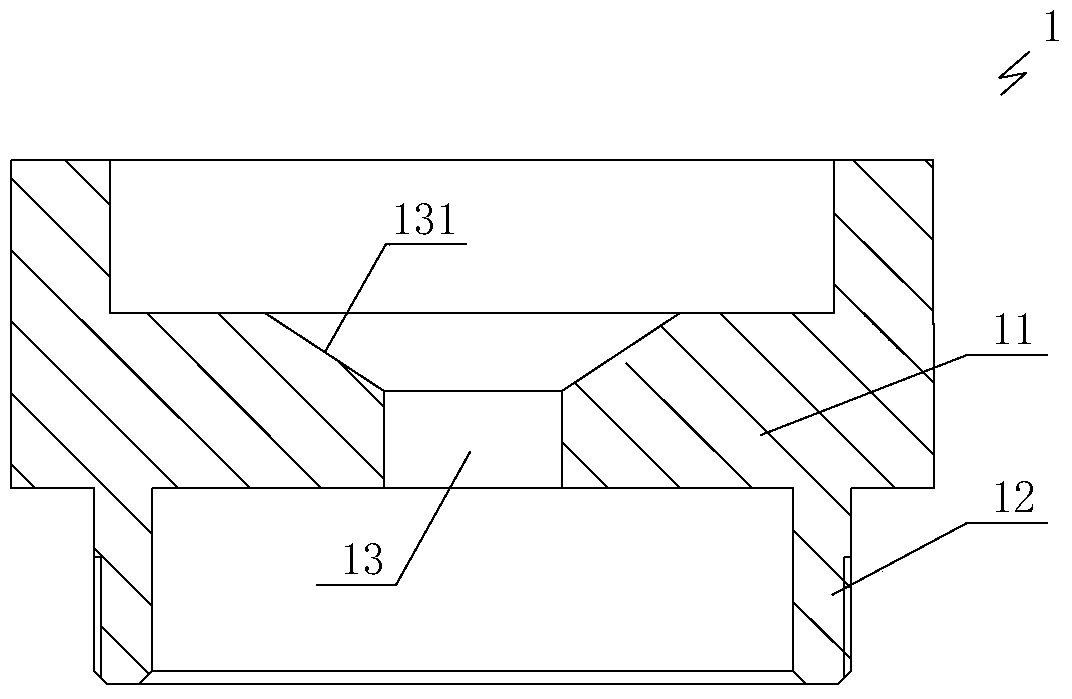

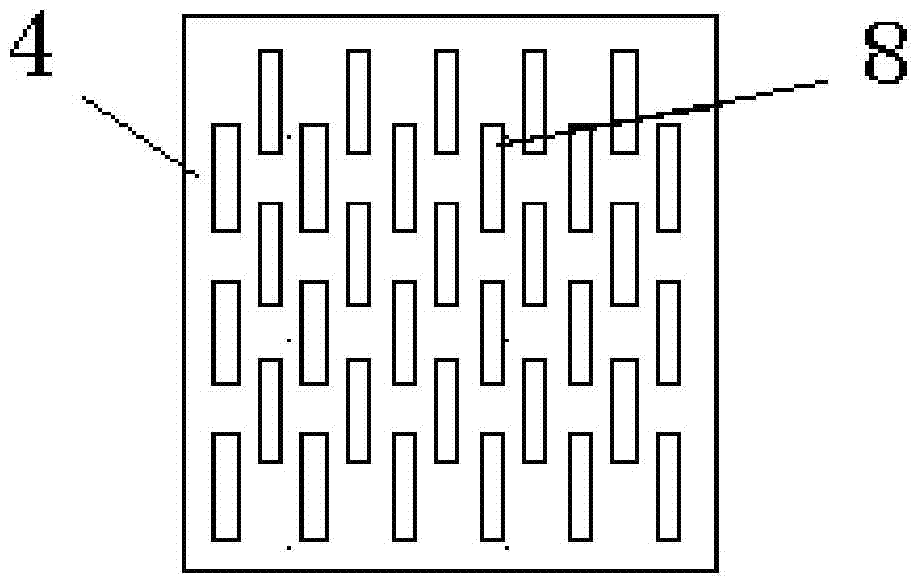

Combined type sieve tube

The invention relates to a combined type sieve tube aiming to overcome the defects of easy blockage of antiparallelogram gaps, poor self-cleaning capability, low pressure-bearing capacity and easily extruded damage of the traditional sand prevention sieve tubes. In the invention, the wall of a base tube is provided with an overflowing hole, and sieve blades are fixedly arranged on the outer circumference of the base tube; one end of an inner hole of each sieve blade is a straight hole, while the other end is a taper hole which is small inside and big outside; the end surface at one end of each sieve blade straight hole is a plane, while the other end surface is uniformly distributed with three or more lug bosses; the wall of the inner hole of each sieve blade is provided with an axial liquid flow trough; the excircle of the base tube is axially provided with a key; the part of the base tube, with a key, is sequentially provided with a gland, a plurality of sieve blades and a gland, and the glands are fixedly connected with the base tube; and the sieve blades are sequentially arrayed in the same direction. The sieve tube has the advantages of reasonable structure, easiness for processing and manufacturing, large seepage area, high sand blocking precision, good anti-blockage effect, high pressure bearing strength and long service life and can be used for extracting liquid with a large discharge quantity and pumping out dust sand to increase the liquidity of liquid, thereby prolonging the extraction life of an oil well and reducing the production cost of oil extraction.

Owner:DAGANG OIL FIELD GRP

A composite perforating gun

ActiveCN110761750BStrong penetrating powerInhibit sheddingFluid removalDetonationStructural engineering

The invention provides a novel composite perforating gun, which belongs to the technical field of oilfield well completion, and includes a gun head, a perforating gun body, and a gun tail. A number of blind holes are opened on the surface of the perforating gun body, and a bullet rack is arranged inside the perforating gun body. , the loading hole opened on the surface of the bullet rack corresponds to the blind hole, the blind hole is in the shape of an inverted cone, and symmetrical blocks are fixed on the inclined surface of the blind hole, and baffles are inserted between the symmetrical blocks. An O-ring is provided at the contact position between the plate and the inclined surface of the blind hole. The invention can better fix the perforating bullet in the charging hole, which ensures the stability of the perforating gun. The design of the blind hole can effectively increase the explosion height of the perforating bullet in the gun body, which is beneficial to improve the safety of the perforating bullet. Penetrating deep, the perforating gun has no burr after detonation, the gun hole does not deform, and it can effectively reduce formation pollution.

Owner:任丘市泰浩石油科技有限公司

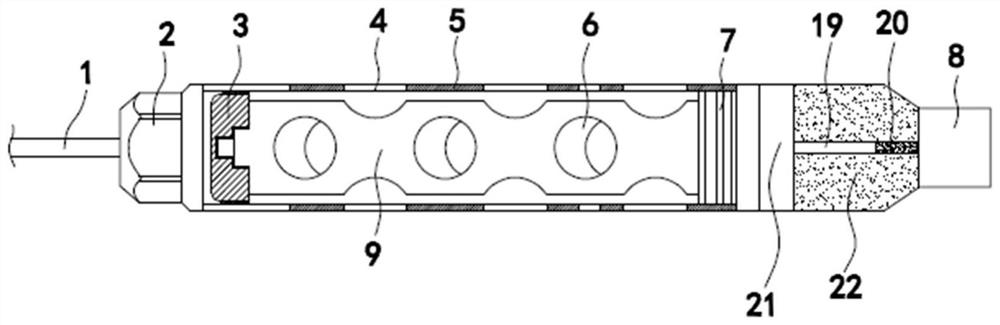

Novel composite perforating gun

ActiveCN110761750AStrong penetrating powerInhibit sheddingFluid removalStructural engineeringBlind hole

The invention provides a novel composite perforating gun and belongs to the technical field of oil field well completion. The novel composite perforating gun comprises a gun head, a perforating gun body and a gun tail, wherein a plurality of blind holes are formed in the surface of the perforating gun body, a bullet rack is arranged in the perforating gun body, bullet loading holes formed in the surface of the bullet rack correspond to the blind holes, the blind holes are in an inverted cone shape, symmetrical clamping blocks are fixedly connected to the inclined surfaces of the blind holes, baffles are inserted between the symmetrical clamping blocks, and O-shaped rings are arranged at the contact parts of the baffles and the inclined surfaces of the blind holes. According to the novel composite perforating gun, perforating bullets can be well fixed in the bullet loading holes, the stability of the perforating gun is guaranteed, the blasting height of the perforating bullets in the gun body can be effectively improved through the design of the blind holes, the penetration depth of the perforating bullets is favorably improved, the perforating gun has no burr after detonation, a gun hole is not deformed, and the stratum pollution can be effectively reduced.

