Completion system of oil and gas wells with regulatably controlling flows of formation fluid or filled fluid in divided sections

A technology for formation fluids and fluid flow, which is applied in the fields of production fluids, wellbore/well components, and earth-moving drilling, etc. It can solve the problems of difficult separation operation, complicated operation, and large operation workload, so as to reduce formation damage and simplify operation. Convenience and the effect of reducing completion costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

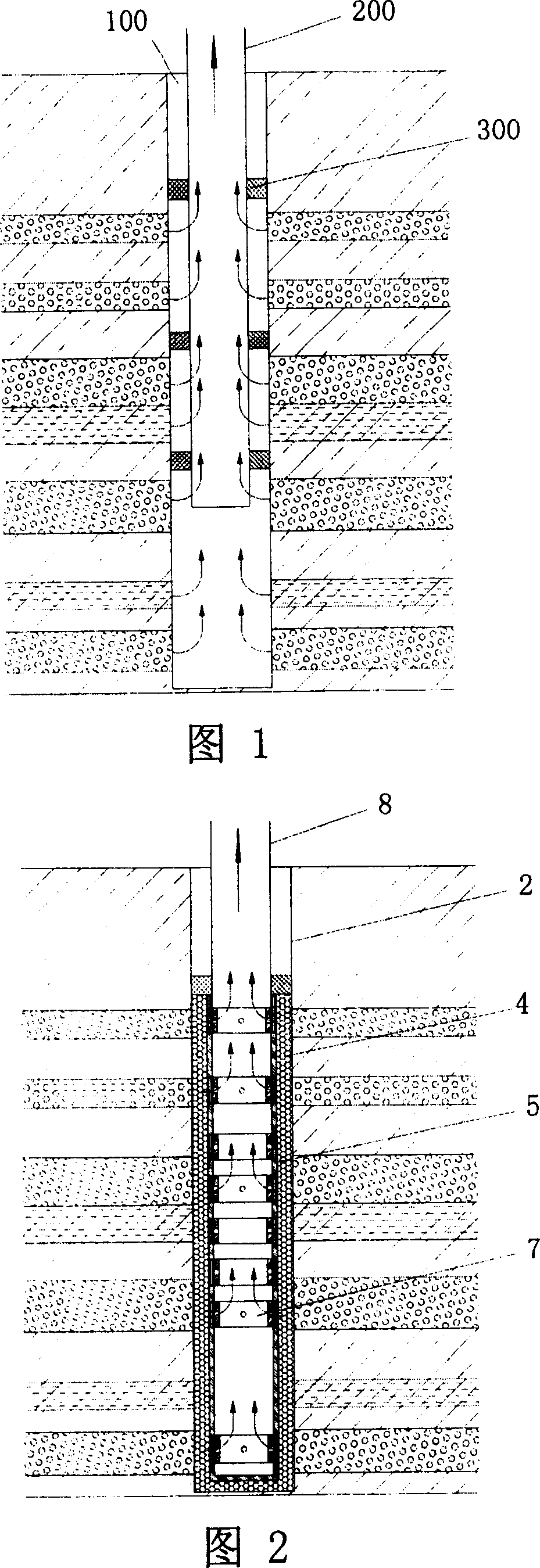

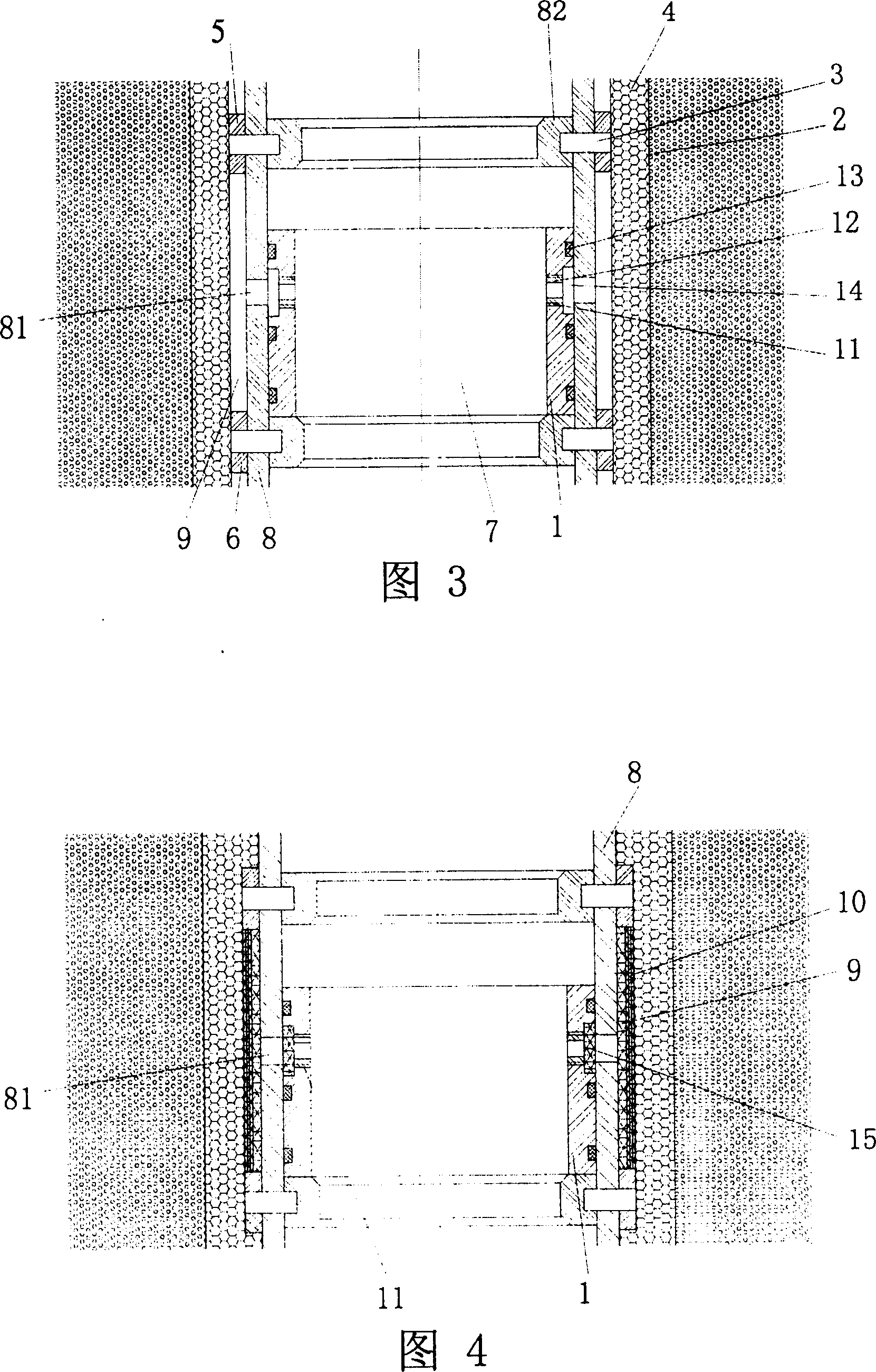

[0055] As shown in FIG. 2 , it is a schematic diagram of the overall structure of the oil and gas well completion system of the oil and gas well completion system for regulating the flow of formation fluid or injection fluid in subdivided sections according to the present invention. It can be seen from the figure that the system is at least composed of the flow regulating string 8 and the porous medium 4 arranged in the oil and gas well; Formation fluid or injection fluid flows axially along the oil and gas well in the annular space, while allowing formation fluid or injection fluid to seep radially along the oil and gas well. Its specific structure is shown in Figure 3. The flow regulating pipe string 8 is provided with a collecting hole 81 and a collecting cavity 9, and the collecting hole 81 is set The outside of the flow regulating string 8 is collected to its inside; or the injection fluid is dispersed from the inside of the flow regulating string 8 to its outside; the in...

Embodiment 2

[0072] As shown in FIG. 4 , it is a schematic structural diagram of Embodiment 2 of the present invention. As can be seen from the figure, when the porous medium 4 is a loose porous medium (for example: formation sand, gravel particles, artificial granular medium), a sand control layer 10 is laid between the first upper isolation ring 5 and the second isolation ring 6, the The sand control layer 10 can be made of solid porous medium or metal mesh or metal fiber or wire-wrapped pipe or slotted pipe; The collecting cavity 9 is covered with a sand control layer 10, and the collecting hole 81 located on the flow regulating pipe string 8 communicates with the collecting cavity 9. Flow cavity 9, and flow into the flow cavity 9 through the manifold hole 81.

[0073] Referring to Fig. 4, on the inner side of the collecting pipe string 8, a sliding sleeve 1 that can slide along the axial direction of the oil and gas well is provided at the position corresponding to the collecting hole...

