Water draining and pressure relieving structure capable of realizing anti-floating

A technology of pressure relief structure and scupper hole, which is used in infrastructure engineering, protection devices, buildings, etc., to achieve the effect of reducing buoyancy, simple structure and avoiding piping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

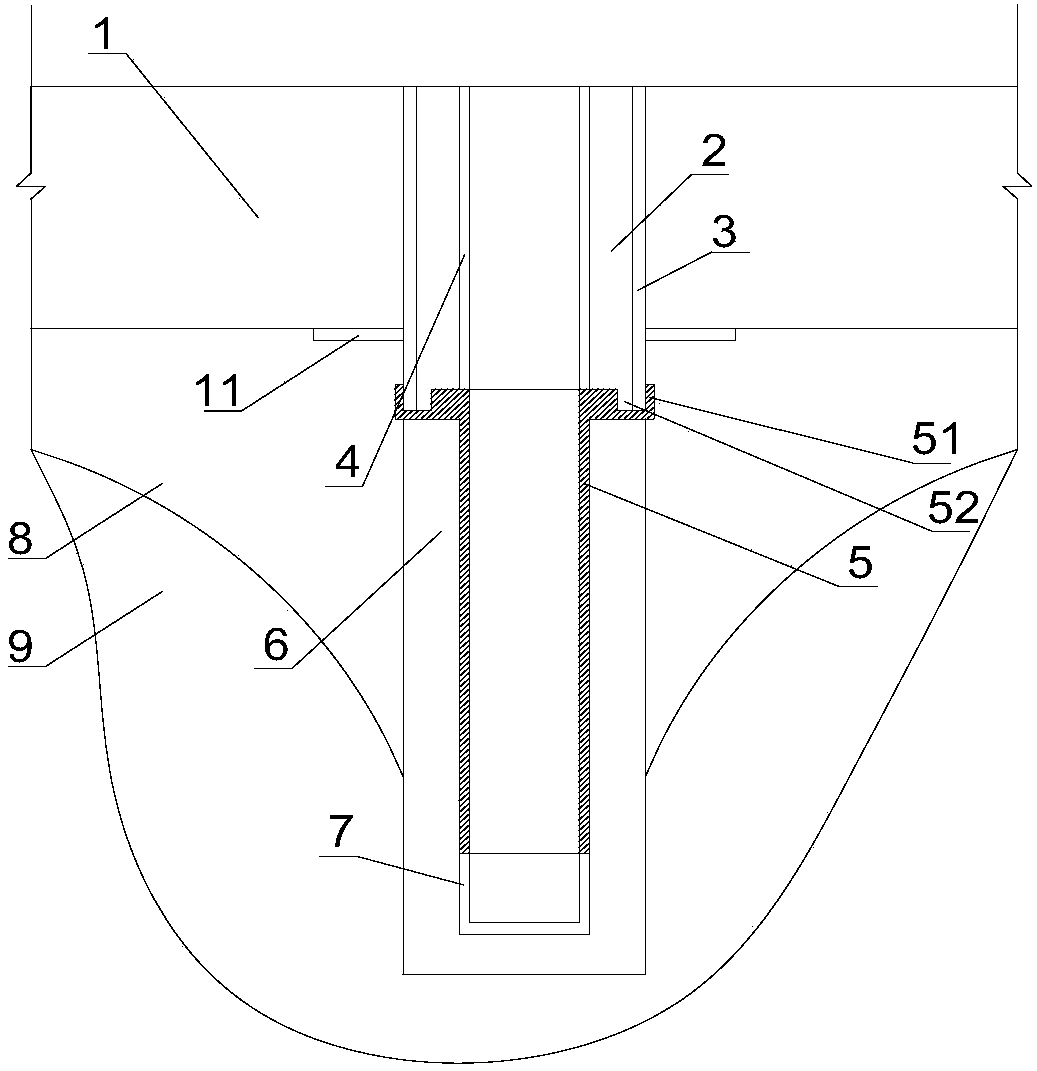

[0029] Such as Figure 1-2 As shown, an anti-floating water release and pressure relief structure is arranged in a drain hole 10 punched on the floor layer 1, and the drain hole 10 penetrates the floor layer 1 from top to bottom. The anti-floating water release and pressure relief structure includes the well wall pipe 4, the slow-expansion water-swelling water-swelling pipe 3, the filter pipe 5, the sedimentation pipe 7, and the water baffle 11, and the slow-expansion water-swelling water-stop pipe 3 is set on the well wall pipe 4. On the outside, a micro-expansion fine stone concrete layer 2 is arranged between the slow-expanding water-expanding water-stop pipe 3 and the well wall pipe 4. inside diameters match. The downward length of the slow-expansion type water-expandable water-stop pipe 3 is greater than the length of the well wall pipe 4, and the pipe thickness of the slow-expansion type water-expansion water-stop pipe 3 is not less than 200mm. The slow-expanding water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com