Owner:任丘市泰浩石油科技有限公司

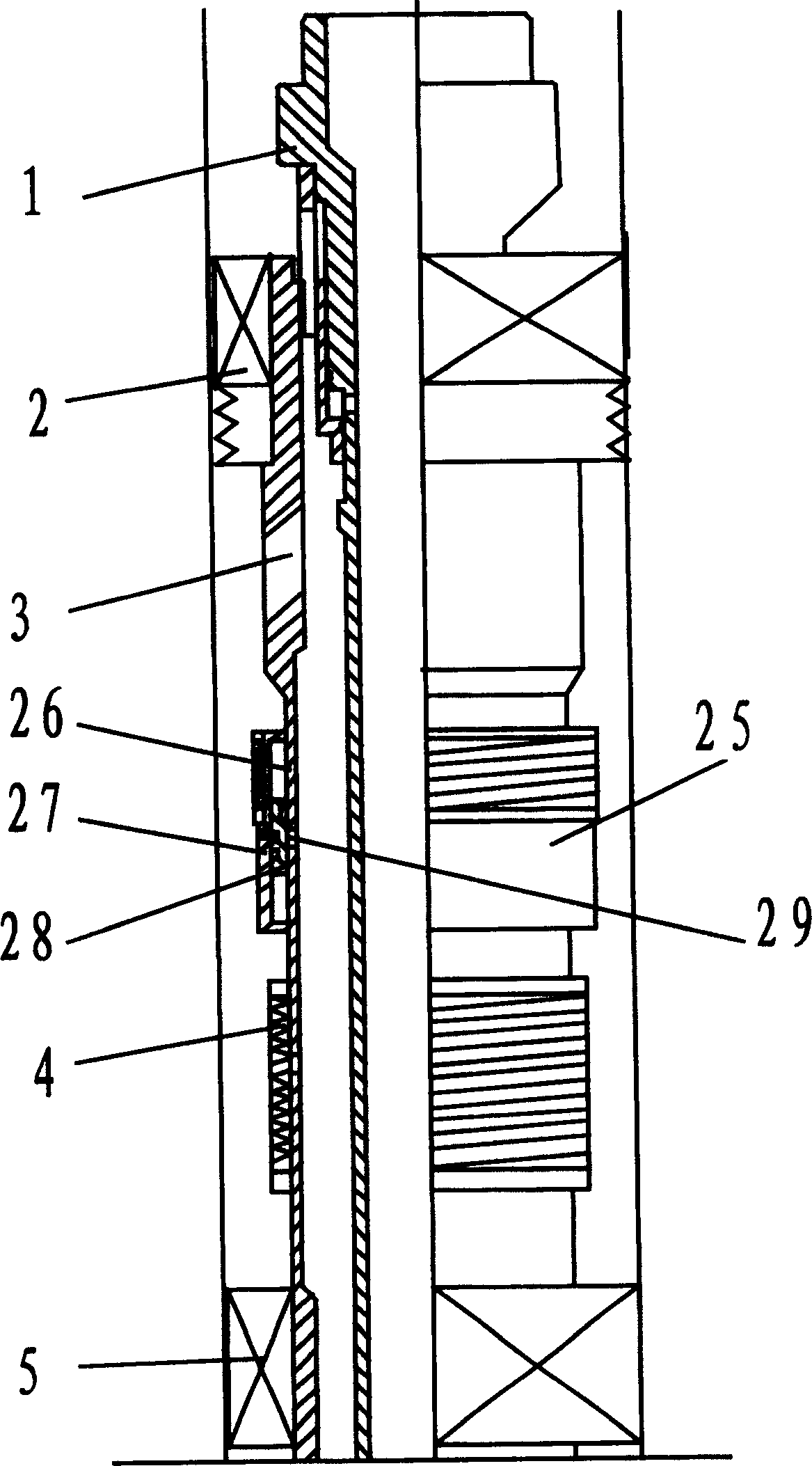

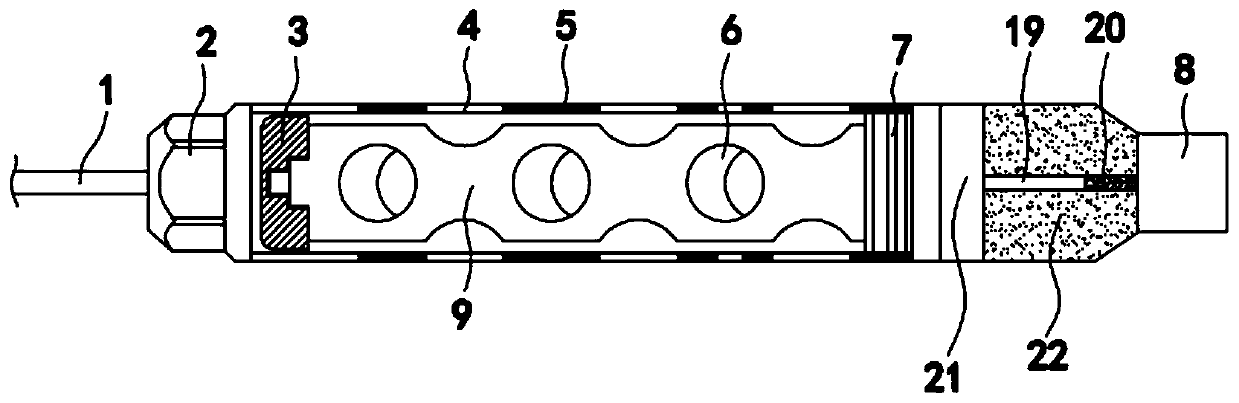

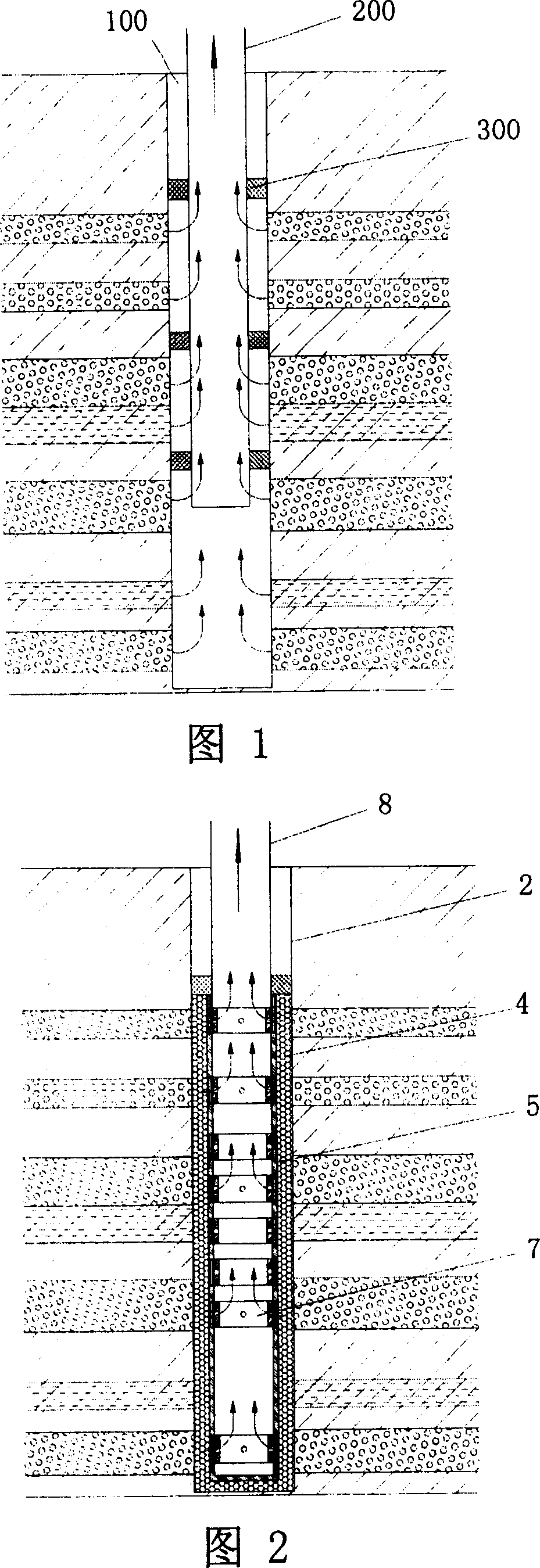

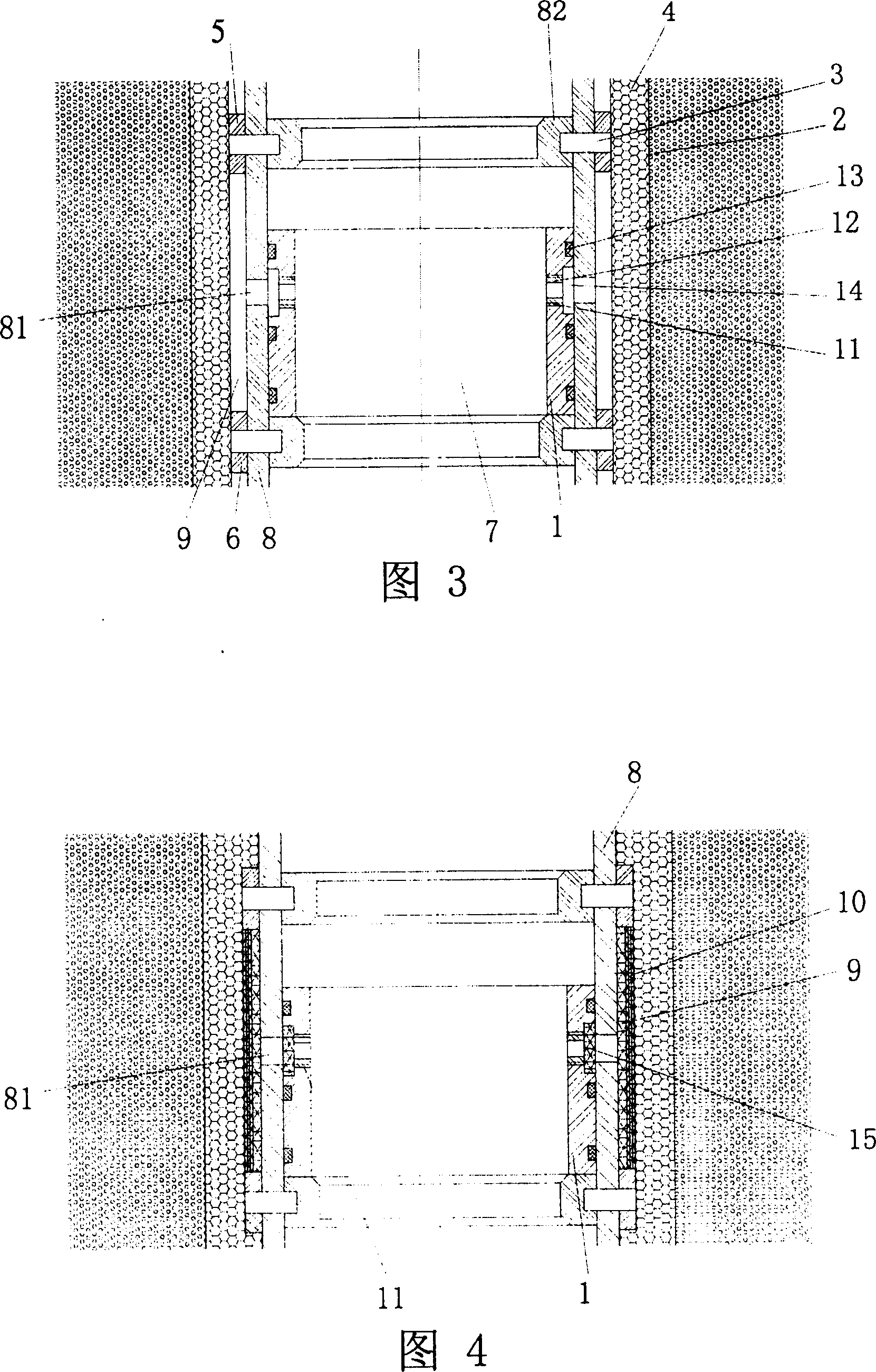

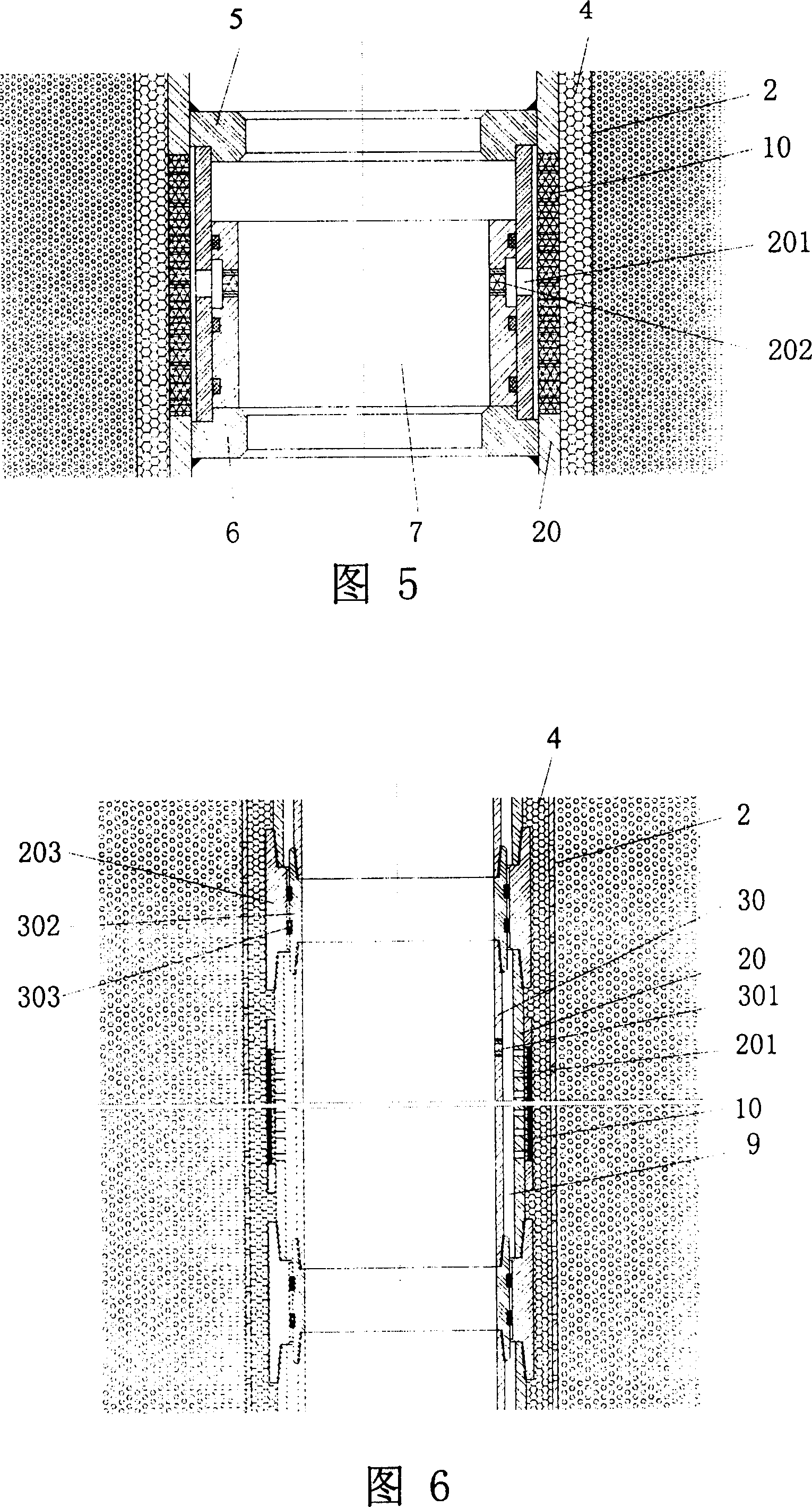

Completion system of oil and gas wells with regulatably controlling flows of formation fluid or filled fluid in divided sections

A finished oil (or gas) well system able to segmentally control the stratum fluid or injected fluid is at least composed of the fluid regulating pipe in the well and the porous medium in the gap between said regulating pipe and well wall. Said fluid regulating pipe has fluid collecting holes, fluid collecting cavities and the flow controllers relative to said fluid collecting holes for regulating the flow of stratum fluid or injected fluid flowing through said fluid collecting hole. It is suitable for the multi-layer oil deposit to pack multiple segments.

Owner:ANTON BAILIN OILFIELD TECH (BEIJING) CO LTD

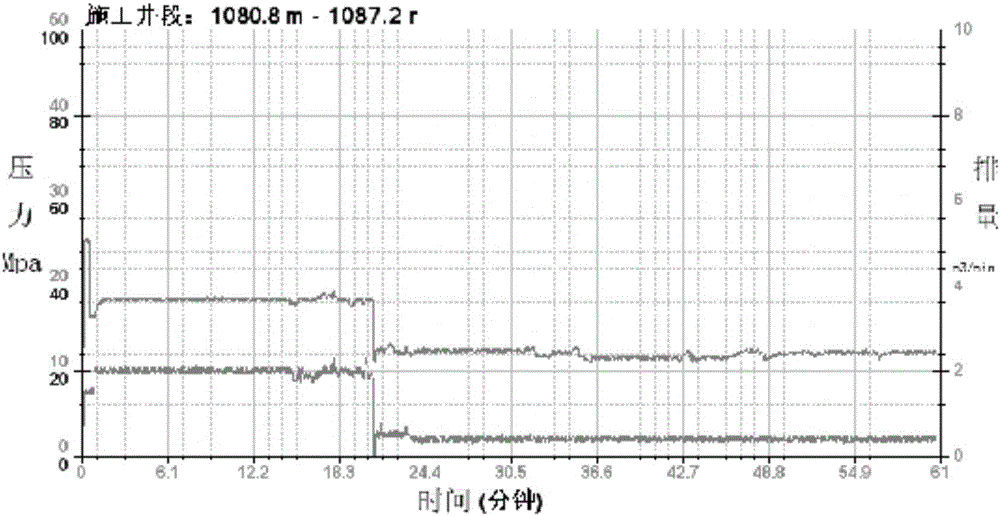

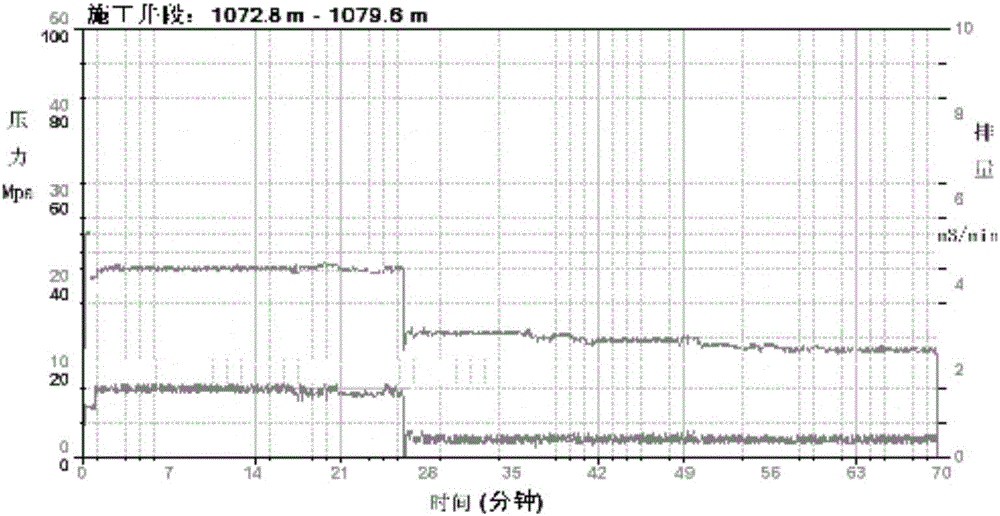

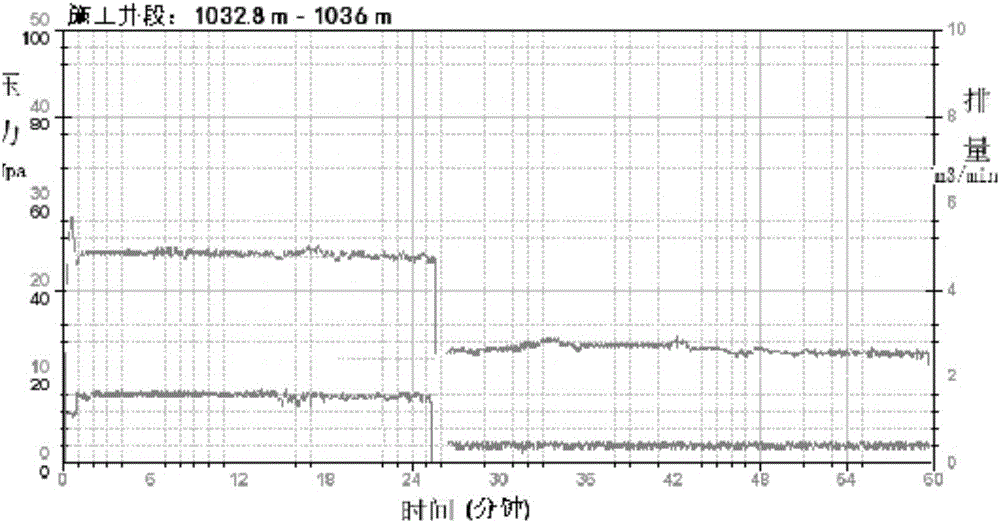

Hydraulic plug removal acidizing technology

The invention provides a hydraulic plug removal acidizing technology. The technology includes the following steps that firstly, a wellhead is detached; secondly, an original well pipe column is lifted out; thirdly, a hydraulic plug removal acidizing pipe column is put down; fourthly, magnetic positioning is conducted; fifthly, high-pressure hydraulic plug removal acidification is conducted; sixthly, a ground pressure test is conducted, wherein the ground pressure test is exerted at 55 Mpa for 10 min, and the test is passed if no puncture or leakage exists; seventhly, a first layer is subjected to hydraulic plug removal acidification; eighthly, steel balls are thrown to hit a sliding sleeve; ninthly, a second layer is subjected to hydraulic plug removal acidification; tenthly, the steel balls are thrown to hit the sliding sleeve; eleventhly, a third layer is subjected to hydraulic plug removal acidification; twelfthly, a well is closed, a reaction is conducted for 12 hours, and then liquid is reversely drained; thirteenthly, the plug removal acidizing pipe column is lifted up; fourteenthly, puncturing washing and measuring are conducted; and fifteenthly, a completion pipe string is put down, wherein a layered water distribution tool and an anti-corrosion oil pipe are put down, and sealing grease is painted; and the wellhead is mounted, and the technology is ended. By the adoption of the technology, a physical method is fully used for increasing the effective penetrating distance of acid liquid in a stratum, the stratum seeping performance is improved within a relatively large range, and therefore the purposes of yield increase and injection increase are achieved.

