Fluid collection device and full surface saturation method for core fluid full surface saturation

A full-surface, core technology, used in earth-moving drilling, wellbore/well components, etc., can solve the problems of small contact area, fast seepage speed, slow seepage speed, etc., to expand seepage area, increase seepage flow, improve The effect of saturation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

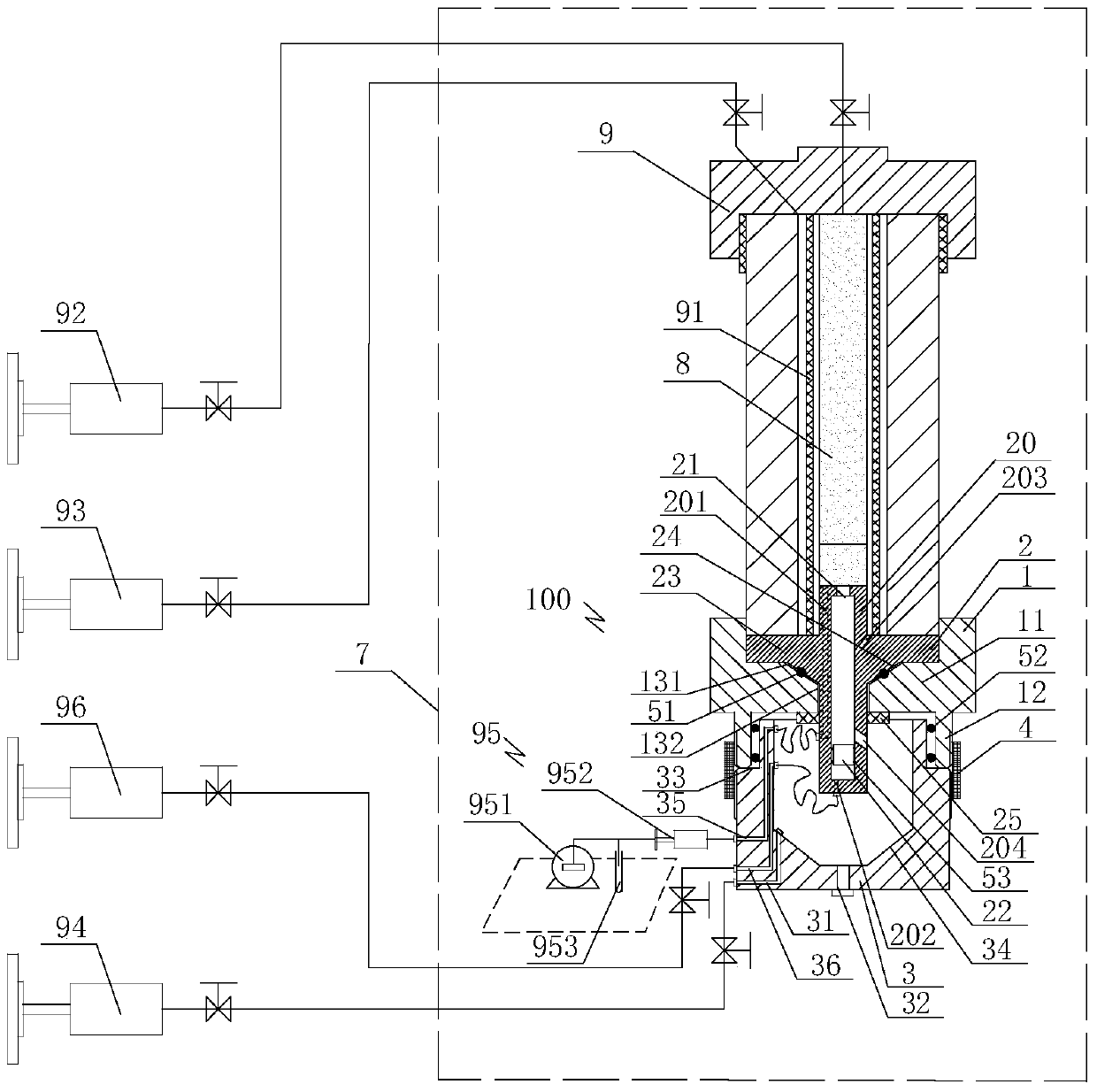

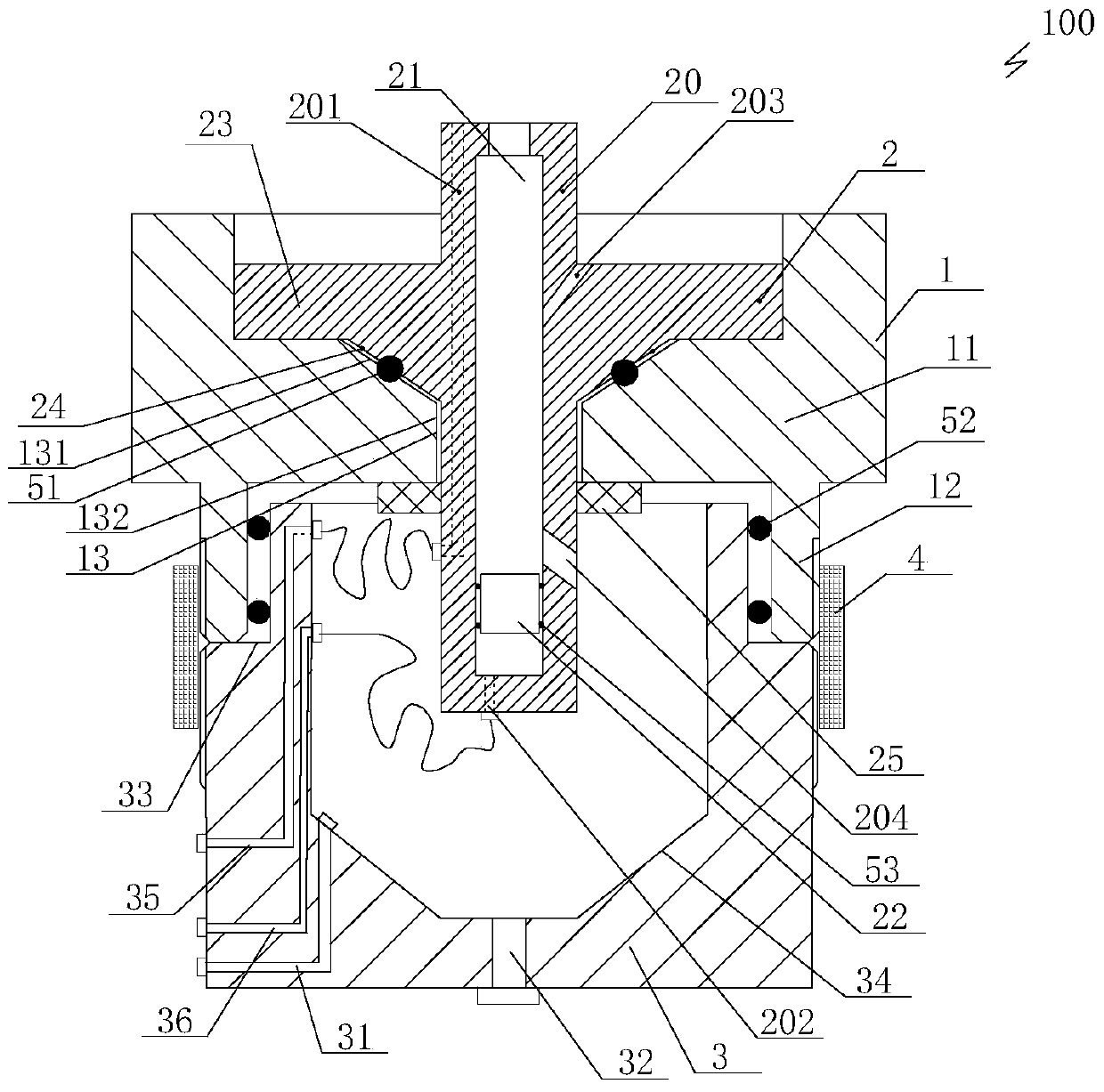

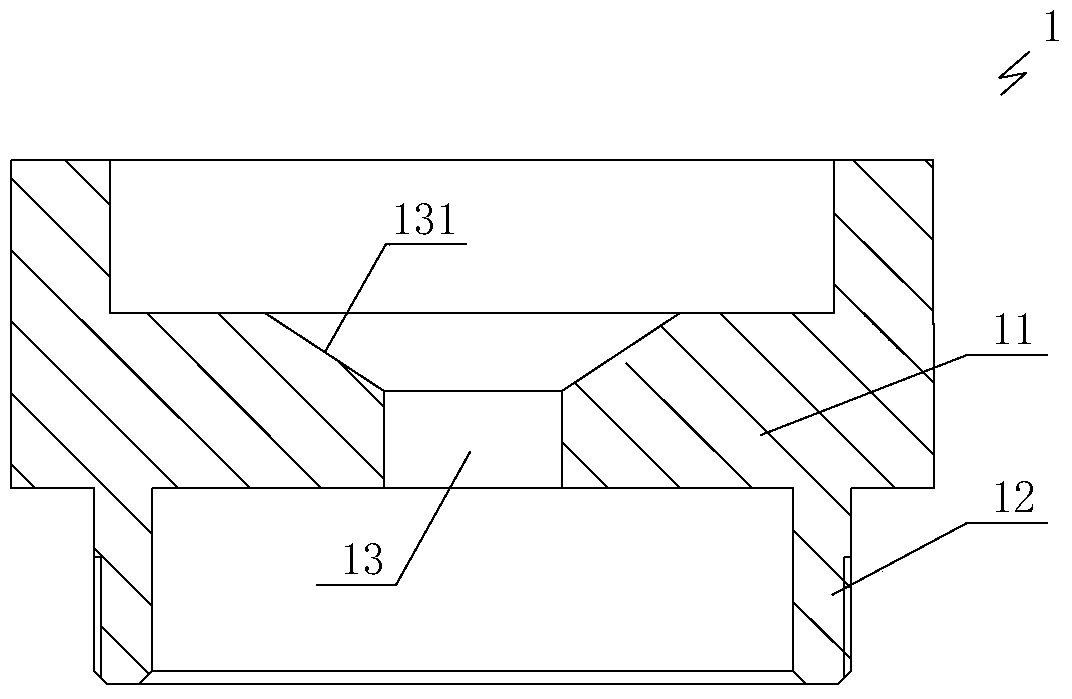

[0049] Such as figure 1 , figure 2 As shown, the present invention provides a liquid collection device 100 with a full-surface saturation of the fluid of the core. The top of the liquid collection device 100 with the full surface saturation of the fluid of the core is fixed and sealed with a core holder 9 with an open bottom. A rock core 8 is fixed in the inner cavity of the device 9, and a radially telescopic sealing rubber cylinder 91 is arranged between the rock core 8 and the inner cavity side wall of the rock core holder 9, and the inner wall of the sealing rubber cylinder 91 and the side wall of the rock core 8 A core annulus is formed between them. During the saturation process, water or oil enters and exits the side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com