Producing process and technology for electronic grade water by intergrated film process

A production process and integrated membrane technology, applied in the field of ultrapure water production technology and process, can solve the problems of low water utilization rate, inability to guarantee qualified water particles of the product, high investment cost, and achieve the effect of ensuring service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

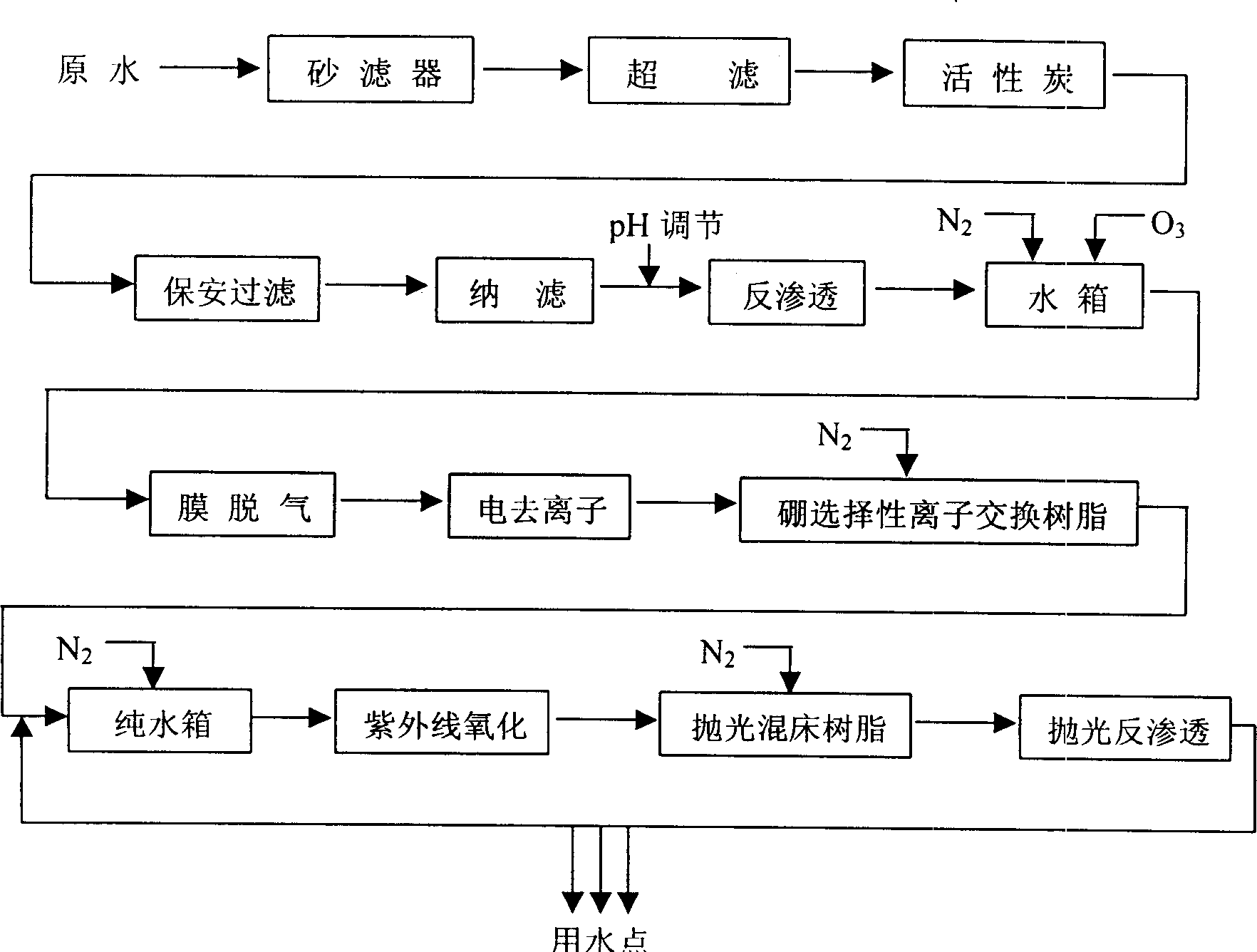

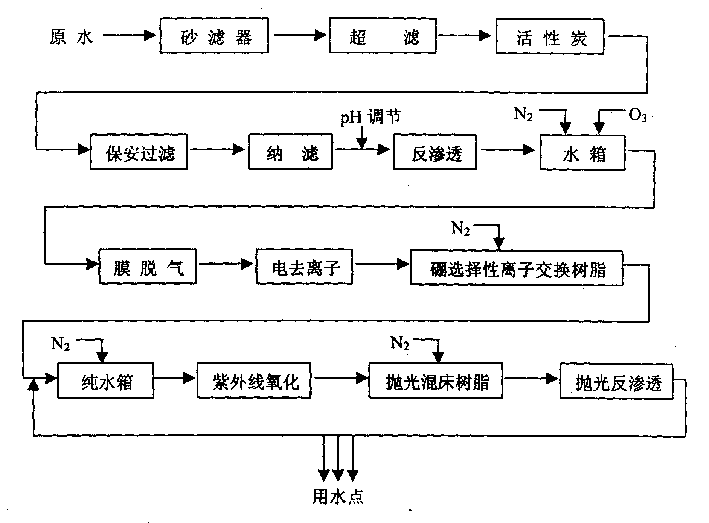

[0051] figure 1 In the process shown, the sand filter-ultrafiltration-activated carbon-security filtration-nanofiltration pretreatment removes suspended solids, particles, pigments, turbidity, organic matter, colloids, microorganisms, calcium and magnesium hardness ions and 50-70 % Salt, the ultrafiltration uses a polyethersulfone ultrafiltration membrane with a molecular weight cut-off of 20,000 to 50,000 Daltons, and the nanofiltration uses an aromatic polyamide ESNAl membrane. Reverse osmosis removes ionic and non-ionic (organic matter, particles, etc.) impurities in the pretreated water. If necessary, adjust the pH between NF and RO, adjust the pH value of the RO inlet water to weakly alkaline, such as pH 9.5, in order to effectively remove TOC and CO 2 And SiO 2 . The RO membrane used is an aromatic polyamide CPA-ULTRAPURE membrane.

[0052] The reverse osmosis pure water tank is protected by nitrogen to avoid secondary air pollution. In addition, fill the water tank with pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com