An integrated isolation and packing tool for sand control and well completion

A technology of sand control and tools, which is applied in the directions of sealing/isolation, production fluid, flushing of wellbore, etc., can solve the problems of high one-time investment cost, single function of process string, and influence on filling quality, etc., and achieve flexible and reliable opening and closing, The effect of expanding the seepage area and reducing the construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

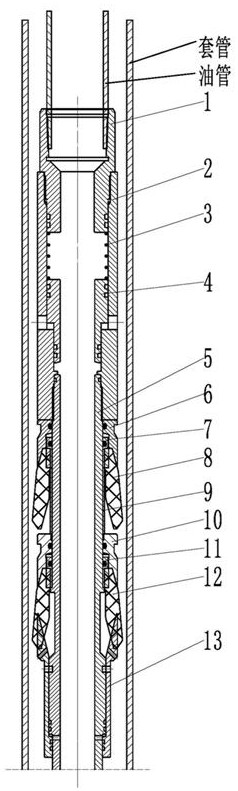

[0033] refer to Figure 1-2 As shown, an integrated isolation and filling tool for sand control and completion includes an upper joint 1, a sealing assembly, a filling assembly and a lower joint 27, as well as a backwashing assembly and a central pipe I5, an upper joint 1, a backwashing assembly, a central pipe I5. The filling assembly and the lower joint 27 are fixedly connected in sequence from top to bottom, and the sealing assembly is sleeved on the outside of the central pipe I5;

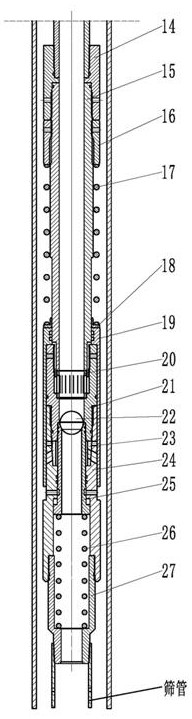

[0034] refer to Image 6 As shown, the filling assembly includes a connecting collar 14, a central tube II 15, an outer spring 17, a long sheath 19, a filter ring 20, a sealing sleeve 21, a filling sleeve 24, a ball seat 25 and an inner spring 26, and the connecting collar 14 is fixedly installed At the lower end of the central pipe I5, it is fixedly connected with the central pipe II15, the sealing sleeve 21, the filling sleeve 24 and the lower joint 27 in sequence from top to bottom; such as...

Embodiment 2

[0042] As a preferred embodiment of the present invention, this embodiment adds an anti-erosion inner ring 23 in the filling sleeve 24 on the basis of the first embodiment, specifically:

[0043] refer to Image 6 and Figure 8 As shown, in this embodiment, the inner wall of the filling sleeve 24 inside the filling hole 28 is provided with an anti-erosion inner ring 23, and the material of the anti-erosion inner ring 23 is a high-strength alloy with high impact resistance.

[0044] The anti-erosion inner ring 23 inside the filling hole 28 is made of high-strength alloy material. The filling hole 28 adopts a scientific flow angle, which can reduce the eddy current erosion during the filling operation, and can withstand the maximum displacement of 5.5 cubic meters per minute and the highest sand ratio. 70% fracturing and filling operations with a maximum pressure of 35MPa and a maximum sand volume of 120 cubic meters.

Embodiment 3

[0046] As a preferred embodiment of the present invention, this embodiment optimizes the structure of the backwash assembly on the basis of the second embodiment, specifically:

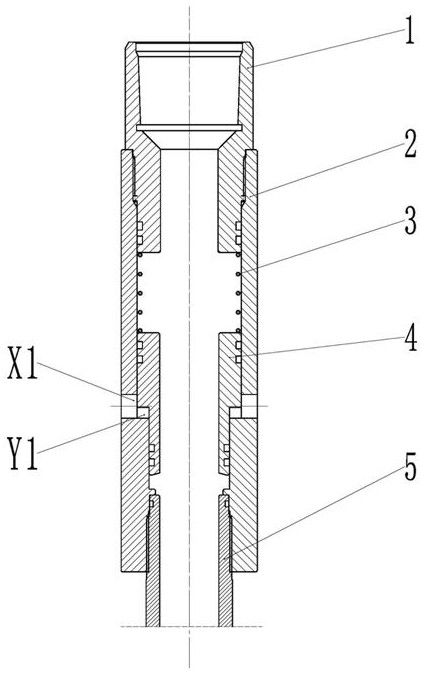

[0047] refer to image 3 As shown, in this embodiment, the backwashing assembly includes a backwashing jacket 2, a backwashing sliding sleeve 4 and a return spring 3, the upper end of the backwashing jacket 2 is fixedly connected with the upper joint 1, and its lower end is fixedly connected with the central pipe I5; The backwashing sleeve 4 is slidably sealed in the inner cavity of the backwashing jacket 2, and a first annular space Y1 is formed between the two; The backwash jacket 2 on the upper part of the limit table is provided with a first through hole X1 that communicates with the first annular space Y1, the upper end of the return spring 3 is in contact with the lower part of the upper joint 1, and its lower end is in contact with the upper part of the backwash sliding sleeve 4 .

[0048] Du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com