The structure of the hydraulic slit testing process string for oil and gas well exploration wells

A technology for hydraulic slitting and process pipe string, applied in wellbore/well components, production fluids, earth-moving drilling, etc., can solve the problems of pollution, insufficient depth of perforation technology, perforation compaction zone, etc., to increase seepage flow The area, the effect of increasing production is good, and the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

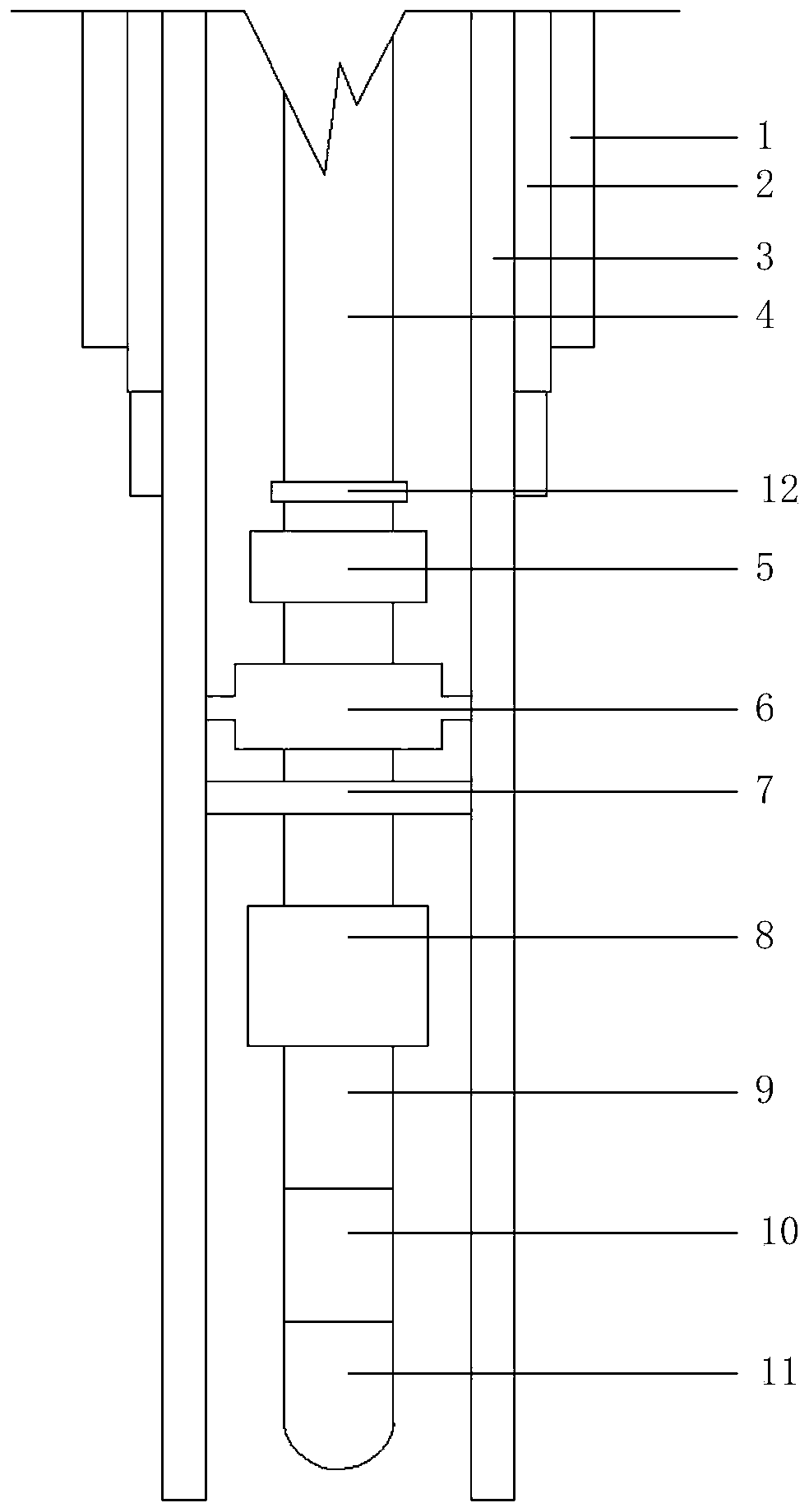

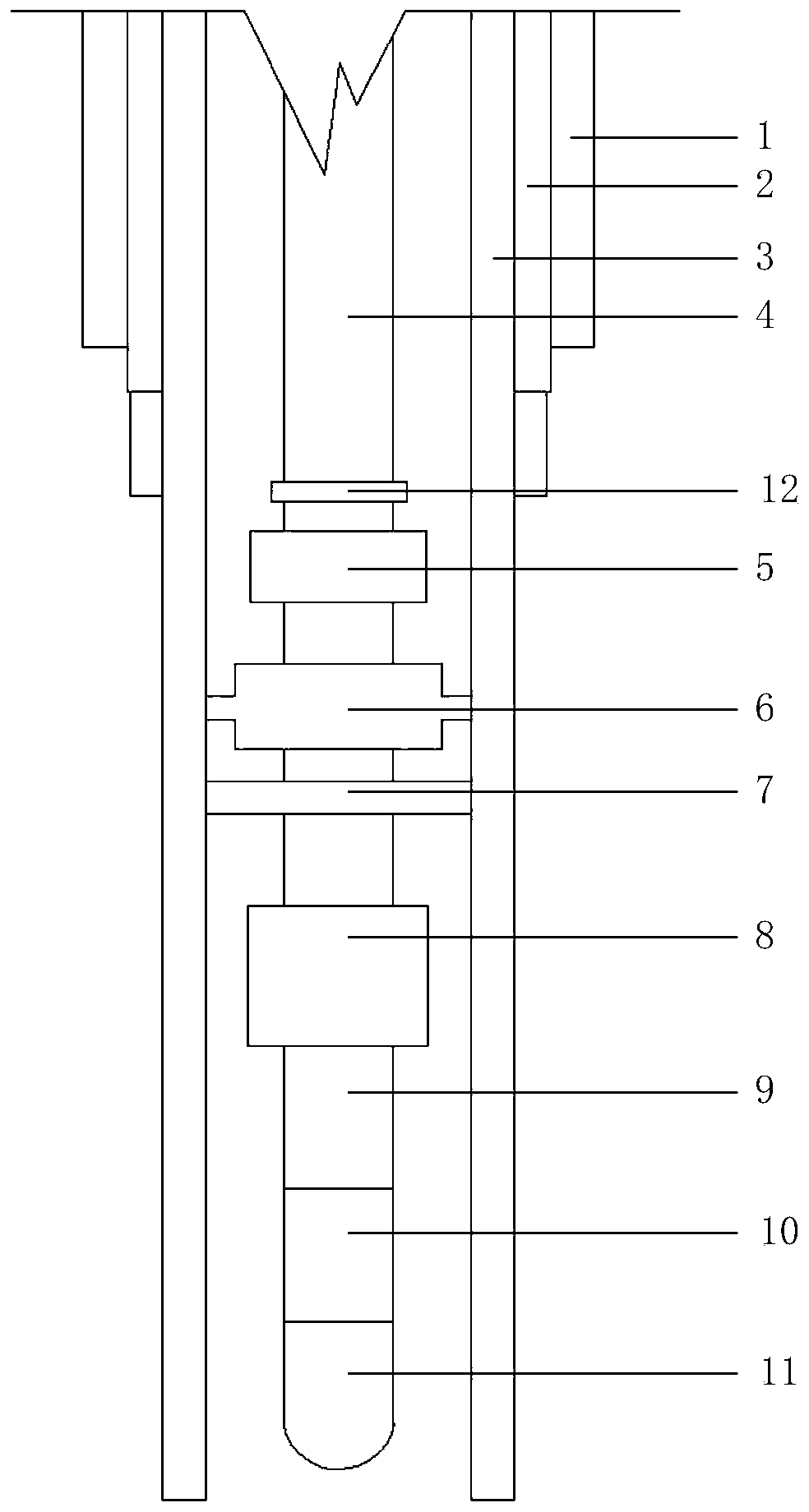

[0012] Such as figure 1 As shown, the present invention provides a structure of oil and gas well exploratory well hydraulic slotting test process string, including oil pipe 4, power component 8, cutter and ball seat nozzle 11, pump seat 12, positioning nipple 5, packer 6 with centralizer7.

[0013] Wherein, the power unit 8 , the cutter and the ball seat nozzle 11 are sequentially assembled on the bottom end surface of the oil pipe 4 .

[0014] The pump base 12, the positioning nipple 5, the packer 6 and the centralizer 7 are sleeved on the outer wall of the tubing 4 in sequence from top to bottom.

[0015] The power part 8 is a telescopic assembly that can drive the cutter and the ball seat nozzle 11 to move up and down in the vertical direction, and its telescopic distance is 20cm. The cutter and the ball seat nozzle can be driven downward by 20cm from the reset position through the telescopic assembly.

[0016] Wherein, the telescopic assembly can adopt a hydraulic teles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com