A hydraulic deblocking acidification process

A plug-removing and hydraulic technology, applied in wellbore/well components, production fluids, earth-moving drilling, etc., can solve the problems of high water injection pressure, formation blockage, affecting water injection volume and crude oil production, etc., to expand the seepage area, improve Seepage conditions and effects of improving seepage patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

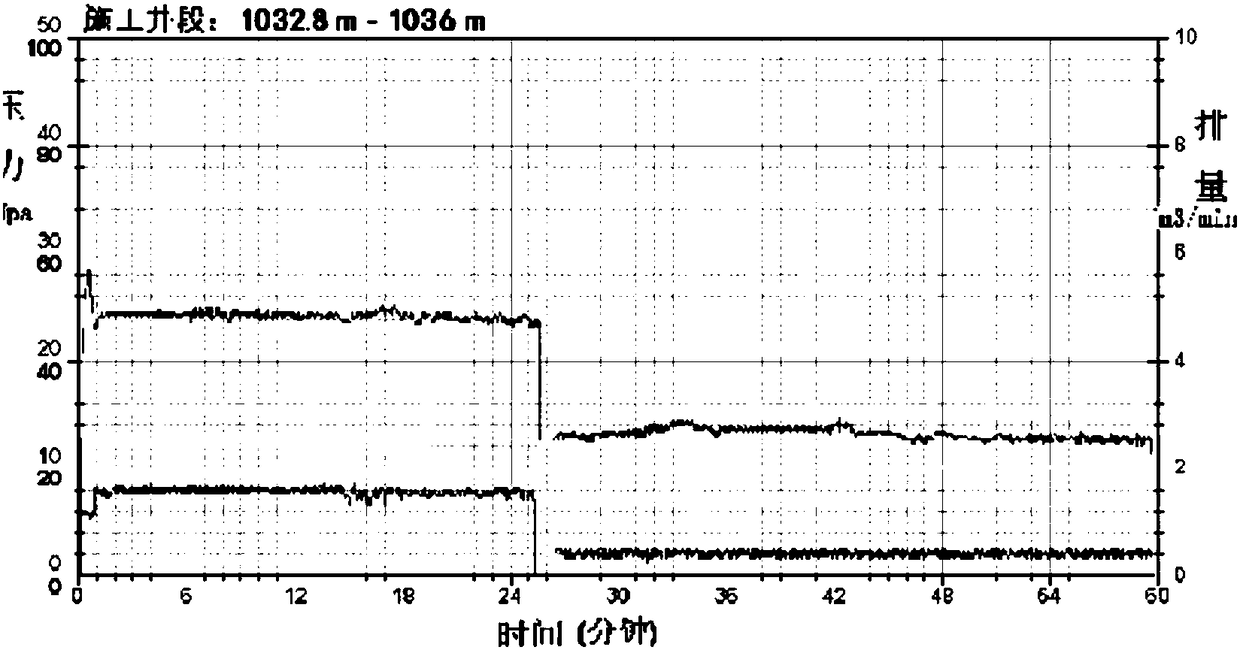

[0029] (1) Remove the wellhead and install the wellhead controller without overflow. (2) Lifting the original well string, pulling out 116 pieces of Φ62mm anti-corrosion tubing, Y341-114YF*0.4 / 0.6 packer level 2, bridge type*1m eccentric water distributor 2 pieces, 50.8 / 47*0.3 ball seat 1 piece, Inspection: the tubing of the original well was seriously waxed. (3) Measuring tubing assembly with hydraulic unblocking and acidizing string. (4) One piece of Φ62mm wire plug under the acidizing pipe string for hydraulic unplugging, Y344-114 packer level 5, 2 sandblasting devices with sliding sleeve, 1 modified sandblasting device, 1 hydraulic anchor of Φ114mm, Φ110mm One safety joint, 114 Φ62mm thickened oil pipes, and a completed depth of 1101.05m. (5) Magnetic positioning, cooperate with the test team to measure magnetic positioning, and the tool depth is qualified. (5) High-pressure hydraulic deblocking acidification preparation, on-site preparation of acid solution 44m 3 , pr...