Owner:DAQING XINZHIHE TECH

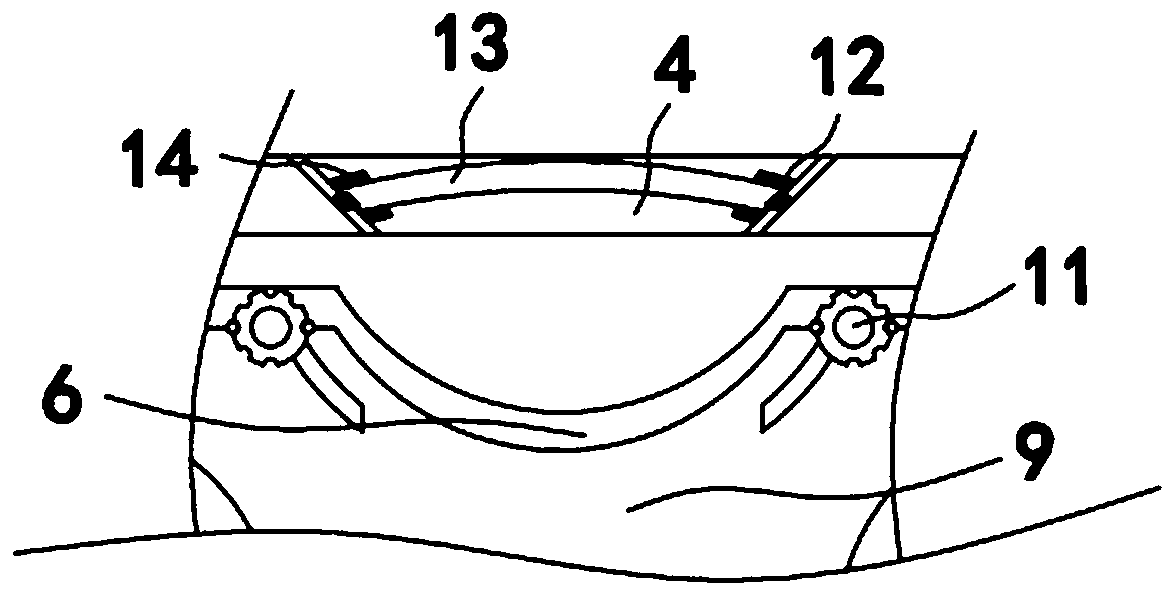

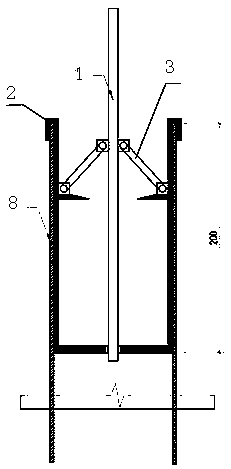

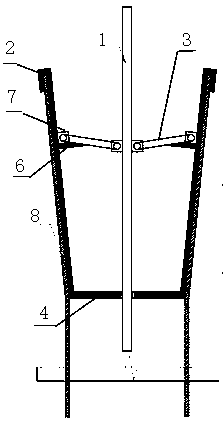

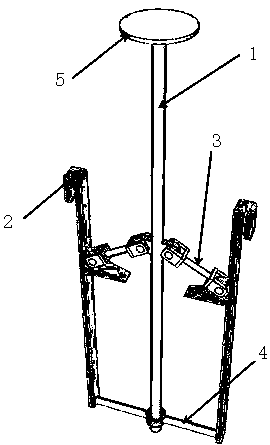

Automatic head-expanding device of side slope support water drain pipe and construction technology for increasing water facing surface

The invention discloses an automatic head-expanding device of a side slope support water drain pipe and a construction technology for increasing a water facing surface. Four symmetrical vertical openings are sawed on a pipe head of the PVC water drain pipe by an electric saw, a mechanical expander is installed, the left and right ends of a sliding fixed rod are respectively connected with a pipe wall fixed plate, the pipe wall fixed plate is connected with a vertical force-bearing rod through a lateral thrust and force transferring rod, and the vertical force-bearing rod passes through the central hole of a circular pipe of the sliding fixed rod; a limiting baffle and a hinged transmission fixed support are arranged at the 2 / 3 position of the upper end of the pipe wall fixed plate, the twoends of the lateral thrust and force transferring rod are connected with the hinged transmission fixed support of the pipe wall fixed plate and a connecting rod support of the vertical force-bearingrod; a layer of water filtering fiber net is wrapped in the range of 250 mm at the bottom of the pipe, and then the net is tied up and fixed by a ribbon around the outer wall of the pipe; by applyingpushing force to the bottom of the pipe, the mechanical expander at the bottom of the pipe can expand the pipe wall in the range of 20 cm at the pipe bottom to the two sides, the expanded pipe wall withstands the soil of the hole wall, the expanded pipe wall expands the water filter net together, the maximum expanding width is increased by 4 cm, the pipe wall is sawed to 1 cm, the area of a waterseepage port is expanded and increased, and the water drain pipe is stabilized at the same time.

Owner:贵州建工第八建设集团有限公司

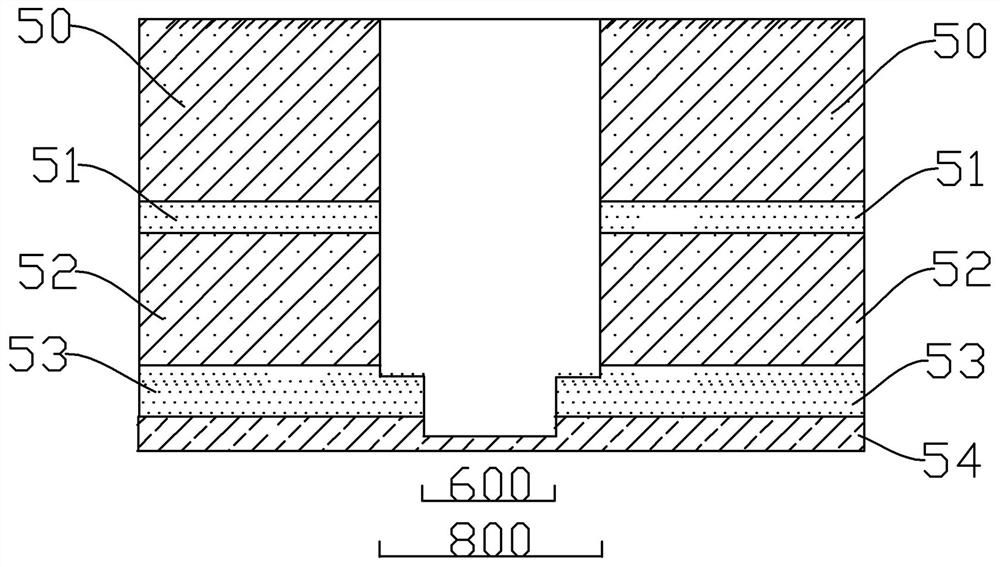

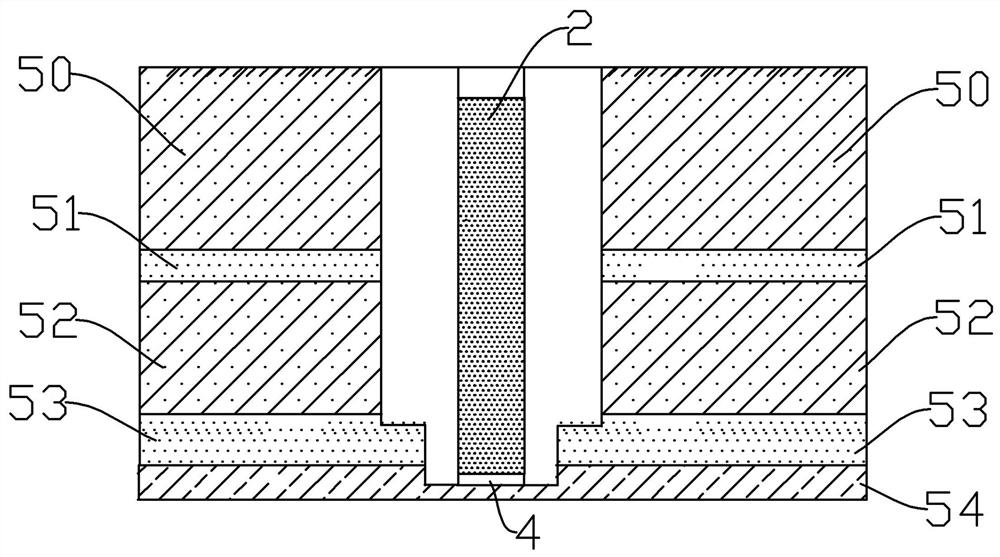

Residual water recharge well construction and recharge method based on shallow geothermal utilization

PendingCN114753447AReduce backfill pressure differenceEnhance natural recharge effectFiltration circuitsDrinking water installationSoil scienceWater filter

The invention discloses a residual water recharge well construction and recharge method based on shallow geothermal utilization. The technical problem that the recharge effect of a single well of an existing recharge well is not ideal is solved. The construction method comprises the steps that 1, the well completion position and the predicted well depth are determined; 2, the construction depth and the reducing depth of the recharge well are determined; 3, first well diameter drilling is carried out; step 4, drilling a well with a second well diameter; 5, a precipitation pipe and a water filter pipe are sequentially placed, a filter material is filled to form a water filter layer, and a water stop material is filled to form a water stop layer; the recharge method comprises the following steps of: 1, discharging residual water into the recharge well by using the water pump; 2, the water pumping amount of a water pump is controlled, and delta Hgt is guaranteed; delta S; and 3, when the water surface of the recharge well rises to the ground height and is still unstable, a pressure pump is started for pressurization and recharge. The single well recharge amount can be effectively increased, the number of recharge wells is reduced, space resources are saved, and the construction cost is reduced.

