Comprehensive processing process and system for cultivation wastewater

A technology for comprehensive treatment of aquaculture wastewater, which is applied in the field of comprehensive treatment methods and treatment systems for aquaculture wastewater in aquaculture areas, can solve problems such as inability to remove nitrogen and phosphorus, single reliance on treatment technology, and eutrophication of water bodies, and achieve improvement Effects of sanitation, improvement of process technology, and contradiction between supply and demand of water for delayed construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

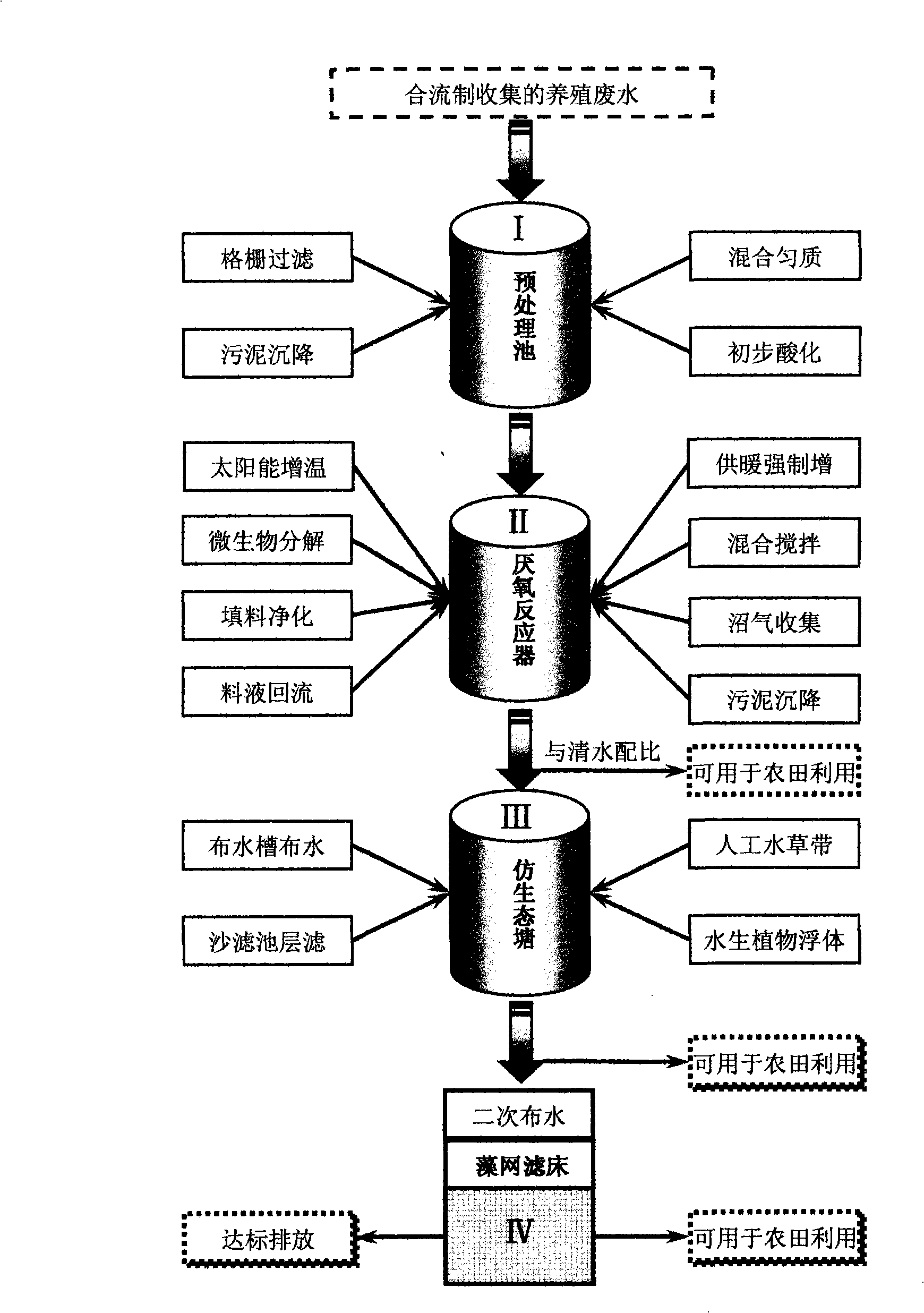

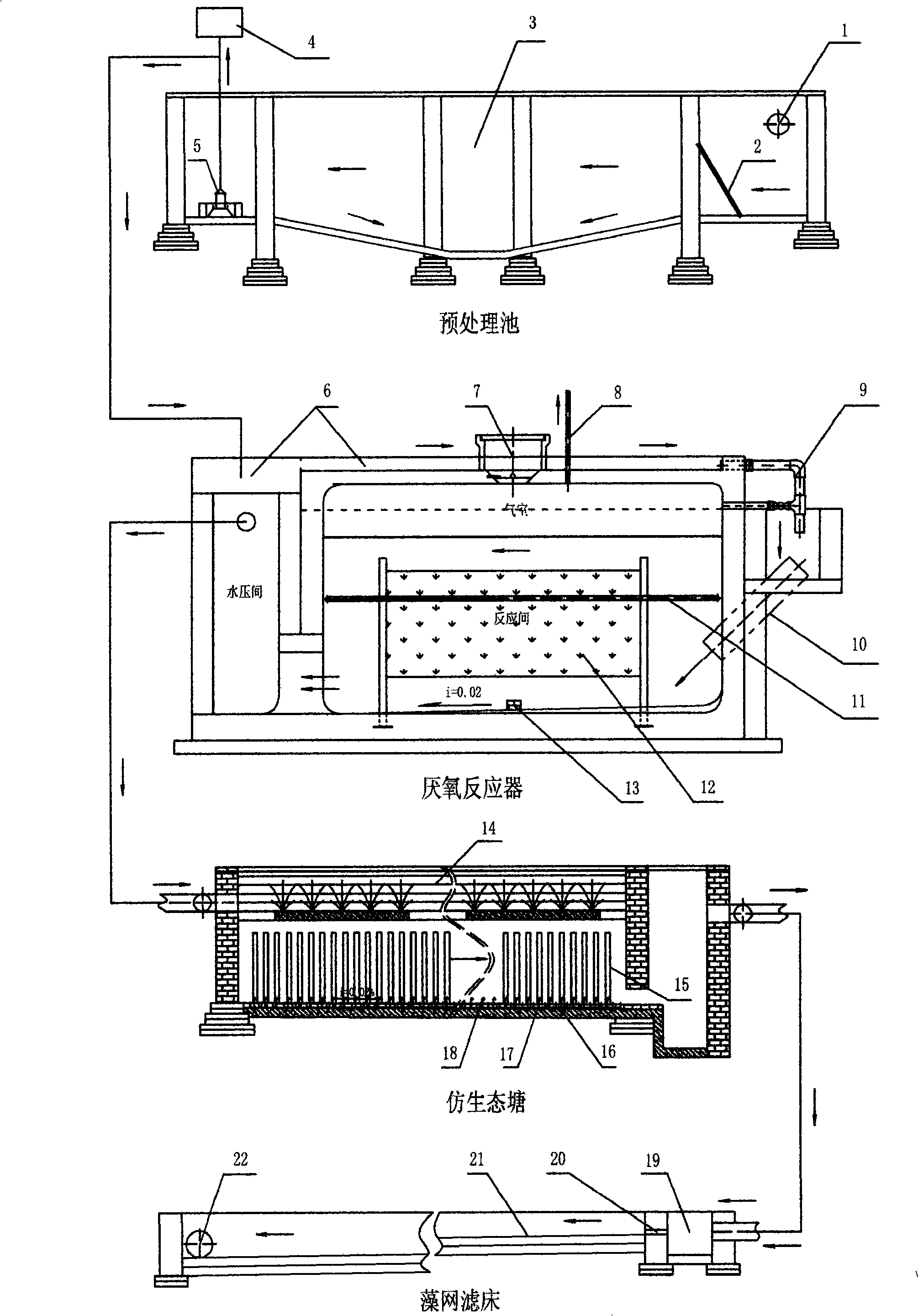

[0041] A comprehensive treatment process for aquaculture wastewater, such as figure 1 with figure 2 As shown, the aquaculture wastewater from pig farms or breeding areas is collected by the sewage collection system, and then transported to the pretreatment tank I through the pipeline from the feed port 1, and after removing impurities through the grid 2, it flows into the middle for sludge settlement and preliminary treatment. Acidification, mixing and homogenization, etc., the settled sludge is regularly pumped out from the sludge collection well 3, and the homogeneous material liquid is transported to the anaerobic reactor II in a regular and quantitative manner by the lift pump 5 under the control of the automatic control system 4, Before entering the anaerobic reactor, the feed liquid is first sent to the warming water tank 6 at the top of the anaerobic reactor, and within a certain retention period, after the sunlight or greenhouse warms up, the feed liquid overflows int...

Embodiment 2

[0043] A comprehensive treatment system for aquaculture wastewater, such as figure 2 As shown, go through the following devices in turn:

[0044] a) Pretreatment pool, for grid filtration, homogeneous mixing and sediment settlement pretreatment;

[0045] b) a plug-flow anaerobic bioreactor, in which heating and anaerobic biofermentation are carried out;

[0046] c) A biomimetic pond system for advanced treatment of aquaculture wastewater, in which aerobic aeration, microbial degradation and plant absorption are performed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com