Embodiment 2

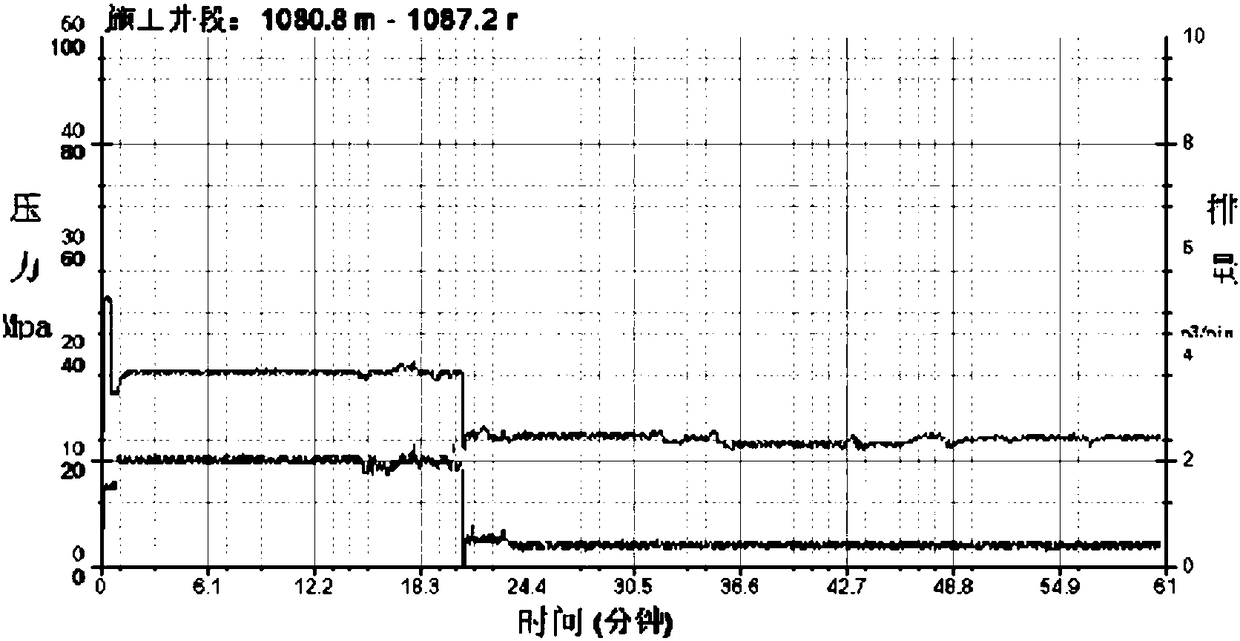

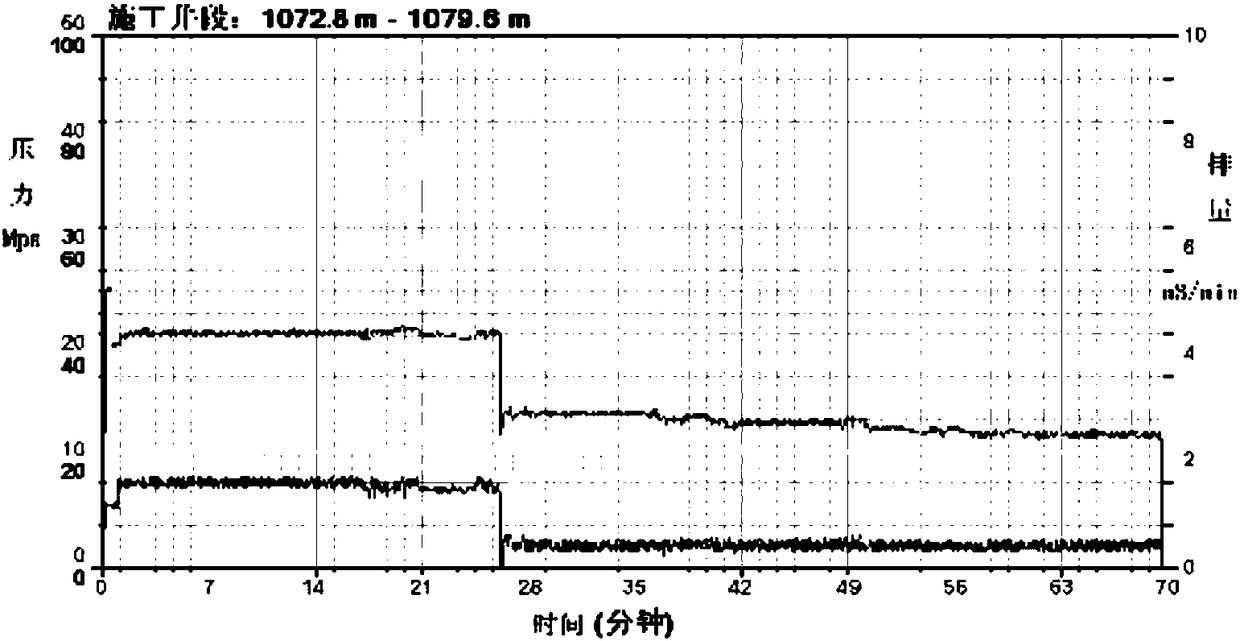

[0031](1) Remove the wellhead and install the wellhead controller without overflow. (2) Pulling out the original well string: pulling out 117 Φ62mm anti-corrosion tubing, Y341-114XM packer level 2, 2 pieces of 665-2 eccentric water distributor, 1 Φ62mm dead plug, inspection: the original well tubing was pulled out intact. (3) Measuring tubing assembly with hydraulic unblocking and acidizing string. (4) Acidizing pipe string with hydraulic unplugging, 1 Φ62mm plug, 3rd grade Y344-114 packer, 1 sandblasting device with sliding sleeve, 1 modified sandblasting device, 1 Φ114mm hydraulic anchor, One Φ110mm safety joint, 113 Φ62mm thickened oil pipes, and a completed depth of 1085.38m. (4) Magnetic positioning, cooperate with the test team to measure magnetic positioning, and the tool depth is qualified. (5) High-pressure hydraulic deblocking acidification preparation, on-site preparation of acid solution 46m 3 , prepare 3 sets of acid tank trucks, 4 sets of water tank trucks, 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com