Embodiment 3

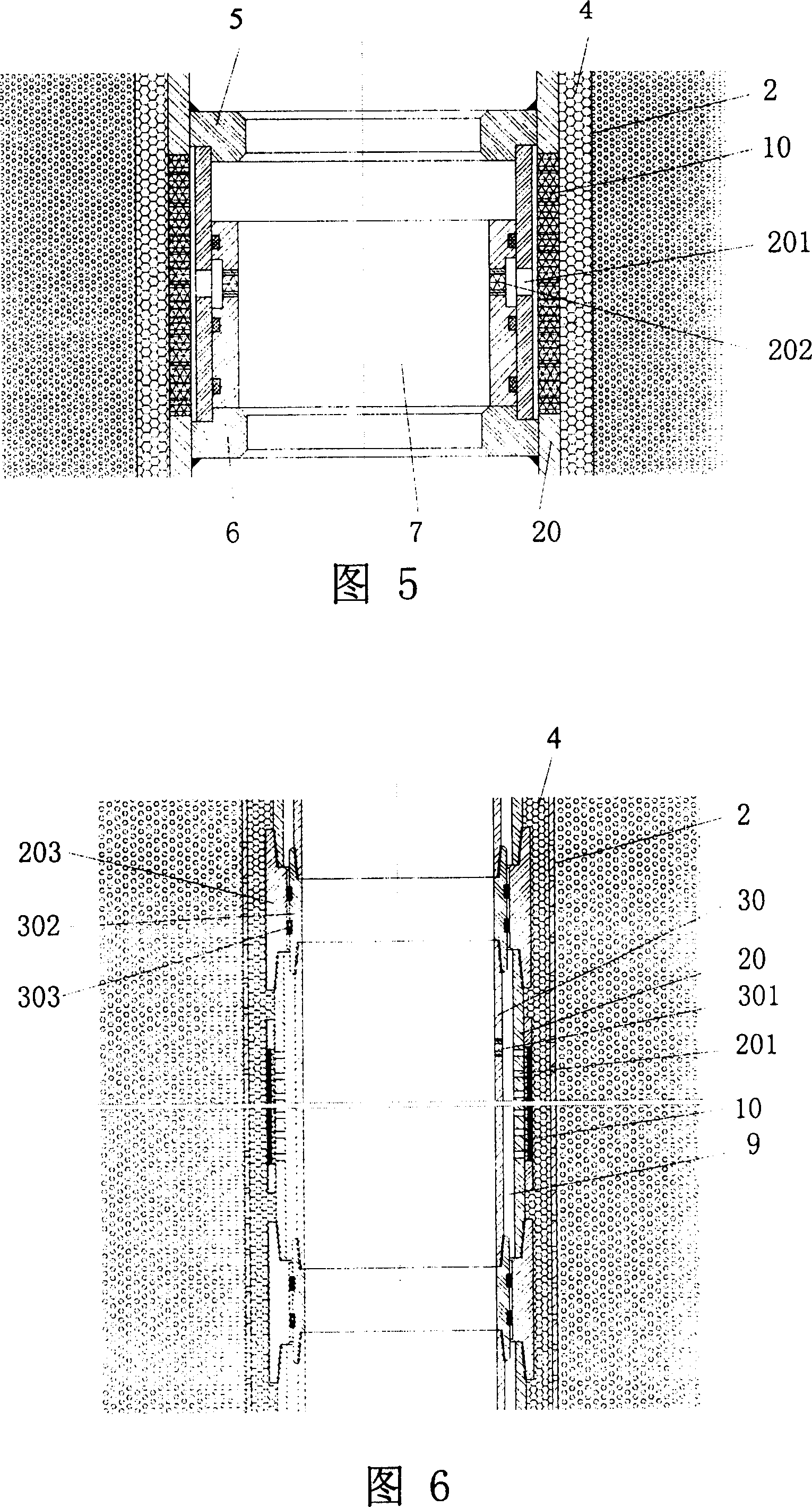

[0077] As shown in FIG. 5 , it is a schematic structural diagram of Embodiment 3 of the present invention. It can be seen from the figure that the system is at least composed of a screen 20 and a porous medium 4 arranged in the oil and gas well; The space flows along the axial direction of the oil and gas well, and at the same time allows the formation fluid or injection fluid to flow radially along the oil and gas well; The outer side is collected to its inner side, or the injection fluid is dispersed from the inner side of the screen pipe 20 to its outer side; the flow control device 7 is provided at the collecting hole 201 inside the screen pipe 20, which is used to control formation fluid or injection fluid from the The manifold 201 flows in or out.

[0078]The screen pipe 20 can be divided into more than one isolation unit by the first and second isolation rings 5, 6, and there are more than two isolation rings 5, 6, and at least one flow control device 7 is arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com