Drainage pipe with replaceable side slope and construction method thereof

A drainage pipe replacement technology, applied in the field of drainage pipes, can solve the problems of loss of drainage function, small opening ratio of drainage pipes, insufficient natural drainage capacity of drainage pipes, etc., and achieve the effect of increasing the contact surface area and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

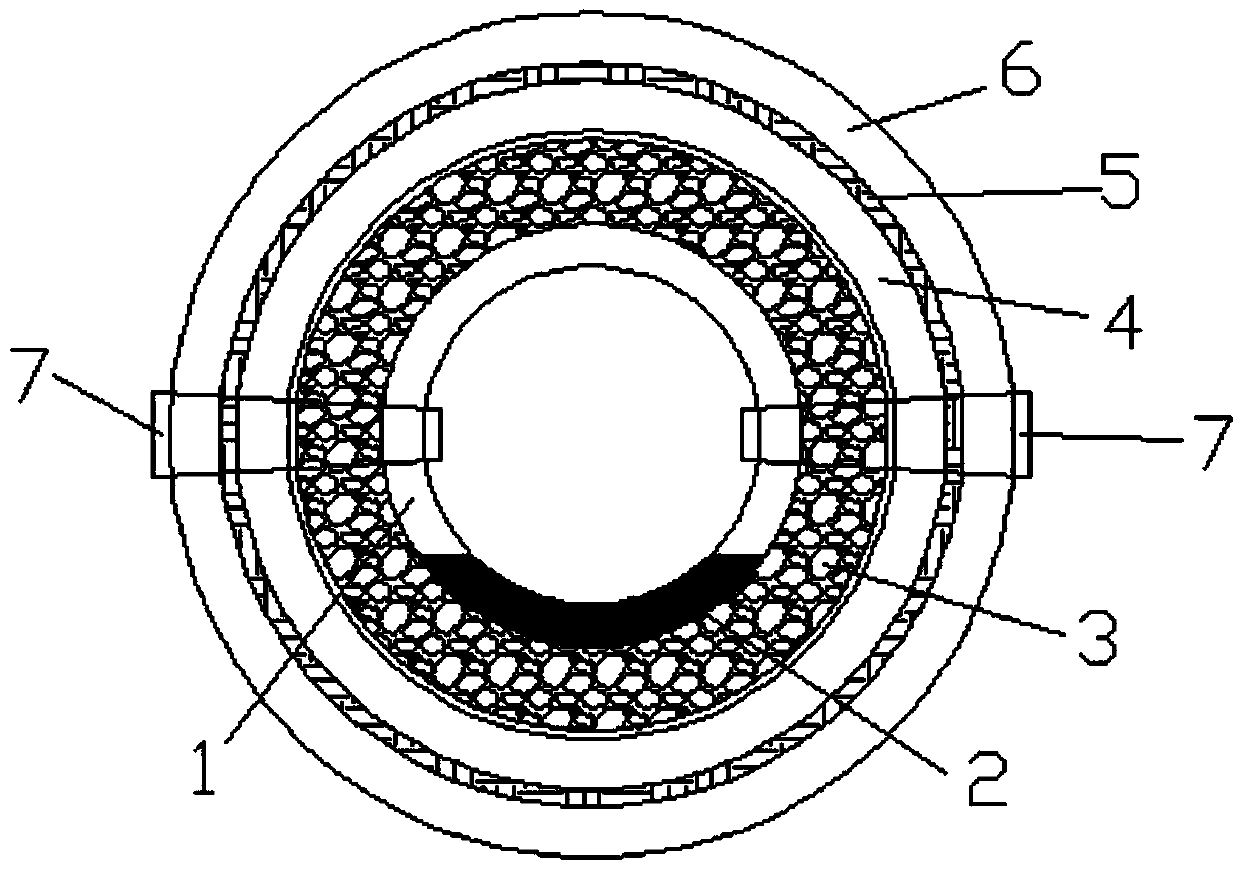

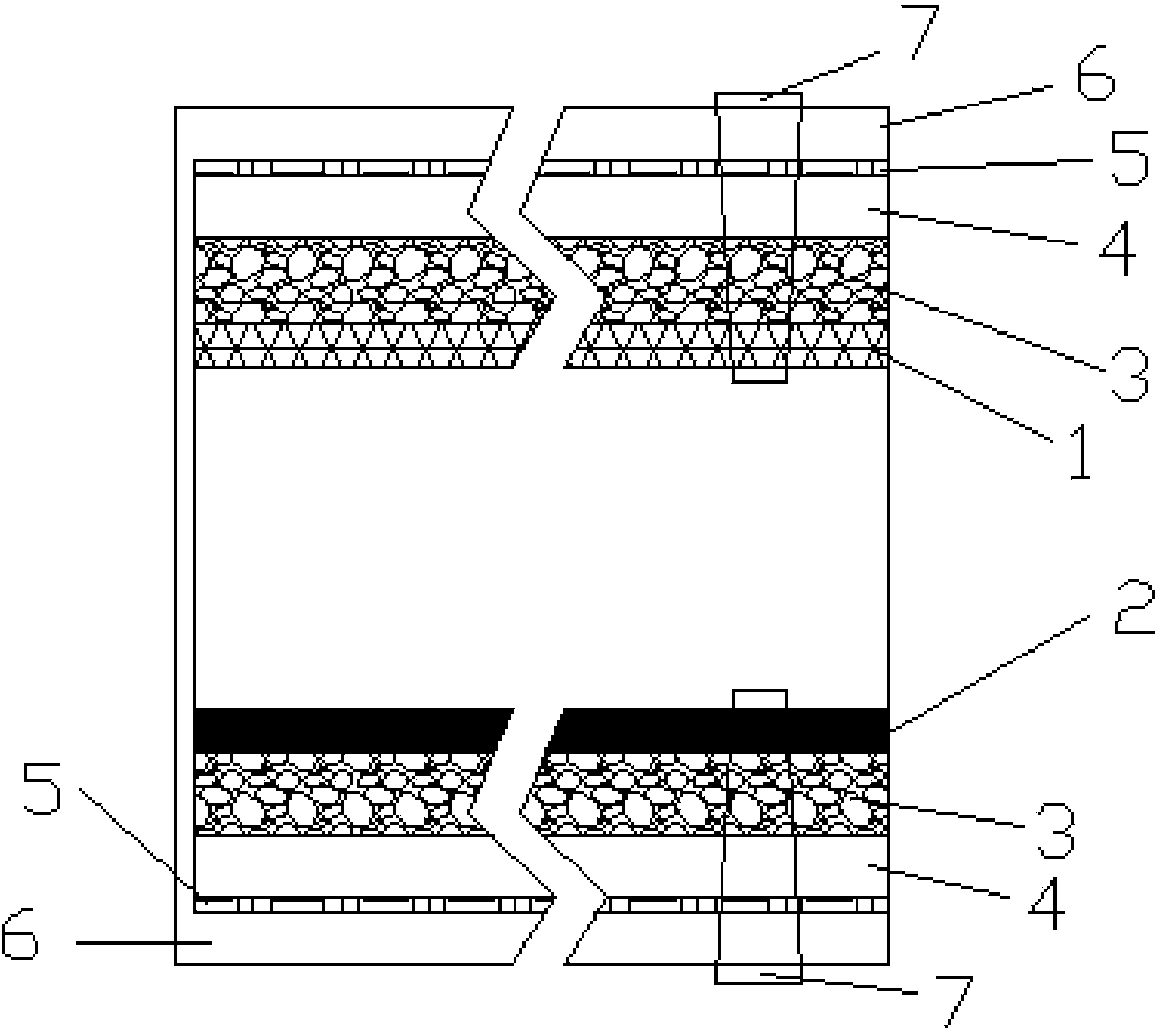

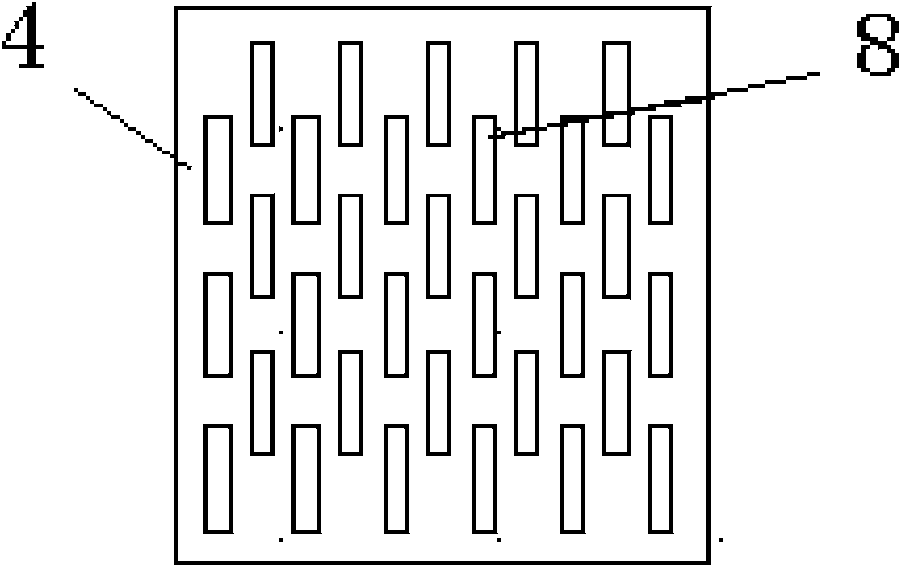

[0025] see figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 The fan-shaped permeable layer 1 is connected with a fan-shaped drain pipe 2 to form a circle. The fan-shaped water-permeable layer 1 is a tough and rigid fiber permeable layer. The fan-shaped drain pipe 2 is a PVC plastic pipe. The periphery is wrapped with a plastic blind ditch pipe filter layer 3, and a cylindrical filter screen 4 is wrapped around the periphery of the plastic blind ditch pipe filter layer 3. The upper part of the circle of the cylindrical filter screen 4 is provided with a through hole, and the lower part of the circle is closed, preferably Ground, the through hole is a rectangular small aperture 8, and the periphery of the cylindrical filter screen 4 is wrapped with a multi-layer geotextile filter layer 5, and the periphery of the geotextile filter l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com