Owner:河南省地质矿产勘查开发局第二地质环境调查院

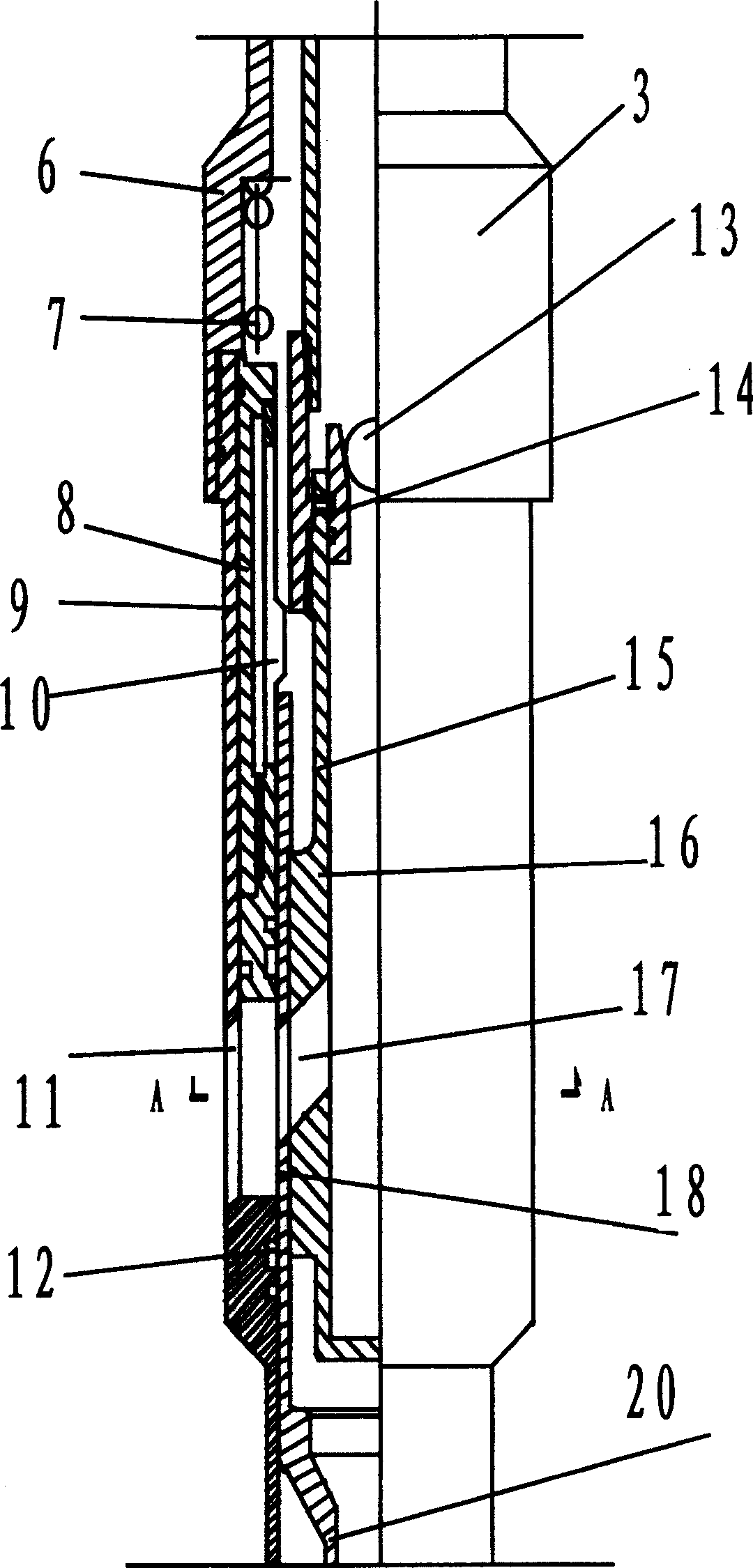

Multifunctional horizontal well completion tubular pile device

ActiveCN101560875BLow costOptimizing screen completion methodsFluid removalSealing/packingAcid washingEngineering

The invention relates to a horizontal well completion tubular pile device, which comprises a screen pipe, an internal washing pipe, a washing tool and a suspended type packer, wherein one end of the screen pipe is connected with the suspended type packer, while the other end is connected with the washing tool; the internal washing pipe is inserted in a sand-protection tubular pileconsisting of the packer and the screen pipe; and the lower end of the internal washing pipe is inserted in the washing tool in a sealed mode. The horizontal well completion tubular pile device finishes the processes of mud-replacement, acid washing and well completion through only one time, thus the cost is relatively low, the screen pipe well completion mode is optimized, and anannular space outside the pipe can be separated by the suspended type packer to effectively prevent well slough with higher seepage area.

Owner:PETROCHINA CO LTD

A gas generation system for improving seepage capacity of tight oil reservoirs and its application

ActiveCN105838347BIncrease seepage areaOvercoming pollutionFluid removalDrilling compositionChemical reactionHigh pressure

The invention provides a gas-producing system capable of improving permeability of a tight oil reservoir and application thereof, belonging to the technical field of oilfield development. The gas-producing system comprises a microcapsule and hydrochloric acid; the microcapsule uses a mixture of urea and sodium nitrite as a core material and a mixture of azodiisobutyronitrile, styrene, methyl methacrylate and methacrylic acid as a capsule dressing. In operation, nitrite and the microcapsule are injected into a stratum to a predetermined depth; and the microcapsule undergoes corrosion under stratum conditions and chemically reacts with hydrochloric acid to produce a great amount of gas and release a great amount of heat, so local high pressure is formed in a predetermined part. According to the invention, effective seepage channels of difficult-to-produce reserves such as an ultralow-permeability oil reservoir and the tight oil reservoir are increased so as to improve permeability, increase local energy of reservoirs and the flowback rate of raffinate, and reduce reservoir contamination, so the purpose of improving the recovery efficiency of the difficult-to-produce reserves is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A smart water and fertilizer irrigation system

ActiveCN109168528BIncrease seepage areaCause rotManure treatmentLiquid fertiliser regulation systemsAgricultural scienceWater storage tank

The invention relates to the technical field of agricultural planting, and particularly relates to a water fertilizer smart irrigation system. The system comprises planting rows, a water circulation device, a water fertilizer irrigation device, a controller and a management module, wherein the water circulation device is used for recycling water drained from soil; the water fertilizer irrigation device comprises a storage tank, an agitation paddle, a discharge pipe and fertilizing pipes; the storage tank is connected with a water storage tank through a circulating pipe; the discharge pipe is connected with the storage tank through a draining pump; the fertilizing pipes are respectively positioned on each planting row and connected with the discharge pipe; each fertilizing pipe comprises apipe body and a helical push rod; and the controller can be used for controlling the water circulation device and the water fertilizer irrigation device according to the management module. The water fertilizer smart irrigation system can be used for dividing planting into several sections and independently each section of planting rows, so that occurrence of growth difference among W oranges can be reduced.

Owner:靖西海越农业有限公司

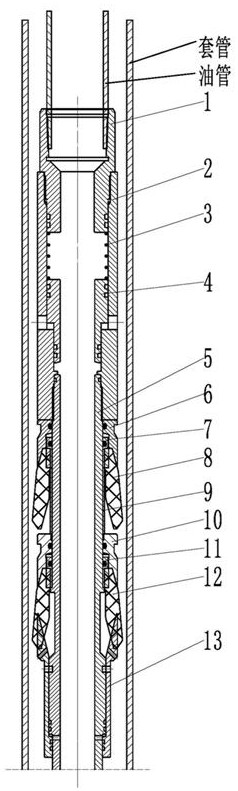

Sand prevention and well completion integrated packing and filling tool

ActiveCN114508326AImprove permeabilityHigh strengthFluid removalFlushingUpper jointStructural engineering

The invention discloses a sand prevention and well completion integrated packing and filling tool, and relates to the technical field of oil and gas well downhole operation tools, the sand prevention and well completion integrated packing and filling tool comprises an upper joint, a sealing assembly, a filling assembly and a lower joint, and further comprises a backwashing assembly and a central pipe I. The upper joint, the backwashing assembly, the central pipe I, the filling assembly and the lower joint are fixedly connected in sequence from top to bottom; the sealing assembly is arranged outside the central pipe I in a sleeving manner; the backwashing assembly is provided with a reset spring, so that the flexibility and the reliability of backwashing operation are enhanced; a filter ring and an anti-erosion inner ring are arranged on the filling assembly, so that the service life of the integrated packing and filling tool is prolonged; the device can be tripped in one time, and backwashing, setting, seal examining, fracturing filling, circulating filling and production operation can be completed under the condition that a tubular column is not lifted or other tools are not tripped in; compared with a traditional operation tool, the operation construction time can be saved by more than half, and the construction cost is greatly reduced.

Owner:山东普瑞思德石油技术有限公司

An integrated isolation and packing tool for sand control and well completion

Owner:山东普瑞思德石油技术有限公司

Novel rainwater perforated strainer suitable for being used in sponge city

The novel rainwater grate of the present invention is suitable for collecting rainwater from roads and squares in sponge cities, and includes a grate body and a grate cover. Holes of a certain diameter are evenly arranged in the upper part. The grate cover plate is a square panel. There are water seepage holes of a certain diameter and a certain width range evenly arranged around the cover plate. There is a certain height of isolation under the cover plate. There are holes of a certain aperture uniformly arranged on the upper and lower parts of the isolation plate, and the diversion reinforcement plate connects the panel and the isolation plate. The new rainwater grate can be made of different materials according to the installation position to meet the load requirements. The invention solves the problem of sand and other heavy particles flowing into the rainwater well, solves the problem of larger floating objects entering the rainwater well, solves the problem of peculiar smell in the rainwater well, and solves the problem of road garbage falling into the rainwater well in dry season.

