Method for preparing electrolytic manganese metal with low-grade pyrolusite wet leaching

A technology of electrolytic manganese and pyrolusite, which is applied in the direction of improving process efficiency, can solve the problems of difficult economic recovery of ore valuable metals, unutilized pyrolusite, and high cost of reduction process, so as to improve resource utilization and price Inexpensive, short response time effect

Inactive Publication Date: 2011-06-15

JISHOU UNIVERSITY +1

View PDF3 Cites 35 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

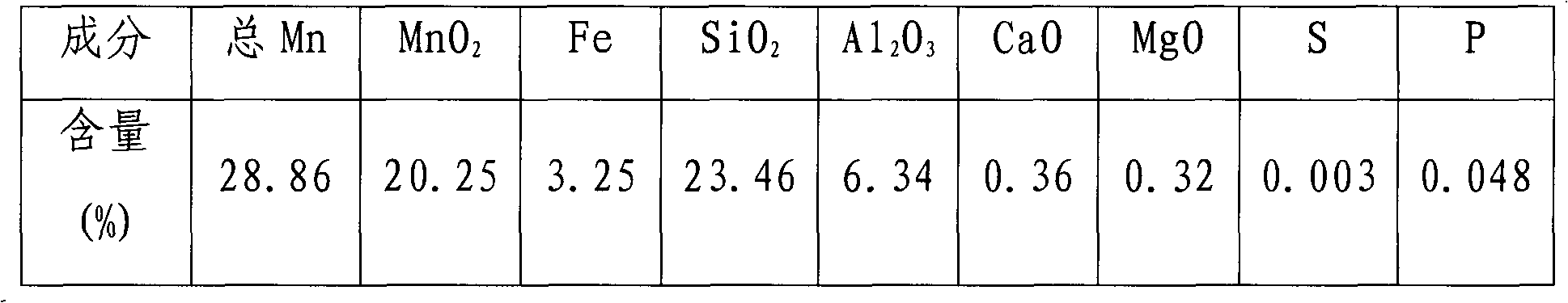

On the other hand, because the smelting of low-grade pyrolusite is difficult, the recovery rate is low, and the cost of the reduction process is too high, it is difficult to economically recover the valuable metals in the ore regardless of the existing pyrolysis process or wet process. , the economic benefits are all restricted by the manganese content of the ore, resulting in a large amount of pyrolusite with a manganese content of 20-25% not being utilized

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for preparing electrolytic manganese metal with low-grade pyrolusite wet leaching, which comprises the following steps of: after low-grade pyrolusite is crushed and screened, mixing slurry with electrolytic manganese anolyte, adding sulfuric acid to control acidity, and reducing high-valent manganese insoluble in water into low-valent manganese readily soluble in water through a redox reaction by using reduced iron powder or waste iron scraps as a reducing agent; controlling certain acidity, reaction temperature and time, stirring and leaching, and then precipitating and filtering; purifying, decontaminating and separating a filter liquor to obtain a pure manganese sulfate solution; and electrolyzing the manganese sulfate solution to obtain an electrolytic manganese product, wherein the leaching rate of manganese is higher than 98%, the recovery rate of manganese is higher than 90%, and the purity of electrolytic manganese metal is higher than 99.8%. The method has the advantages that the raw materials of the reducing agent have wide sources and low price, the reaction time is short, the conditions of the leaching process are mild, the leaching rate of manganese is high, the purification process is simple, and the process route of the present carbonic acid manganese ore for preparing electrolytic manganese metal is not changed.

Description

A method for preparing electrolytic metal manganese by wet leaching of low-grade pyrolusite technical field The invention relates to a method for preparing electrolytic metal manganese by wet leaching of low-grade pyrolusite as raw material. Background technique my country's manganese resources are abundant but not rich. The ascertained resource reserves are 640 million tons. The ore types are mainly manganese carbonate ore, followed by manganese oxide ore and iron-manganese ore. Most of them are poor manganese ore, and rich manganese ore only accounts for 6-8 %. The technology of producing electrolytic manganese with carbonate ore as raw material is mature, ranks the international leading level, and is widely adopted by domestic enterprises. With years of mining, my country's rich manganese ore resources have declined sharply. At present, the shortage of manganese ore resources is restricting the production and sustainable development of manganese products in my country....

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22B3/08C22B3/44C22B47/00

CPCY02P10/20

Inventor 颜文斌高峰申永强熊绍锋石综胜

Owner JISHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com