Owner:吕武学

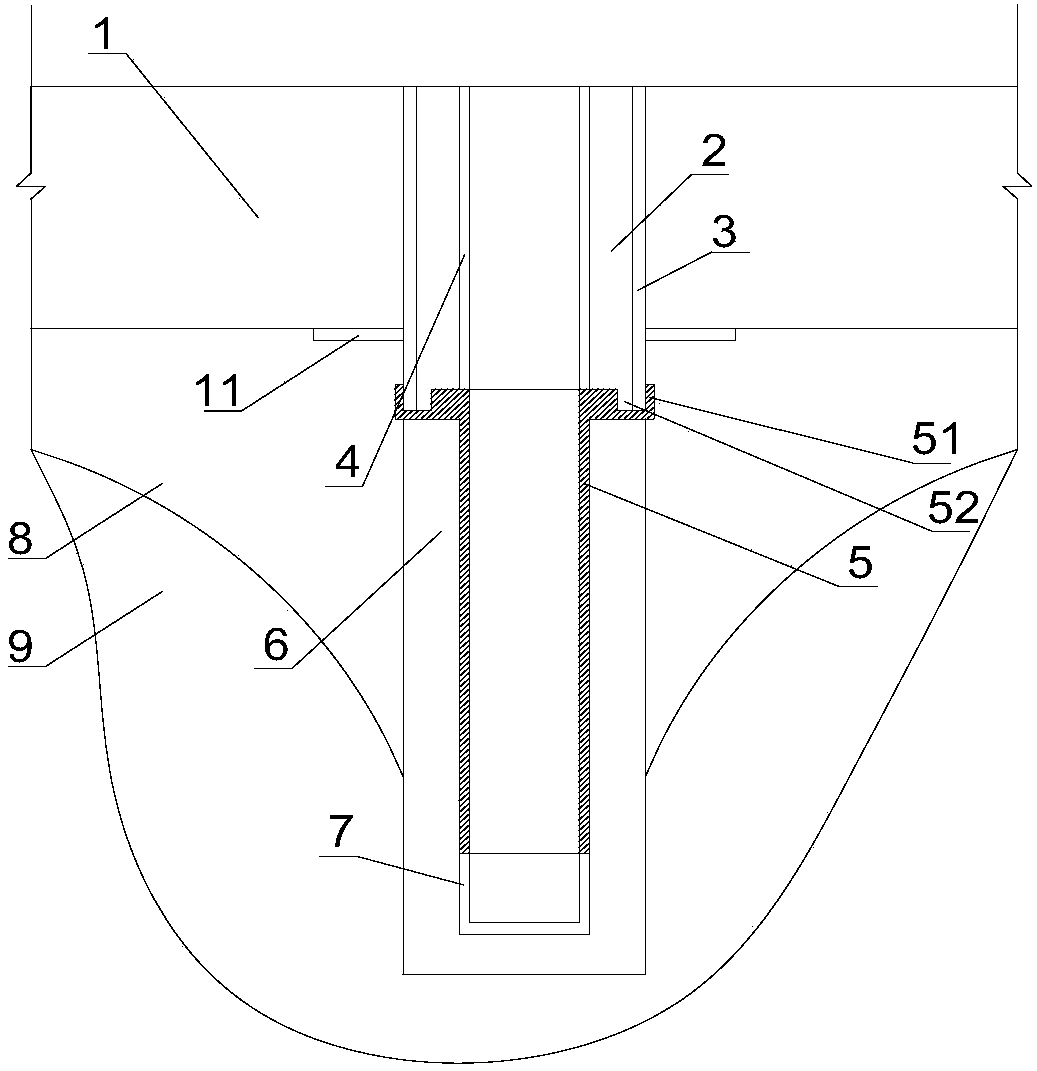

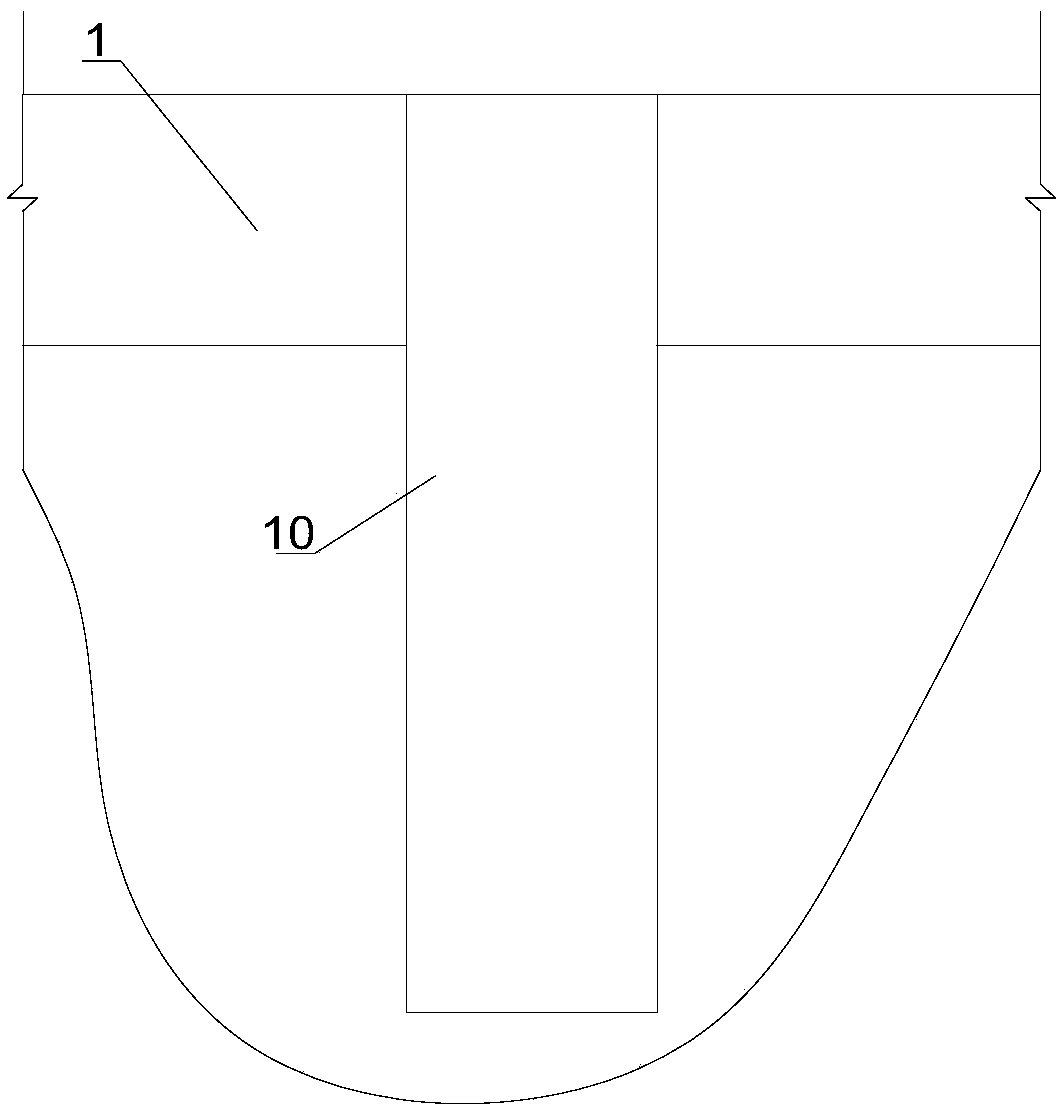

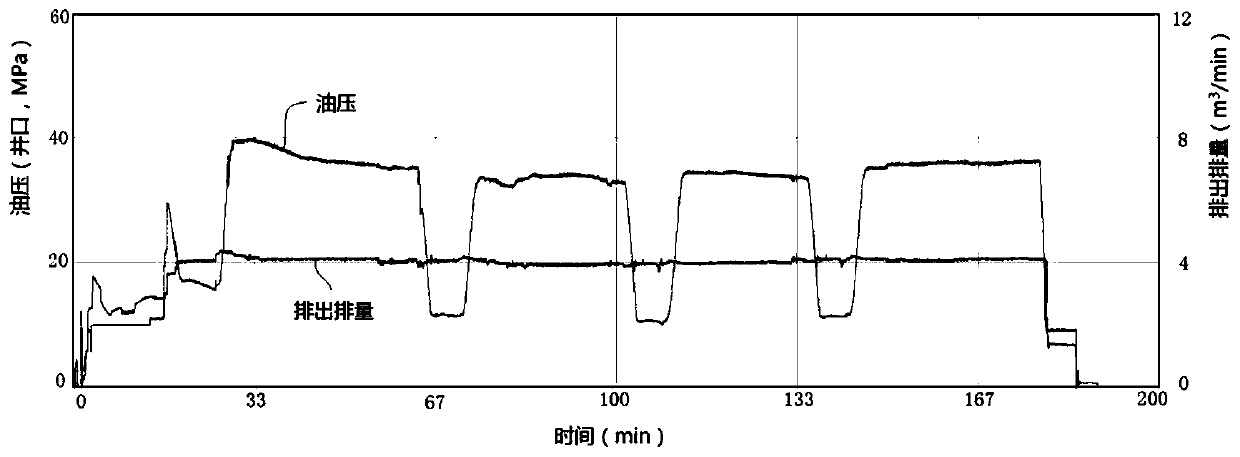

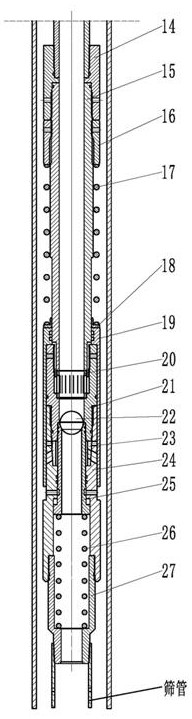

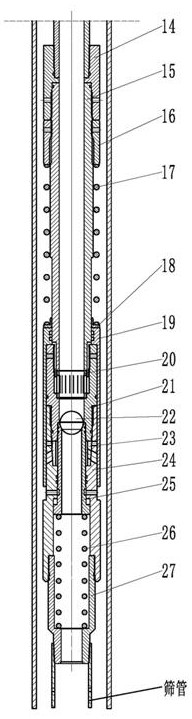

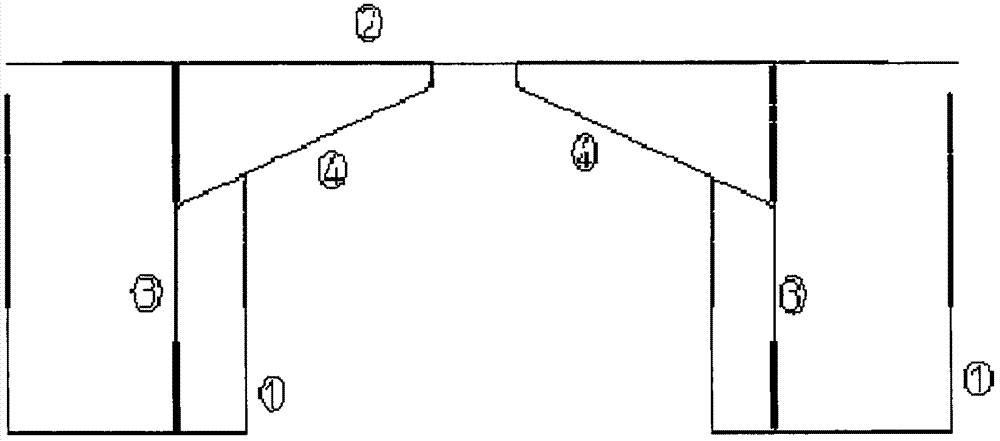

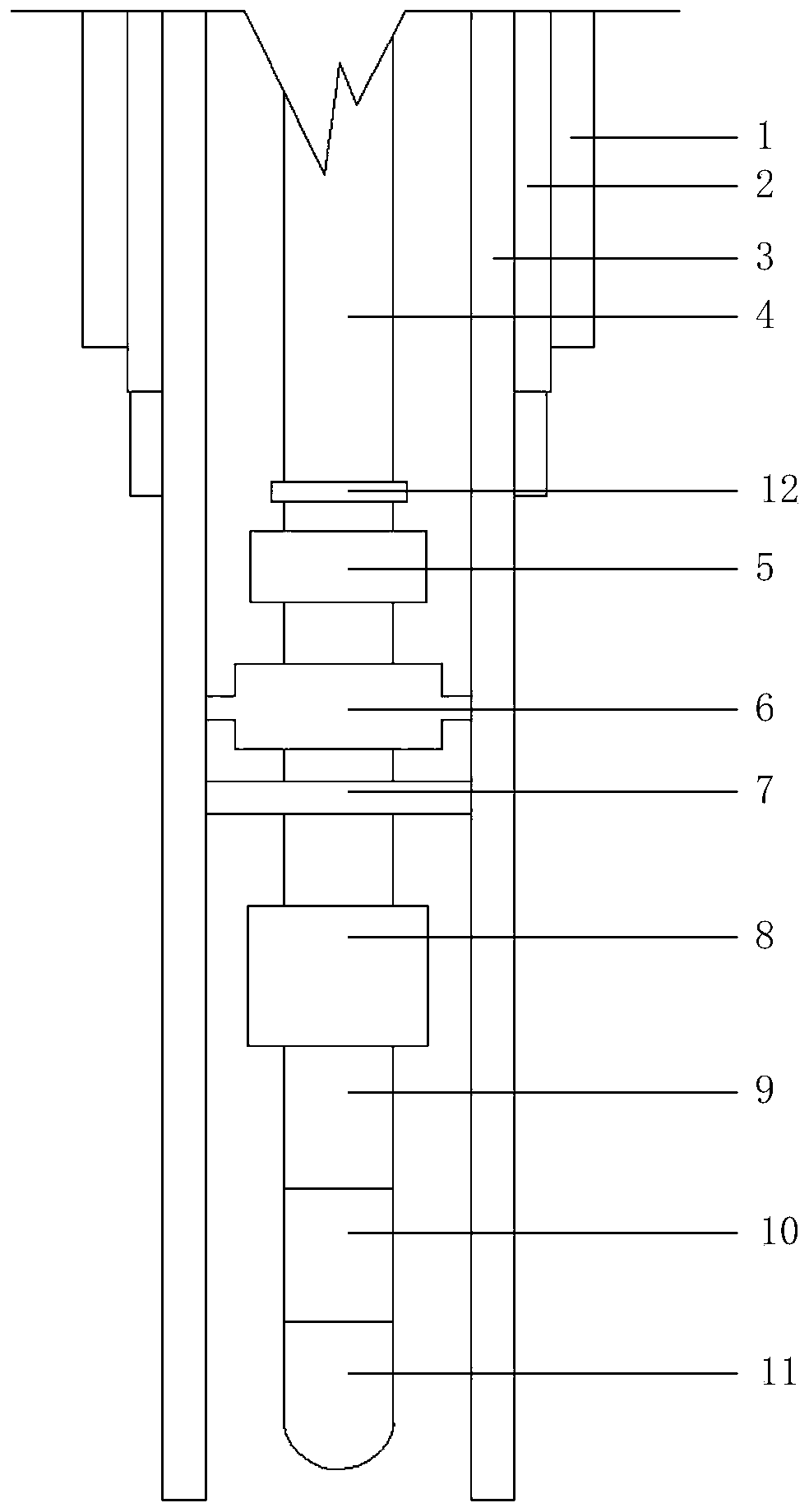

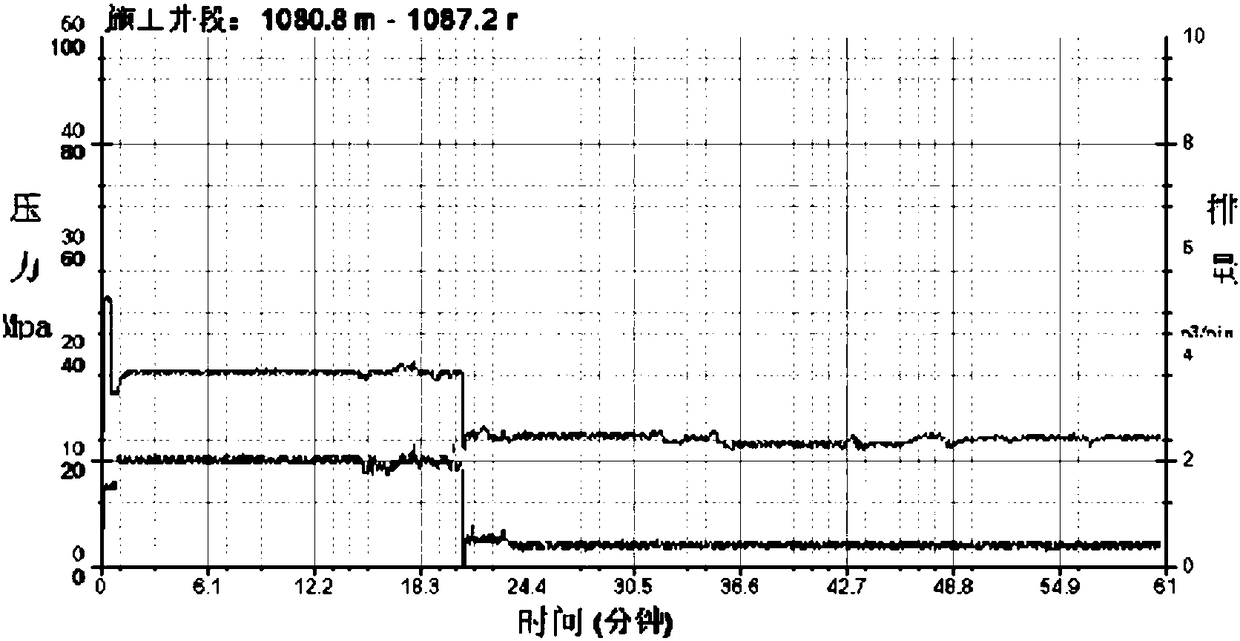

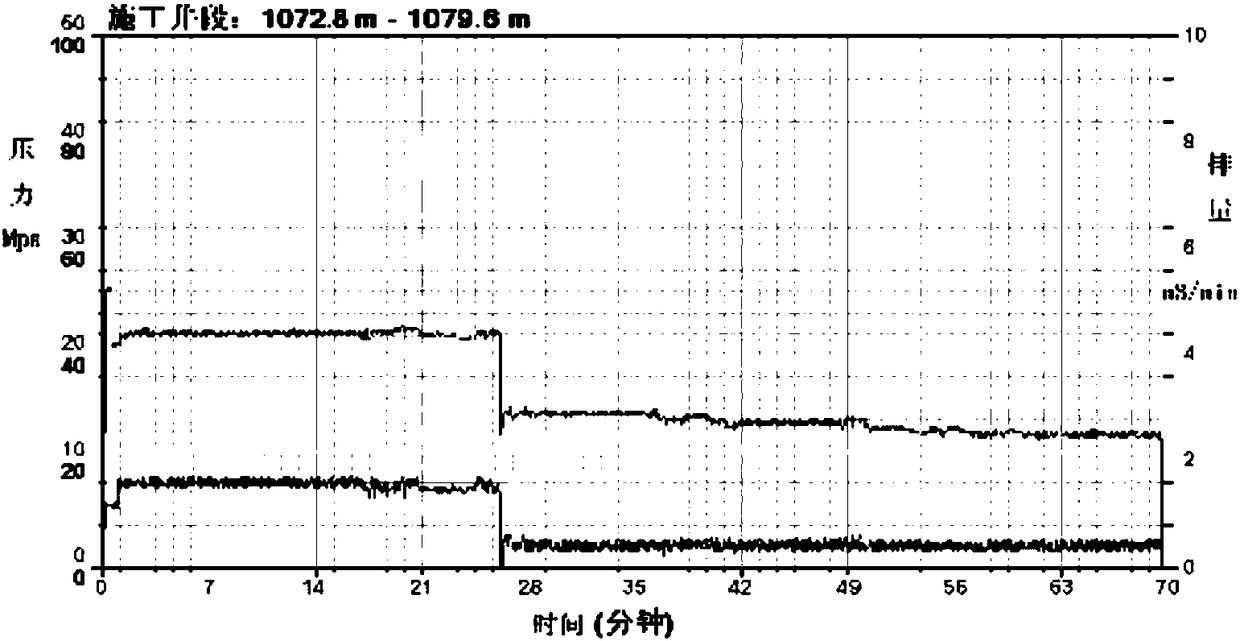

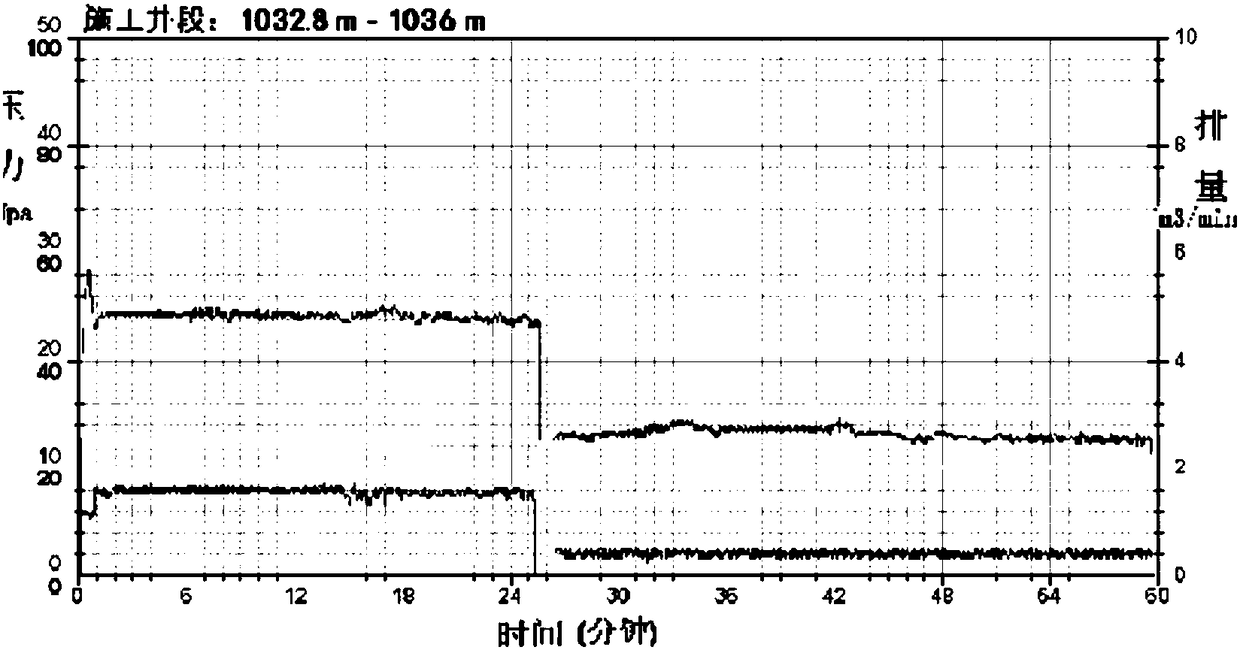

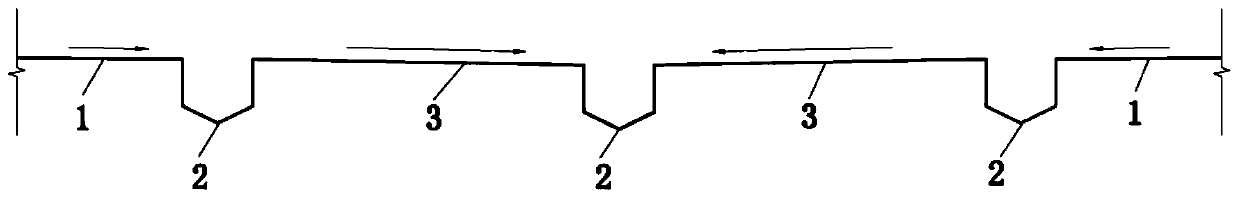

The structure of the hydraulic slit testing process string for oil and gas well exploration wells

The invention provides an oil and gas well test pit water power kerf test process tubular column structure. The structure comprises an oil tube (4), the lower portion of the oil tube (4) is successively docked with a power part (8), one or more cutters and ball heads (11), the outer wall of the oil tube (4) is successively provided with, from top to bottom, a pump seat (12), a positioning short section (5), a packer (6) and a centralizer (7). Compared with the conventional perforating technique, the oil and gas well test pit water power kerf test process tubular column structure solves the problem of insufficient depth of the perforating technique, perforating compacted belt and pollution, and simultaneously increases seepage area; compared with hydraulic fracturing, the construction is simple, the cost is low, the produced cracks are easy to control, and the effect of production increase and injection increase is obvious.

Owner:BEIJING HUAHUI GEOXPLORA TECH CO LTD

A hydraulic deblocking acidification process

Hydraulic deblocking acidification process. The process includes the following steps: (1), removing the wellhead; (2), lifting the original well pipe string; (3), launching the hydraulic unplugging acidizing string; (4), magnetic positioning; (5), high-pressure hydraulic unplugging acidizing; (6), ground pressure test: ground pressure test 55Mpa, 10min no puncture and no leakage pressure test qualified; (7), hydraulic unblocking acidification layer 1; (8), ball slipping sleeve; (9), hydraulic unblocking acidification 2 (10), ball-throwing sliding sleeve; (11), 3 layers of hydraulic unplugging and acidification; (12), flowback after 12 hours of well shut-in reaction; (13), starting and unplugging acidizing string; (14), (15) Lower completion string: lower stratified water distribution tools, anti-corrosion tubing, coated with sealing grease; wellhead and finishing. This application fully uses physical methods to increase the effective penetration distance of acid liquid in the formation, and improves the permeability of the formation in a large range, so as to achieve the purpose of increasing production and injection.

Owner:DAQING XINZHIHE TECH

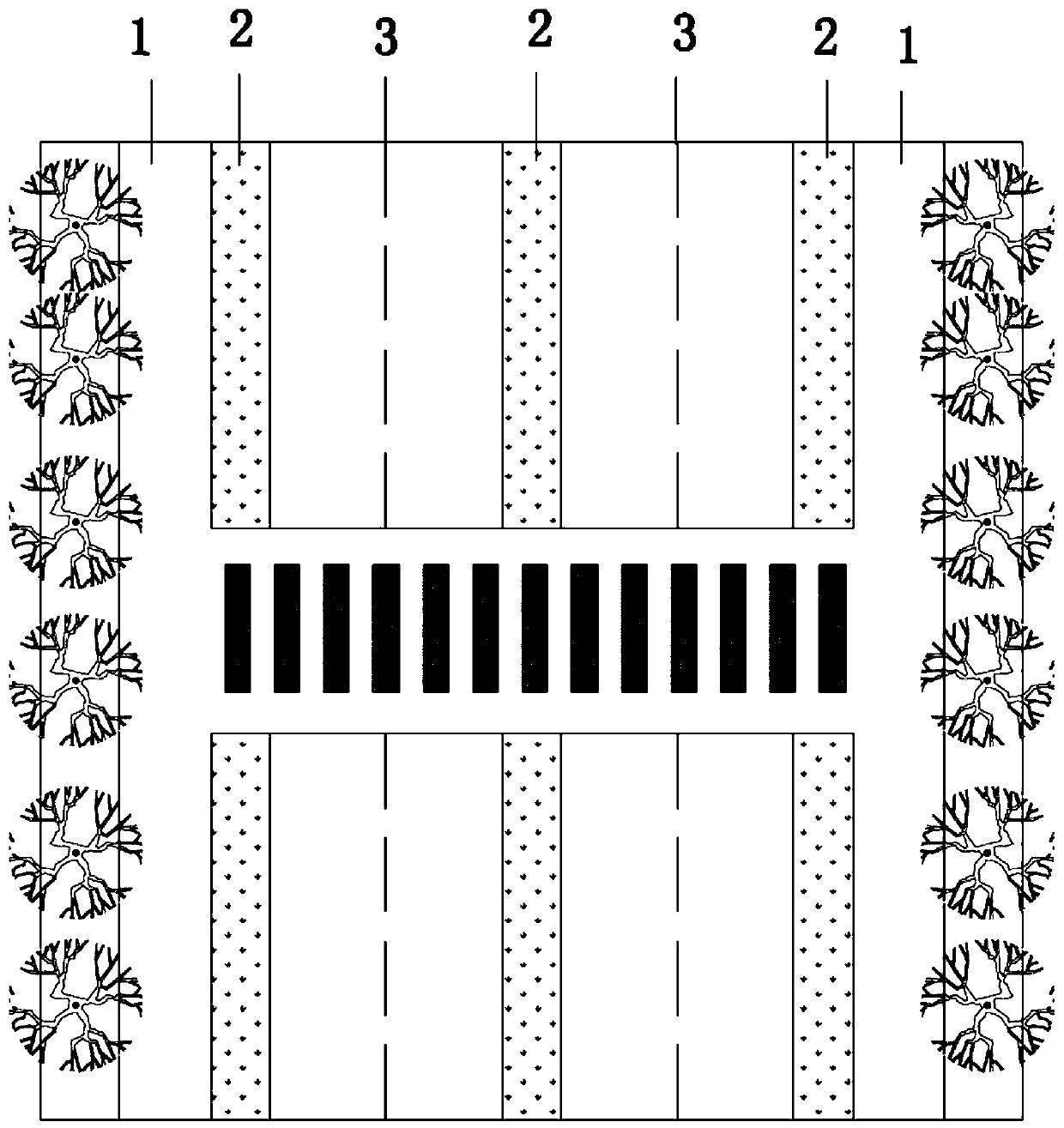

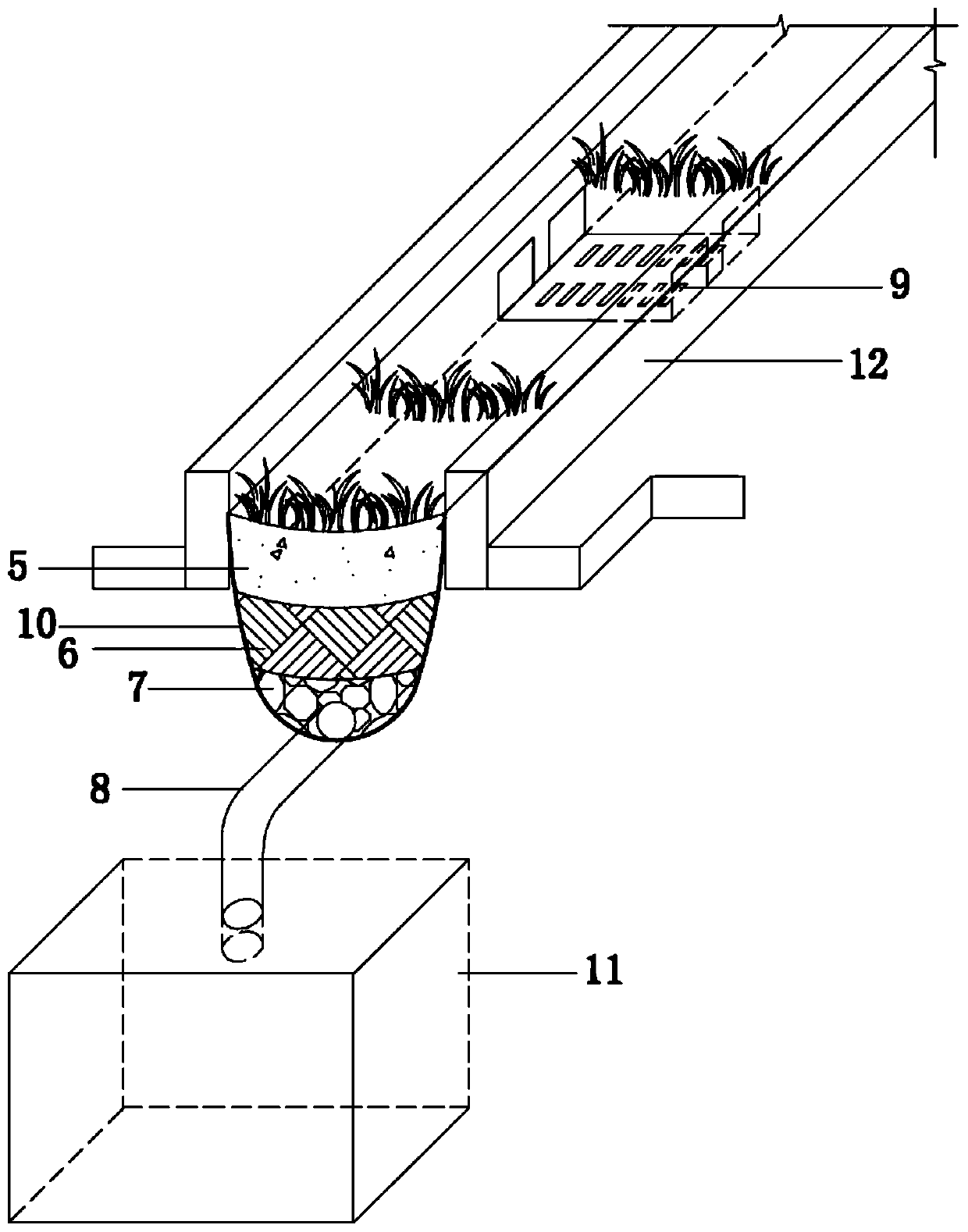

Municipal administration road rainwater reuse facility based on bioretention zone system

InactiveCN110528661AShorten the time for runoff to convergeIncrease the slope of the two-way cross slopeSewerage structuresPaving gutters/kerbsPlant rootsRoad surface

The invention discloses a municipal administration road rainwater reuse facility based on a bioretention zone system. Through the gradient of a cross slope of a V-type pavement, rainwater runoff on the both sides of a road is aggregated into a bioretention zone, so that the rainwater discharge time is shortened to a certain extent; then absorption of pollutants by plant roots, removal of rainwaterrunoff suspended solids (SS) by the planting soil layer and removal of nitrogen and phosphorus by microorganisms in the planting soil layer are carried out after rainwater enters the bioretention zone, then the rainwater enters an artificial filler layer, and the pollutants are further removed in the artificial filler layer; and the rainwater reaches a gravel layer and is drained into a perforated drainage pipe through the gravel layer to enter an impounding reservoir. The device achieves adjustment of the pavement structure, treatment of the pollutants in the rainwater runoff entering the bioretention zone and storage of rainwater, so that the problem of water shortage is alleviated to a certain extent.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Fluid collection device and full surface saturation method for core fluid full surface saturation

ActiveCN107620592BIncrease percolation fluxAccurate measurementBorehole/well accessoriesRock coreMechanical engineering

Owner:PETROCHINA CO LTD

A slope replaceable drainage pipe and its construction method

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com